High-concentration carbon black master batch for polyethylene geomembrane

A polyethylene and geomembrane technology, applied in the field of polyethylene carbon black master, can solve the problems of reduced stress cracking resistance, low strength, low melt index, etc., and achieve stress concentration, high shear strength, and narrow particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

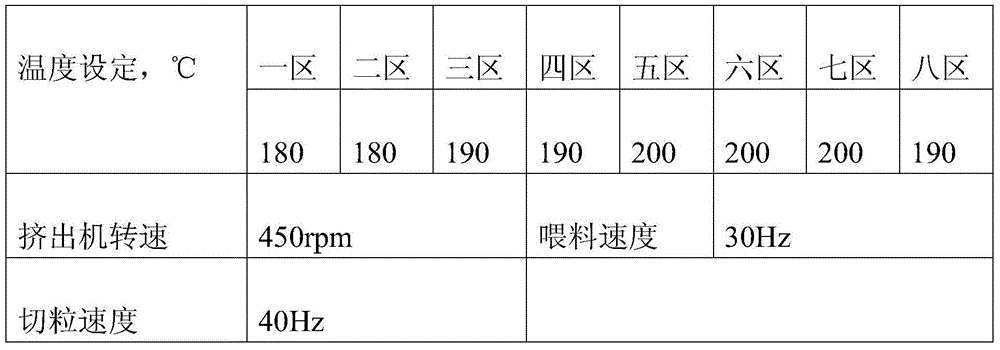

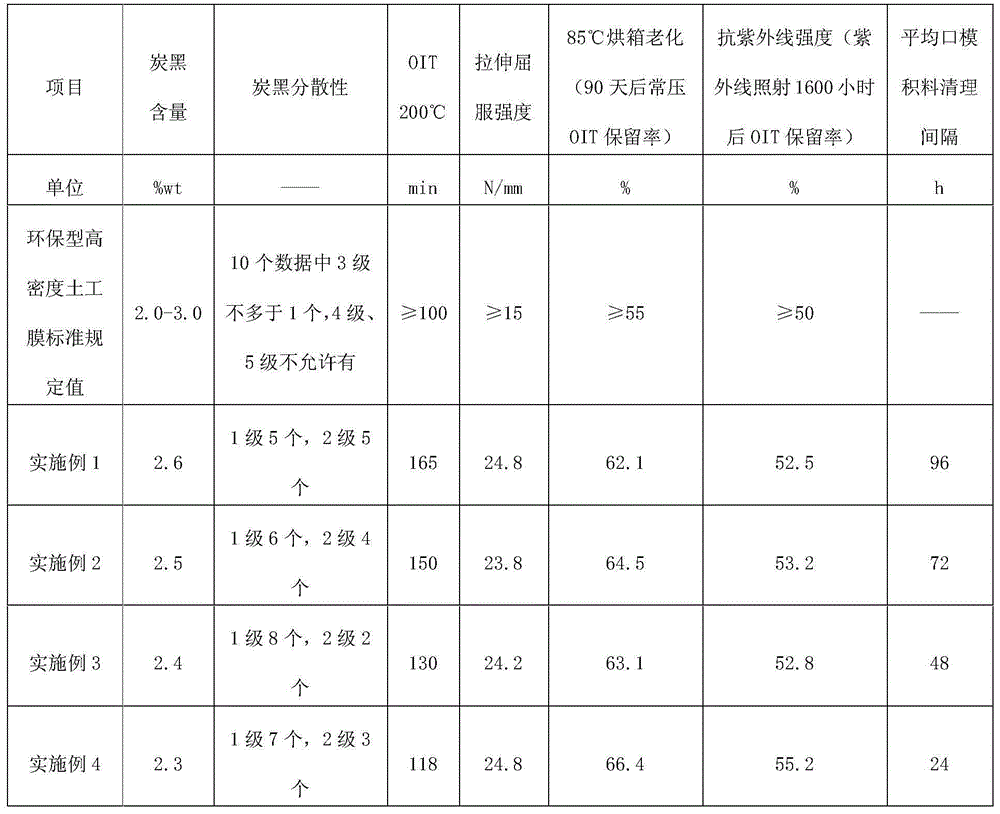

Embodiment 1

[0027] High-density polyethylene (brand: T60-800, produced by Zhongsha Tianjin Petrochemical Co., Ltd.), linear low-density polyethylene (brand: 7042, produced by Daqing Petrochemical), carbon black (brand: XPB366, produced by Degussa Company, primary Particle size 22 ± 2nm), antioxidant 1076 (brand CHINOX1076, produced by Double Bond Chemical Co., Ltd.), antioxidant 618 (brand: CHINOX618, produced by Double Bond Chemical Co., Ltd.), fluorocarbon polymer (brand: 5920A , produced by 3M Company in the United States) according to high-density polyethylene 23%, linear low-density grade ethylene 10%, carbon black 55%, antioxidant 10765%, antioxidant 6185%, fluorocarbon polymer PPA5920 (vinylidene fluoride, six Fluoropropylene, tetrafluoroethylene copolymer) 2% ratio, add in the banbury mixer, banbury to 130 ℃, discharge; through single-screw extruder granulation, extruding temperature 180 ℃, make the present invention Polyethylene masterbatch.

[0028] The prepared polyethylene co...

Embodiment 2

[0031] Color masterbatch production, film blowing process are the same as in Example 1, and the specific formula is as follows: high-density polyethylene (trademark: T50-2000, produced by Zhongsha Tianjin Petrochemical Co., Ltd.) 25%, linear low-density polyethylene (trademark: 0209AA , produced by Dushanzi Petrochemical) 12%, carbon black (brand: XPB367, produced by Degussa Company, primary particle size 22±2nm) 53%, antioxidant 2462, 2'-methylenebis(4-methyl- 6-tert-butylphenol) 1.5%, antioxidant 1010 (brand AT10, produced by Jinhai Yabao) 3.0%; antioxidant 168 (brand: AT168, produced by Jinhai Yabao) 4.5%, tetrafluoroethylene homopolymer 1 %.

Embodiment 3

[0033] The production of color masterbatch and film blowing process are the same as in Example 1, and the specific formula is as follows: high-density polyethylene (brand: 8920, produced by Daqing Petrochemical) 35%, linear low-density polyethylene (brand: 7042N, produced by Dushanzi Petrochemical) 7.92%, carbon black (brand: XPB367, produced by Degussa Company, primary particle size 22 ± 2nm) 50%, antioxidant 300 (brand CHINOX300, produced by Double Bond Chemical Co., Ltd.) 4%; antioxidant 168 ( 2,4-di-tert-butylphenyl)phosphite 2%, antioxidant DLTP (brand: CHINOX DLTP, produced by Double Bond Chemical Co., Ltd.) 3%, fluorocarbon polymer (vinylidene fluoride, hexafluoro Propylene copolymer) 0.08%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com