Magnetic composite powder for ferroferric oxide nanometer crystal modified carbon nanometer pipe and its preparation method

A technology of ferroferric oxide and carbon nanotubes, which is applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of few research reports on the orientation of carbon nanotubes, achieve high wrapping rate and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

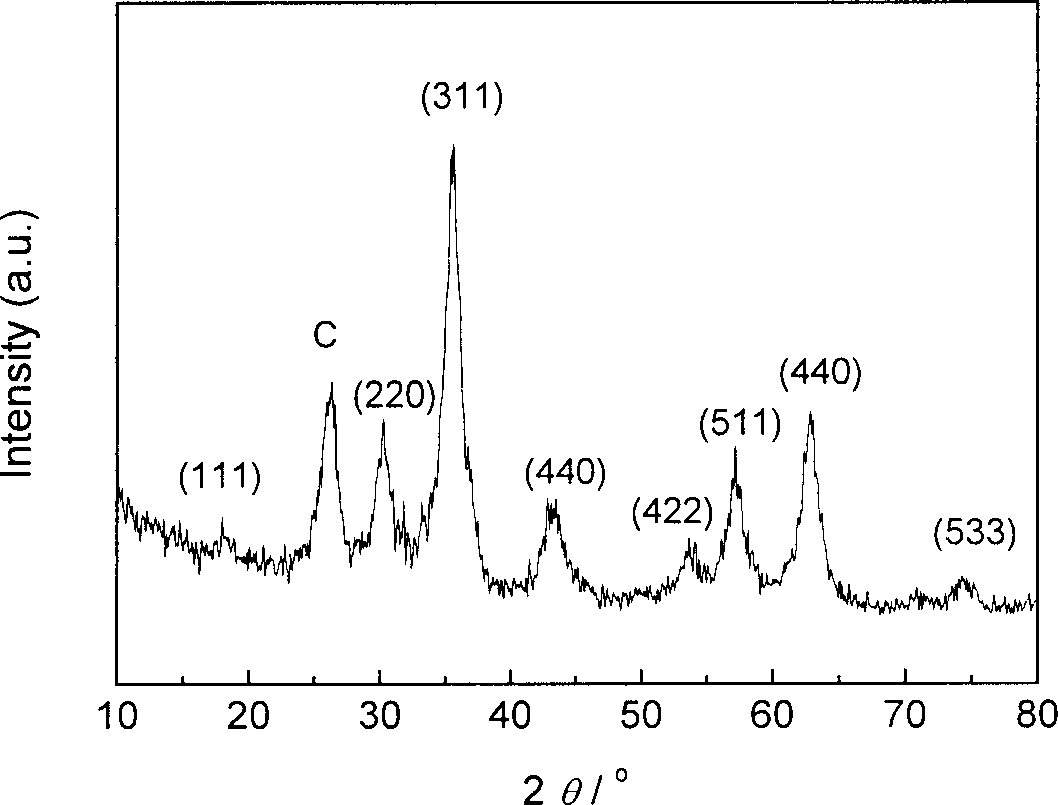

[0025] The multi-walled carbon nanotubes were baked in an oven at 140° C. for 24 hours to remove moisture in the carbon nanotubes, and then refluxed in concentrated nitric acid for 6 hours, washed with deionized water, and dried. 0.35g iron triacetylacetonate was dissolved in 50mL 2-pyrrolidone to obtain a red transparent solution. Add 100 mg of acid-treated carbon nanotubes to the above solution, ultrasonically disperse for 30 minutes, and then pour it into a three-necked bottle. One port of the three-necked bottle is connected to a condenser tube, and the other port is filled with nitrogen or argon gas, and refluxed in a silicone oil bath at 245 ° C. 0.5 hour, then naturally cooled to room temperature. A mixed solution of methanol / ether with a volume ratio of 1:3 was added to cause the product to settle, and then washed with acetone for 3 times, and dried to obtain a composite powder of carbon nanotubes wrapped with nano-Fe3O4. figure 1 The X-ray diffraction spectrum of the...

