High-viscosity special mortar for prefabricated building and preparation method of high-viscosity special mortar

A prefabricated and construction technology, applied in construction, building components, building maintenance, etc., can solve the problems of asphalt materials not easy to disperse, poor combination with high-viscosity mortar, easy free aggregation and flow, etc., to ensure no agglomeration Migration, good construction performance, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

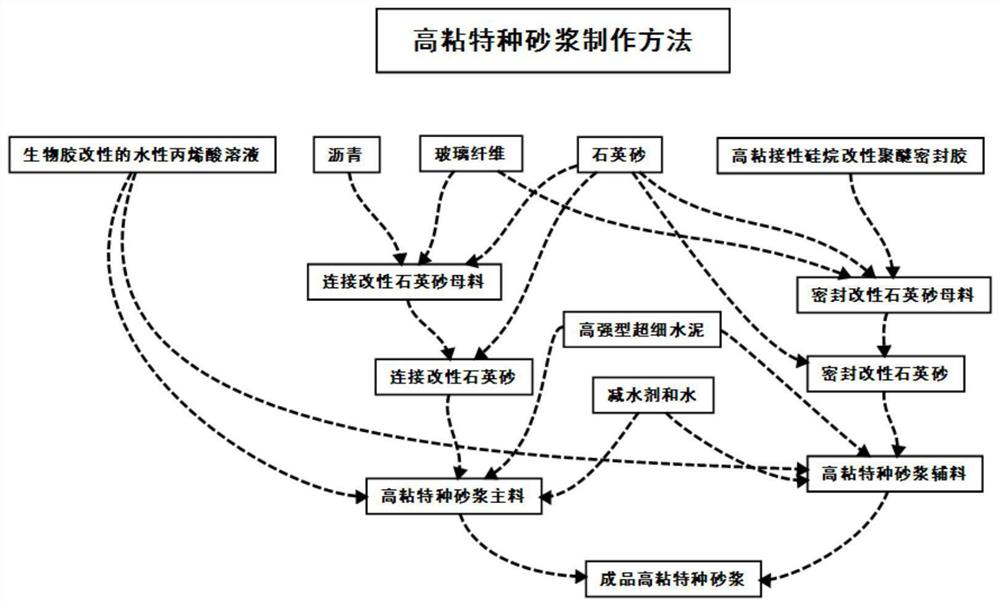

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, manufacture of prefabricated building components: Pour the high-viscosity special mortar of the present application into the mold of prefabricated building components, and use the vibrating rod to vibrate those modified quartz that are well combined with asphalt-containing glass fibers and quartz sand The sand will not migrate and accumulate. If the method of masterbatch is not used, the same amount of glass fiber and asphalt is directly added to the quartz sand and stirred. No matter how uniform the mixing is, the process of shaking will inevitably lead to the migration and accumulation of glass fiber and asphalt, forming A large number of weak links seriously attenuate the life of components. After shaking, use hydraulic presses, heavy boards, road rollers, scrapers and other tools to flatten the high-viscosity special mortar of this application, fit the mold well, and let it stand for 1-5 hours It can be removed from the mold without conventional standin...

Embodiment 2

[0049] Embodiment 2, assembly of prefabricated building components: when assembling buildings, first spray or scrape an appropriate amount of high-viscosity special mortar on the junction of prefabricated building components, then perform assembly and compaction, and finally scrape off excess High-viscosity special mortar can improve the bonding performance of components, form a smooth whole, and improve earthquake resistance and crack resistance.

Embodiment 3

[0050] Example 3, maintenance and remediation after partial damage of the prefabricated building: due to various reasons, the prefabricated building is partially damaged, and the conventional remedial scheme has poor combination and poor material compatibility, so it cannot be tightly combined, and the damage will continue to be repaired in the future, and the damage will be aggravated For repairing with the high-viscosity special mortar of this application, it is necessary to cut and chisel out a certain material repair accommodation space, then fill in the high-viscosity special mortar, press it with a wooden board or metal board coated with a thin layer of vegetable oil and let it stand for more than 6 hours , and then demolded, due to the interaction between the microscopic asphalt-containing glass fiber modified quartz sand and the combination of the colloidal components in the high-viscosity special mortar, the repaired part is closely combined with the original component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com