Patents

Literature

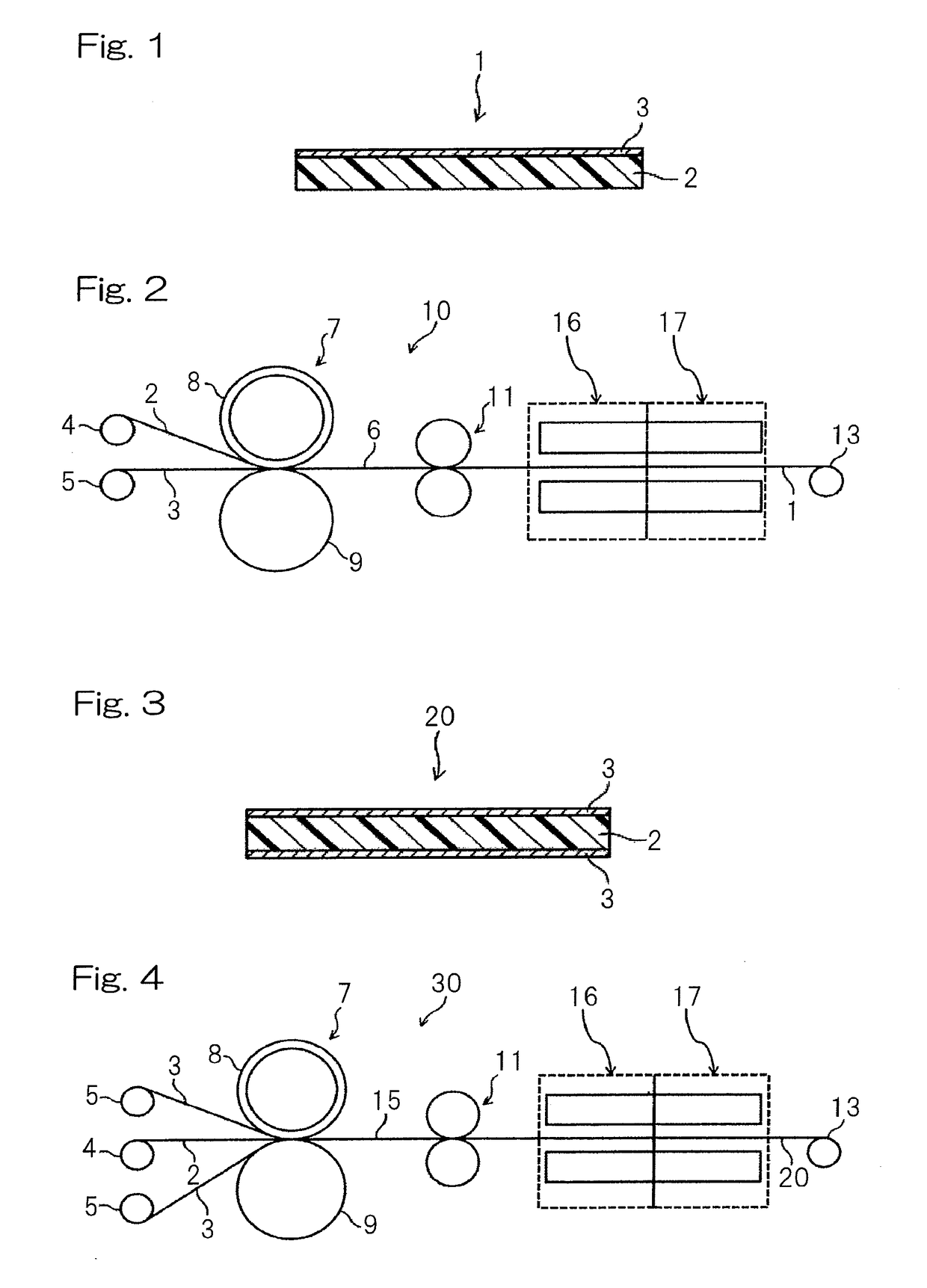

34results about How to "High-frequency characteristic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

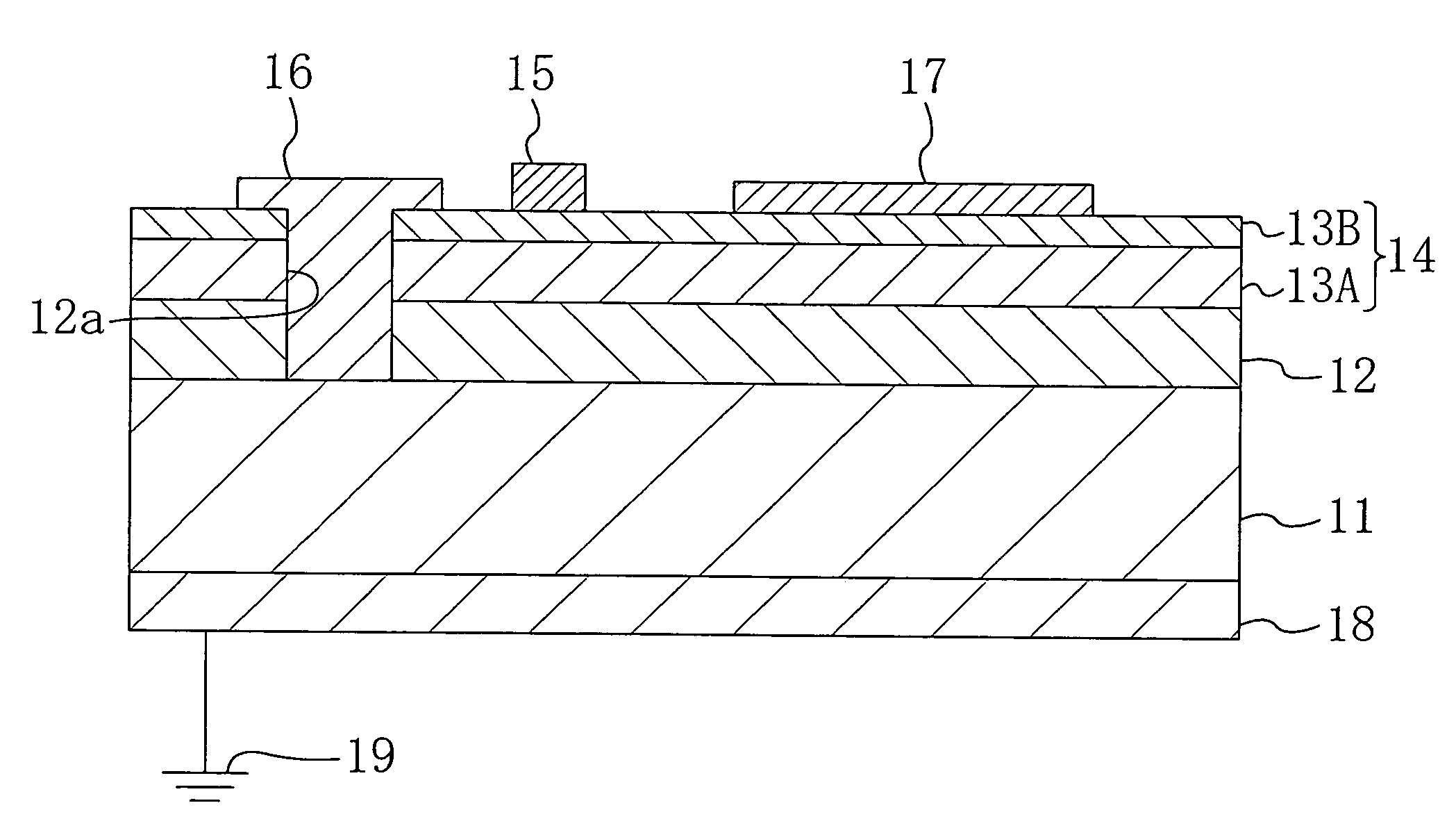

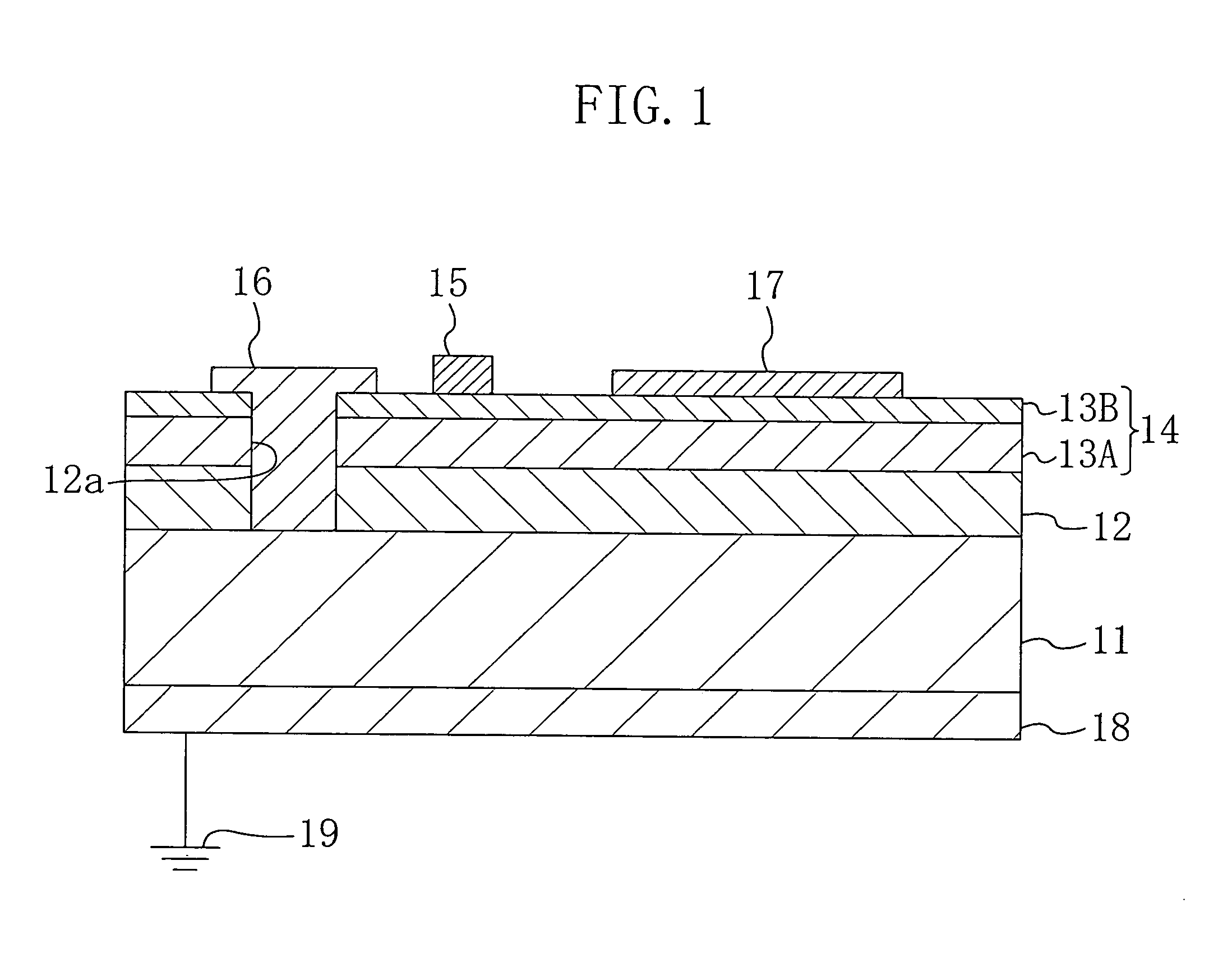

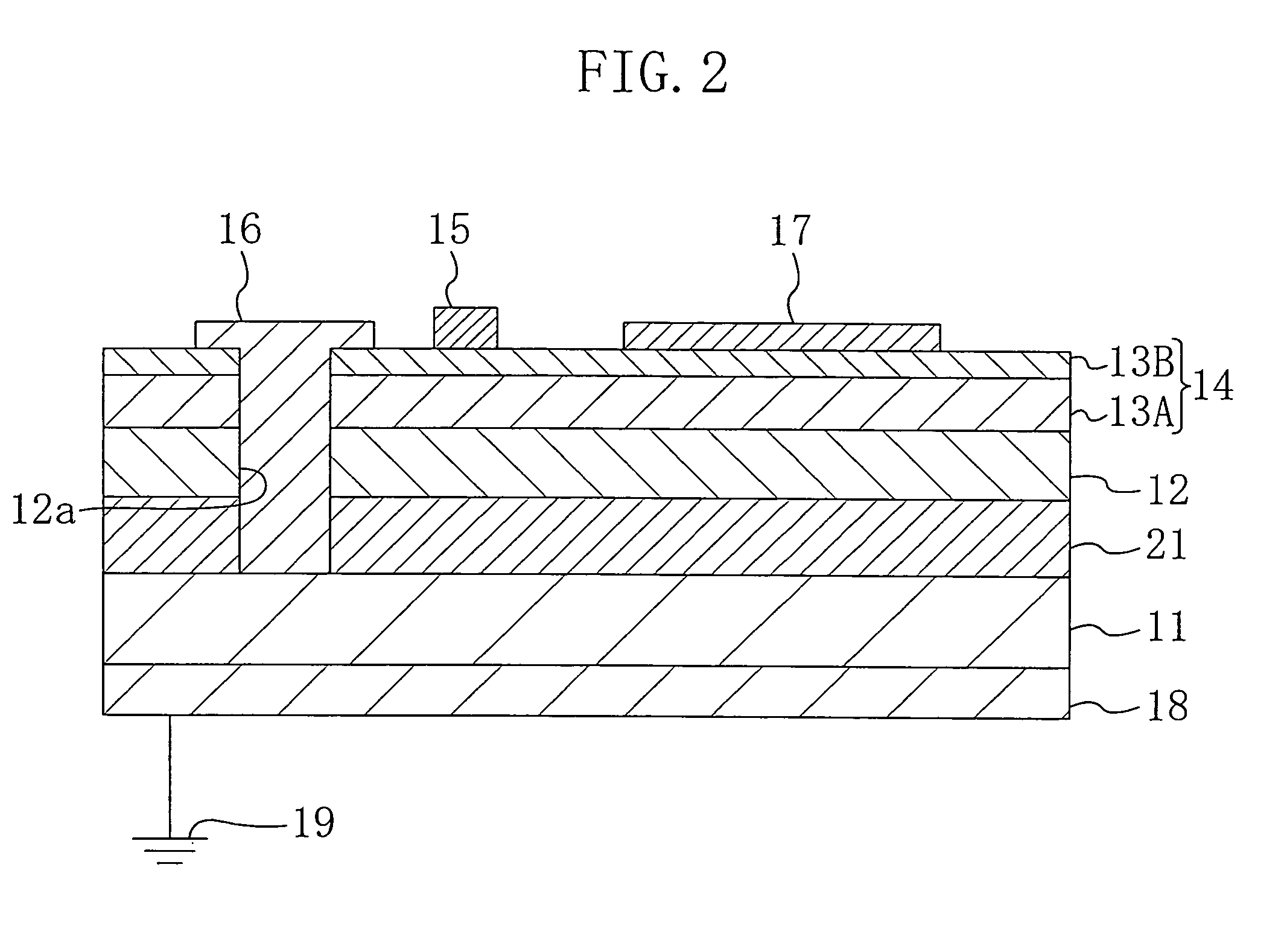

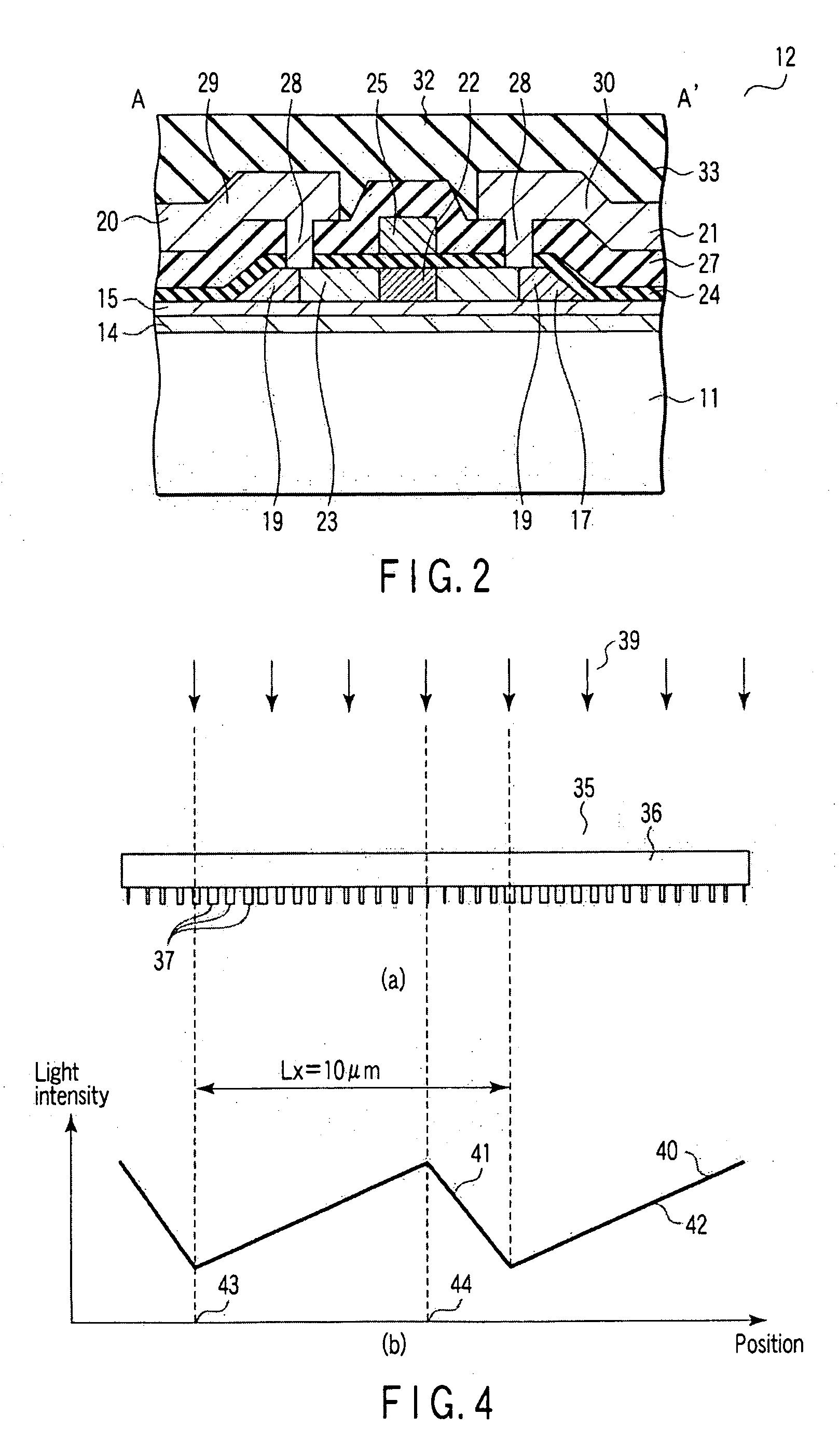

Semiconductor device

ActiveUS20050001235A1Promote formationObstruction is producedLaser active region structureSemiconductor/solid-state device manufacturingHigh resistanceDevice material

