Hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and emulsion polymerization preparation method thereof

A technology of polyperfluoroethylene propylene and hexafluoropropylene, which is applied in the field of preparation of polyperfluoroethylene propylene resin and its emulsion polymerization, can solve the problems of short alkyl side chains and poor modification effect, and achieve low volatile matter and high polymerization Fast speed and stable response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

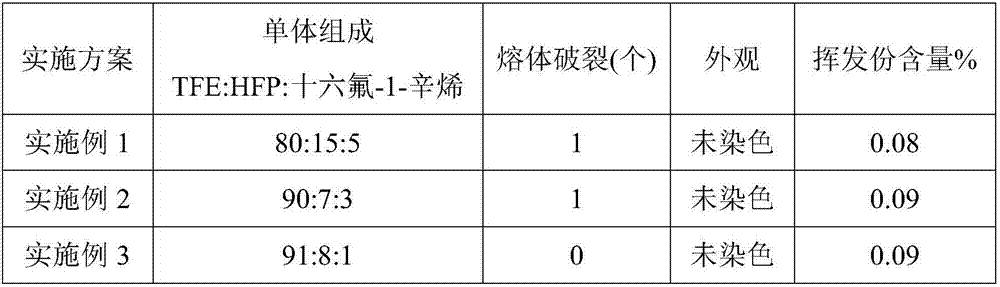

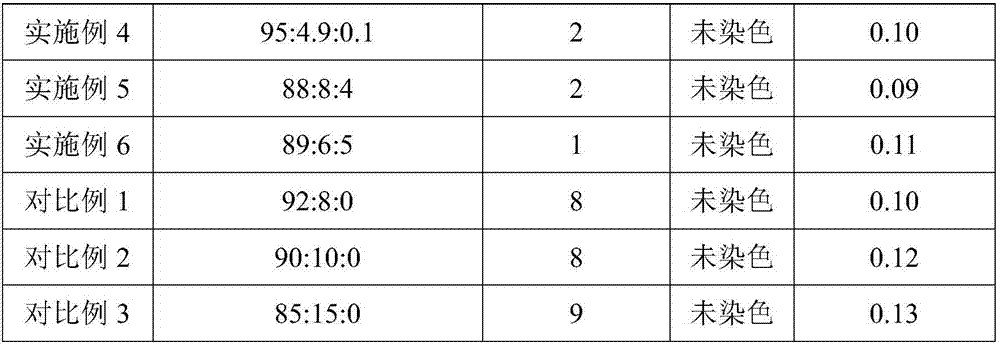

Examples

Embodiment 1

[0029] Add 3000g of pre-added comonomers (including 72mol% of hexafluoropropylene (hereinafter referred to as HFP), 20mol% of tetrafluoroethylene (hereinafter referred to as TFE), 8mol% of hexadecafluoro-1-octene) in a 5L reactor , Then the reactor was heated to 60° C. with stirring, and then 3.2 g of perfluorocyclohexyl peroxide was added to it. At this time, the set pressure of the reactor was 1.5 MPa, and the pressure was maintained by adding comonomers (including 20 mol% HFP and 80 mol% TFE) during the copolymerization process. Copolymerization was carried out until 1200 g of additional comonomer was consumed. After the copolymerization process is finished, the reaction product is cooled to 40° C., and the balance valve connecting the reactor to the post-processing equipment in the closed space is opened. The post-processing equipment is connected with the monomer vapor direct cooler and the condensate collector. The reactants are sent from the polymerization reactor to ...

Embodiment 2

[0031] Add 2500g pre-added comonomers (comprising 79mol% of HFP, 20mol% of TFE, 1mol% of hexadecafluoro-1-octene) in the 5L reactor, then the reactor is heated to 40°C under stirring, after that To this was added 4 g of perfluorocyclohexyl peroxide. At this time, the set pressure of the reactor was 1.3 MPa, and the pressure was maintained by adding comonomers (including 7 mol% HFP, 88 mol% TFE, and 5 mol% hexadecafluoro-1-octene) during the copolymerization process. After 200 g of these mixtures were consumed, 0.3 g of cyclohexane was added to the reactor and the copolymerization was continued. Copolymerization was carried out until 1200 g of additional comonomer was consumed. After the copolymerization process is finished, the reaction product is cooled to 40° C., and the balance valve connecting the reactor to the post-processing equipment in the closed space is opened. The post-processing equipment is connected with the monomer vapor direct cooler and the condensate colle...

Embodiment 3

[0033]Add 1200g dichloropentafluoropropane, 2500g pre-added comonomer (comprising 77mol% of HFP, 20mol% of TFE, 3mol% of hexadecafluoro-1-octene) in the 5L reactor, then the reactor is under stirring condition It was heated to 20° C., and then 4 g of perfluorocyclohexyl peroxide was added thereto. At this time, the set pressure of the reactor was 1.1 MPa, and the pressure was maintained by adding comonomers (including 11 mol% of HFP, 88 mol% of TFE, and 1 mol% of hexadecafluoro-1-octene) during the copolymerization process. After 200 g of these mixtures were consumed, 0.15 g of cyclohexane was added to the reactor and the copolymerization was continued. Copolymerization was carried out until 1200 g of additional comonomer was consumed. After the copolymerization process is finished, the reaction product is cooled to 40° C., and the balance valve connecting the reactor to the post-processing equipment in the closed space is opened. The post-processing equipment is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com