Transparent and breathable fish tank and preparing method thereof

A transparent, fish tank technology, applied in the field of aquaculture utensils, can solve the problems of disorder, fish tank ornamental and ventilation effect not reaching technical effect, not continuous and other problems, achieving good ventilation effect, improving mechanical strength, and improving the effect of heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

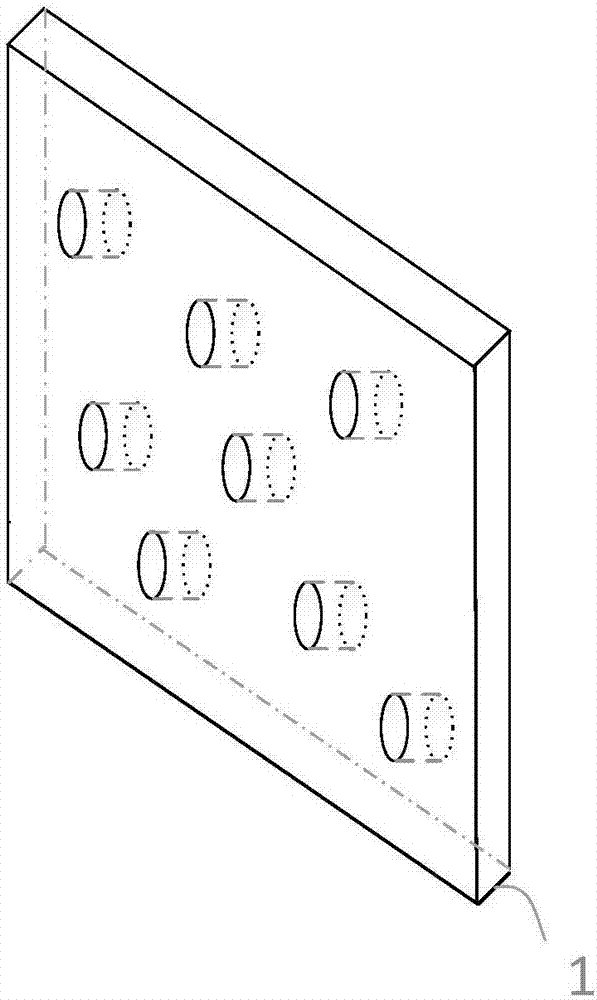

Image

Examples

Embodiment 1

[0047] (1) Weighing by weight percentage: 77% of thermoplastic resin particles, 20% of hydrophobic materials, and 3% of metal nanowires.

[0048] (2) After drying, the thermoplastic resin particles are evenly mixed with hydrophobic materials and metal nanowires, and then poured into the barrel of an injection molding machine for injection molding at a set temperature and pressure.

[0049] (3) Carry out laser cutting of the block finished product formed in step (2) vertically to the thickness direction of the block product in space to obtain a plate of the required size with uniform thickness, and soak the plate in 4mol / L dilute nitric acid for 10 hours, After taking it out, rinse it repeatedly with clean water 2-3 times to remove residual dilute nitric acid.

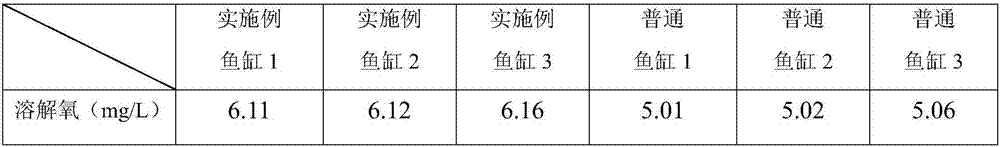

[0050] (4) Splice and assemble the plates in step (3) to obtain the required fish tank, and carry out the air permeability test on the fish tank: take three commercially available common fish tanks with the same size an...

Embodiment 2

[0054] (1) Weighing by weight percentage: 81% of thermoplastic resin particles, 15% of hydrophobic materials, and 4% of metal nanowires.

[0055] (2) After drying, the thermoplastic resin particles are evenly mixed with hydrophobic materials and metal nanowires, and then poured into the barrel of an injection molding machine for injection molding at a set temperature and pressure.

[0056] (3) Carry out laser cutting of the block finished product formed in step (2) along the space perpendicular to the thickness direction of the block product to obtain a plate of the required size with uniform thickness, and soak the plate in 5mol / L dilute nitric acid for 8 hours, After taking it out, rinse it repeatedly with clean water 2-3 times to remove residual dilute nitric acid.

[0057] (4) Splice and assemble the plates in step (3) to obtain the required fish tank, and carry out the air permeability test on the fish tank: take three commercially available common fish tanks with the sam...

Embodiment 3

[0061] (1) Weighing by weight percentage: 85% of thermoplastic resin particles, 10% of hydrophobic materials, and 5% of metal nanowires.

[0062] (2) After drying, the thermoplastic resin particles are evenly mixed with hydrophobic materials and metal nanowires, and then poured into the barrel of an injection molding machine for injection molding at a set temperature and pressure.

[0063] (3) Carry out laser cutting of the block-shaped finished product formed in step (2) along the space perpendicular to the thickness direction of the block-shaped finished product to obtain a plate of the required size with uniform thickness, and soak the plate in 6mol / L dilute nitric acid for 6 hours, After taking it out, rinse it repeatedly with clean water 2-3 times to remove residual dilute nitric acid.

[0064] (4) Splice and assemble the plates in step (3) to obtain the required fish tank, and carry out the air permeability test on the fish tank: take three commercially available common ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com