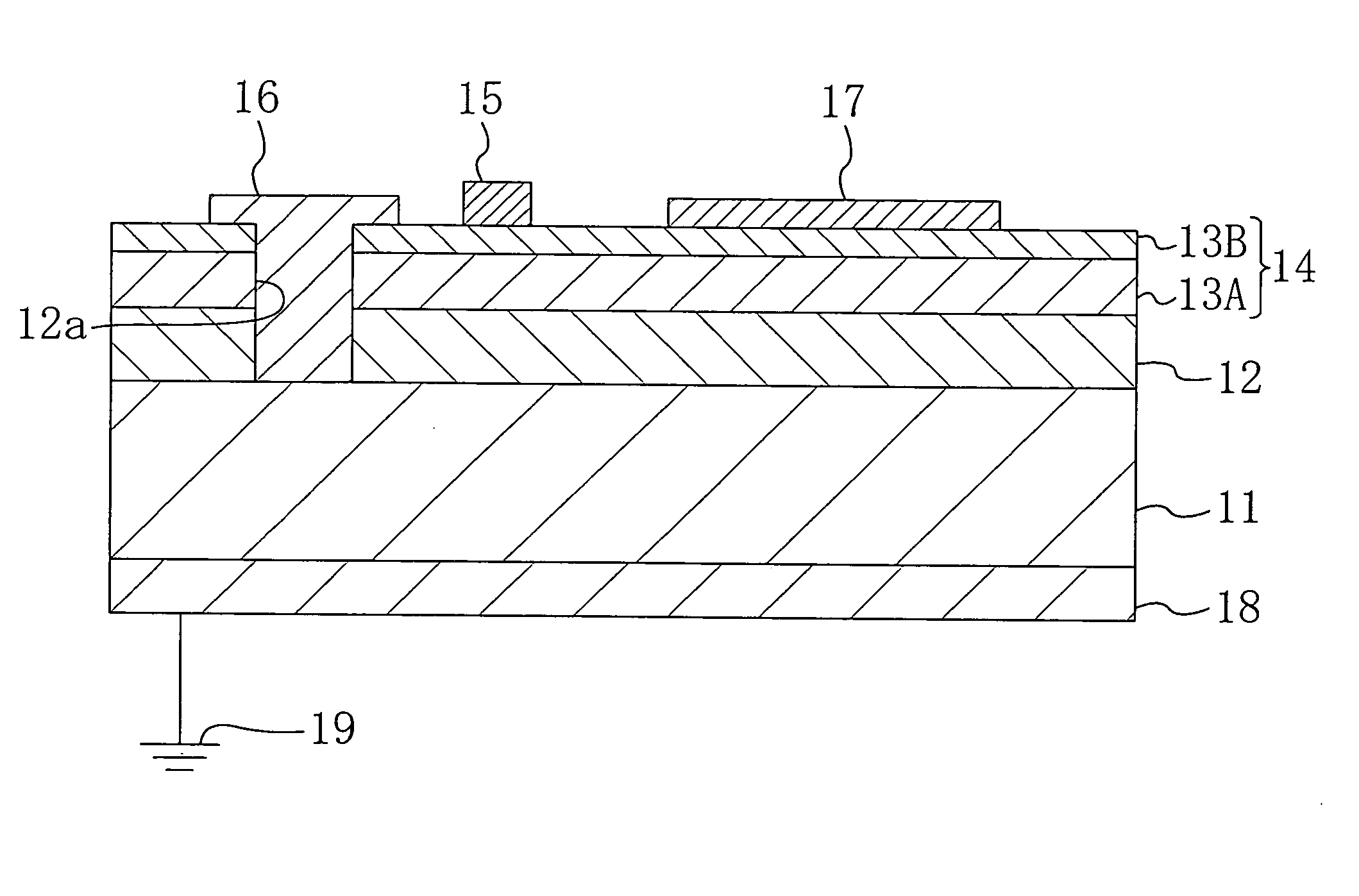

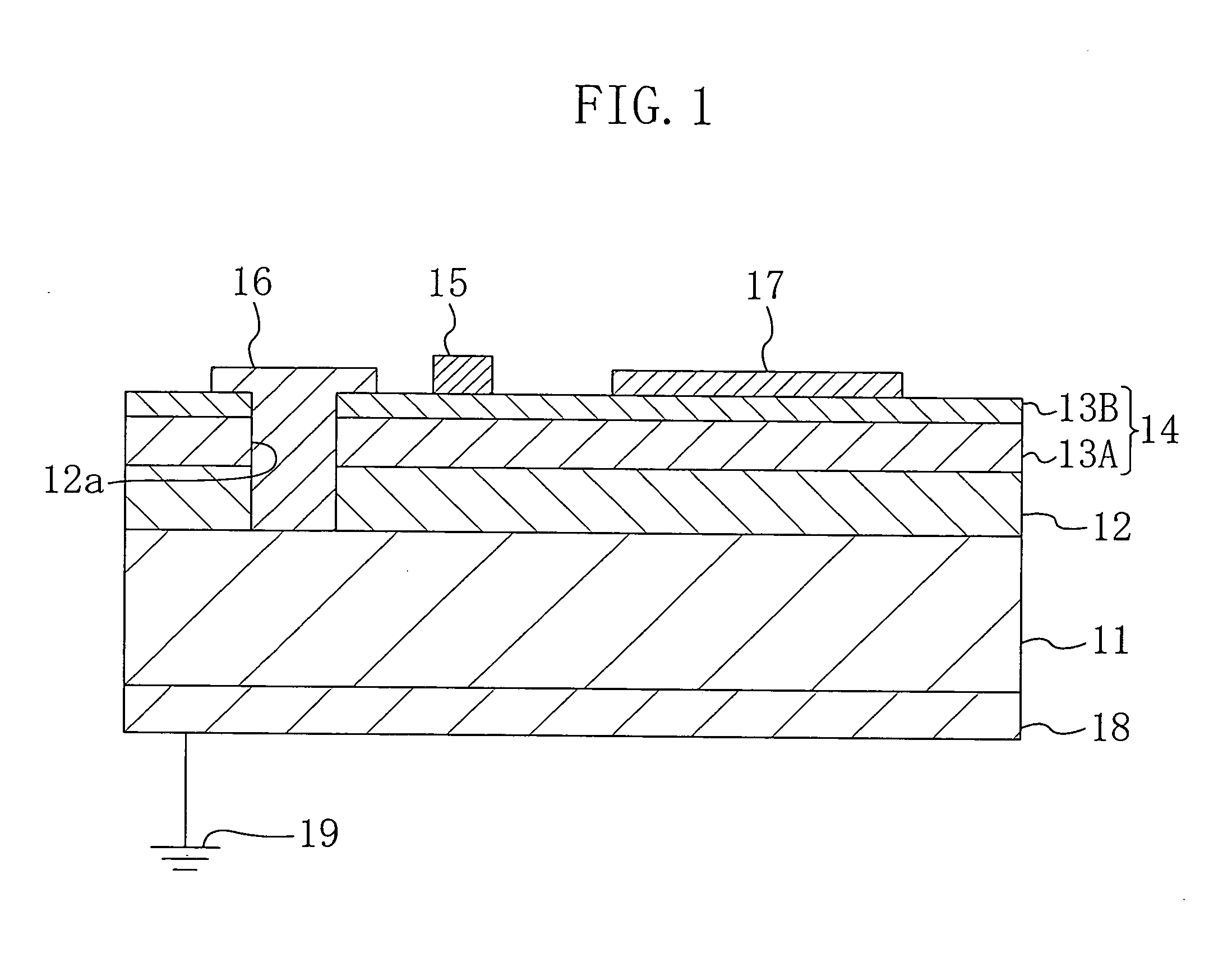

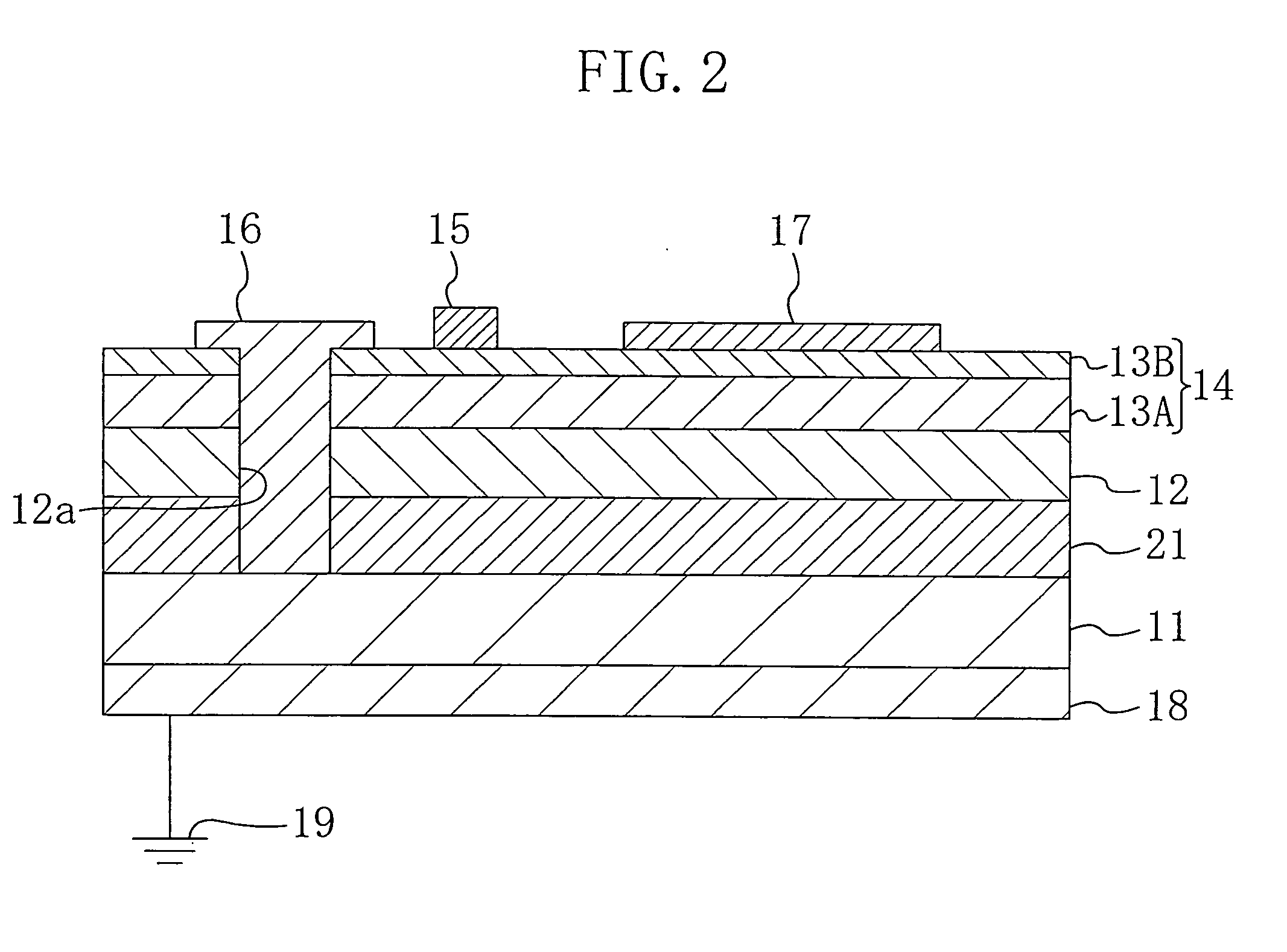

A semiconductor device has: a buffer layer formed on a conductive substrate and made of AlxGa1-xN with a high resistance; an element-forming layer formed on the buffer layer, having a channel layer, and made of undoped GaN and N-type AlyGa1-yN; and a source electrode, a drain electrode and a gate electrode which are selectively formed on the element-forming layer. The source electrode is filled in a through hole provided in the buffer layer and the element-forming layer, and is thus electrically connected to the conductive substrate.

Owner:PANASONIC CORP

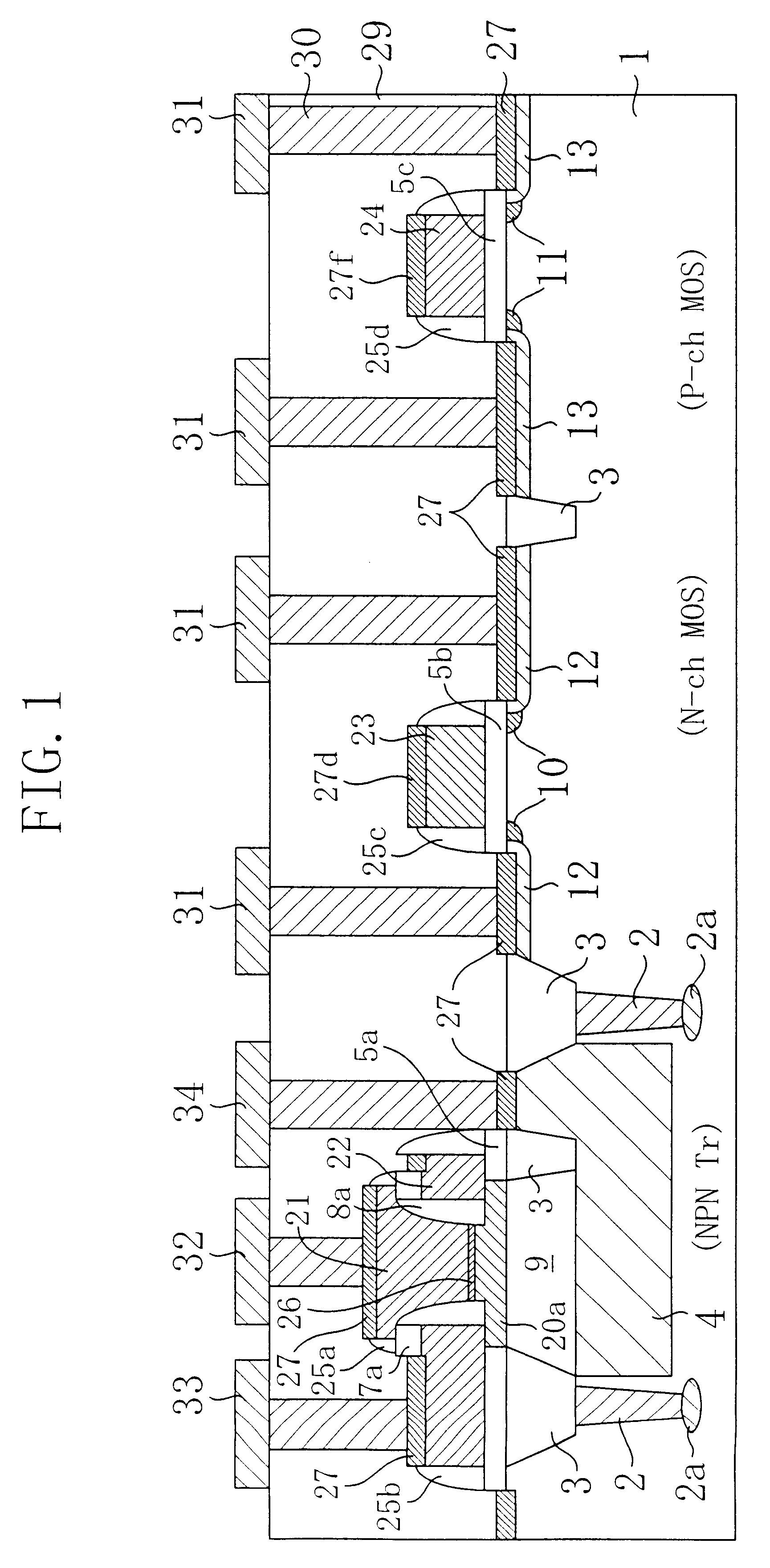

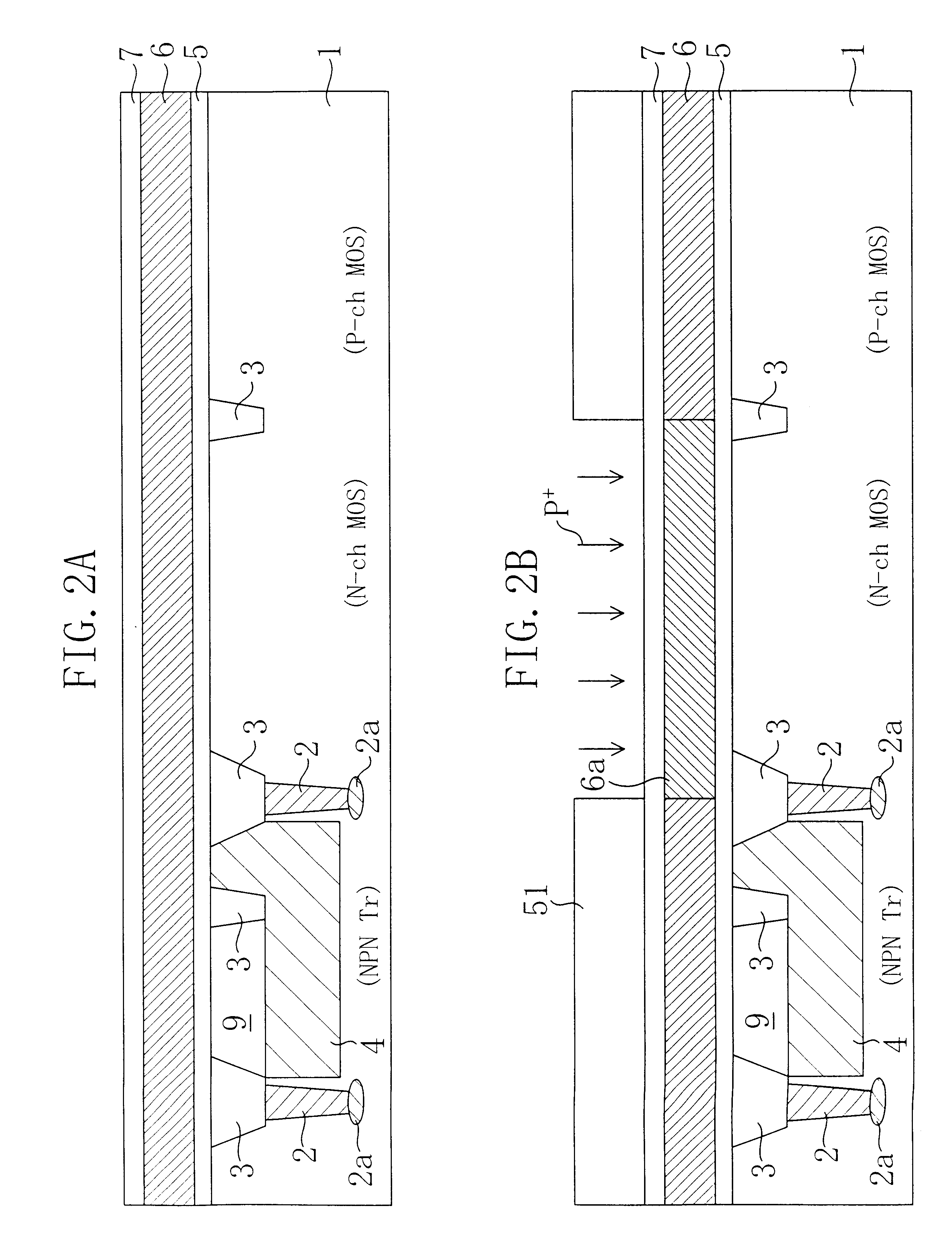

Semiconductor device and method for fabricating the same

InactiveUS6399993B1Reduce the number of stepsIncrease productivityTransistorSolid-state devicesCMOSThermal expansion

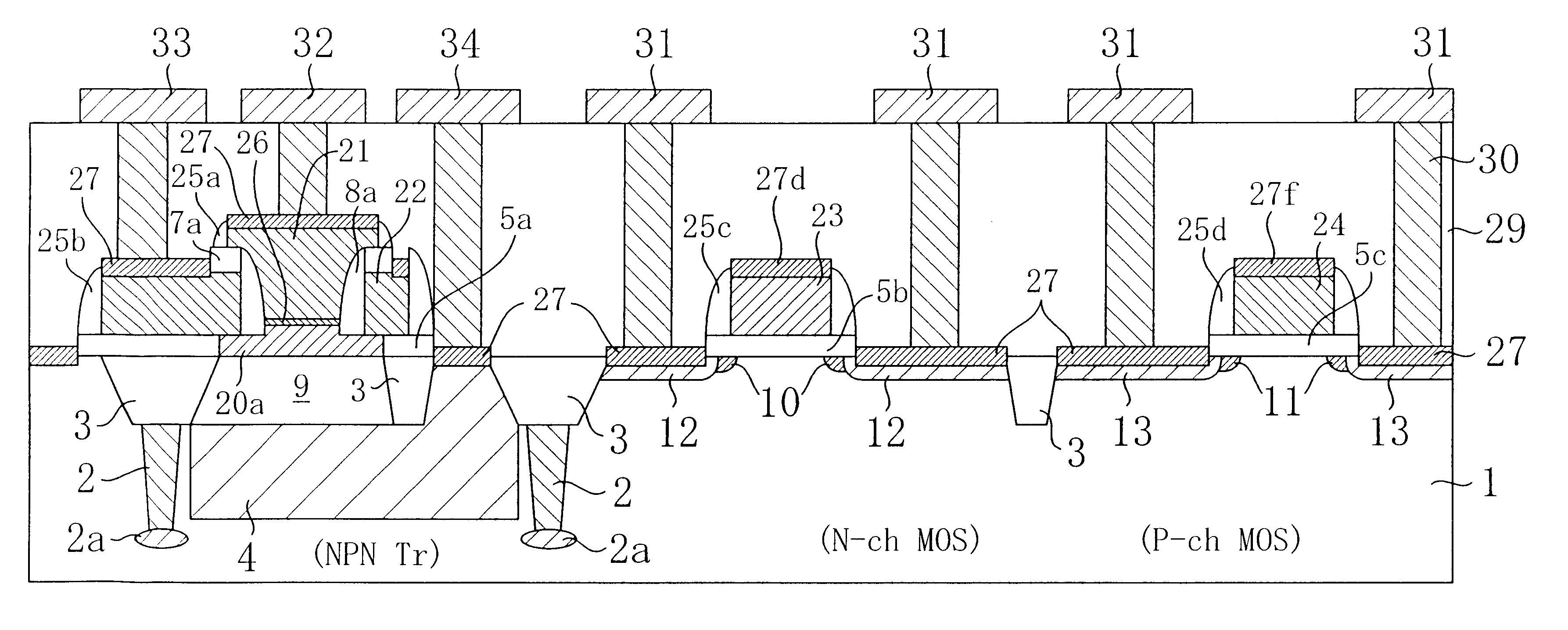

In a bipolar transistor block, a base layer (20a) of SiGe single crystals and an emitter layer (26) of almost 100% of Si single crystals are stacked in this order over a collector diffused layer (9). Over both edges of the base layer (20a), a base undercoat insulating film (5a) and base extended electrodes (22) made of polysilicon are provided. The base layer (20a) has a peripheral portion with a thickness equal to that of the base undercoat insulating film (5a) and a center portion thicker than the peripheral portion. The base undercoat insulating film (5a) and gate insulating films (5b and 5c) for a CMOS block are made of the same oxide film. A stress resulting from a difference in thermal expansion coefficient between the SiGe layer as the base layer and the base undercoat insulating film 5a can be reduced, and a highly reliable BiCMOS device is realized.

