Stress cracking-resistant PC (Polycarbonate) material and preparation method thereof

A technology of stress cracking resistance and composite materials, which can be used in textiles and papermaking, fiber treatment, plant fibers, etc., and can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: A PC material resistant to stress cracking, including components in parts by mass as shown in Table 1.

[0054] Its preparation method comprises the following steps:

[0055] Step 1, mixing PC, PE and PET with 25 (wt)% white mineral oil to obtain a premix;

[0056] Step 2, the 75 (wt)% white mineral oil and antioxidant that add are mixed evenly with the premix that step 1 obtains by proportioning;

[0057] Step 3, in the mixed material that step 2 obtains, add titanium dioxide, MBS resin, nano CaCO again according to the proportioning in Table 1 3 , modified plant fiber / PE composite material, 1250-mesh talcum powder (the mass ratio of silicon dioxide and magnesium oxide contained in talc powder is 2.5:1) and 3055 high-temperature fuchsia, mixed evenly and extruded at 260°C out, pelletized, and dried the pellets at a temperature of 120° C. for 3 hours to prepare a PC material.

Embodiment 2-6

[0058] Example 2-6: A PC material resistant to stress cracking. The difference from Example 1 is that its components and contents are different, and it includes the components in parts by mass as shown in Table 1.

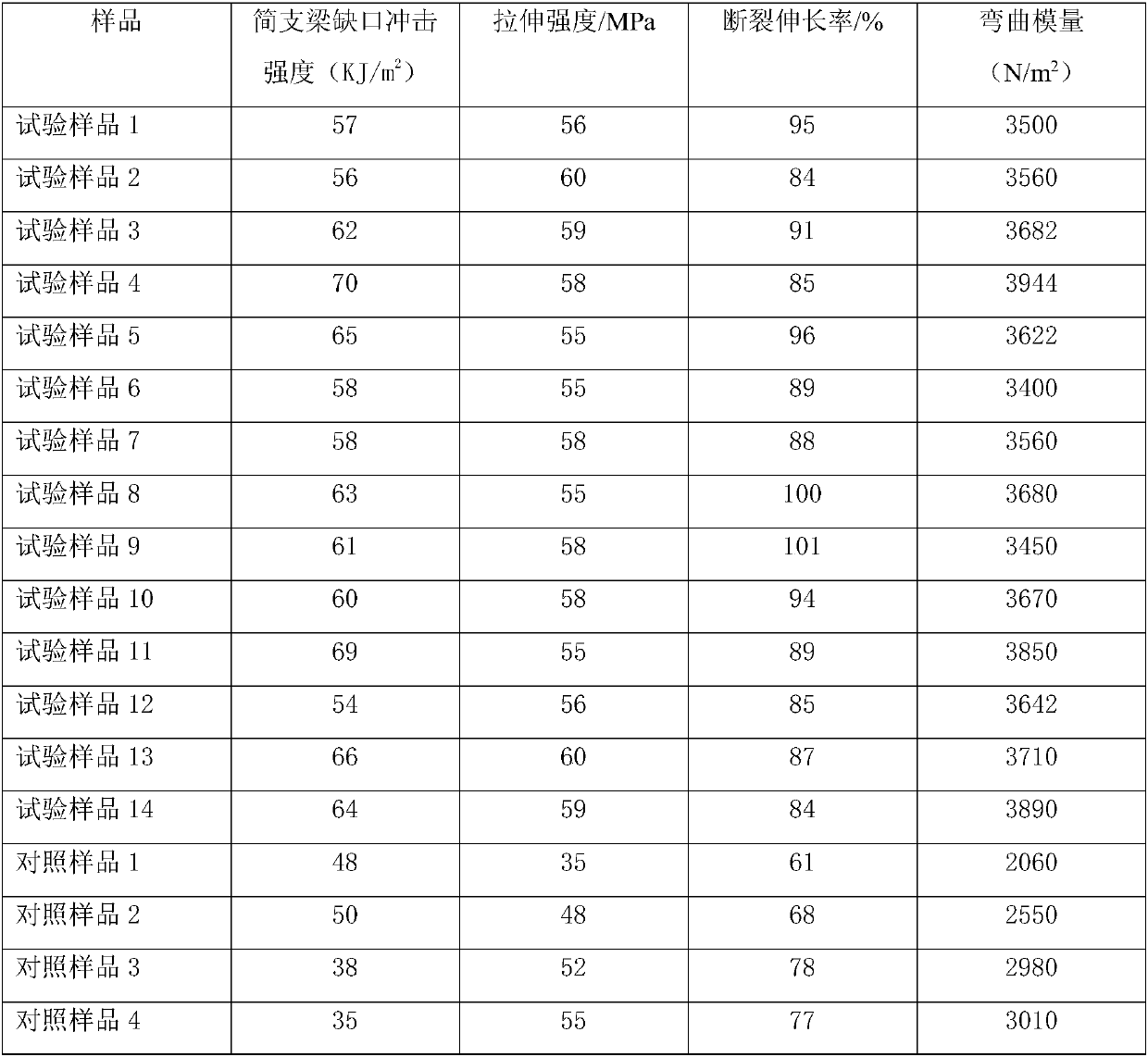

[0059] The components of the mass parts of Examples 1-6 in a PC material resistant to stress cracking in Table 1

[0060]

Embodiment 7

[0061] Example 7: A PC material resistant to stress cracking, the difference from Example 1 is that 0.5 parts of a transesterification inhibitor is also used in the PC material, and the transesterification inhibitor is NaH 2 PO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com