Hexadecafluoro-1-octene modified polyperfluoroethylene propylene resin and its bulk polymerization preparation method

A technology of polyperfluoroethylene propylene and bulk polymerization, which is applied in the field of polyfluoroethylene propylene resin modification, can solve the problems of poor modification effect, large fluorine-containing wastewater, short alkyl side chains, etc., and achieve fast reaction rate, The effect of less usage and low volatile content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

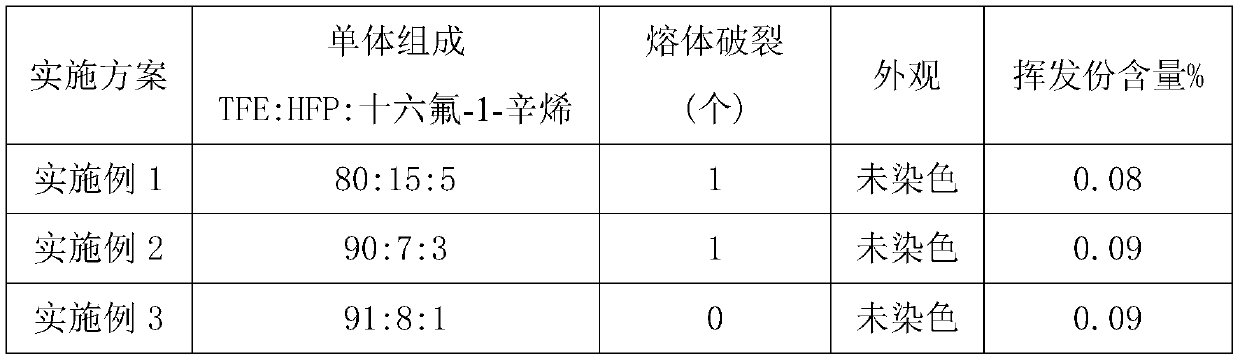

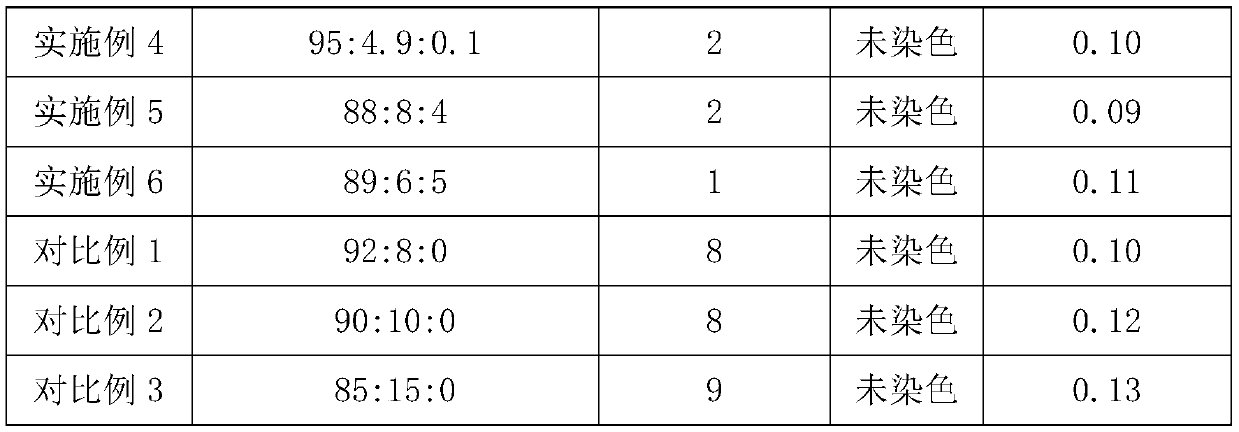

Examples

Embodiment 1

[0026] Add 3000g of pre-added comonomers (including 72mol% of hexafluoropropylene (hereinafter referred to as HFP), 20mol% of tetrafluoroethylene (hereinafter referred to as TFE), 8mol% of hexadecafluoro-1-octene) in a 5L reactor , Then the reactor was heated to 60° C. with stirring, and then 3.2 g of perfluorocyclohexyl peroxide was added to it. At this time, the set pressure of the reactor was 1.5 MPa, and the pressure was maintained by adding comonomers (including 20 mol% HFP and 80 mol% TFE) during the copolymerization. Copolymerization was carried out until 1200 g of additional comonomer was consumed. After the copolymerization process is finished, the reaction product is cooled to 40° C., and the balance valve connecting the reactor to the post-processing equipment in the closed space is opened. The post-processing equipment is connected with the monomer vapor direct cooler and the condensate collector. The reactants are sent from the polymerization reactor to the post...

Embodiment 2

[0028] Add 2500g pre-added comonomers (comprising 79mol% of HFP, 20mol% of TFE, 1mol% of hexadecafluoro-1-octene) in the 5L reactor, then the reactor is heated to 40°C under stirring, after that To this was added 4 g of perfluorocyclohexyl peroxide. At this time, the set pressure of the reactor was 1.3 MPa, and the pressure was maintained by adding comonomers (including 7 mol% HFP, 88 mol% TFE, and 5 mol% hexadecafluoro-1-octene) during the copolymerization process. After 200 g of these mixtures were consumed, 0.3 g of cyclohexane was added to the reactor and the copolymerization was continued. Copolymerization was carried out until 1200 g of additional comonomer was consumed. After the copolymerization process is finished, the reaction product is cooled to 40° C., and the balance valve connecting the reactor to the post-processing equipment in the closed space is opened. The post-processing equipment is connected with the monomer vapor direct cooler and the condensate colle...

Embodiment 3

[0030]Add 1200g dichloropentafluoropropane, 2500g pre-added comonomer (comprising 77mol% of HFP, 20mol% of TFE, 3mol% of hexadecafluoro-1-octene) in the 5L reactor, then the reactor is under stirring condition It was heated to 20° C., and then 4 g of perfluorocyclohexyl peroxide was added thereto. At this time, the set pressure of the reactor was 1.1 MPa, and the pressure was maintained by adding comonomers (including 11 mol% of HFP, 88 mol% of TFE, and 1 mol% of hexadecafluoro-1-octene) during the copolymerization process. After 200 g of these mixtures were consumed, 0.15 g of cyclohexane was added to the reactor and the copolymerization was continued. Copolymerization was carried out until 1200 g of additional comonomer was consumed. After the copolymerization process is finished, the reaction product is cooled to 40° C., and the balance valve connecting the reactor to the post-processing equipment in the closed space is opened. The post-processing equipment is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com