Magnetic composite metal organic framework material of multi-stage structure and manufacturing method thereof

A metal framework material, magnetic metal technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, light water/sewage treatment, etc., can solve the problems of cumbersome preparation process and long preparation time, etc. Achieve the effect of simplifying the preparation process, enriching the preparation method, and improving the absorption efficiency of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of Fe-88B precursor solution: first weigh 2.496g FeCl 3 6H 2 O (the added FeCl 3 The mass is 0.42g) into 40mL of ethylene glycol solvent, then 0.3668g of terephthalic acid is added, and finally it is fully dissolved by ultrasonic dispersion to form a uniform solution.

[0024] (2) Addition of reducing agent and complexing agent: transfer the solution in (1) to an oil bath at 80° C., and after magnetically stirring for 5 minutes, first add 0.71 g of sodium citrate, and magnetically stir for 15 minutes. Then 0.49 g of anhydrous sodium acetate was added, and the stirring reaction was continued for 15 min to obtain a mixed solution.

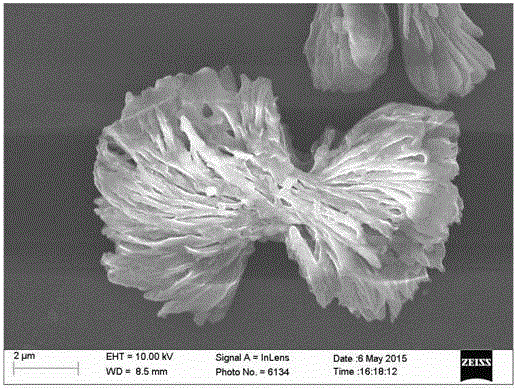

[0025] (3) Hydrothermal reaction: Add the mixed solution in (2) into a 50 mL polytetrafluoroethylene-lined reactor, then raise the temperature to 200° C. and keep it warm for 10 h. After cooling to room temperature, centrifugation, washing with DMF, washing with anhydrous methanol, and vacuum drying at 80°C, the lamellar str...

Embodiment 2

[0027] (1) Preparation of FeBTC precursor solution: first weigh 1.664g FeCl 3 6H 2 O (the added FeCl 3 The mass is 0.24g) into 40mL of ethylene glycol solvent, and then 0.72g of 1,3,5-trimellitic acid is added, and finally it is fully dissolved by ultrasonic dispersion to form a uniform solution.

[0028](2) Addition of reducing agent and complexing agent: transfer the solution in (1) to an oil bath at 80° C., and after magnetically stirring for 5 minutes, first add 0.47 g of sodium citrate, and magnetically stir for 10 minutes. Then 0.98 g of anhydrous sodium acetate was added, and the stirring reaction was continued for 10 min to obtain a mixed solution.

