Free movement device of seat

A motion device, free technology, applied in the direction of movable seats, transportation and packaging, body, etc., can solve the problems of unsatisfactory seat safety and comfort, and achieve the effect of solving comfort, easy mass production, and low failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the drawings and embodiments.

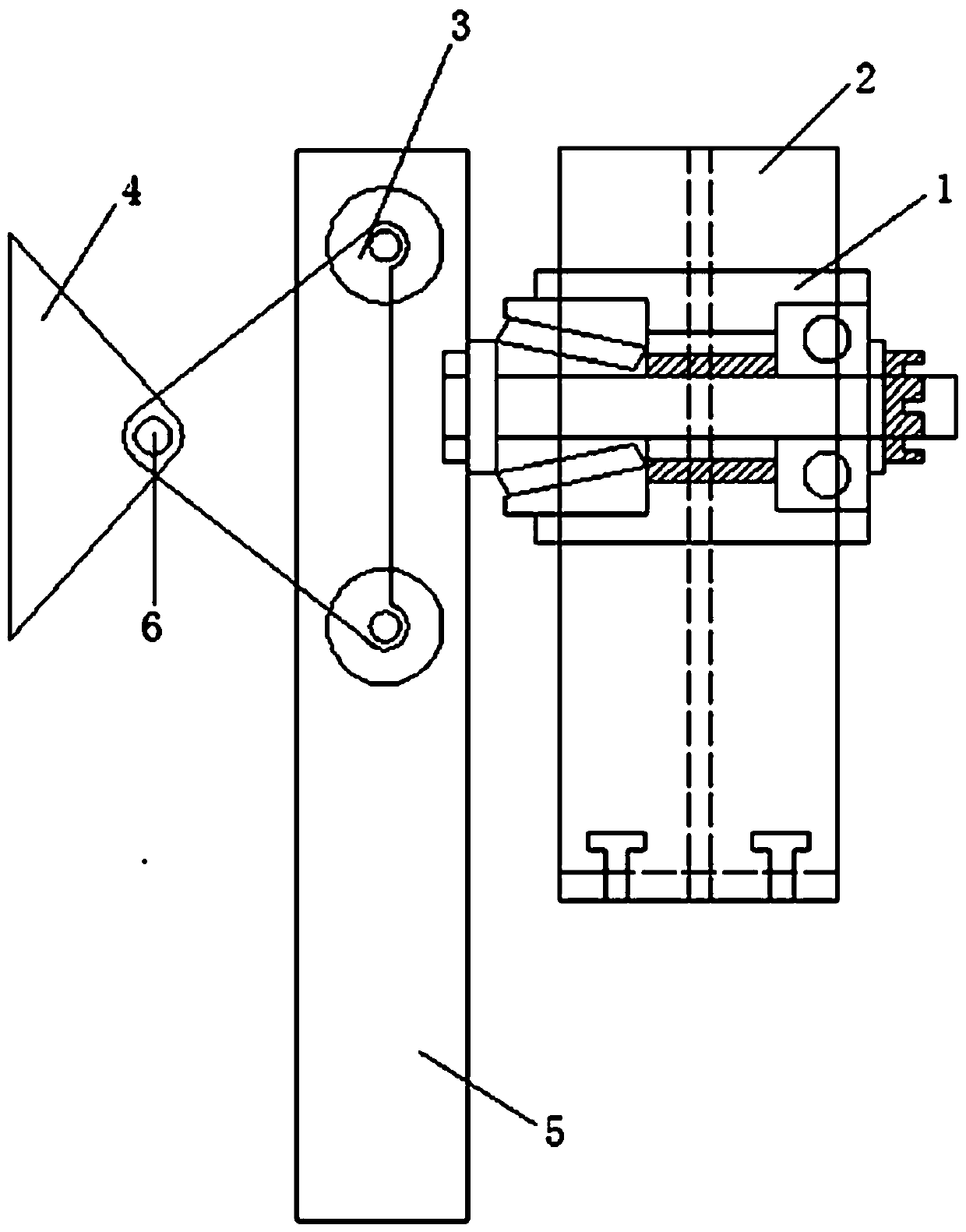

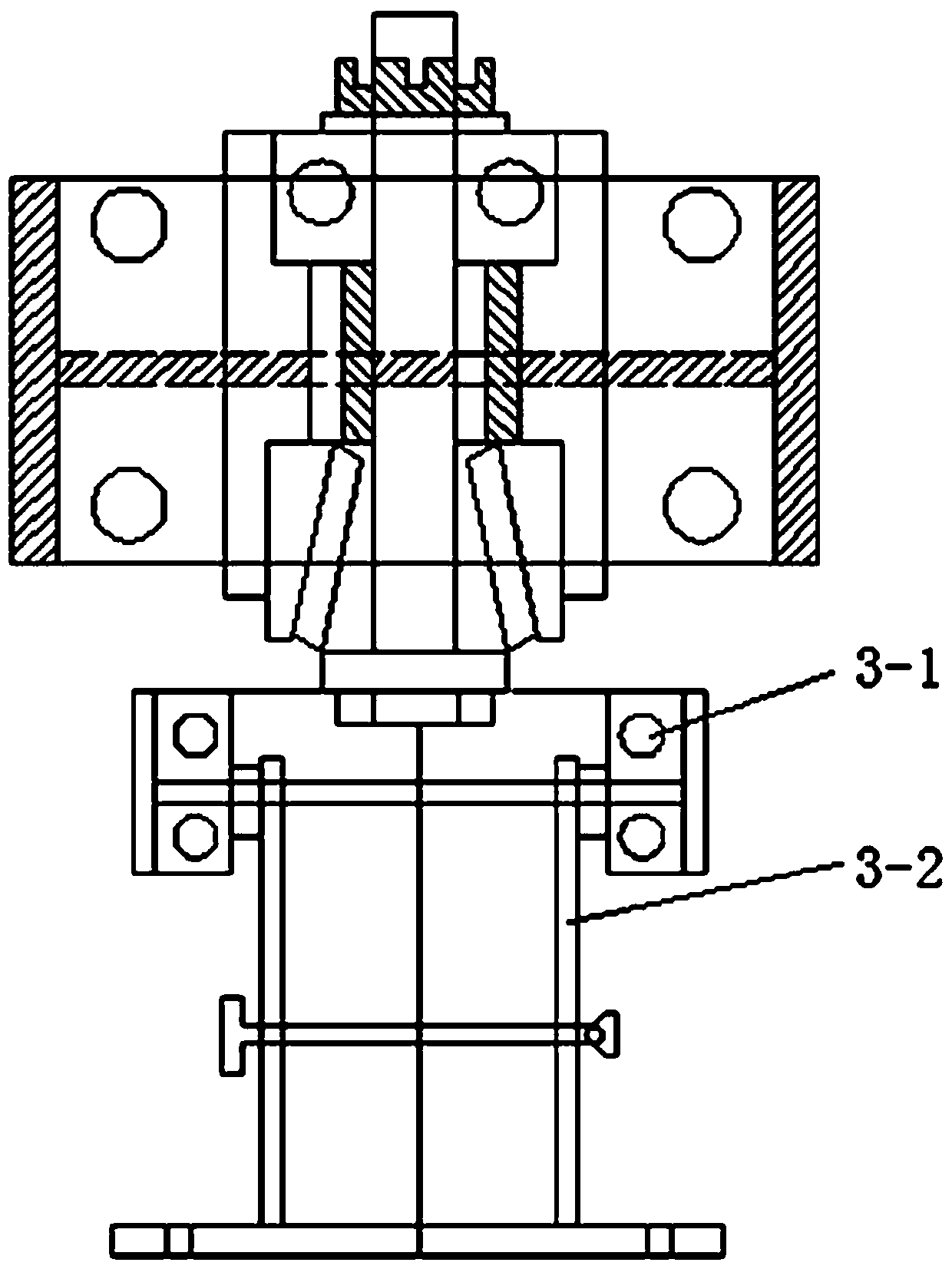

[0020] With reference to the drawings, this embodiment includes a load-bearing rotating shaft 1, a rotating shaft body fixing frame 2, a longitudinal sliding frame 3, a seat back fixing block 4, a vertical sliding frame 5 and a connecting pin 6; The shaft fixing frame 2 is connected, the load-bearing rotating shaft 1 is connected with the longitudinal sliding frame 3, the longitudinal sliding frame 3 is installed on the vertical sliding frame 5, and the vertical sliding frame 5 is connected to the seat through a connecting pin 6 The seat back fixing block 4 is connected.