Owner:PANASONIC CORP

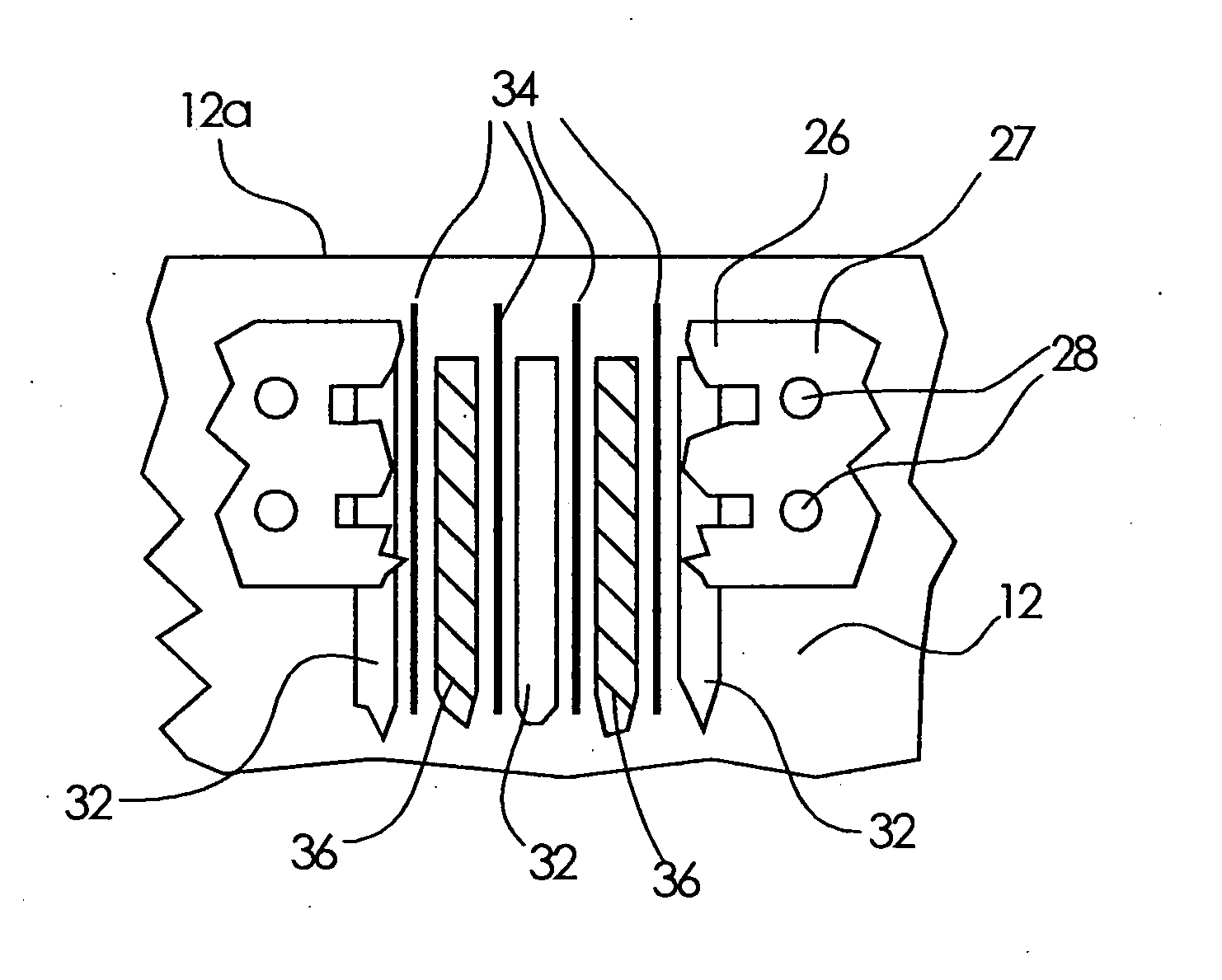

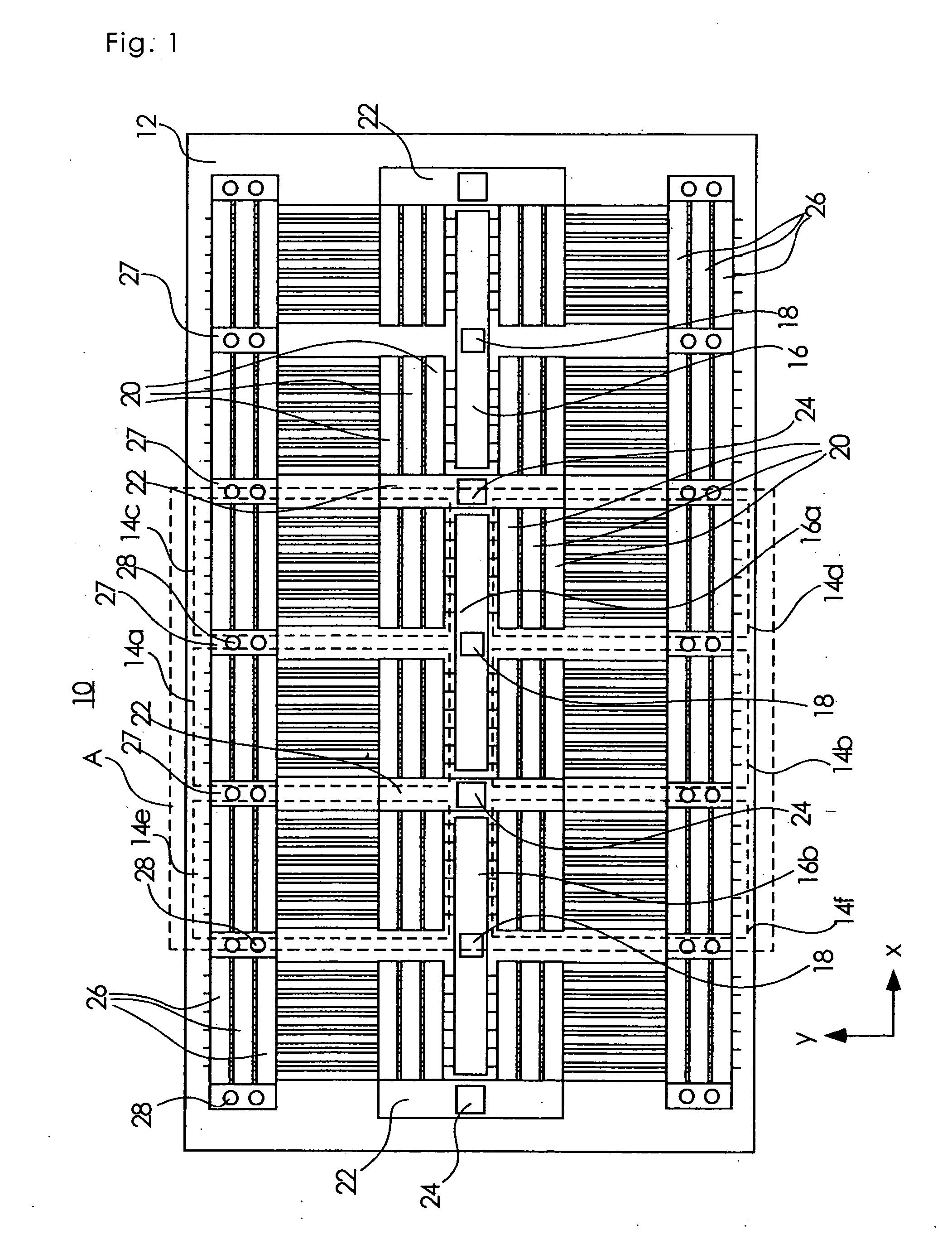

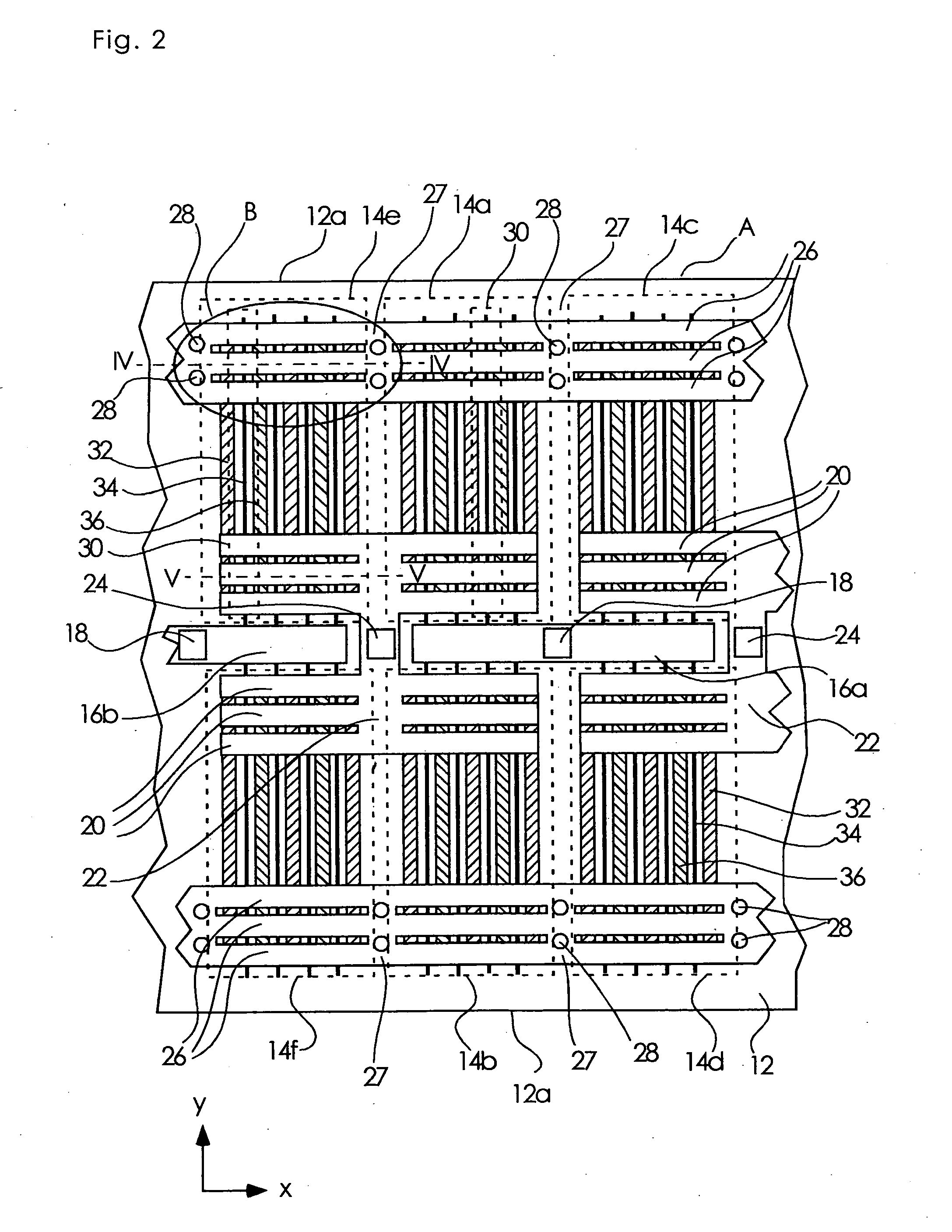

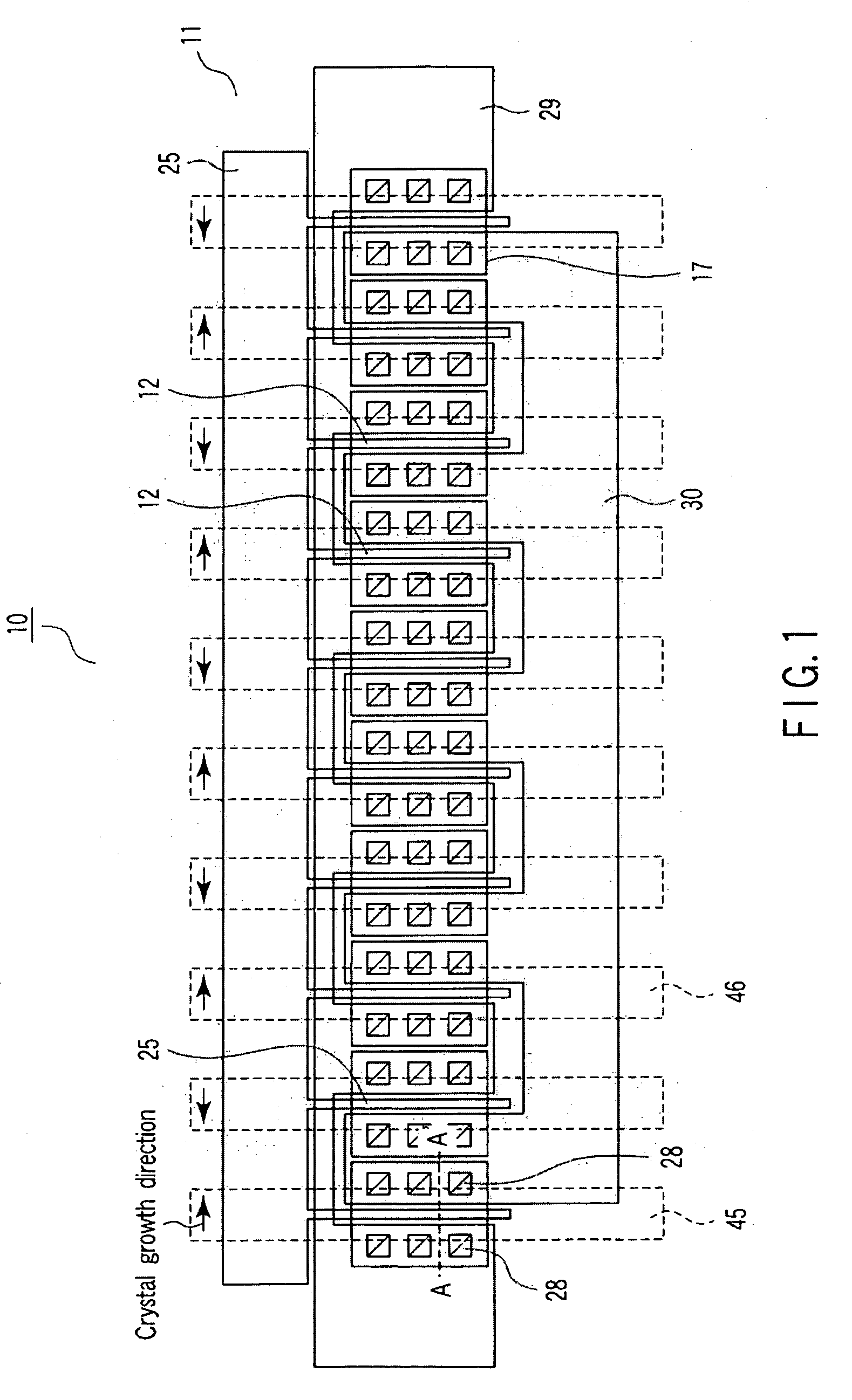

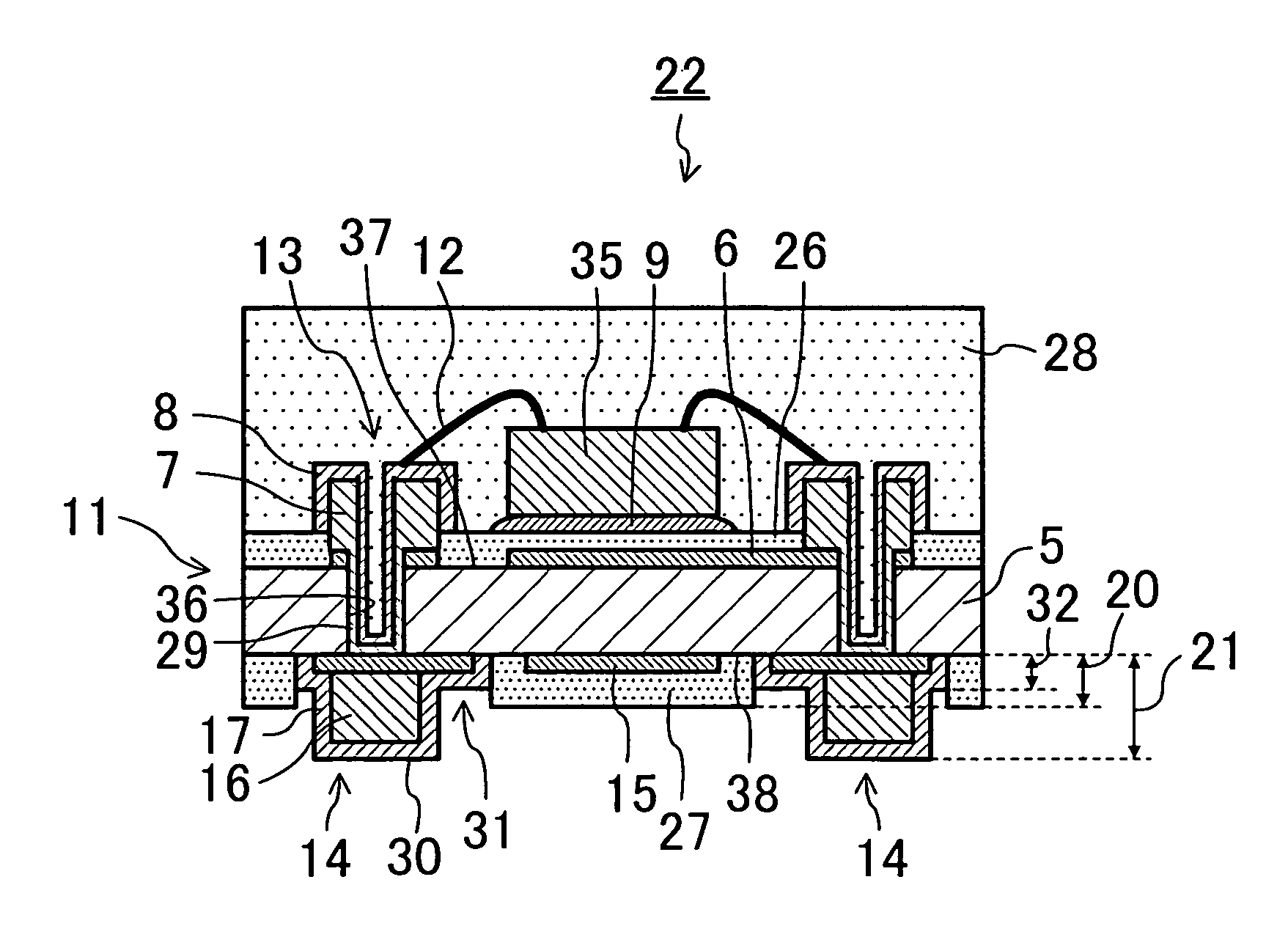

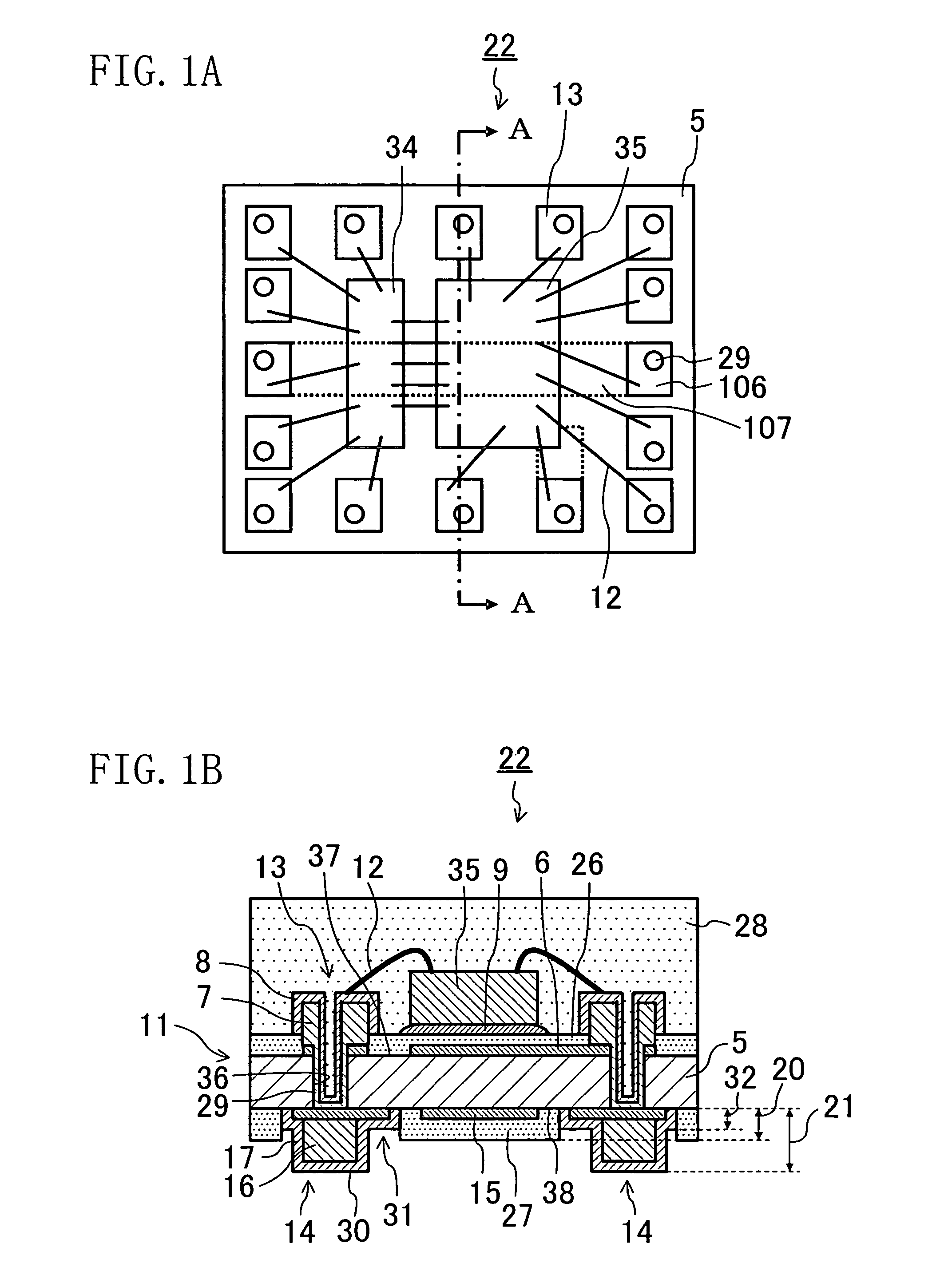

High-frequency semiconductor device

InactiveUS20050133829A1Good high speed performanceHigh power outputTransistorSemiconductor/solid-state device detailsSemiconductorSemiconductor device

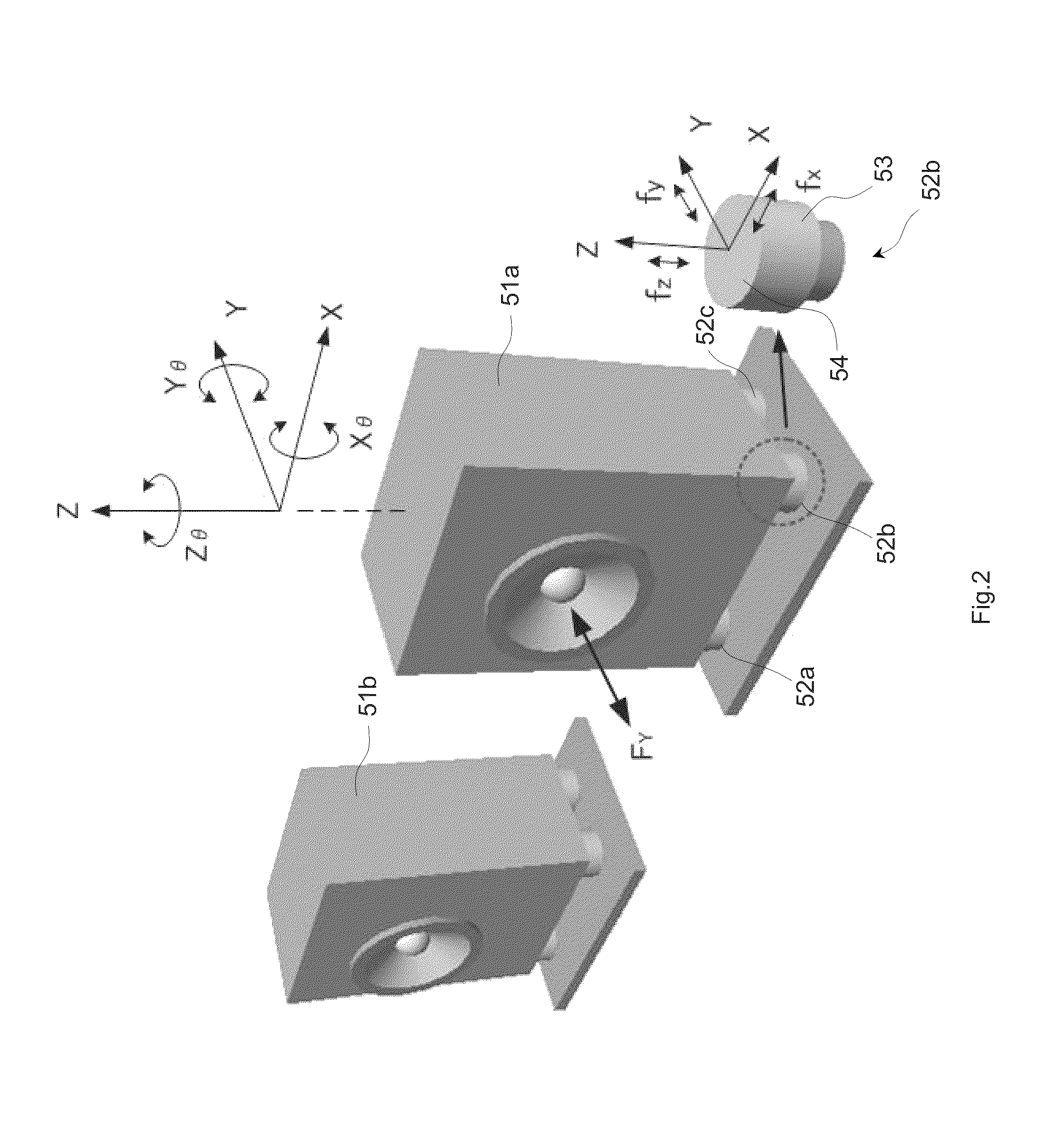

A high-frequency semiconductor device includes: a first cell which includes of gate electrodes on a surface of an epitaxial layer of a substrate, drain electrodes and source electrodes alternately located relative to the gate electrodes, a source electrode connection wiring striding over the gate electrodes and the drain electrodes and connecting the source electrodes, and a drain electrode connection wiring striding over the gate electrodes and the source electrodes and connecting the drain electrodes; a second cell which has the same configurations as the first cell, is located in an extended direction of each of the gate electrodes of the first cell, and has the drain electrode connection wiring proximate to the drain electrode connection wiring of the first cell; and a gate electrode bar located between the drain electrode connection wirings of the first and second cells, and to which the gate electrodes of the first and second cells are connected.

Owner:MITSUBISHI ELECTRIC CORP

Field effect transistor semiconductor device

ActiveUS7078743B2Avoid leakage currentPromote formationLaser active region structureSemiconductor/solid-state device manufacturingHigh resistanceField-effect transistor

A semiconductor device has: a buffer layer formed on a conductive substrate and made of AlxGa1-xN with a high resistance; an element-forming layer formed on the buffer layer, having a channel layer, and made of undoped GaN and N-type AlyGa1-yN; and a source electrode, a drain electrode and a gate electrode which are selectively formed on the element-forming layer. The source electrode is filled in a through hole provided in the buffer layer and the element-forming layer, and is thus electrically connected to the conductive substrate.

