Polyethylene resin molding material for container lid

A polyethylene-based resin and molding material technology, applied in bottle/container caps, capping containers with caps, applications, etc., can solve the problems of insufficient molding speed, insufficient stress cracking resistance, and reduced stress cracking resistance etc. to achieve excellent food safety, high fluidity, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

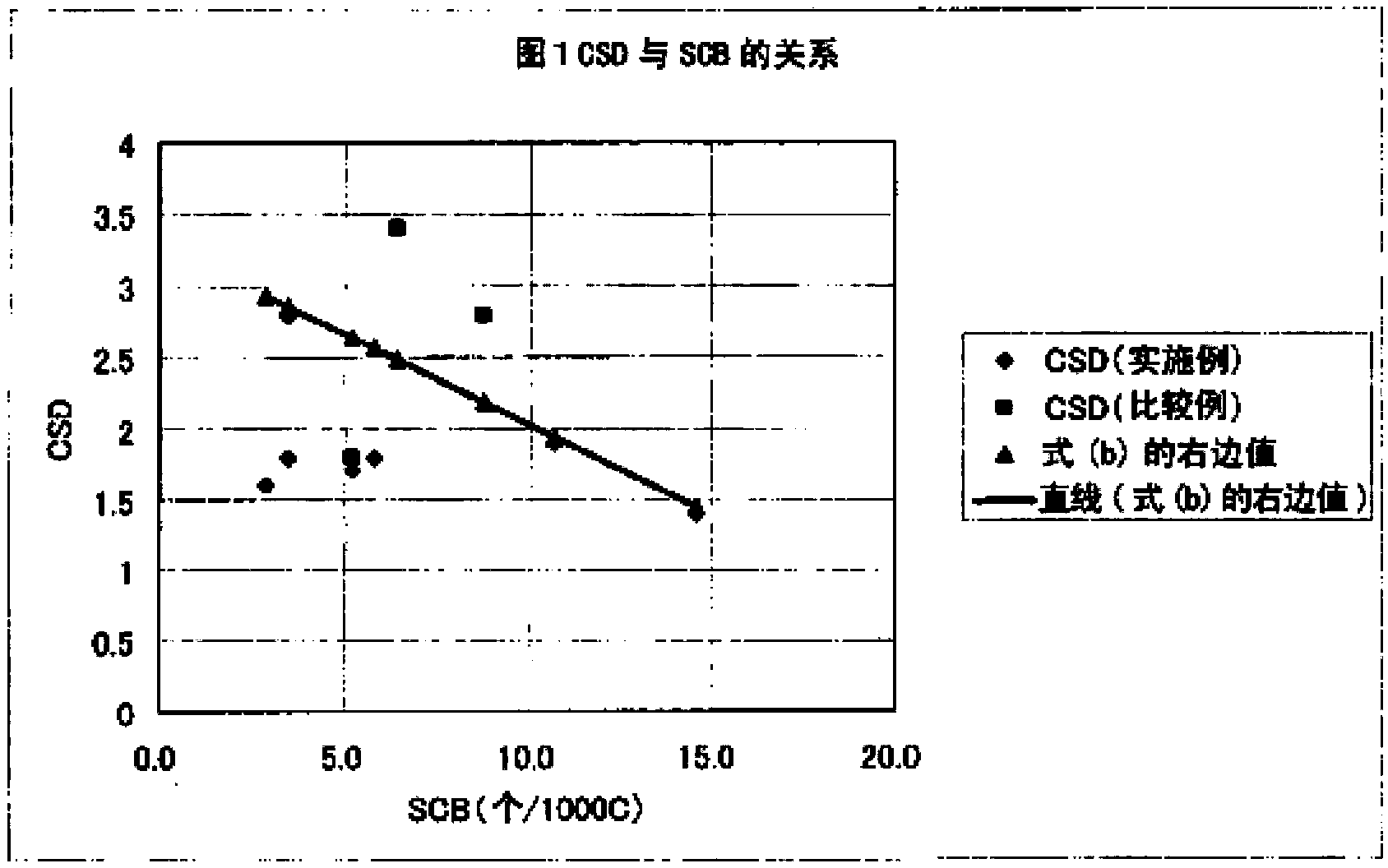

Method used

Image

Examples

Embodiment 1

[0210] (manufacture of catalyst)

[0211] 115 g of magnesium ethoxide, 151 g of tri-n-butoxytitanium monochloride, and 37 g of n-butanol were mixed at 150° C. for 6 hours and homogenized. Then lower the temperature to 60°C and add n-hexane to form a homogeneous solution. Next, 457 g of ethyl aluminum sesquichloride (ethyl aluminum sesquichloride) was dripped at predetermined temperature, and it stirred for 1 hour. The generated precipitate was washed with n-hexane to obtain 210 g of a catalyst component. The resulting solid was dried to form a powder. This powder contained 11.0% by weight of Mg and 10.5% by weight of Ti.