Embodiment 2

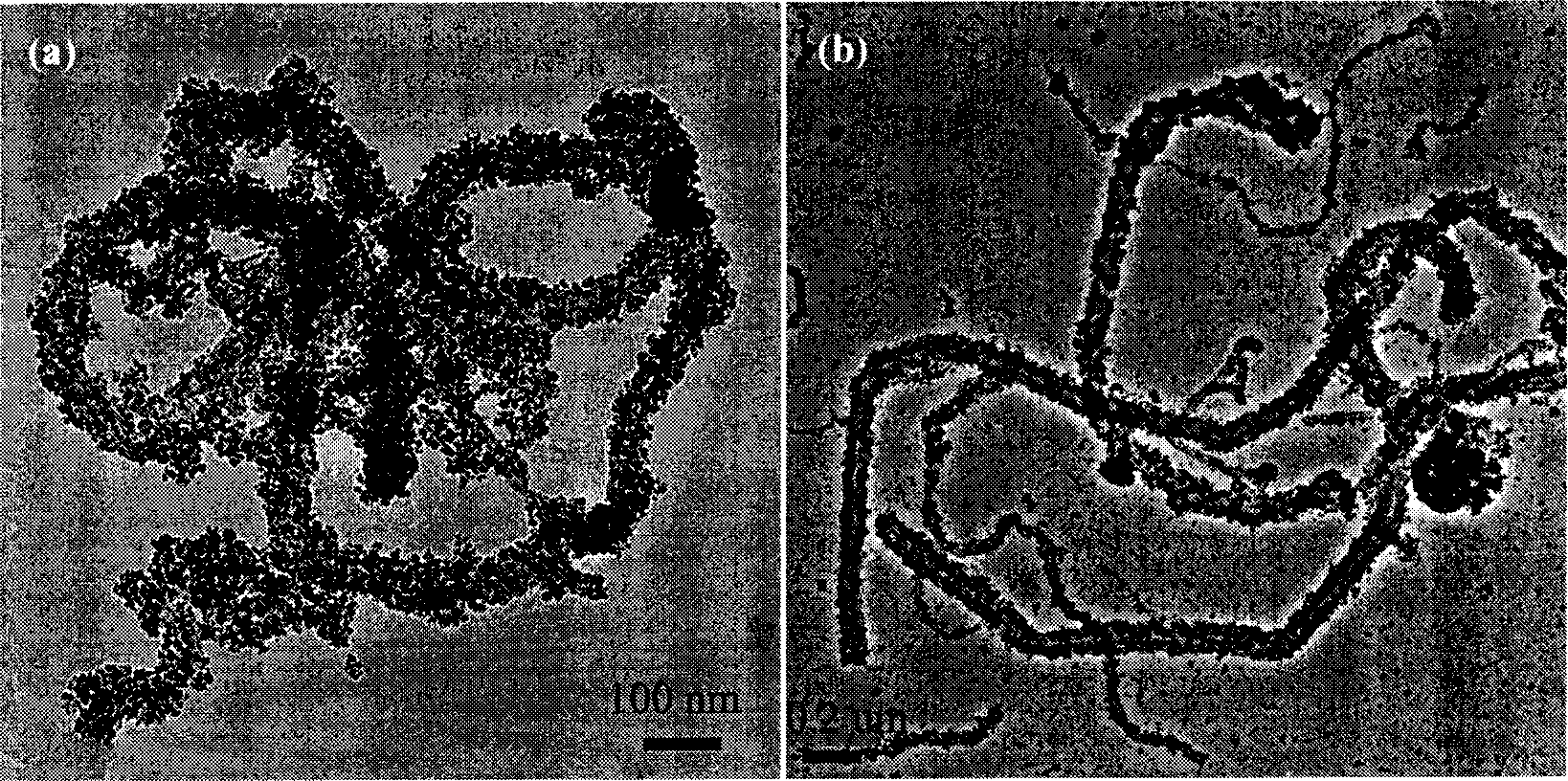

[0027] The multi-walled carbon nanotubes were baked in an oven at 140° C. for 24 hours to remove moisture in the carbon nanotubes, and then refluxed in concentrated nitric acid for 6 hours, washed with deionized water, and dried. 0.35g of ferric chloride was dissolved in 50mL of 2-pyrrolidone to obtain an orange-red transparent solution. Add 100 mg of acid-treated carbon nanotubes to the above solution, ultrasonically disperse for 60 minutes, and then pour it into a three-necked bottle. One port of the three-necked bottle is connected to a condenser tube, and the other port is filled with nitrogen or argon gas, and refluxed in a silicone oil bath at 245 ° C. 3 hours, then naturally cooled to room temperature. A mixed solution of methanol / ether with a volume ratio of 1:3 was added to cause the product to settle, washed with acetone for 5 times, and dried to obtain a composite powder of carbon nanotubes wrapped with nano-ferric oxide. figure 2 (b) is a transmission electron mi...