Owner:PANASONIC CORP

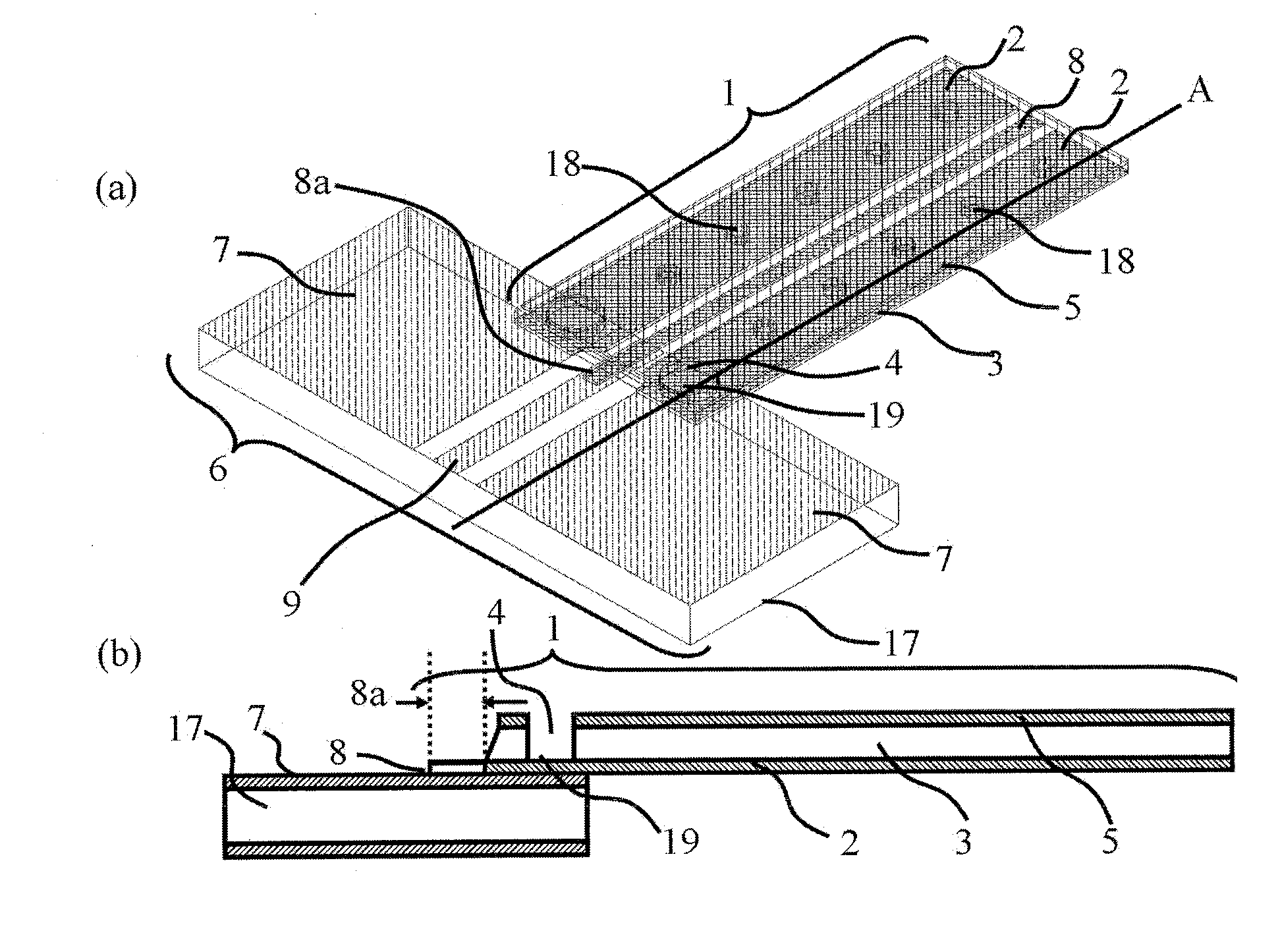

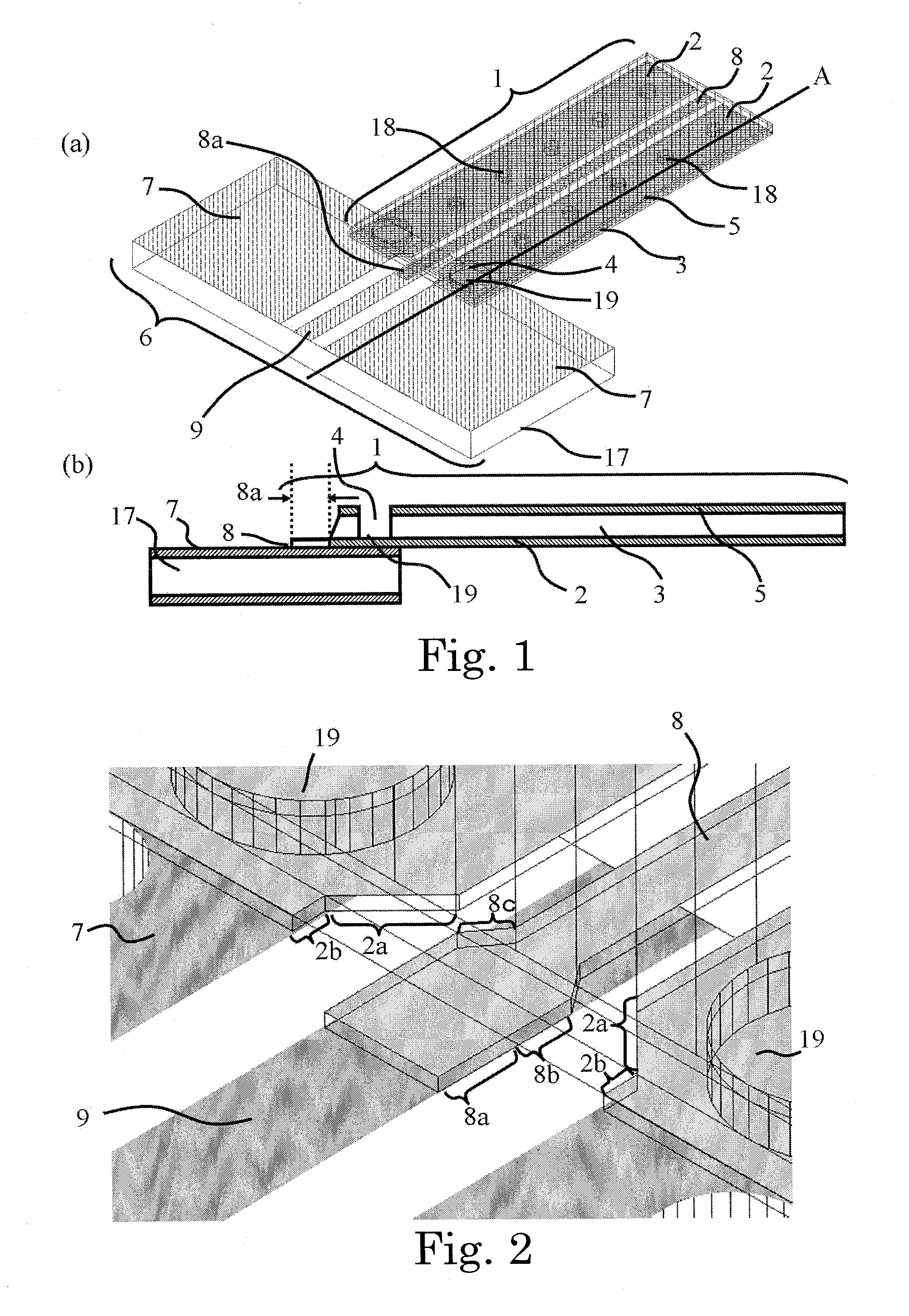

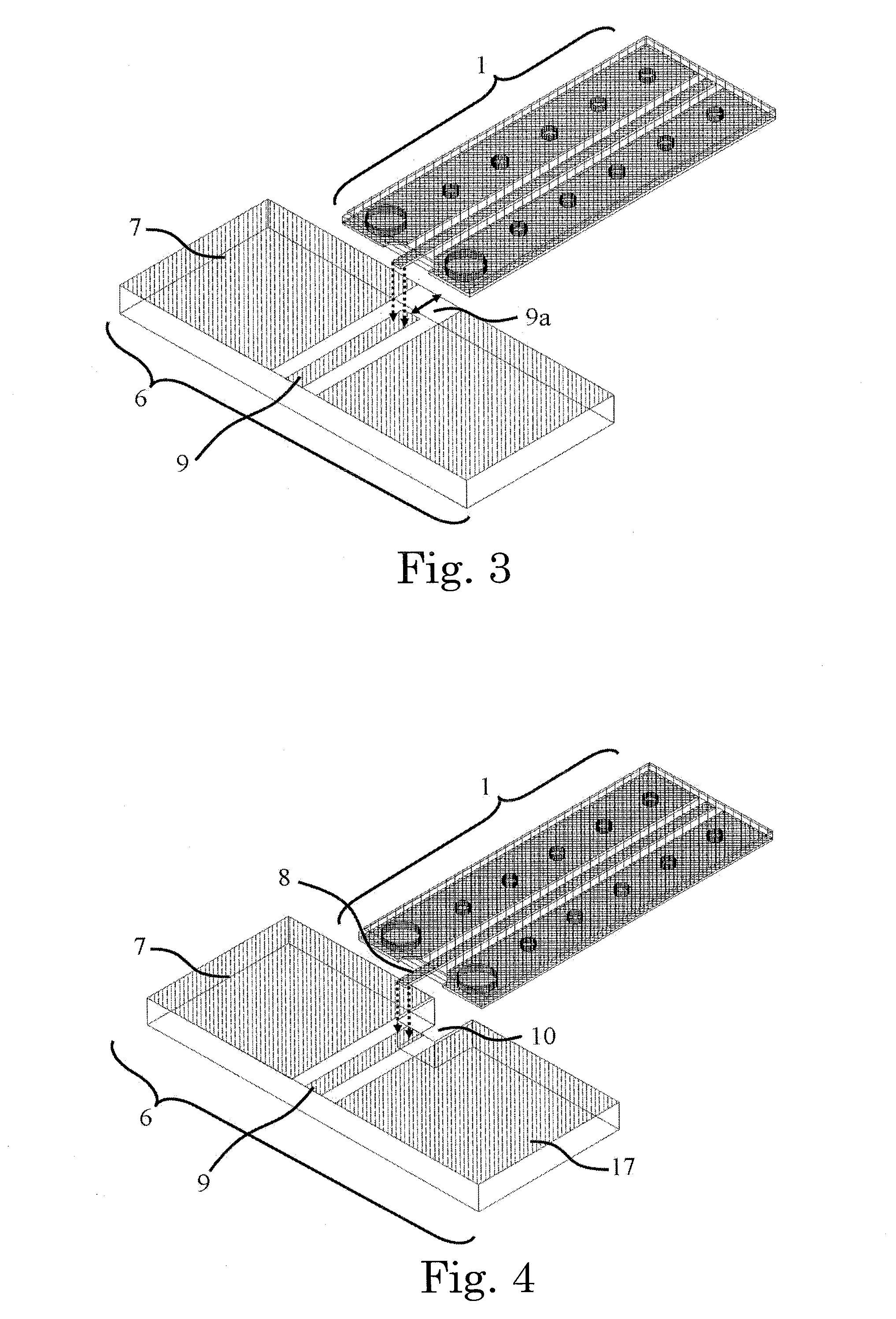

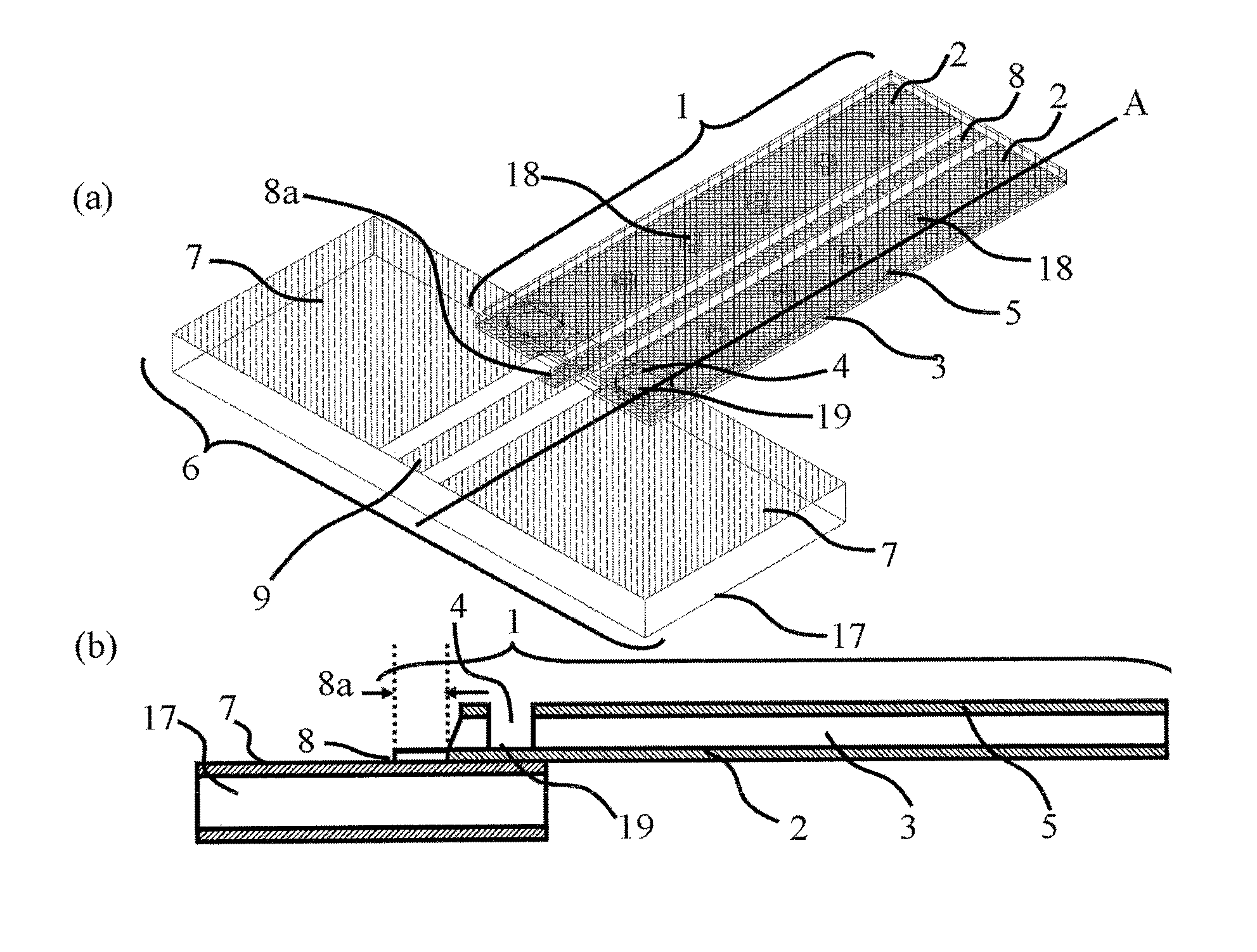

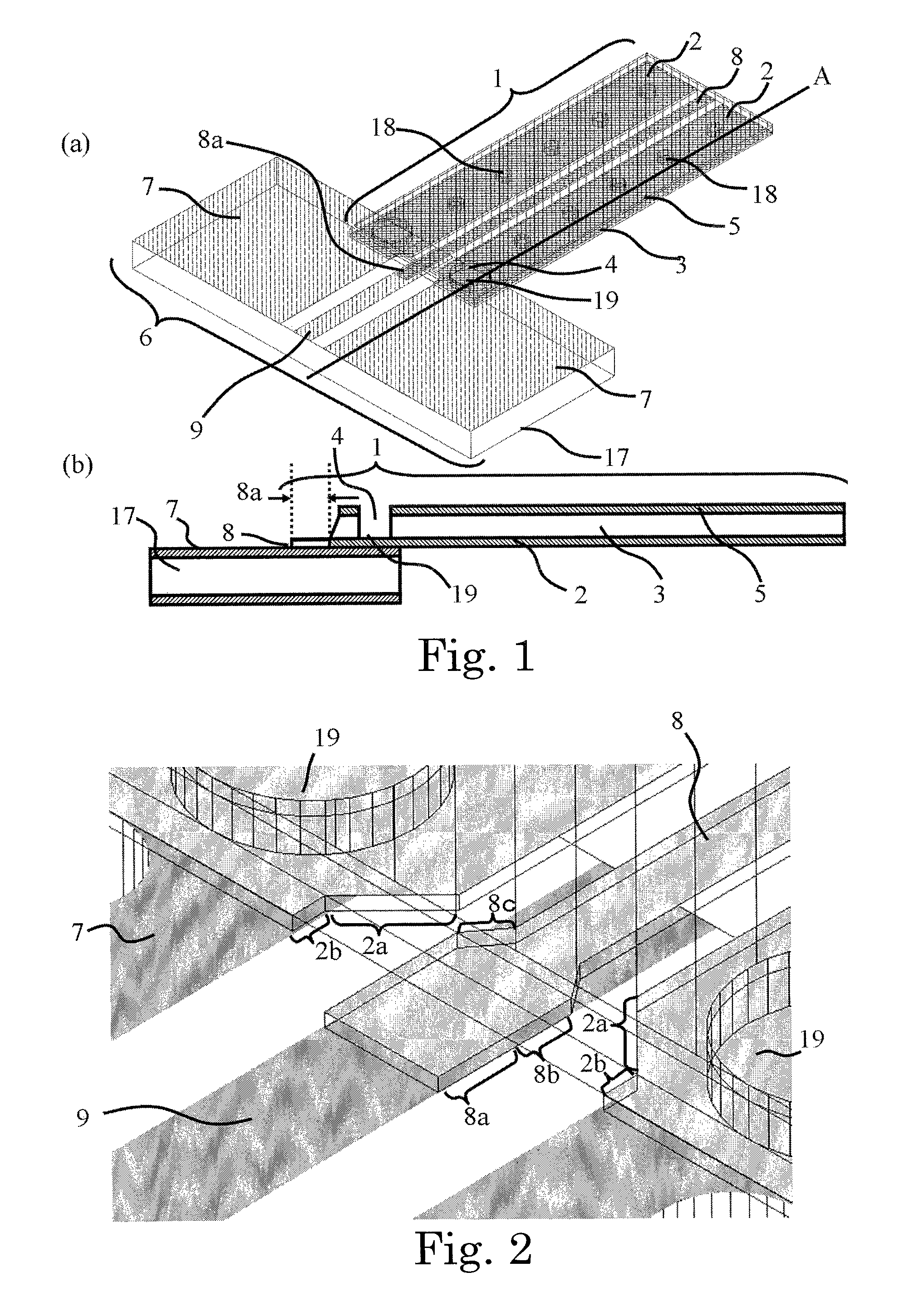

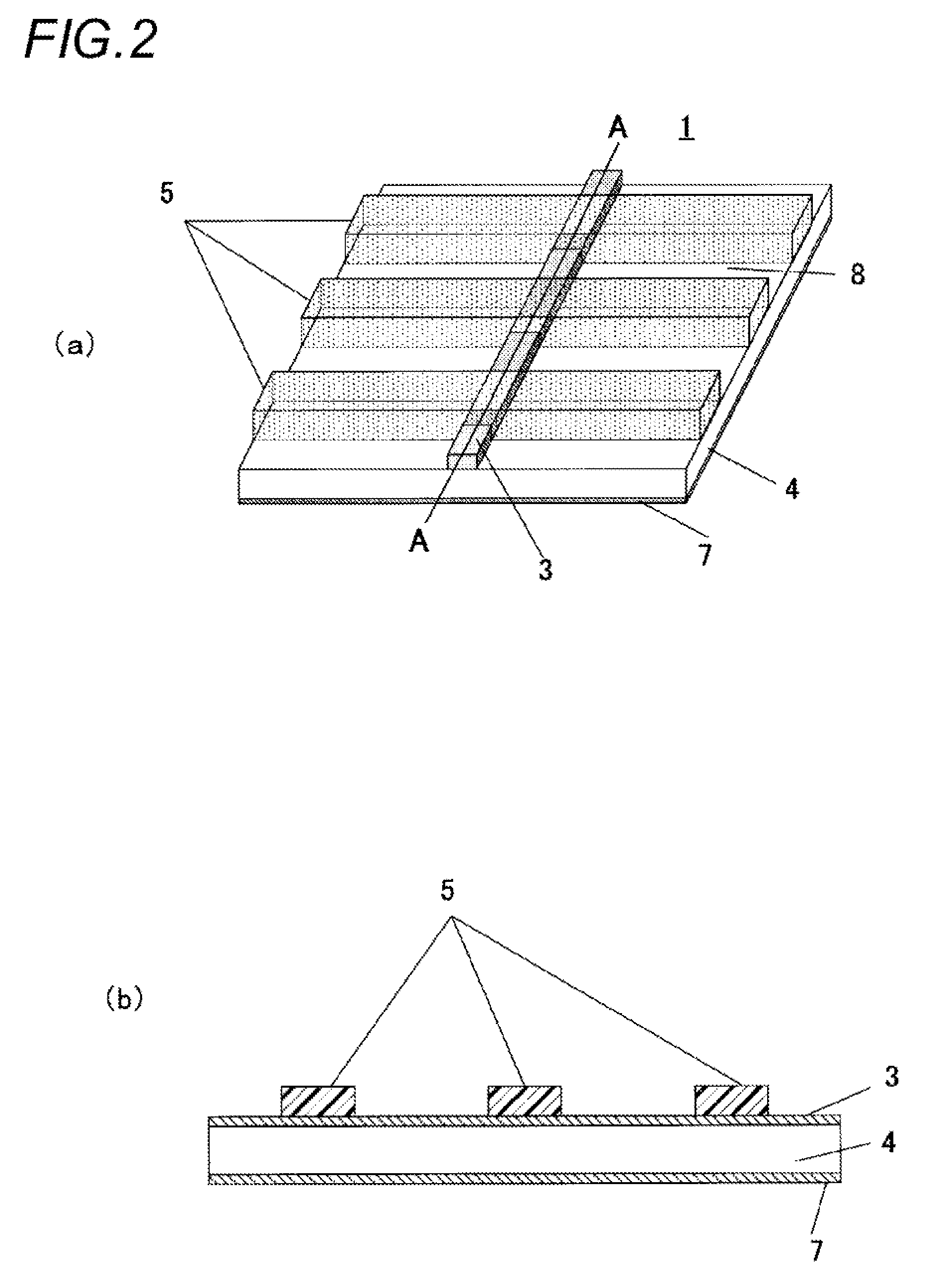

Substrate and substrate module

ActiveUS20070126524A1Enhanced strengthOptimizationMultiple-port networksCross-talk/noise/interference reductionTransmission lineEngineering

A substrate module includes a first substrate and a second substrate. The first substrate comprises a base material; a transmission line in which a signal line is sandwiched between two ground patterns, on the surface of the base material; a ground pattern on the rear surface of the base material; and an exposed portion in which the ground pattern on the substrate surface is exposed by partially cutting out the base material and the ground pattern on the substrate rear surface. The second substrate comprises a base material and a transmission line in which a signal line is sandwiched between two ground patterns, on the surface of the base material. In connecting a transmission line of the first substrate and that of the second substrate, the ground patterns of the first and second substrates are fused with each other at the exposed portion and fixed.

Owner:FUJITSU LTD

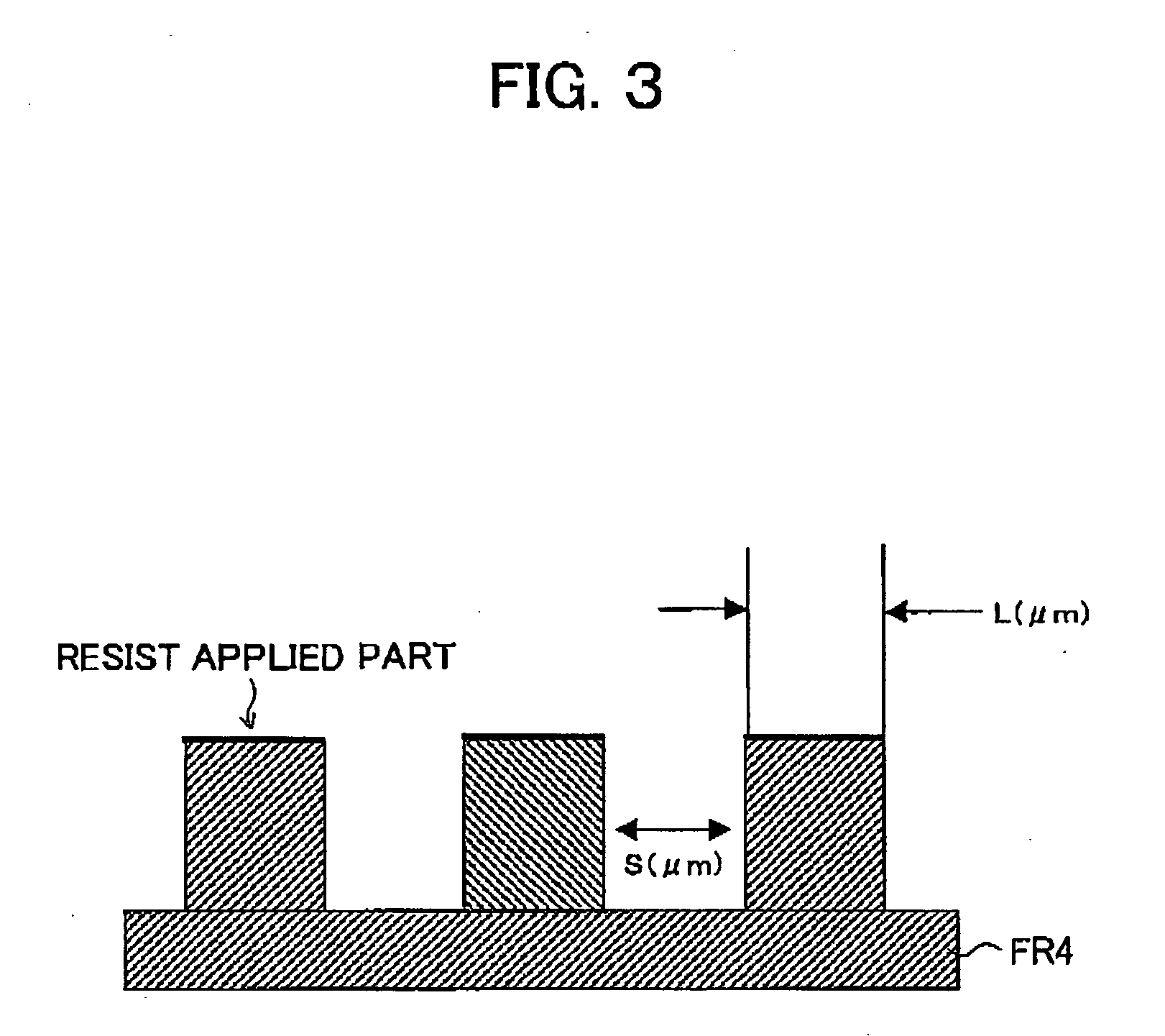

Surface treated copper foil and circuit board

InactiveUS20060088723A1High frequency characteristicHigh peel strengthInsulating substrate metal adhesion improvementPrinted circuit aspectsCopper foilMetallurgy

A surface treated copper foil having high frequency characteristics, capable of forming fine pattern and having sufficient peel strength, wherein surface roughness Rz of roughening treated surface made by adhering roughening particles on at least one surface side of untreated copper foil is 0.6 to 1.5 μm and a brightness value is 35 or smaller; and a circuit board, on which wiring pattern is formed by the same surface treated copper foil, are provided.