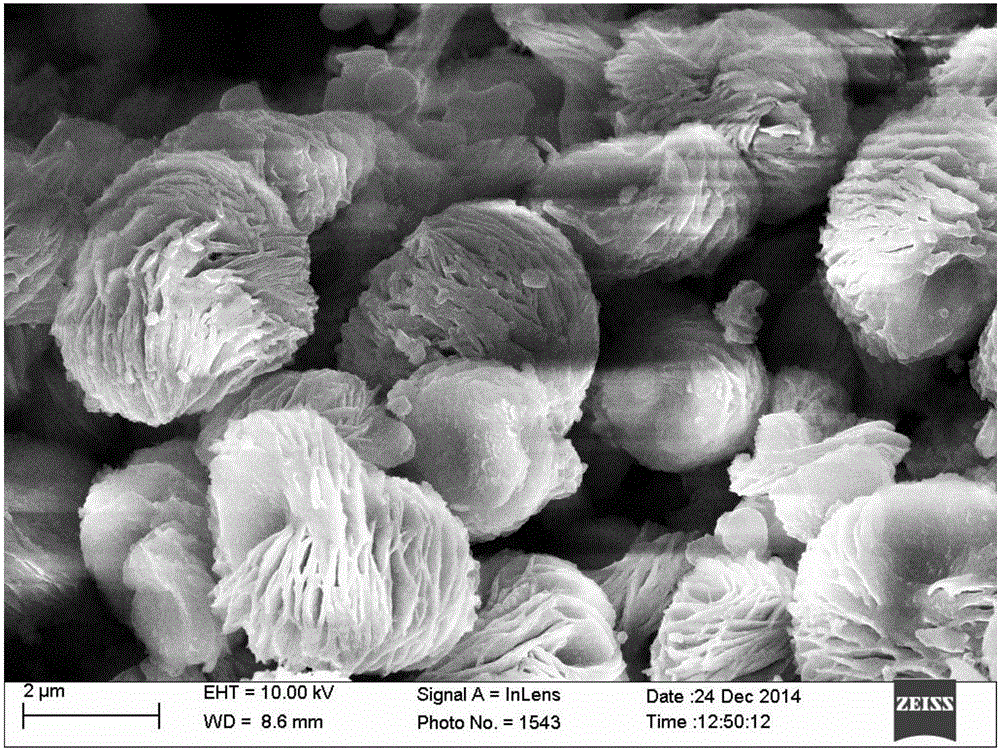

[0029] (3) Hydrothermal reaction: Add the mixed solution in (2) into a 50 mL polytetrafluoroethylene-lined reactor, then raise the temperature to 200° C. and keep it warm for 8 hours. After cooling to room temperature, centrifugation, washing with DMF, washing with anhydrous methanol, and vacuum drying at 80°C, the mult...

Embodiment 3

[0031] (1) Preparation of Cr-MIL-101 precursor solution: first weigh 2.460g Cr(NO 3 ) 3 9H 2 O and FeCl 3 6H 2 O0.47g was added to 40mL of ethylene glycol solvent, and then 0.3668g of terephthalic acid was added, and finally it was fully dissolved by ultrasonic dispersion to form a uniform solution.

[0032] (2) Addition of reducing agent and complexing agent: transfer the solution in (1) to an oil bath at 80° C., and after magnetically stirring for 5 minutes, first add 0.47 g of sodium citrate, and magnetically stir for 10 minutes. Then 0.98 g of anhydrous sodium acetate was added, and the stirring reaction was continued for 10 min to obtain a mixed solution.

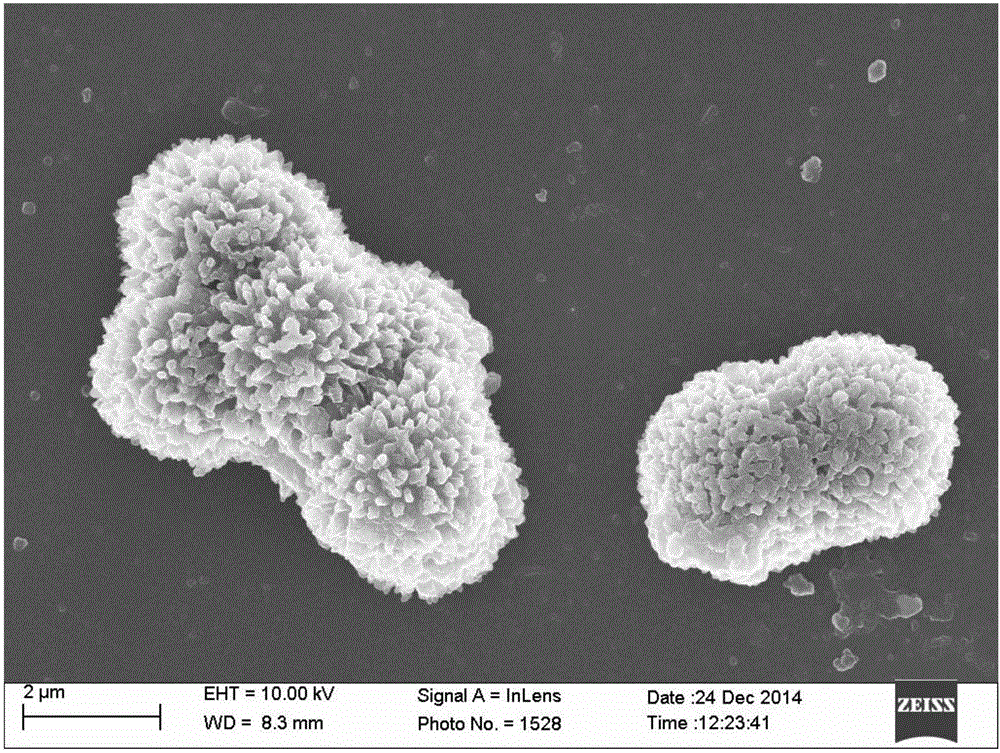

[0033] (3) Hydrothermal reaction: Add the mixed solution in (2) into a 50 mL polytetrafluoroethylene-lined reactor, then raise the temperature to 200° C. and keep it warm for 8 hours. After cooling to room temperature, centrifugation, washing with DMF, washing with anhydrous methanol, and vacuum drying at 80°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com