Embodiment 3

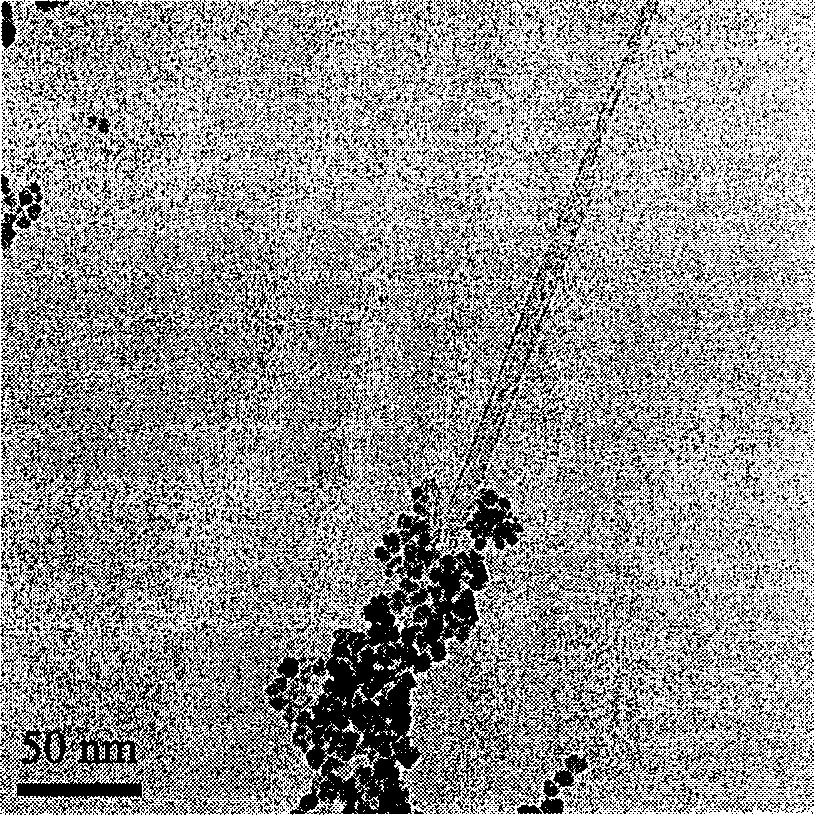

[0029] The multi-walled carbon nanotubes in Example 1 are replaced with single-walled carbon nanotubes, and other conditions remain unchanged, and a composite powder of ferric oxide / single-walled carbon nanotubes can be obtained. image 3 is the transmission electron microscope photo of the obtained typical ferroferric oxide / single-walled carbon nanotube composite material. At the mouth, the particle size is about 7nm. This structure is an ideal structure for single-walled carbon nanotubes to be used in electronic devices, because the ferroferric oxide is only located at its ports, and it only plays a directional guiding role and does not affect the physical properties of the tube body itself.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com