Owner:FURUKAWA ELECTRIC CO LTD

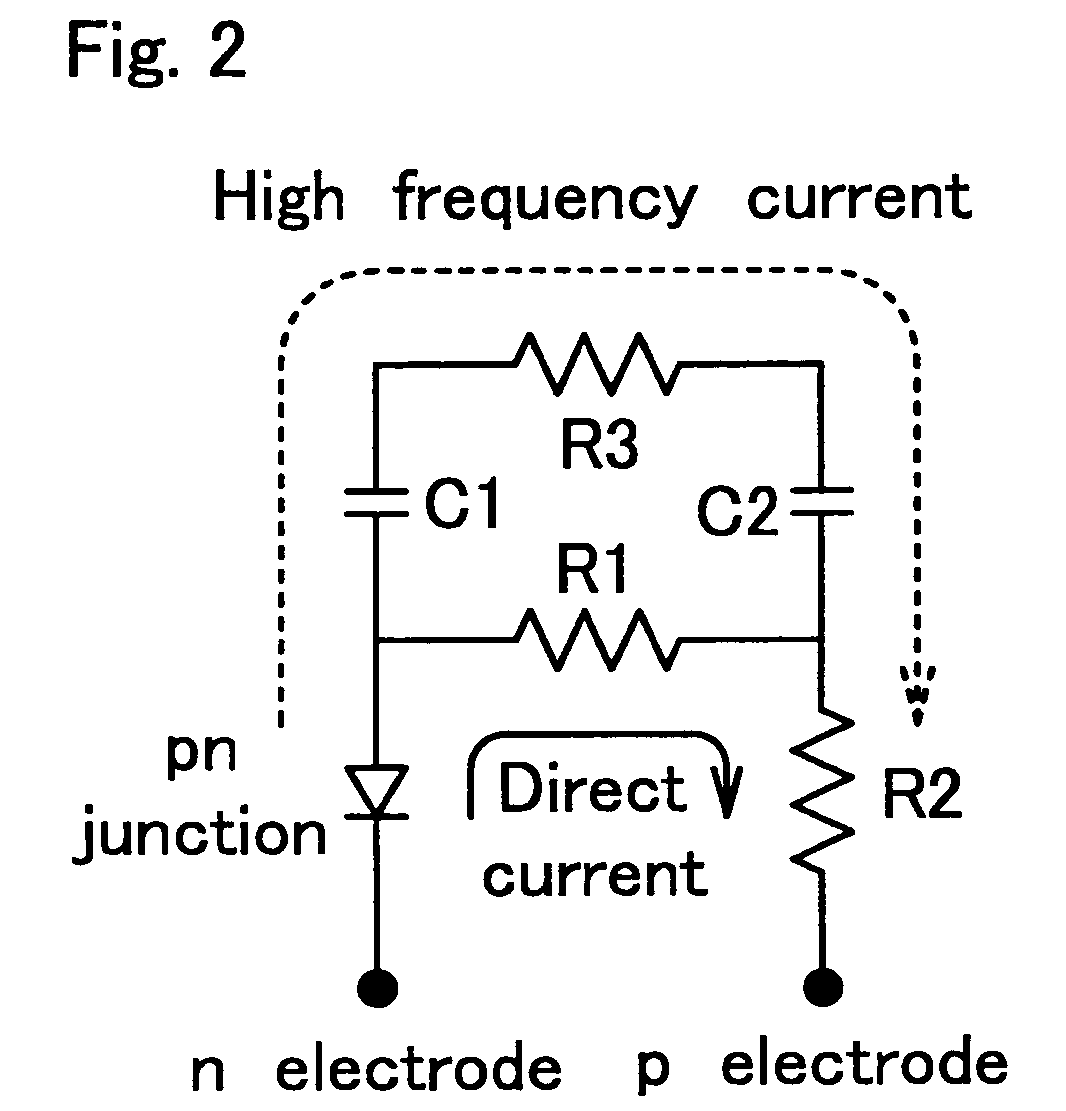

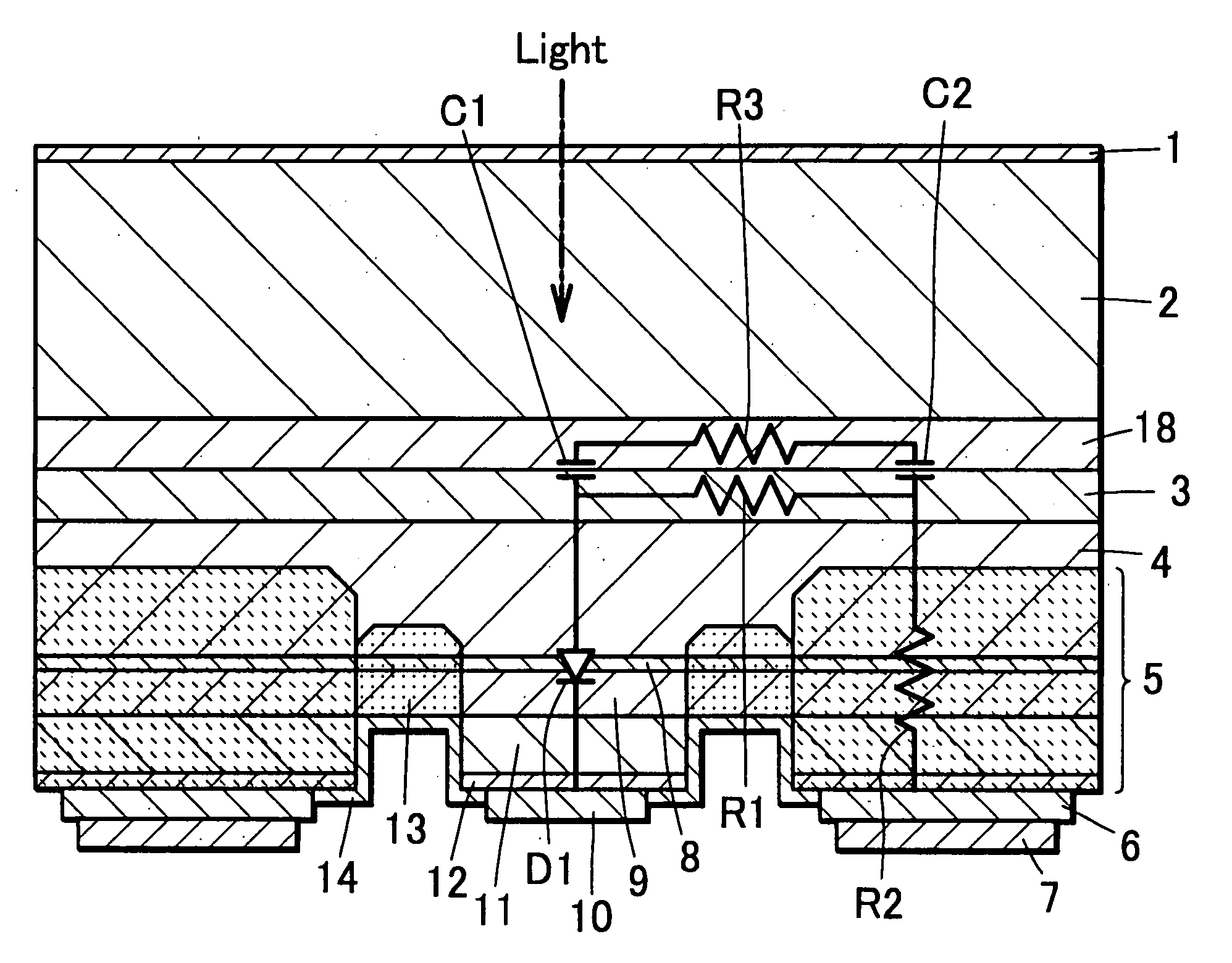

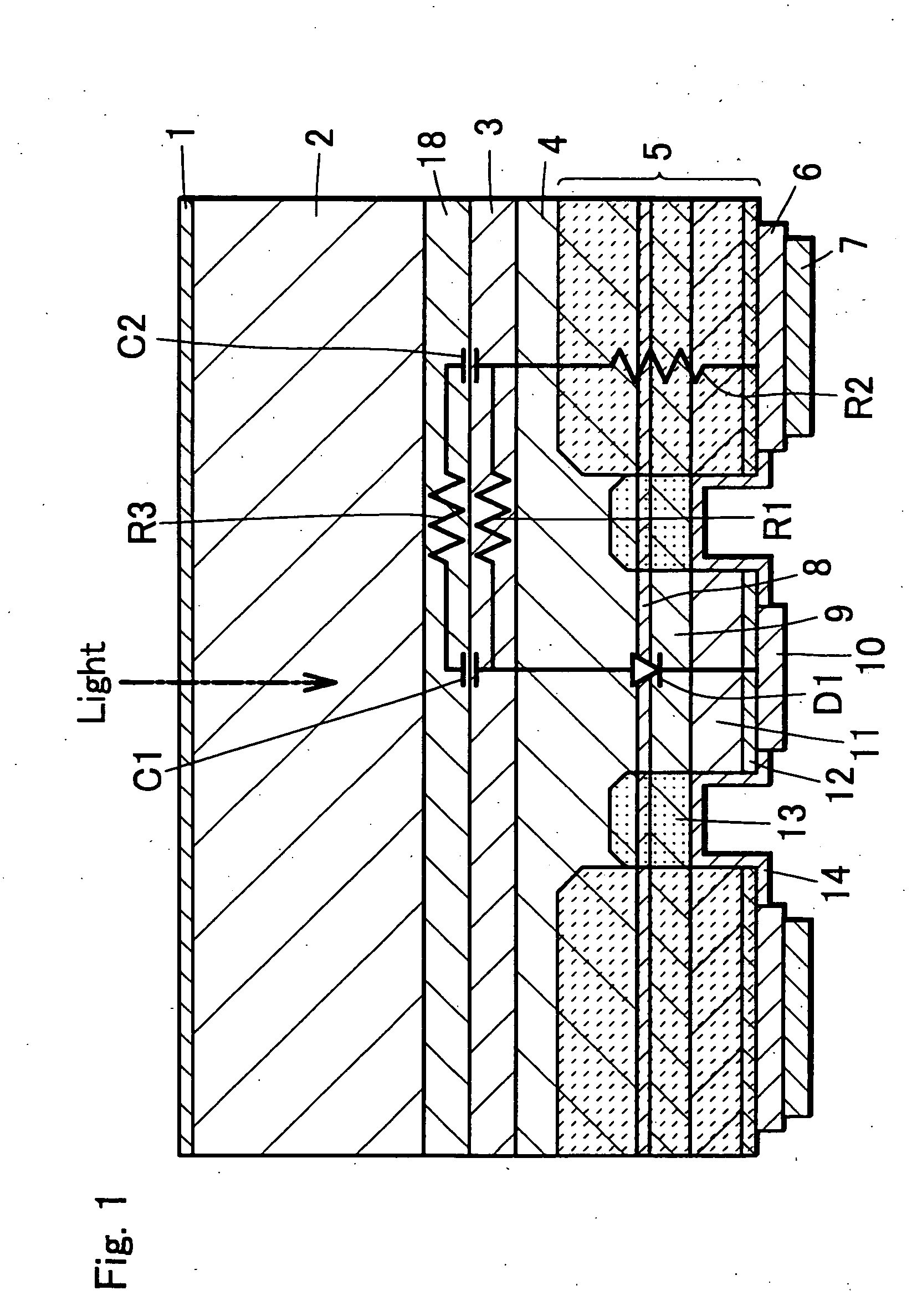

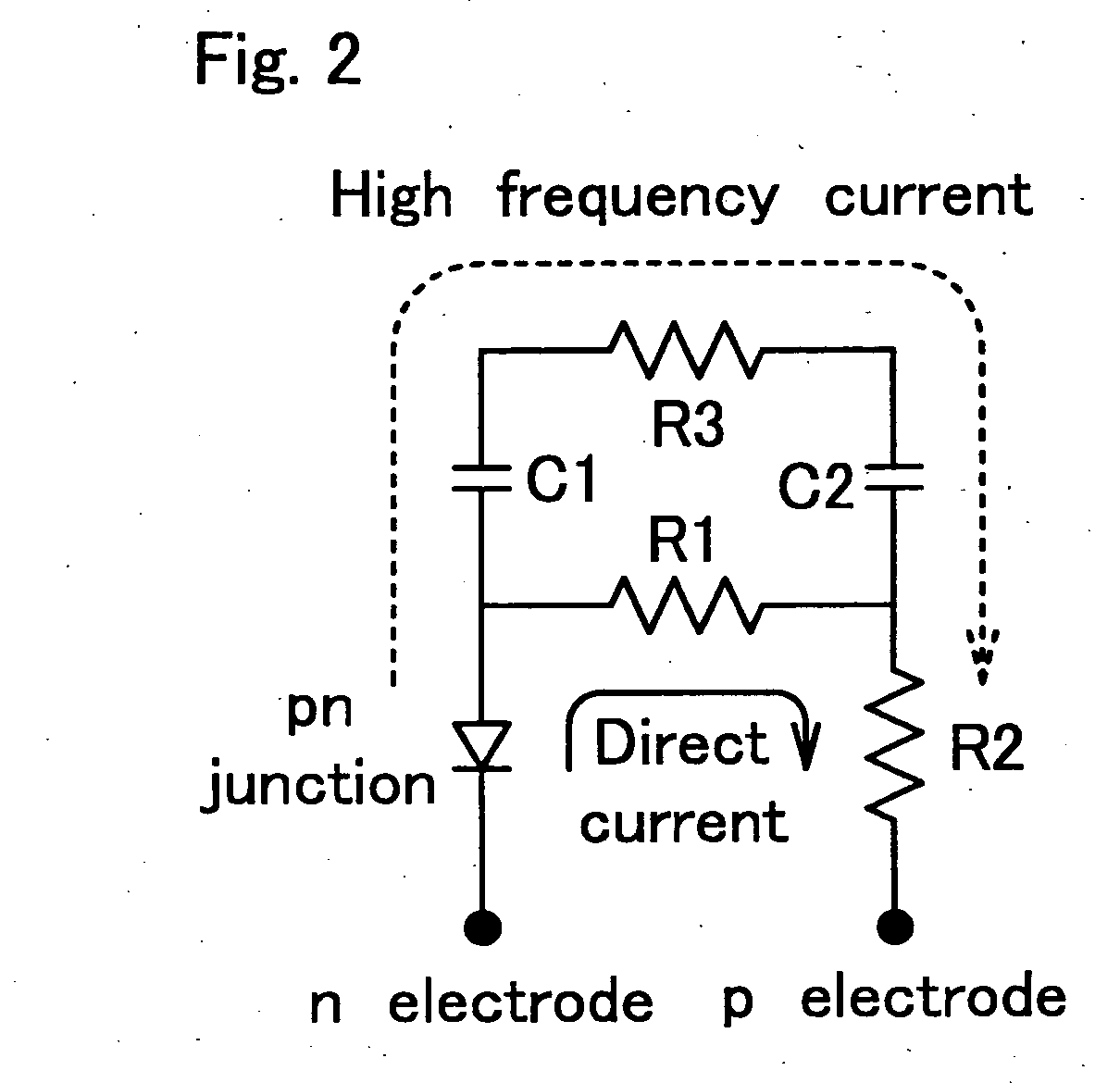

Semiconductor device

InactiveUS7038251B2Reduce resistanceLower resistanceSemiconductor devicesAlternating currentSemi insulating

A semiconductor device has a structure reducing resistances to a high frequency current. The semiconductor device includes a semi-insulating substrate, a first n-type layer made of a compound semiconductor, and a first p-type layer made of a compound semiconductor in which a signal current flows in a lateral direction, parallel to the semi-insulating substrate. The first p-type layer is sandwiched between the semi-insulating substrate and the first n-type layer. A second n type layer made of a compound semiconductor is between the semi-insulating substrate and the first p type layer. An alternating current component of the signal current flows through the second n type layer.

