High-specific-capacitance bacterial cellulose-based flexible nitrogen-doped graphene supercapacitor electrode material and preparation method and application thereof

A technology of nitrogen-doped graphene and bacterial cellulose, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problem that the specific surface area is not fully utilized, the specific capacitance is not fully utilized, and the crystals are not directly connected. Connection and other issues to achieve the effect of enhancing the electron transfer rate, improving the defects of structural damage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The steps of the preparation method of bacterial cellulose-based flexible nitrogen-doped graphene polypyrrole supercapacitor electrode material of the present invention are as follows:

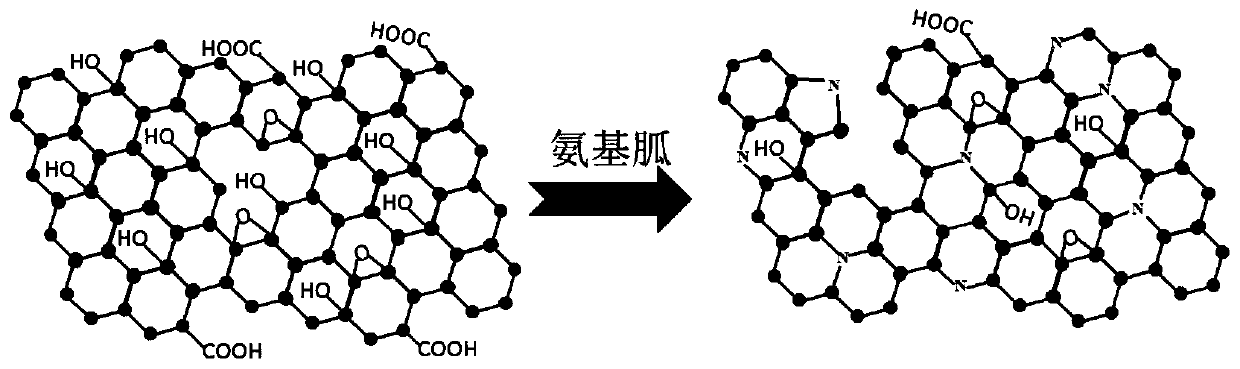

[0036] (1) Add nitrogen source to 50-100mL of 2mg·mL -1 In the graphene oxide (GO) dispersion, the time of mixing and ultrasonic dispersion is 1~2h; then the hydrothermal reaction is carried out in the range of 80℃~160℃ for 3~24h, after the reaction is completed, it is centrifuged, washed and dried to obtain nitrogen-doped reduced graphite oxide Alkenes, add water and mix well to make 1mg mL -1 Nitrogen-doped reduced graphene oxide dispersions.

[0037] The nitrogen source is aminoguanidine, urea or hydrazine hydrate-ammonia water; wherein:

[0038] When aminoguanidine is used, the mass ratio of aminoguanidine to graphene oxide is 0.6g:(0.1-0.2)g; and NaOH is used to adjust the pH to 11-13, and then the hydrothermal reaction is performed.

Embodiment 1

[0051] (1) Mix 50mL of GO (2mg·mL -1 ) ultrasonic treatment, place in a 250mL three-necked flask, add 0.6g of aminoguanidine under high-speed stirring, adjust the pH to 12 (black viscous shape) with NaOH, stir and react at 80°C for 12h, centrifuge and wash with ethanol and deionized water after the reaction To neutral, dry to obtain aminoguanidine nitrogen-doped reduced graphene oxide, add water and mix evenly to make 1mgmL -1 Nitrogen-doped reduced graphene oxide dispersions.

[0052] (2) Py monomer (0.25mL) and p-toluenesulfonic acid (665mg) were slowly added to the prepared 50mL BC suspension (2.8mg·mL -1 ), ultrasonically dispersed for 1 h to form a Py / BC suspension.

[0053] (3) Transfer the Py / BC suspension to ice water and stir vigorously. Then, an aqueous solution of ferric chloride containing 973 mg of ferric chloride was added dropwise to the Py / BC suspension, and stirred continuously for 6 h to obtain a PPy / BC suspension at 0-5°C.

[0054] (4) After polymerizati...

Embodiment 2

[0062] (1) Mix 70mL of GO (2mg·mL -1 ), adjust the pH to 10 with ammonia water, add 2 mL of hydrazine hydrate, and stir for 10 minutes. Transfer to a reaction kettle, react at 80°C for 3 hours, and after the reaction is completed, wash with ethanol and deionized water to neutrality. Get hydrazine-ammonia nitrogen-doped reduced graphene oxide, add water and mix well to make 1mg mL -1 Nitrogen-doped reduced graphene oxide dispersions.

[0063] (2) Py monomer (0.25mL) and p-toluenesulfonic acid (665mg) were slowly added to the prepared 50mL BC suspension (2.8mg·mL -1 ), ultrasonically dispersed for 1 h to form a Py / BC suspension.

[0064] (3) Transfer the homogeneous Py / BC suspension to ice water and stir vigorously. Then, an aqueous solution of ferric chloride containing 973 mg of ferric chloride was added dropwise to the Py / BC suspension, and stirred continuously for 6 h to obtain a PPy / BC suspension at 0-5°C.

[0065] (4) After polymerization, 32 mL of 1 mg·mL -1 The nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com