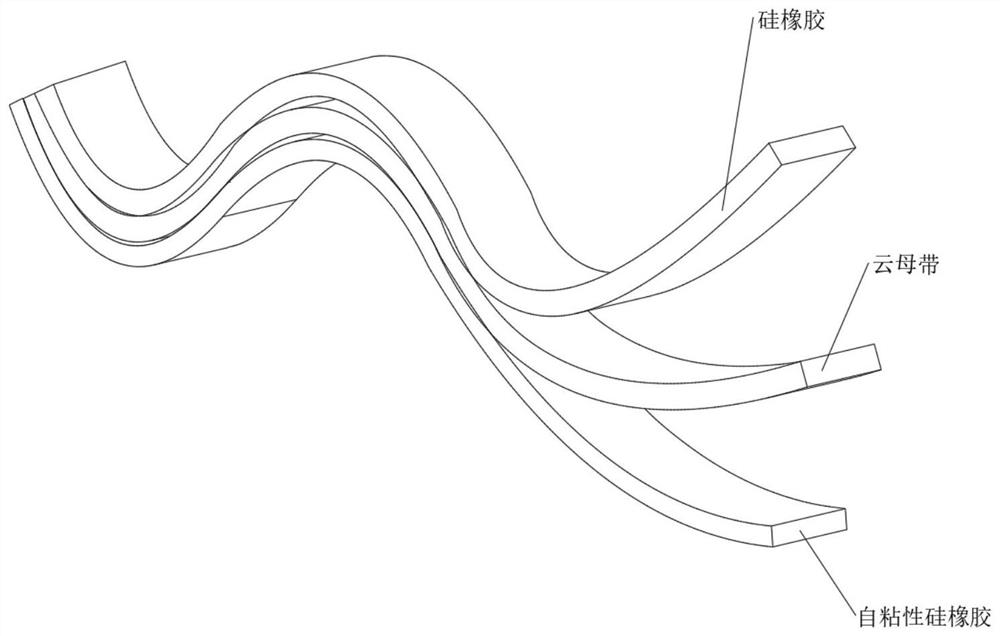

A kind of ceramic silicon rubber composite tape with mica layer and preparation method thereof

A technology of ceramic silicone rubber and silicone rubber, which is applied in the direction of mica, rubber insulator, film/sheet adhesive, etc., to achieve the effect of improving strength, small internal stress and preventing relative slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

