High-dielectric-constant resin composition and application thereof

A technology of high dielectric constant and resin composition, applied in the field of antenna substrate, high dielectric constant composite material and prepreg and copper clad laminate made of the same, and high dielectric constant resin composition, can solve the problem. E-type glass fiber cloth has low dielectric constant, low glass transition temperature, and large dielectric loss of the cured product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

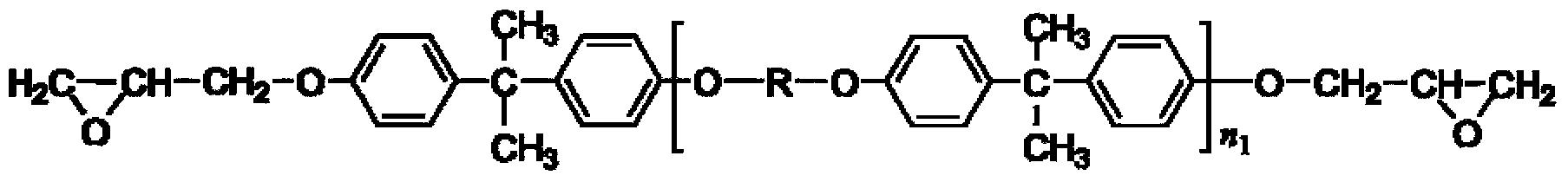

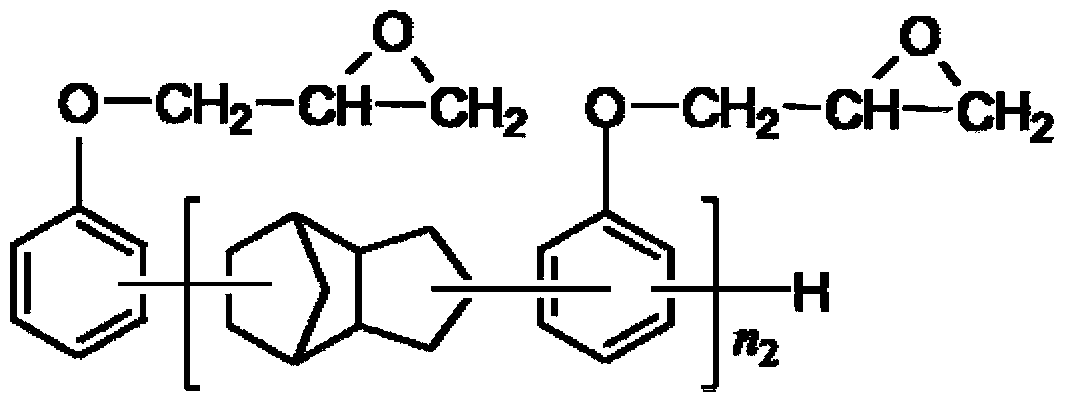

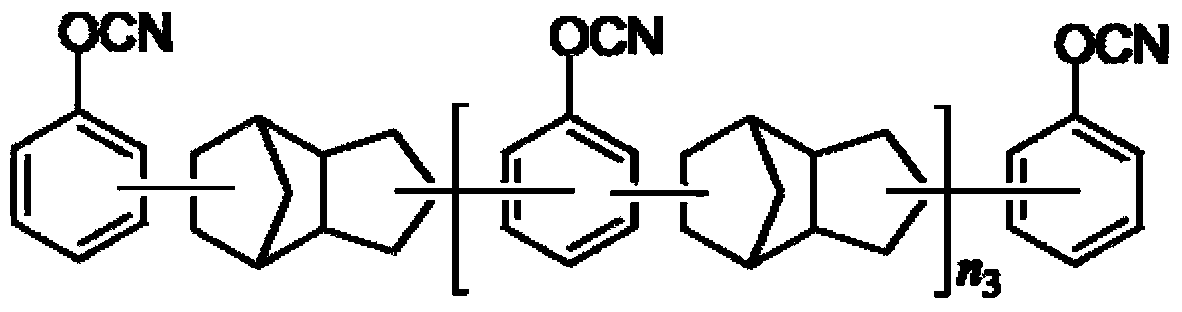

[0115] Take a suitable container, add 10 parts by mass of flexible epoxy resin EXA-4816, 30 parts by mass of dicyclopentadiene type novolac epoxy resin HP-7200L, 15 parts by mass of brominated epoxy resin EPICLON153-60M, 10 parts by mass Parts of phenolic novolac epoxy resin PNE177, 25 parts by mass of dicyclopentadiene type cyanate resin XU-71787, 26.8 parts by mass of active ester resin, and an appropriate amount of solvent to stir for a certain period of time, and then add an appropriate amount of accelerator Zinc octanoate and 4-dimethylaminopyridine, continue to stir evenly, and finally add 415 parts by mass of barium titanate high dielectric constant filler BT-300, fully stir, emulsify and disperse to form a glue. Immerse the above glue with high dielectric constant glass fiber cloth, and control it to a suitable thickness (control the mass content of high dielectric constant glass fiber cloth to be 10%), and then dry to remove the solvent to obtain a prepreg. The prepre...

Embodiment 2

[0117] Take a suitable container, add 10 parts by mass of flexible epoxy resin EXA-4822, 30 parts by mass of dicyclopentadiene type novolac epoxy resin HP-7200L, 15 parts by mass of brominated epoxy resin EPICLON153-60M, 10 parts by mass EPPN-501H of three phenolic methane type epoxy resins, 25 mass parts of dicyclopentadiene type cyanate resin XU-71787, 27.3 mass parts of active ester resins, and an appropriate amount of solvent are stirred for a certain period of time, and then Add an appropriate amount of accelerator zinc octoate and 4-dimethylaminopyridine, continue to stir evenly, and finally add 416 parts by mass of barium titanate high dielectric constant filler BT-300, fully stir, and emulsify and disperse to form a glue. Use high dielectric constant glass fiber cloth to impregnate the above glue solution, and control it to a suitable thickness (control the mass content of high dielectric constant glass fiber cloth to be 40%), and then dry to remove the solvent to obtai...

Embodiment 3

[0119]Take a suitable container, add 10 parts by mass of flexible epoxy resin EXA-4816, 30 parts by mass of dicyclopentadiene type novolac epoxy resin HP-7200L, 15 parts by mass of brominated epoxy resin EPICLON153-60M, 10 parts by mass Parts of tetraphenol ethane type epoxy resin EPON1031, 25 parts by mass of dicyclopentadiene type cyanate resin XU-71787, active ester resin of 25.8 parts by mass, and an appropriate amount of solvent are stirred for a certain period of time, and then added Appropriate amount of accelerator zinc octoate and 4-dimethylaminopyridine, continue to stir evenly, and finally add 411 parts by mass of barium titanate high dielectric constant filler BT-300, fully stir, and emulsify and disperse to form a glue. Use high dielectric constant glass fiber cloth to impregnate the above glue solution, and control it to a suitable thickness (control the mass content of high dielectric constant glass fiber cloth to be 20%), and then dry to remove the solvent to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com