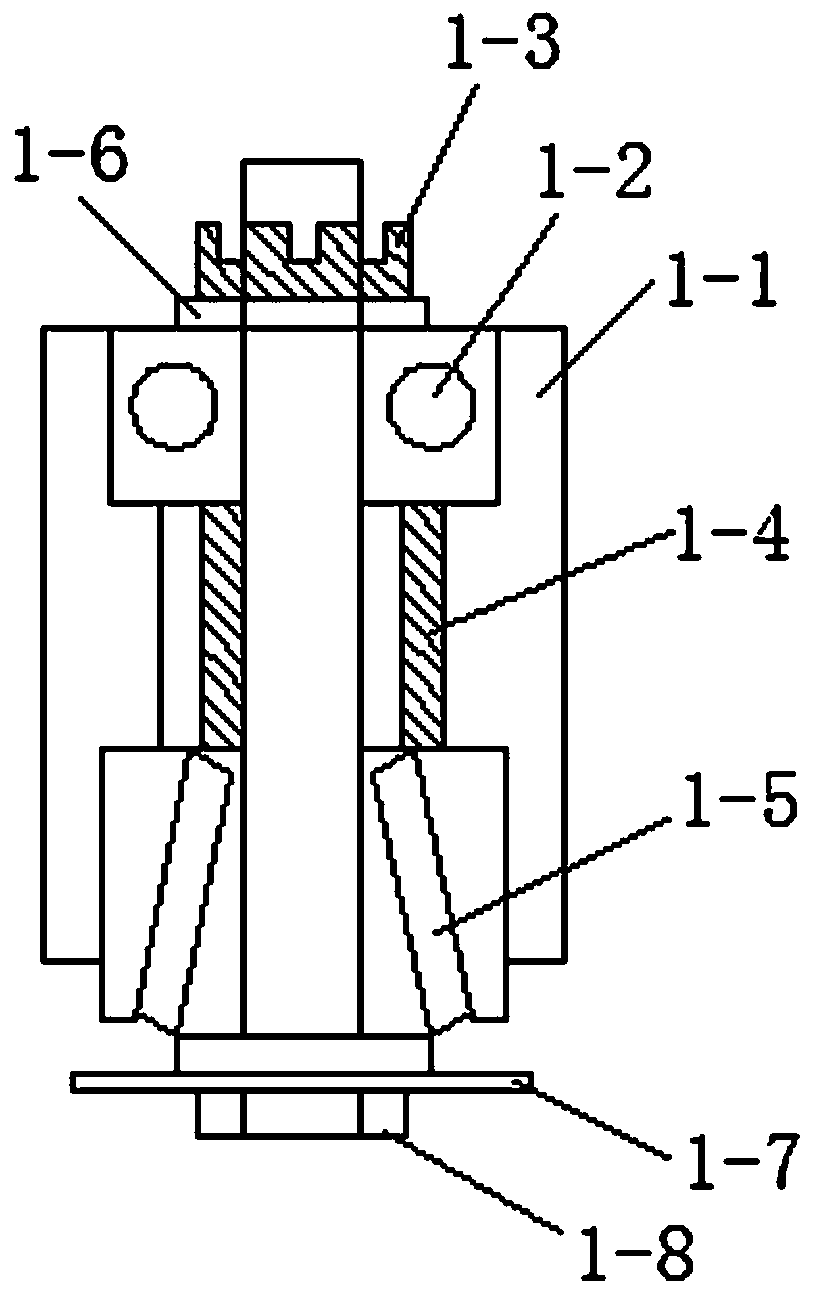

[0021] In this embodiment, the load-bearing rotating shaft 1 includes a load-bearing rotating shaft body 1-1, a deep groove ball bearing 1-2, a slotted nut 1-3, a top column 1-4 between the bearings, a tapered bearing 1-5, Spring washer 1-6, flat washer 1-7, rotating screw 1-8; the deep groove ball bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com