Preparation method for water purifier capable of synchronously removing ammonia nitrogen and phosphorus in waste water

A water purifying agent and wastewater technology, which can be used in adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., and can solve problems such as low effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

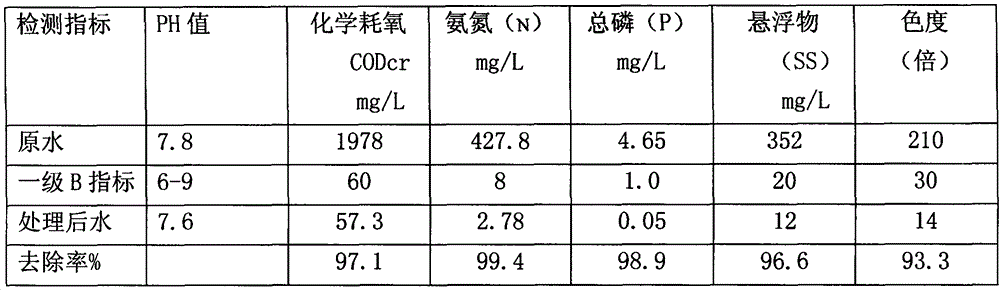

Embodiment 1

[0030] (1) Get ferrous chloride content and be that 30%, hydrochloric acid content are that 1 ton of steel pickling waste liquor is squeezed into reactor.

[0031] (2) 50 kilograms of industrial ferrous chloride solids of 95% content are added, and solids are all dissolved under stirring.

[0032] (3) Adding 40 kilograms of magnesium oxide content under stirring is that the magnesite powder of 55% or more, 20 kilograms of calcium oxide content are the limestone powder of 55% and react with the hydrochloric acid in the steel material pickling waste liquor;

[0033] (4) After the mineral powder is completely dissolved and reacted, the reaction product is aerated and oxidized;

[0034] (5) After the oxidation reaction, the solution was aged for 12 hours to make the reaction more complete and then filtered. After testing, the ferric chloride content in the solution reached more than 38% as required by the content index and then cooled, filtered and packaged.

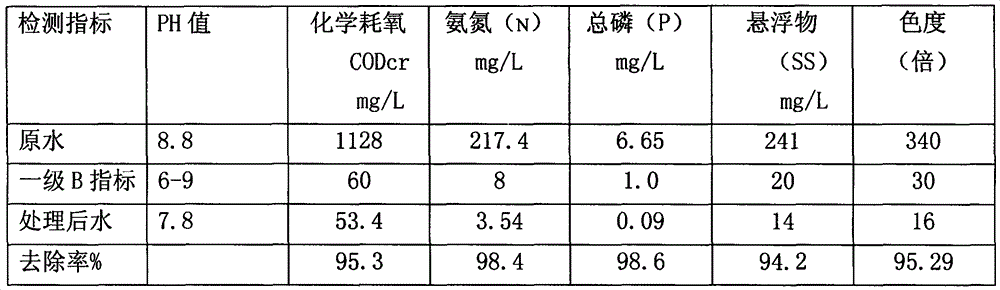

Embodiment 2

[0036] (1) Get ferrous chloride content and be that 30%, hydrochloric acid content are that 1 ton of steel pickling waste liquor is squeezed into reactor.

[0037] (2) 50 kilograms of industrial ferrous chloride solids of 95% content are added, and solids are all dissolved under stirring.

[0038] (3) Adding 30 kilograms of magnesium oxide content under stirring is that the magnesite powder of 55% or more, 30 kilograms of calcium oxide content are that the limestone powder of 55% reacts with the hydrochloric acid in the steel material pickling waste liquor;

[0039] (4) After the mineral powder is completely dissolved and reacted, the reaction product is aerated and oxidized;

[0040] (5) After the oxidation reaction, the solution is aged for 12 hours to make the reaction more complete and filtered to detect the ferric chloride content in the solution. If it needs to be concentrated, it can be concentrated by steam evaporation to make the ferric chloride content in the solutio...

Embodiment 3

[0044] (1) getting ferrous chloride content is 33%, and hydrochloric acid content is 1 ton of steel material pickling waste liquor that is 7% and squeezes into reactor.

[0045] (2) Add 20 kilograms of industrial ferrous chloride solids of 95% content, and make solids all dissolve under stirring.

[0046] (3) adding 30 kilograms of magnesia content under stirring is that the magnesia powder of 55% or more, 30 kilograms of calcium oxide content are the limestone powder of 55% and react with the hydrochloric acid in the steel material pickling waste liquor;

[0047] (4) After the mineral powder is completely dissolved and reacted, the reaction product is aerated and oxidized;

[0048] (5) After the oxidation reaction, the solution is aged for 12 hours to make the reaction more complete and filtered, and the solution can be concentrated by steam evaporation, so that the ferric chloride content in the solution reaches the content index requirement of 96% and then cooled, broken an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com