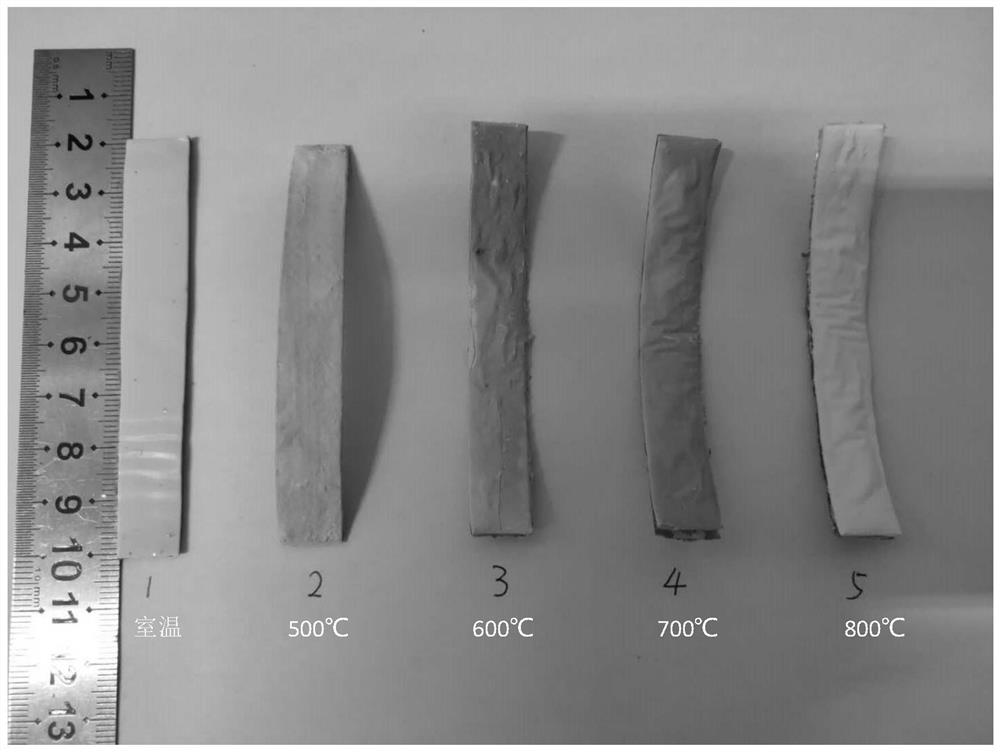

Examples

Embodiment 1

[0029] At room temperature, mix 100 g of methyl vinyl silicone rubber on a two-roll open mill. The gap between the two rolls is 2-5mm at the beginning. After mixing for 5-20min, the gap between the rolls is adjusted to a small one, and the mixing is continued until the silicone rubber is covered. After rolling, add 50g of fumed silica and 1g of high vinyl silicone oil to mix evenly, then add 20g of calcium carbonate and 10g of low-melting glass powder and continue to mix for 5-20 minutes, then pass through the thin film to obtain a thickness of 0.1 -2mm ceramicized silicone rubber sheet; at room temperature, mix 50g methyl vinyl silicone rubber raw rubber on a two-roll open mill until the silicone rubber is wrapped, add 50g fumed silica, 1g high Vinyl silicone oil, 10 g of aluminum hydroxide, and 5 g of antimony trioxide were mixed uniformly, and then 15 g of rosin pentaerythritol ester was added to continue mixing, and finally a thin sheet was passed to obtain a self-adhesive ...

Embodiment 2

[0036] At room temperature, mix 100g of methyl vinyl silicone rubber on a two-roll open mill. The gap between the two rolls is 2-4mm at the beginning. After mixing for 10-20min, the gap between the rolls is adjusted to a small one, and the mixing is continued until the silicone rubber is covered. After rolling, add 30g of fumed silica and 2g of high vinyl silicone oil to mix evenly, then add 20g of wollastonite and 10g of low-melting glass powder and continue to mix for 5-20min, then pass through the thin sheet to obtain a thickness of 0.1 -2mm silicone rubber sheet; at room temperature, mix 70g methyl vinyl silicone rubber raw rubber on a two-roll open mill until the silicone rubber wraps the roll, add 50g fumed silica, 1g high vinyl Silicone oil and 15g aluminum hydroxide to make it evenly mixed, then add 10g rosin pentaerythritol ester to continue mixing, and finally pass through the lower sheet to obtain a self-adhesive silicone rubber sheet with a thickness of 0.5-1mm; pas...

Embodiment 3

[0038] At room temperature, mix 100 g of methyl vinyl silicone rubber on a two-roll open mill. The gap between the two rolls is 2-5mm at the beginning. After mixing for 5-20min, the gap between the rolls is adjusted to a small one, and the mixing is continued until the silicone rubber is covered. After rolling, add 50g of precipitation method white carbon black and 1g of hydroxysilicone oil to make it evenly mixed, then add 20g of mica and 10g of zinc borate and continue to mix for 5-20min, then pass through the thin sheet to obtain a silicone rubber sheet with a thickness of 0.5-2mm ; At room temperature, mix 100 g of methyl phenyl vinyl silicone rubber raw rubber on a two-roller open mill until the silicone rubber wraps the roll, add 40 g of fumed silica, 1 g of high vinyl silicone oil, 15 g of Antimony trioxide to make it evenly mixed, then add 15g of tetradecyl borate to continue mixing, and finally pass through the lower sheet to obtain a self-adhesive silicone rubber shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com