[0212] (manufacturing of polymers)

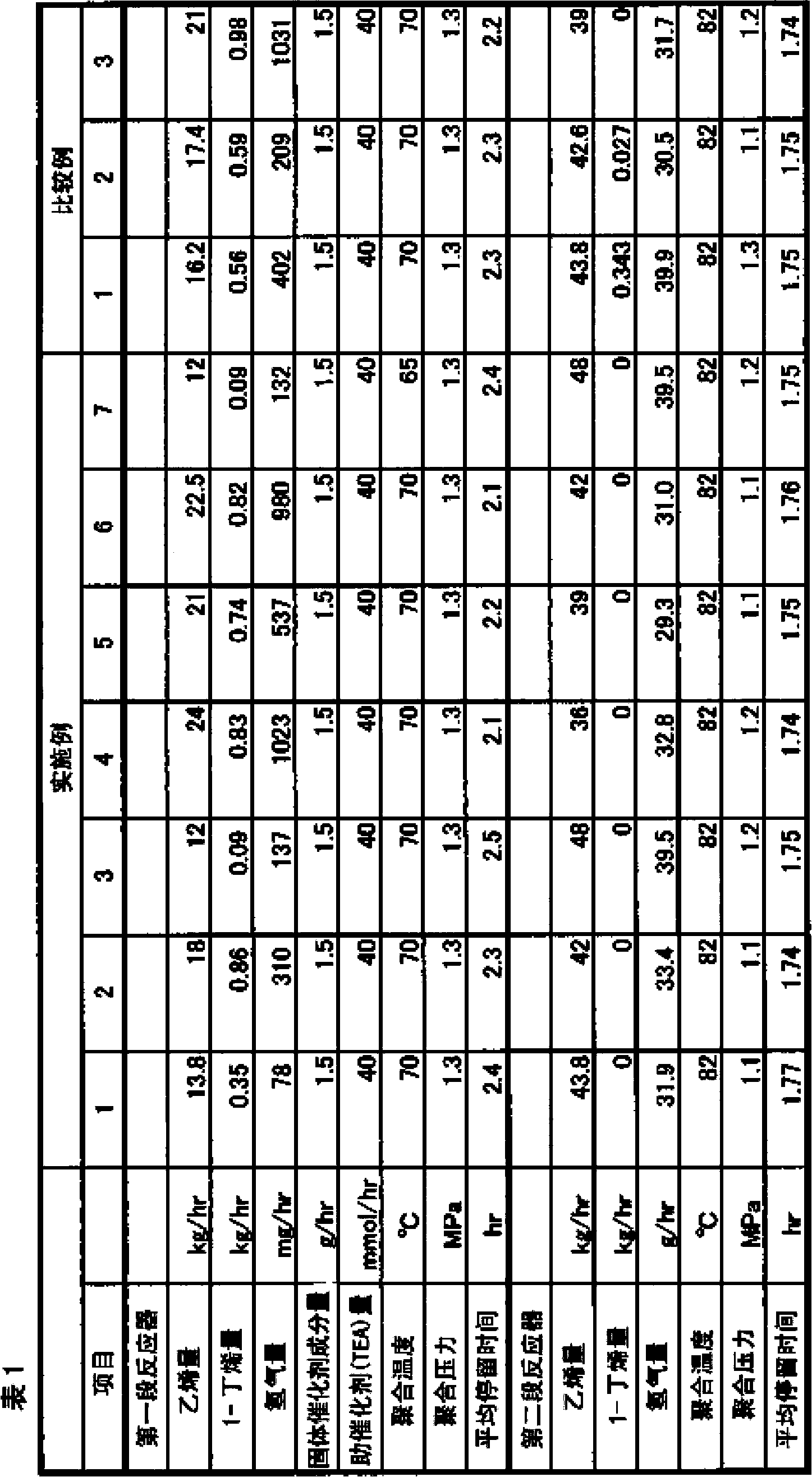

[0213] The solid catalyst component obtained above (production of the catalyst) was continuously supplied at 1.5 g / hr from the catalyst supply line to the first-stage polymerizer having an internal volume of 200 liters as the first-stage reactor, and was supplied from the organometallic compound supply line with Supp...

