Filler capable of improving heat-resistant strength of EVA hot melt adhesive

A heat-resistant strength and filler technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive additives, etc., can solve stress crack resistance, tensile strength, toughness decline, elongation at break, etc. Elongation, flexural strength, hardness attenuation, general heat resistance, etc., to achieve the effect of reducing curing shrinkage, increasing melt index, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

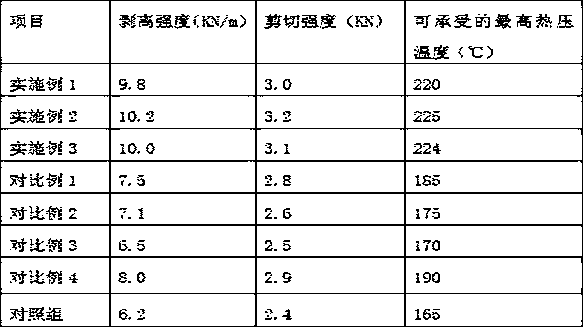

Examples

Embodiment 1

[0018] A filler for improving the heat-resistant strength of EVA hot-melt adhesives, which is made of the following components in parts by weight: 12 parts of silicon dioxide, 3.5 parts of xonotlite, 1.8 parts of graphite flakes, 1.0 parts of aluminum silicate fiber, six 0.5 parts of potassium titanate, 5 parts of polyvinyl alcohol, 3 parts of starch, 25 parts of concentrated sulfuric acid, 1.5 parts of hydrogen peroxide, 15 parts of distilled water, and 30 parts of deionized water. The preparation method includes the following steps:

[0019] (1) Grind silicon dioxide and xonotlite into 150-mesh powder, put them into a four-necked flask together with graphite flakes, add concentrated sulfuric acid dropwise through a separatory funnel under cooling in an ice-water bath at 0°C and mechanically stir for 35 Minutes, then add potassium hexatitanate, react at 15°C for 2 hours, then slowly add deionized water to dilute, and raise the temperature to 60°C;

[0020] (2) Add hydrogen pe...

Embodiment 2

[0028] A filler for improving the heat-resistant strength of EVA hot-melt adhesives, made of the following components in parts by weight: 13 parts of silicon dioxide, 3.6 parts of xonotlite, 1.9 parts of graphite flakes, 1.2 parts of aluminum silicate fiber, six 0.6 parts of potassium titanate, 6 parts of polyvinyl alcohol, 3.5 parts of starch, 28 parts of concentrated sulfuric acid, 1.8 parts of hydrogen peroxide, 18 parts of distilled water, and 35 parts of deionized water. The preparation method includes the following steps:

[0029] (1) Grind silicon dioxide and xonotlite into 160-mesh powder, put them into a four-neck flask together with graphite flakes, add concentrated sulfuric acid dropwise through a separatory funnel under cooling in an ice-water bath at 1°C and mechanically stir for 40 Minutes, then add potassium hexatitanate, react at 18°C for 2.5 hours, then slowly add deionized water to dilute, and raise the temperature to 65°C;

[0030] (2) Add hydrogen peroxid...

Embodiment 3

[0038] A filler for improving the heat-resistant strength of EVA hot-melt adhesives, made of the following components in parts by weight: 15 parts of silicon dioxide, 3.8 parts of xonotlite, 2.0 parts of graphite flakes, 1.5 parts of aluminum silicate fiber, six 0.8 parts of potassium titanate, 7 parts of polyvinyl alcohol, 4 parts of starch, 30 parts of concentrated sulfuric acid, 2.0 parts of hydrogen peroxide, 20 parts of distilled water, and 40 parts of deionized water. The preparation method includes the following steps:

[0039] (1) Grind silicon dioxide and xonotlite into 180-mesh powder, put them into a four-neck flask together with graphite flakes, add concentrated sulfuric acid dropwise through a separatory funnel under cooling in an ice-water bath at 2°C and mechanically stir for 45 Minutes, then add potassium hexatitanate, react at 20°C for 3 hours, then slowly add deionized water to dilute, and raise the temperature to 70°C;

[0040](2) Add hydrogen peroxide dropw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com