A radiation-crosslinked halogen-free flame-retardant polyurethane elastomer and its preparation method

A polyurethane elastomer, cross-linked technology, used in insulators, plastic/resin/wax insulators, electrical components, etc., can solve the problem of tensile strength, tear strength, water resistance can not meet the requirements, heat aging performance is average, TPU problems such as poor flame retardancy, to achieve the effect of increased rigidity, high physical and mechanical properties, and improved stress crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

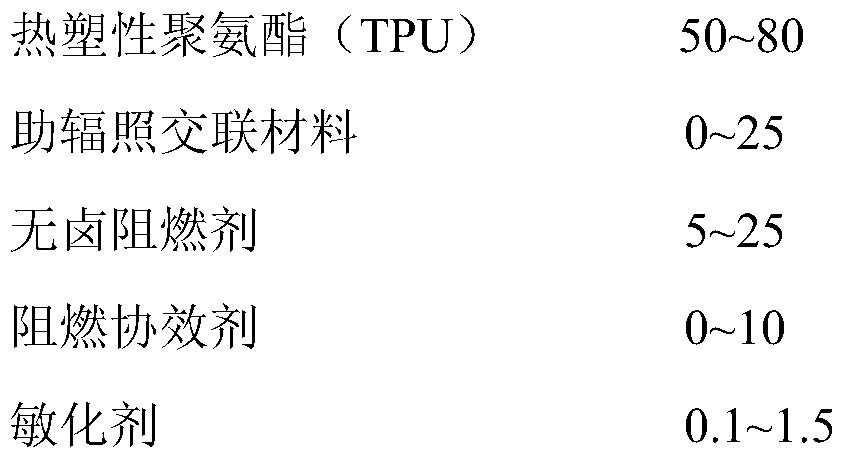

Method used

Image

Examples

Embodiment 1

[0037] Weigh raw materials according to the following formula in parts by weight: 77 parts of polybutadiene type TPU, 13 parts of melamine urate, 6 parts of aluminum hypophosphite, 3 parts of zinc borate, 1.5 parts of TAIC, 0.2 parts of antioxidant, and 3 parts of other additives parts (1.5:1:0.5 of colorants, lubricants and light stabilizers).

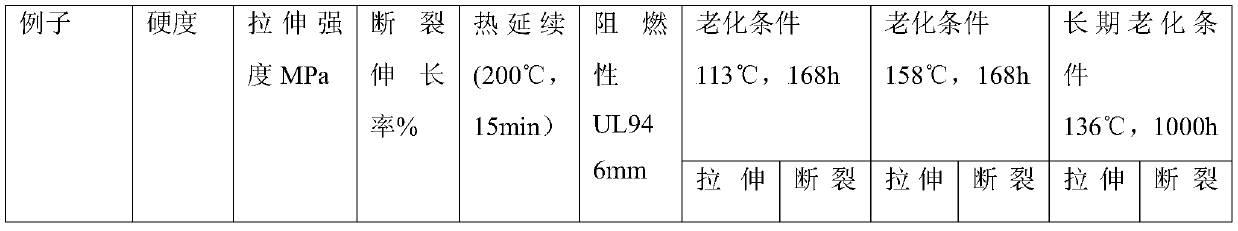

[0038] Put the polybutadiene type TPU into the oven and bake at 95°C for 1.5 hours, then put all the raw materials into the high mixer for stirring, and then carry out basic granulation through the twin-screw extruder, the host of the twin-screw extruder The rotation speed is 250r / min, and the extrusion temperature is 165°C; finally, the finished product (cable sheath) is injected into the finished product (cable sheath) with the granules, and then various performance tests are carried out after irradiation cross-linking with a radiation dose of 15Mard. The results are shown in Table 1 .

Embodiment 2

[0040] Weigh the raw materials according to the following parts by weight formula: 77 parts of polybutadiene type TPU (thermoplastic polyurethane), 13 parts of melamine urate, 6 parts of aluminum hypophosphite, 3 parts of zinc borate, TMPTMA (trimethylolpropane trimethyl Acrylate) 1 part, antioxidant 0.2 part, non-flame retardant additive 3 parts (1.5:1:0.5 colorant, lubricant and light stabilizer).

[0041] Put the polybutadiene type TPU in an oven and bake at 105°C for 1 hour; then mix all the raw materials in a high mixer, and then carry out basic granulation through a twin-screw extruder, the host speed of the twin-screw extruder is 250r / min, and the extrusion temperature is 150°C; finally, the finished product (film) is injected into the finished product (film) with a radiation dose of 10Mard, and various performance tests are carried out after irradiation cross-linking. The results are shown in Table 1.

Embodiment 3

[0043] Raw materials are weighed according to the formula in parts by weight: 67 parts of polybutadiene thermoplastic polyurethane, 10 parts of EVM, 13 parts of melamine urate, 6 parts of aluminum hypophosphite, 3 parts of zinc borate, 1 part of TMPTMA, 0.2 part of antioxidant, 3 parts of non-flame retardant additives (1.5:1:0.5 of colorants, lubricants and light stabilizers).

[0044] Put the TPU in an oven and bake at 90°C for 2 hours; then mix all the raw materials in a high-mixer, and then perform basic granulation through a twin-screw extruder. The main engine speed of the twin-screw extruder is 250r / min. The temperature is 180°C; finally, the finished product (cable sheath) is injected into the finished product (cable sheath), and various performance tests are carried out after cross-linking with a radiation dose of 10Mard. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com