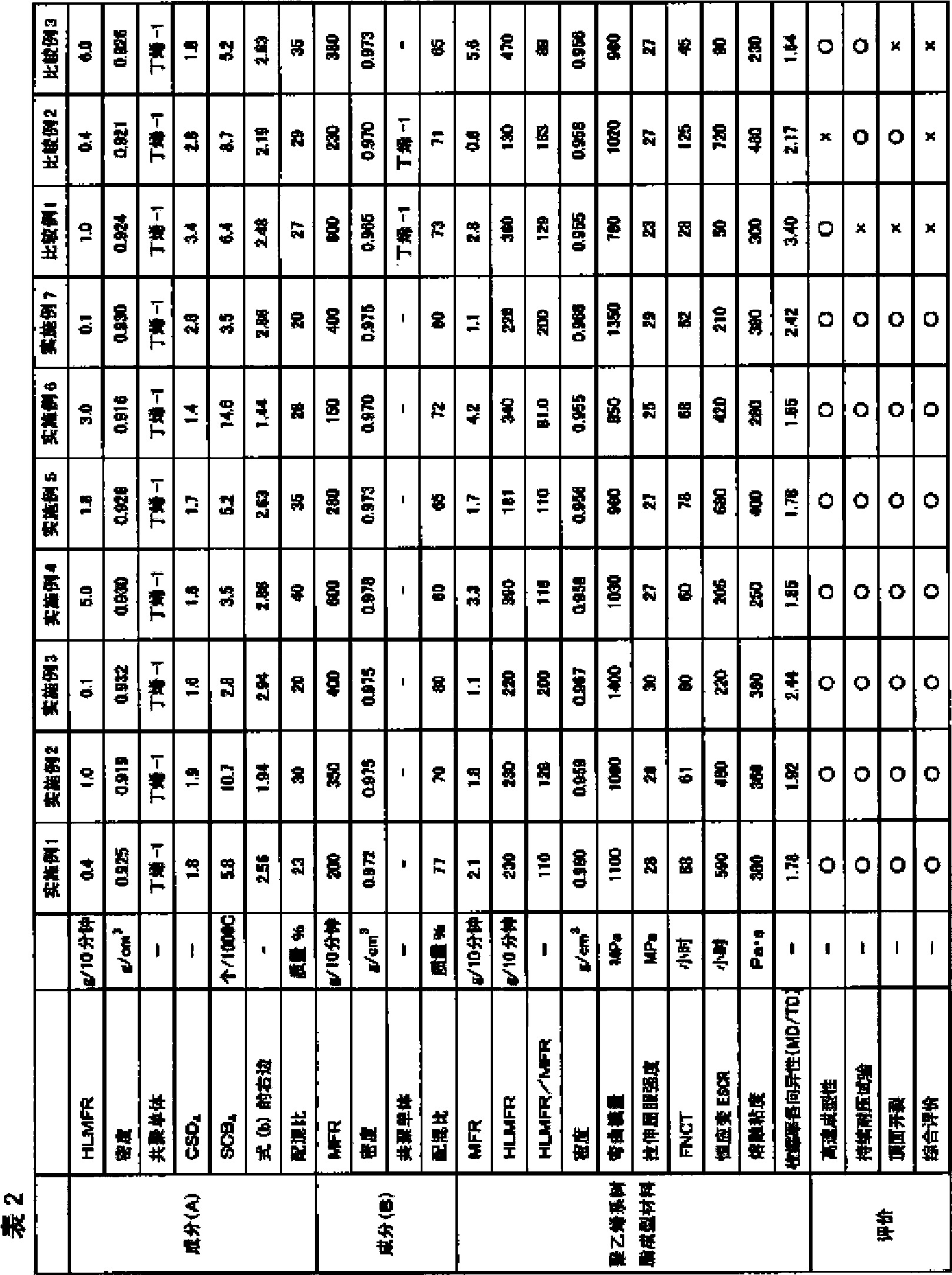

Embodiment 2~7

[0219] Except for the conditions shown in Table 1, it carried out similarly to Example 1, and obtained the ethylenic polymer. The "component (A)" and "component (B)" polymerized by the above-mentioned method were mixed in the ratio shown in Table 2, and the polyethylene-type resin molding material of this invention was manufactured. Table 2 shows the evaluation results of the obtained materials. The obtained material has high tensile yield strength, excellent mechanical properties such as flexural modulus, and is excellent in applicability to container caps requiring durability and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com