Preparation method and application of pyrophosphate modified biochar

A technology of pyrophosphate and biochar, applied in biofuels, chemical instruments and methods, coke ovens, etc., can solve problems such as heavy metal pollution in water bodies and soils, achieve improved adsorption and fixation capabilities, simple steps, and good repair effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

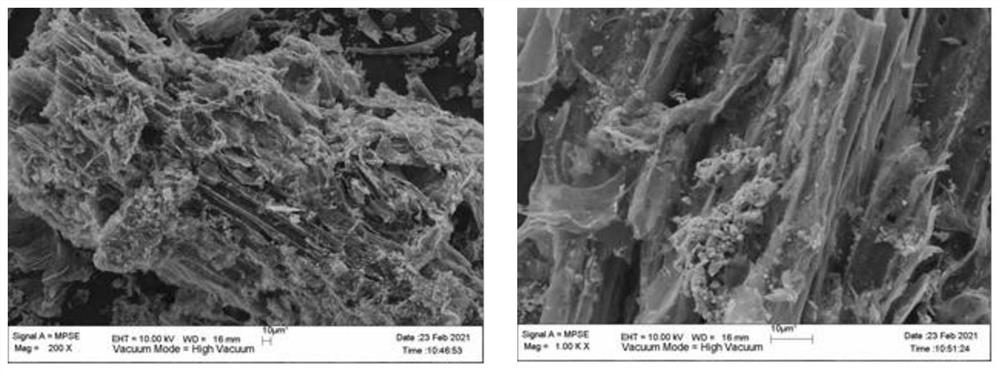

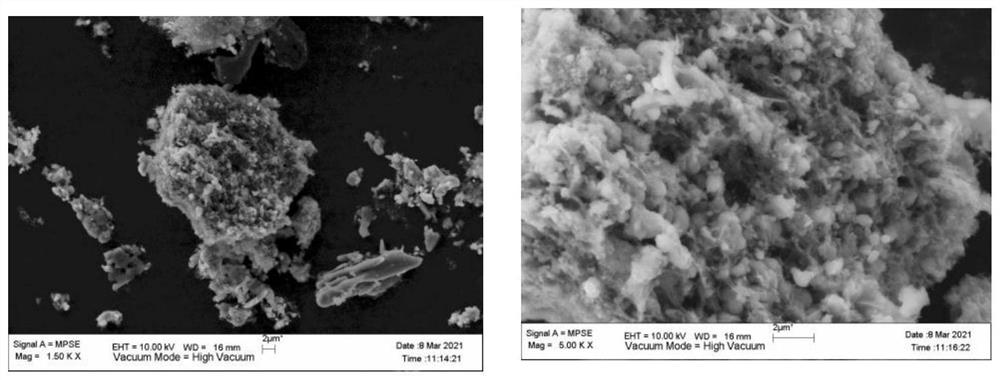

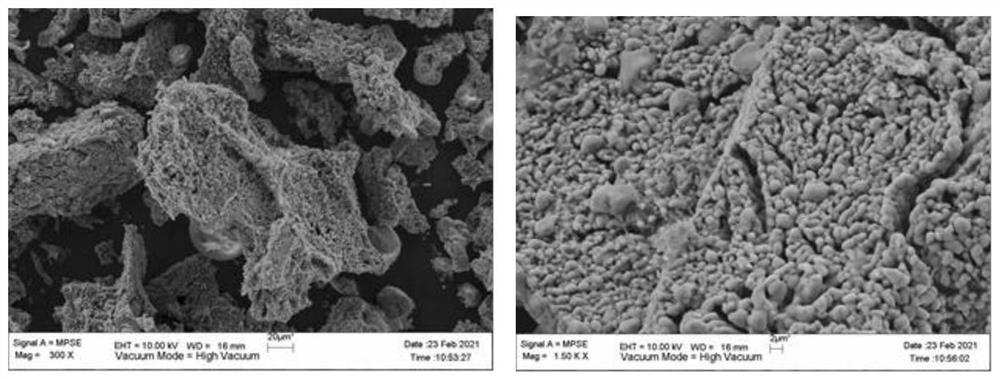

Image

Examples

Embodiment 1

[0042] A preparation method of sodium pyrophosphate modified biochar, comprising the following steps:

[0043] Step 1. Pretreatment of agricultural, forestry and animal husbandry wastes

[0044] The agricultural, forestry and animal husbandry wastes are crushed into 1 cm pieces, and the moisture content is below 35% by natural drying;

[0045] Step 2. Ball Milling Treatment

[0046] Add 10g of agricultural, forestry and animal husbandry waste and distilled water pulverized in step 1 into the agate ball mill in a ratio of 1:10, and add 200g of agate balls. -1 Step 3. Hydrothermal carbonization Pour the ball-milled biomass in step 2 into a hydrothermal reaction kettle, add distilled water in a ratio of 5:1, hydrothermally heat it at 200 °C for 6 hours, and dry to obtain a prepared hydrothermal biomass carbon;

[0047] Step 4. Doping and Pyrolytic Carbonization of Pyrophosphate

[0048] (1) Mix the hydrothermal biochar in step 3, sodium pyrophosphate and distilled water accordi...

Embodiment 2

[0052] A preparation method of sodium pyrophosphate modified biochar, comprising the following steps:

[0053] Step 1. Pretreatment of agricultural, forestry and animal husbandry wastes

[0054] The agricultural, forestry and animal husbandry waste is crushed into 1 cm pieces and blocks, and the moisture content is below 25% by natural drying;

[0055] Step 2. Ball Milling Treatment

[0056] Add 10g of agricultural, forestry and animal husbandry waste and distilled water pulverized in step 1 into the agate ball mill in a ratio of 1:5, and add 150g of agate balls, and ball mill in a planetary ball mill at a speed of 220r·min-1 for 12h;

[0057] Step 3. Hydrothermal Carbonization

[0058] Pour the ball-milled biomass in step 2 into a hydrothermal reactor, add distilled water in a ratio of 10:1, hydrothermally heat it at 220°C for 5 hours, and dry to obtain hydrothermal biochar;

[0059] Step 4. Doping and Pyrolytic Carbonization of Pyrophosphate

[0060] (1) Mix the hydrothe...

Embodiment 3

[0064] A preparation method of sodium pyrophosphate modified biochar, comprising the following steps:

[0065] Step 1. Pretreatment of agricultural, forestry and animal husbandry wastes

[0066] The agricultural, forestry and animal husbandry wastes are crushed into 1 cm segments and blocks, and the moisture content is below 20% by natural drying;

[0067] Step 2. Ball Milling Treatment

[0068] Add 10g of agricultural, forestry and animal husbandry waste and distilled water pulverized in step 1 into the agate ball mill in a ratio of 1:8, and add 200g of agate balls, and ball mill in the planetary ball mill at a speed of 200r·min-1 for 4h;

[0069] Step 3. Doping and Pyrolytic Carbonization of Pyrophosphate

[0070] (1) Mix the biomass, sodium pyrophosphate and distilled water in step 2 according to the mass ratio of 1:1:5, and use a stirrer to stir at a speed of 700r·min-1 for 5h at room temperature;

[0071] (2) The above materials are dried and placed in an atmosphere fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com