Owner:MITSUBISHI ELECTRIC CORP

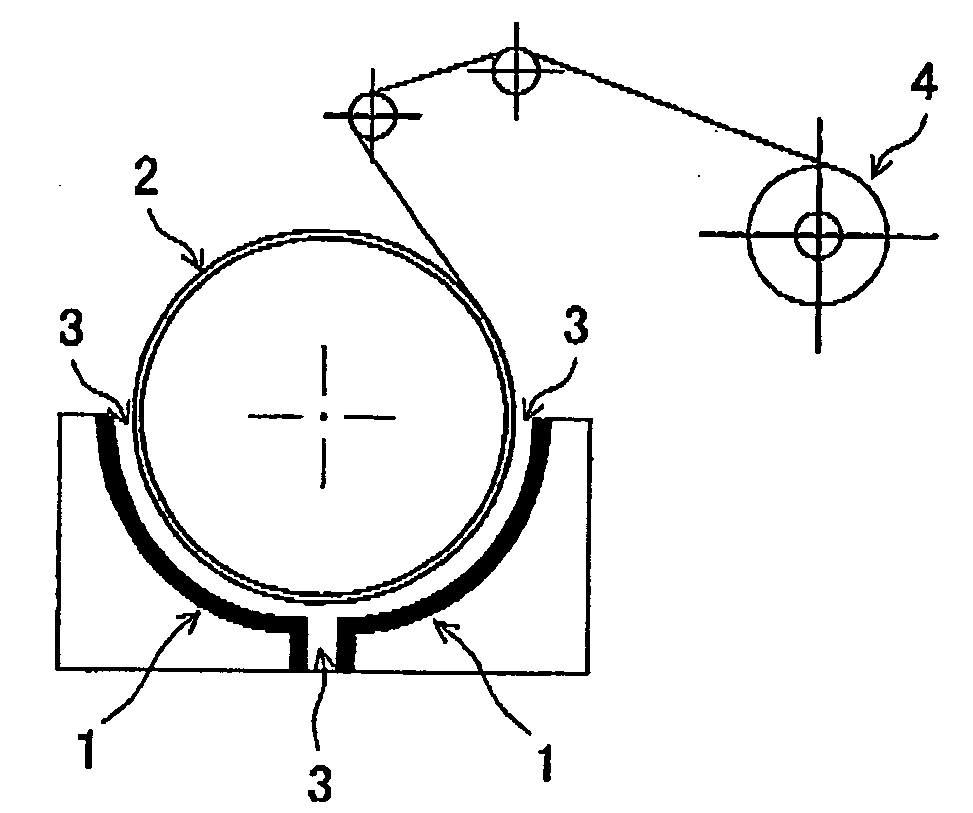

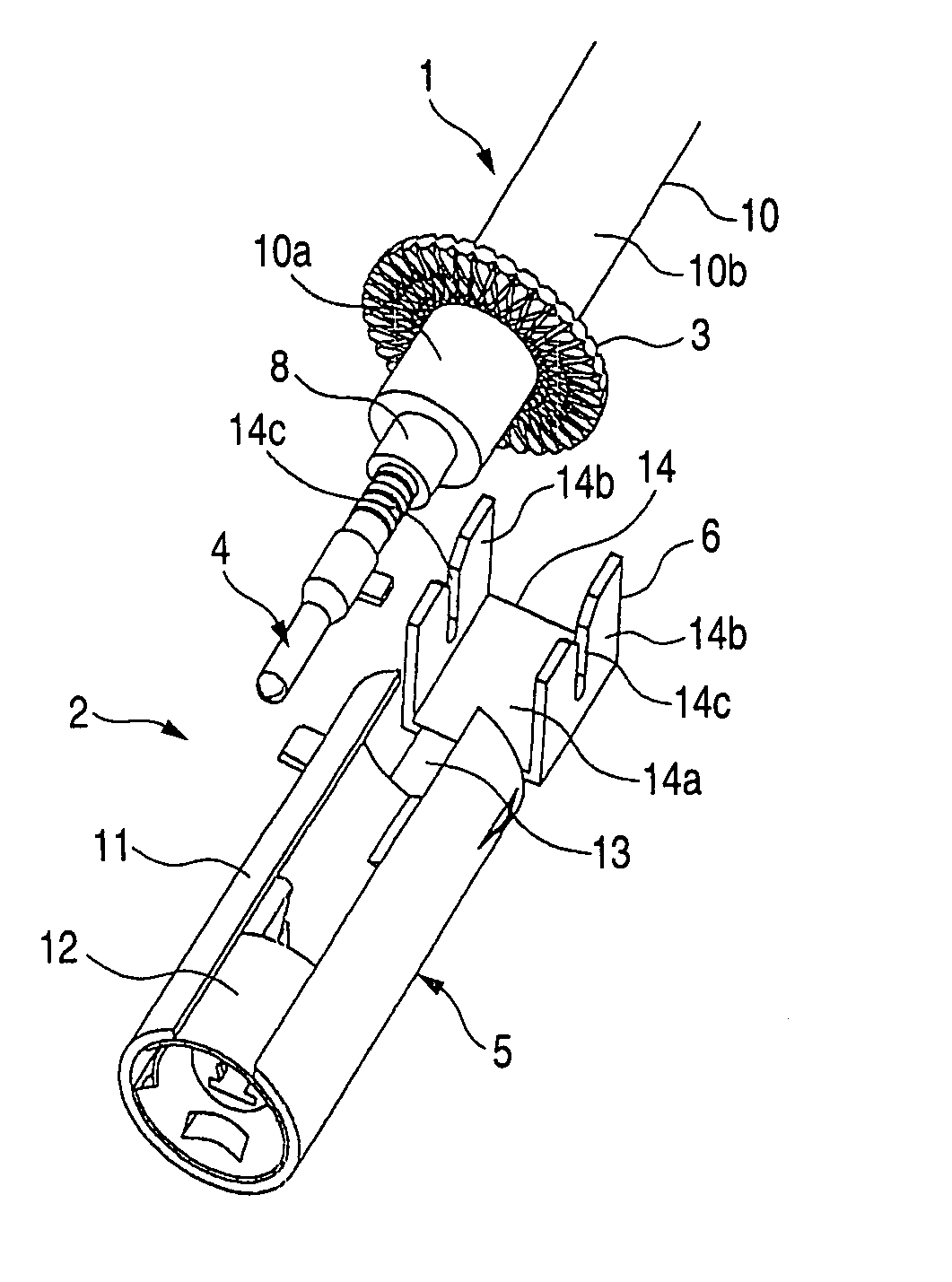

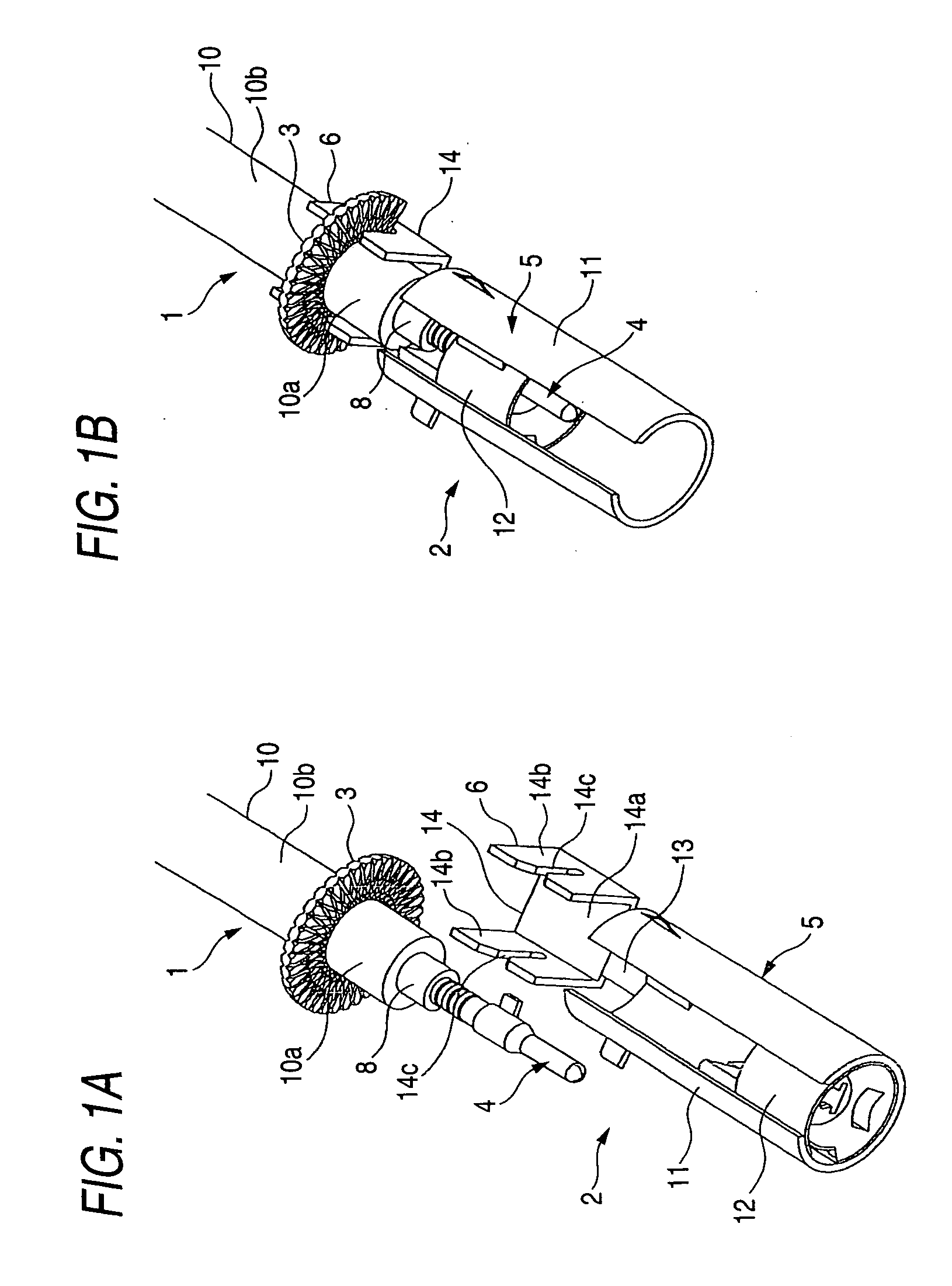

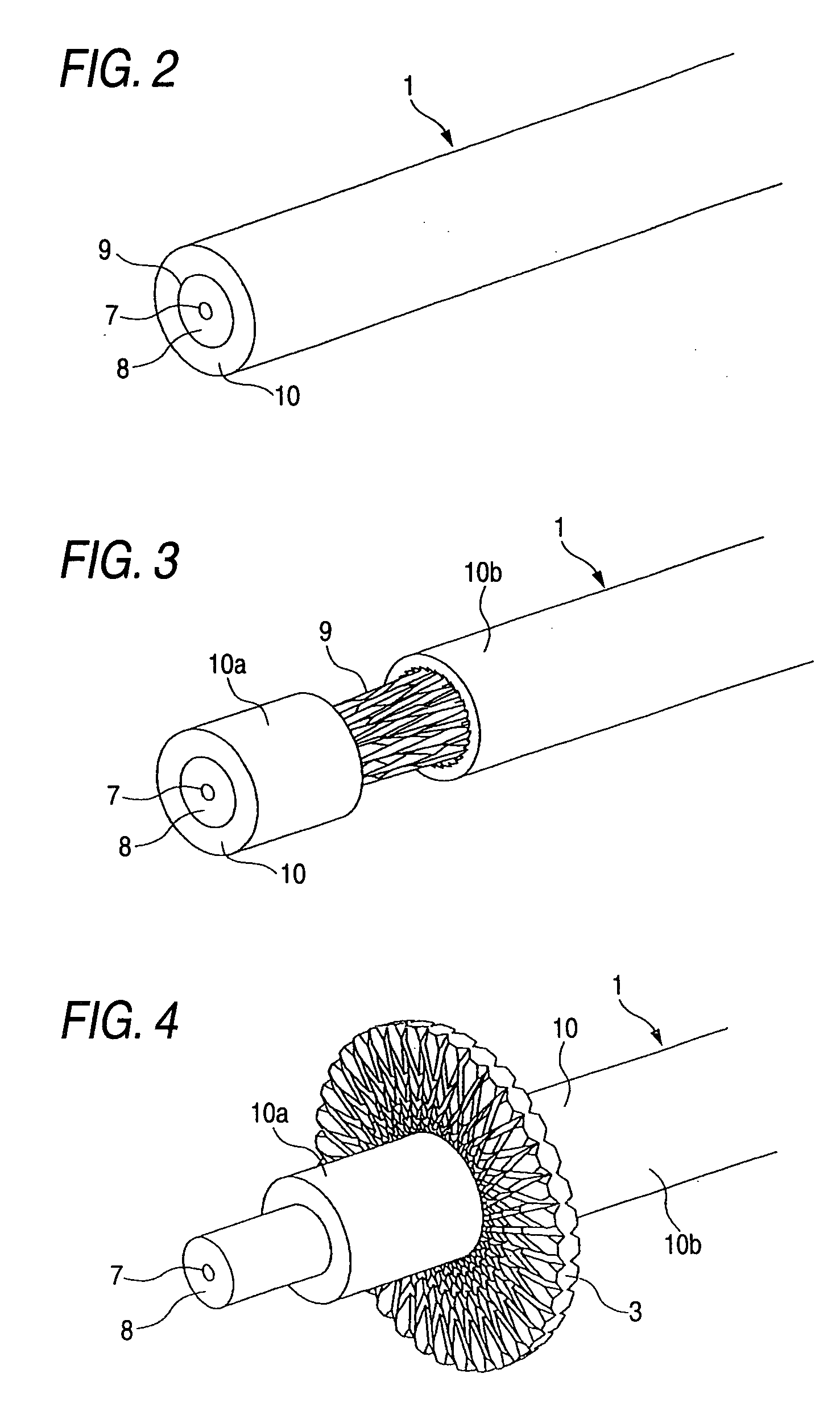

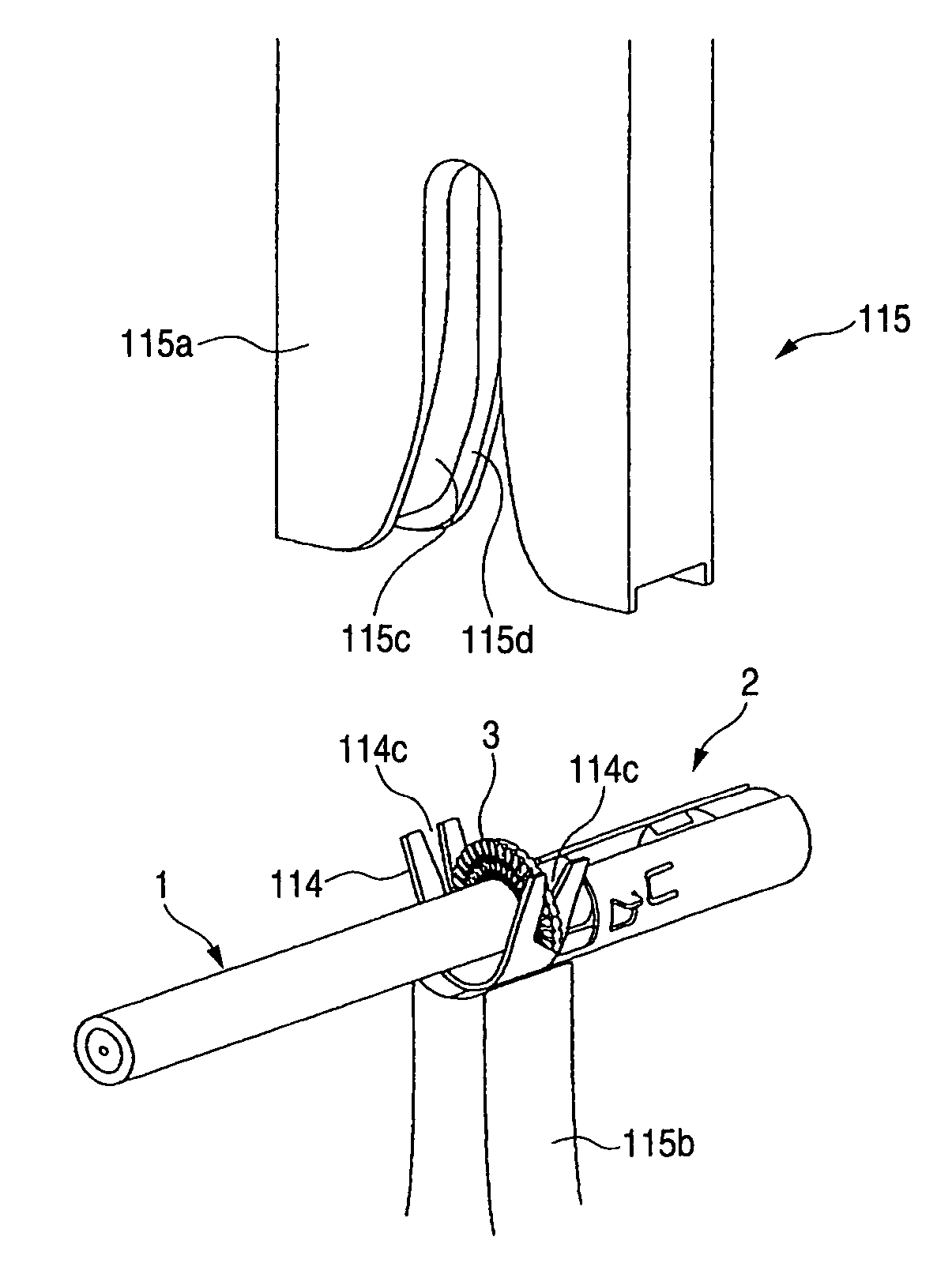

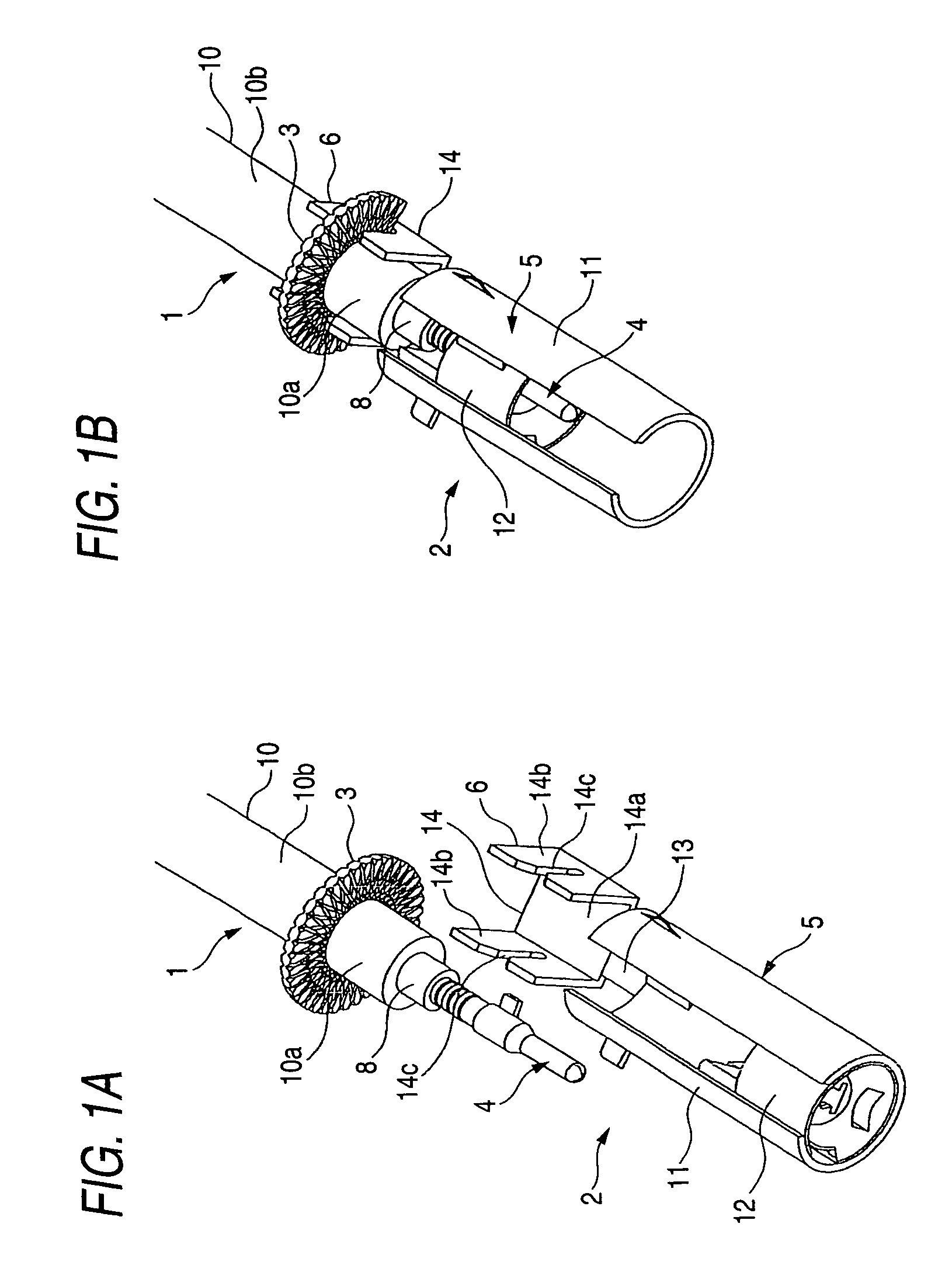

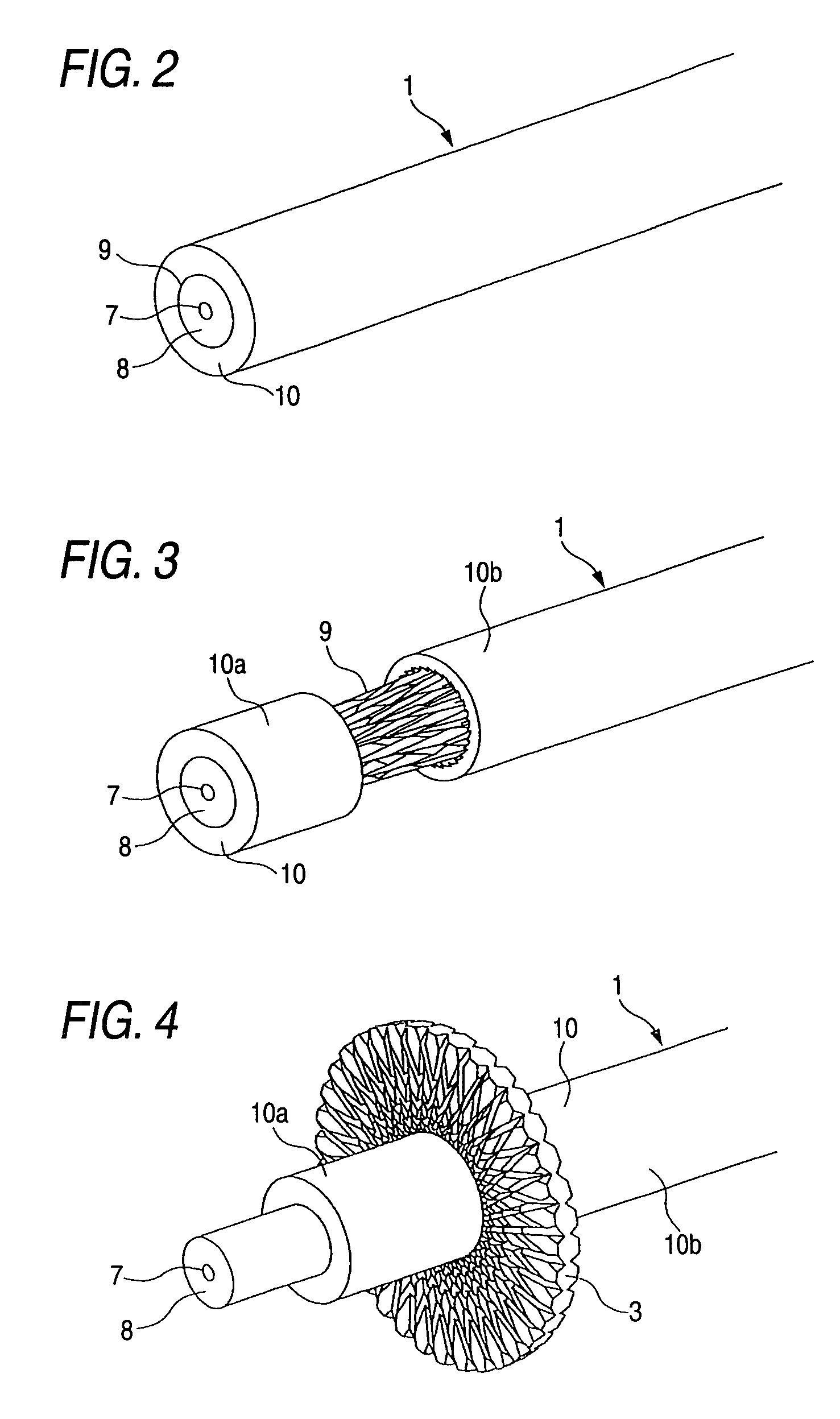

Coaxial cable end-processing structure, coaxial cable shielding terminal and press-fastening apparatus

InactiveUS20060216998A1More tensile strengthEasy to carryAntenna connectorsConnections effected by permanent deformationCoaxial cableElectrical and Electronics engineering

An intermediate portion of an insulating sheath of a coaxial cable is removed, and a first insulating sheath portion is drawn toward a second insulating sheath portion, so that a braid is projected into an annular shape outwardly from an interval between opposed ends of the first and second insulating sheath portions to form an annular projecting braid portion, and this annular projecting braid portion is fixed so as to be connected to a portion (that is, a braid fixing portion) of a coaxial cable shielding terminal for connection to an end portion of the coaxial cable. This connecting and fixing operation is effected by press-contacting or press-clamping.

Owner:YAZAKI CORP

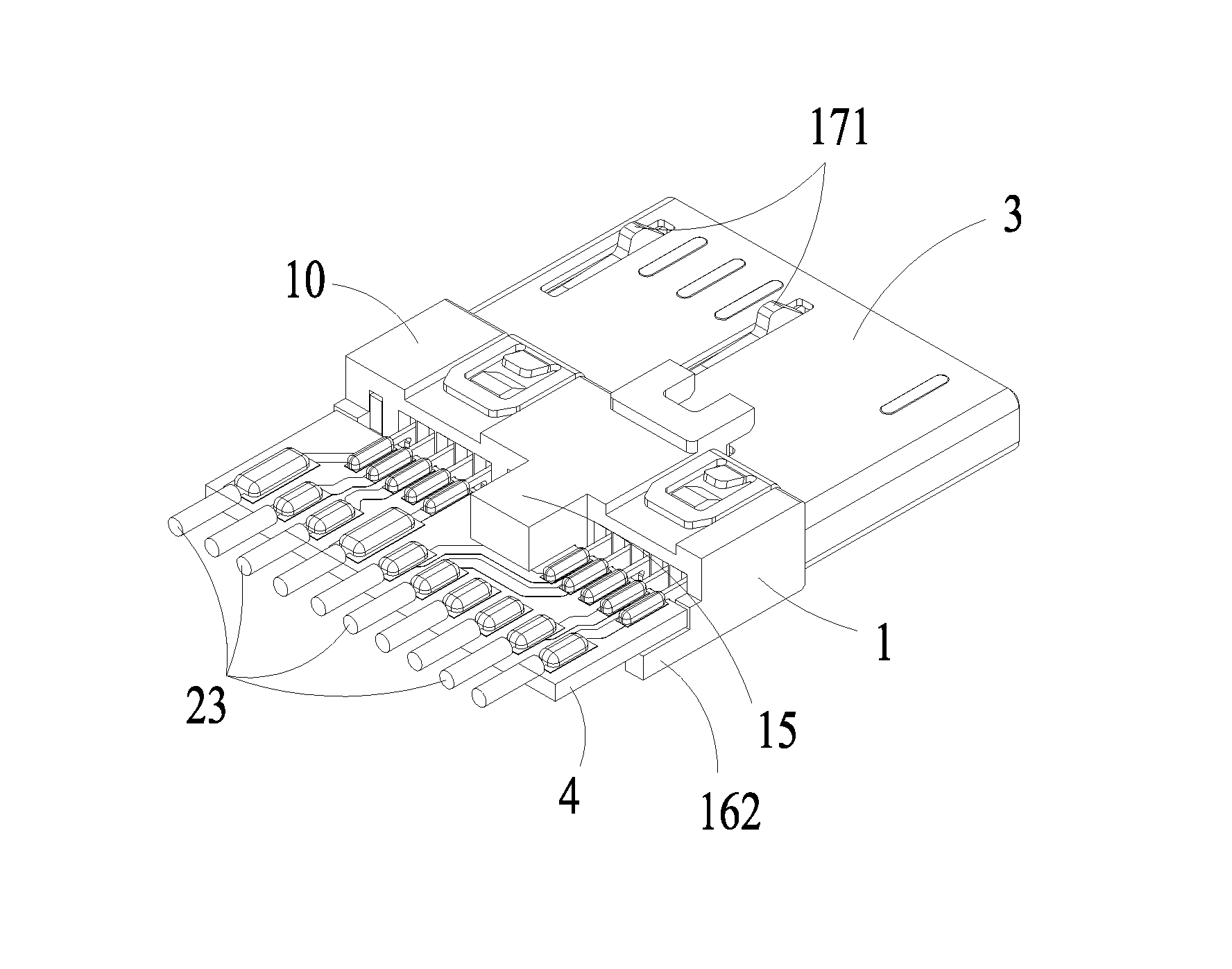

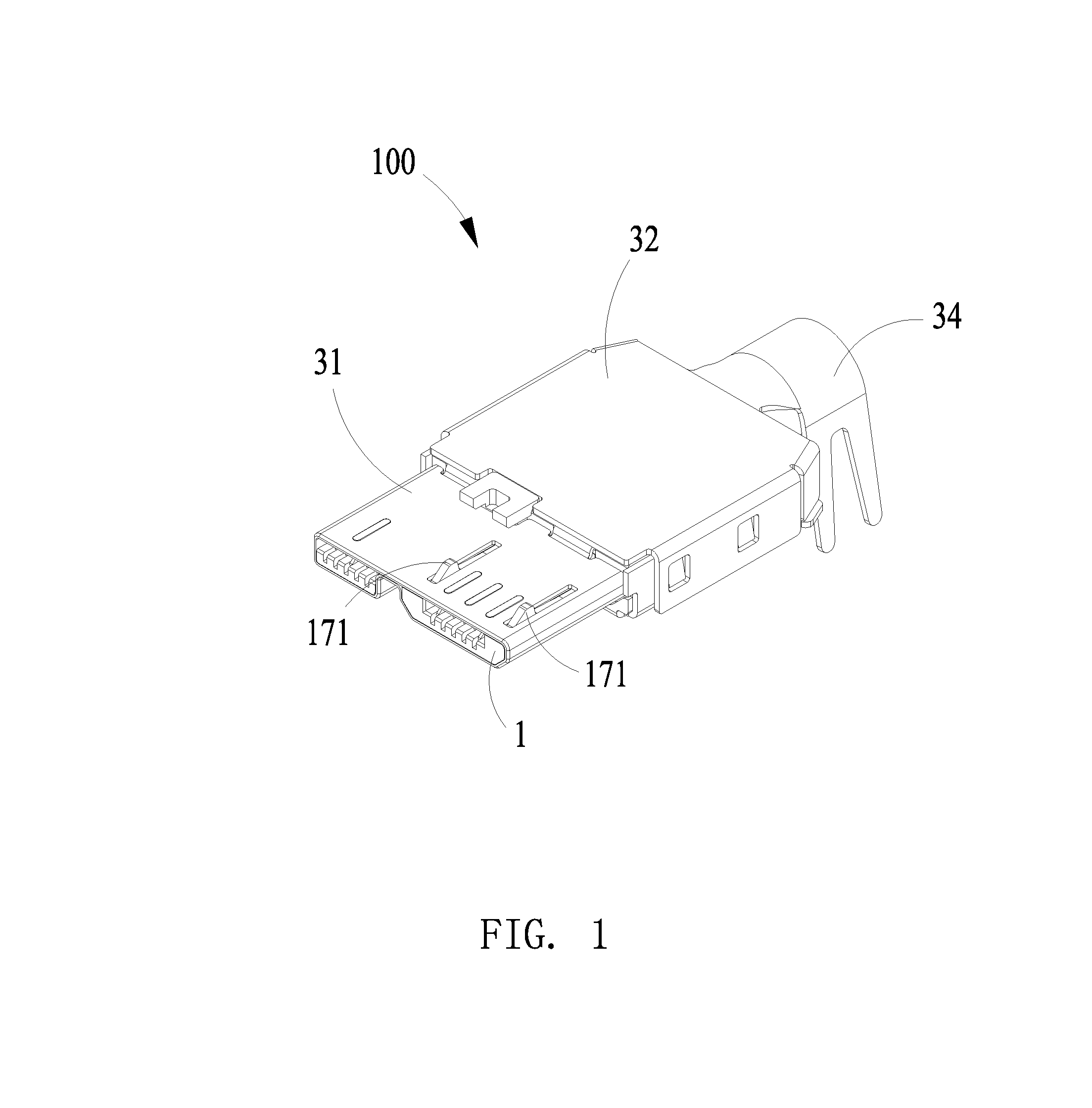

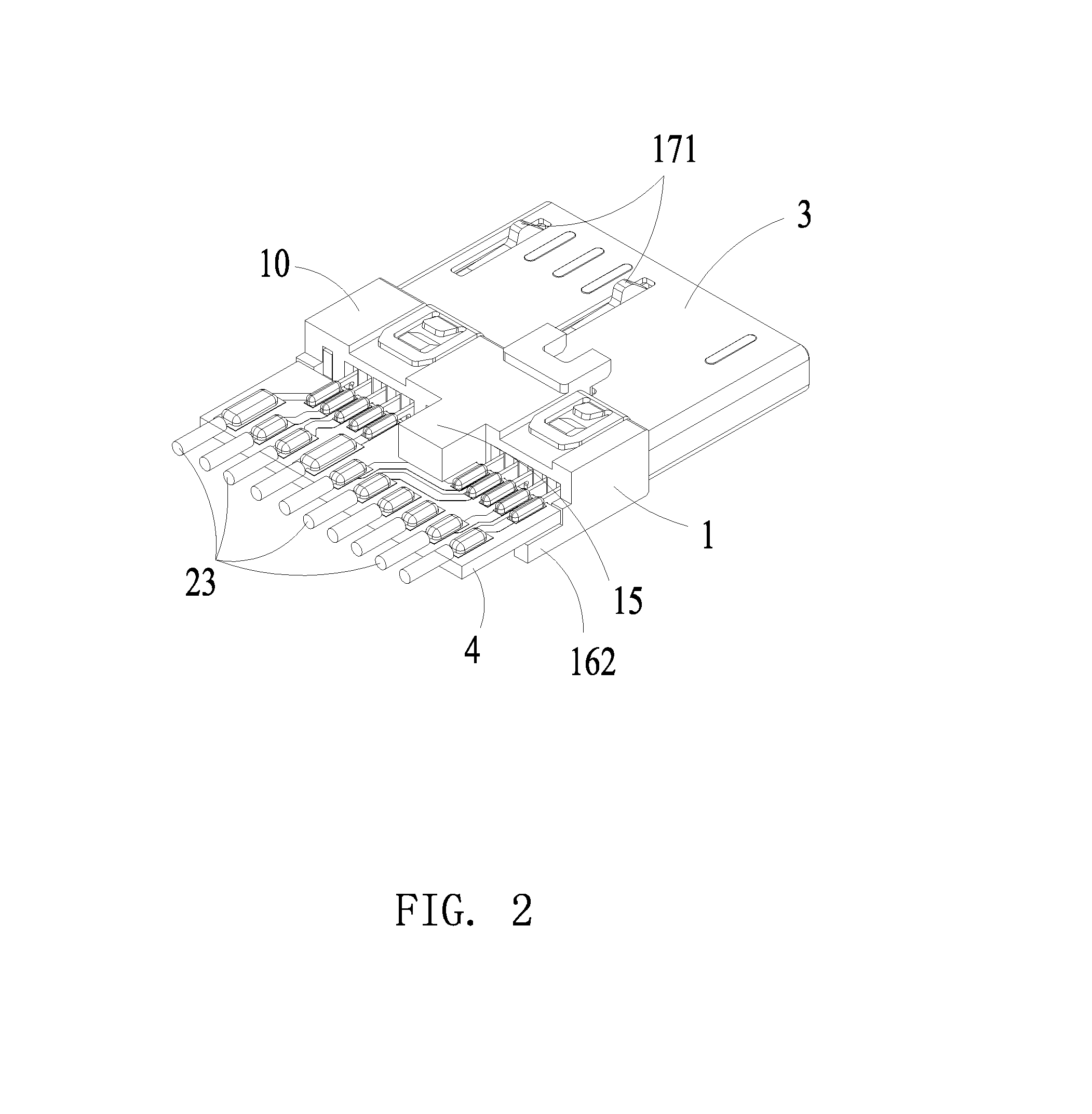

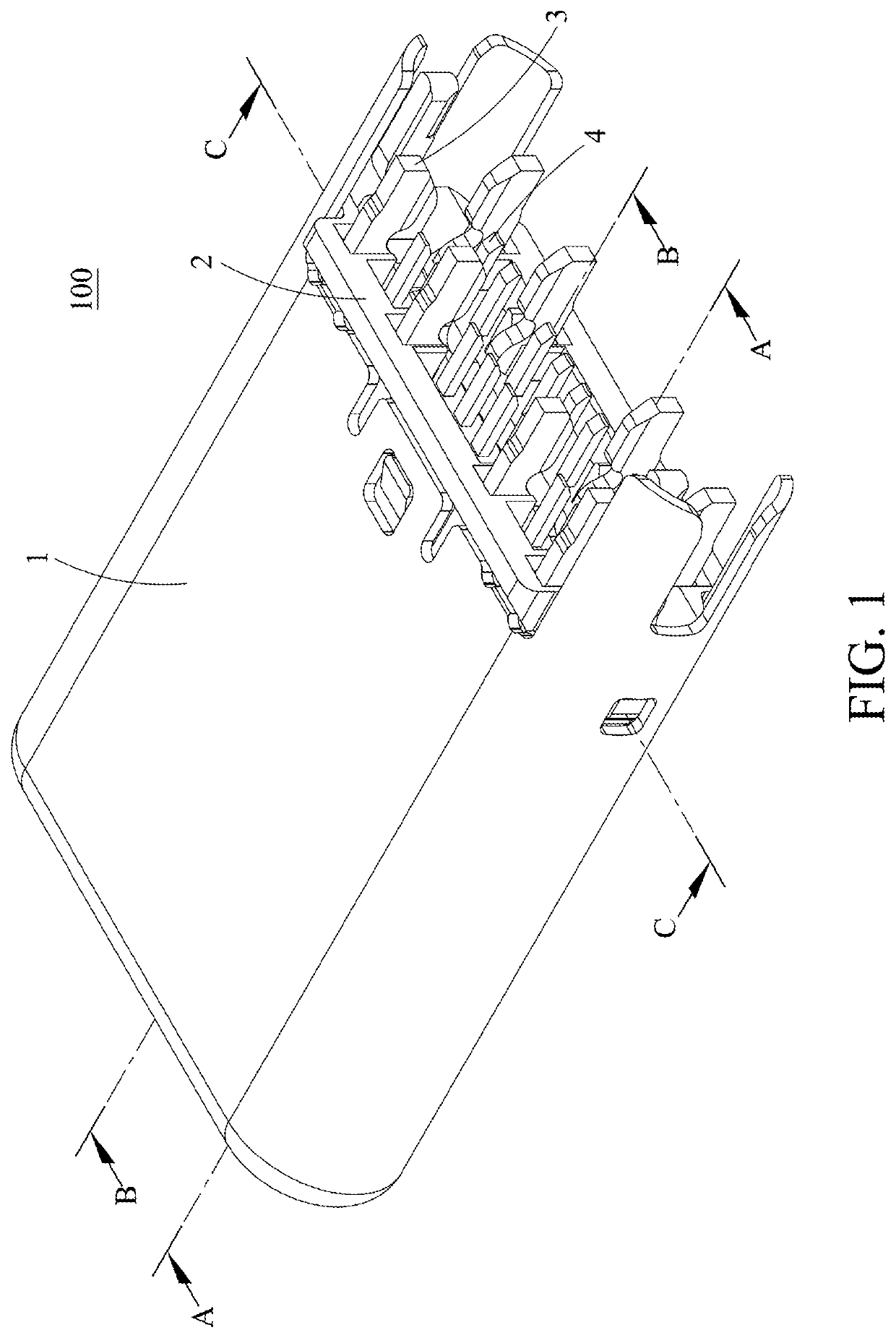

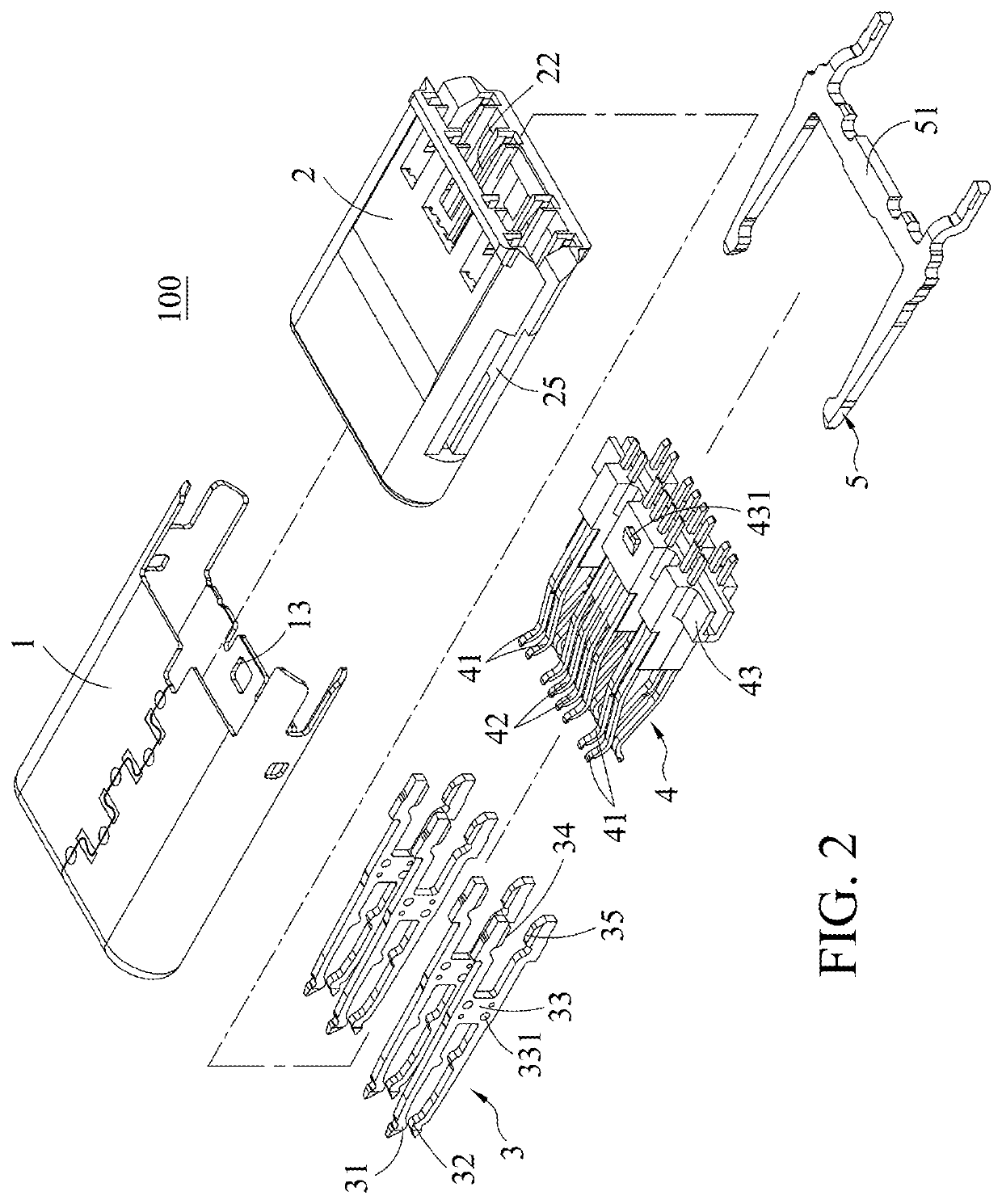

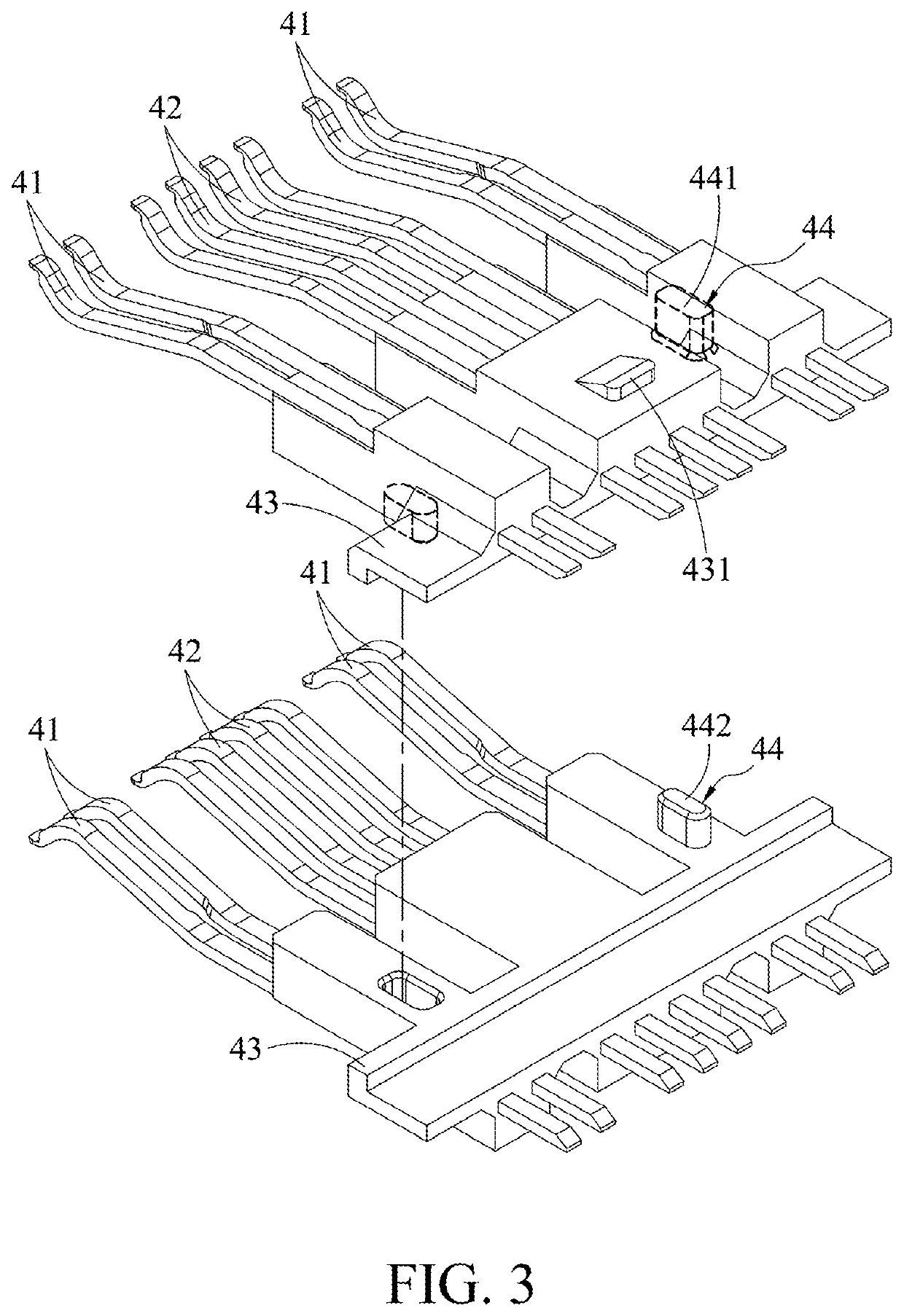

Cable Connector with Inner Circuit Board for Connecting with Cables

InactiveUS20130109242A1Improve assemble efficiencyHigh frequency characteristicElectric discharge tubesCoupling device detailsContact groupSoldering

A cable connector compatible to USB 3.0 standard includes an insulative housing having, a number of contacts and an inner circuit board for establishing electrically connection between the contacts and cables. The contacts are divided into a first contact group including a number of first contacts and a second contact group including a number of second contacts. The inner circuit board includes a first soldering area having a number of separated first pads connected to the first and the second contacts. The first pads include a first grounding pad connected to a grounding contact of the second contacts. The second soldering area includes a number of separated second pads connected to the cables. At least two adjacent or separated second pads are electrically connected to the first grounding pad for improving high frequency characteristics.

Owner:LUXSHARE PRECISION IND SHENZHEN

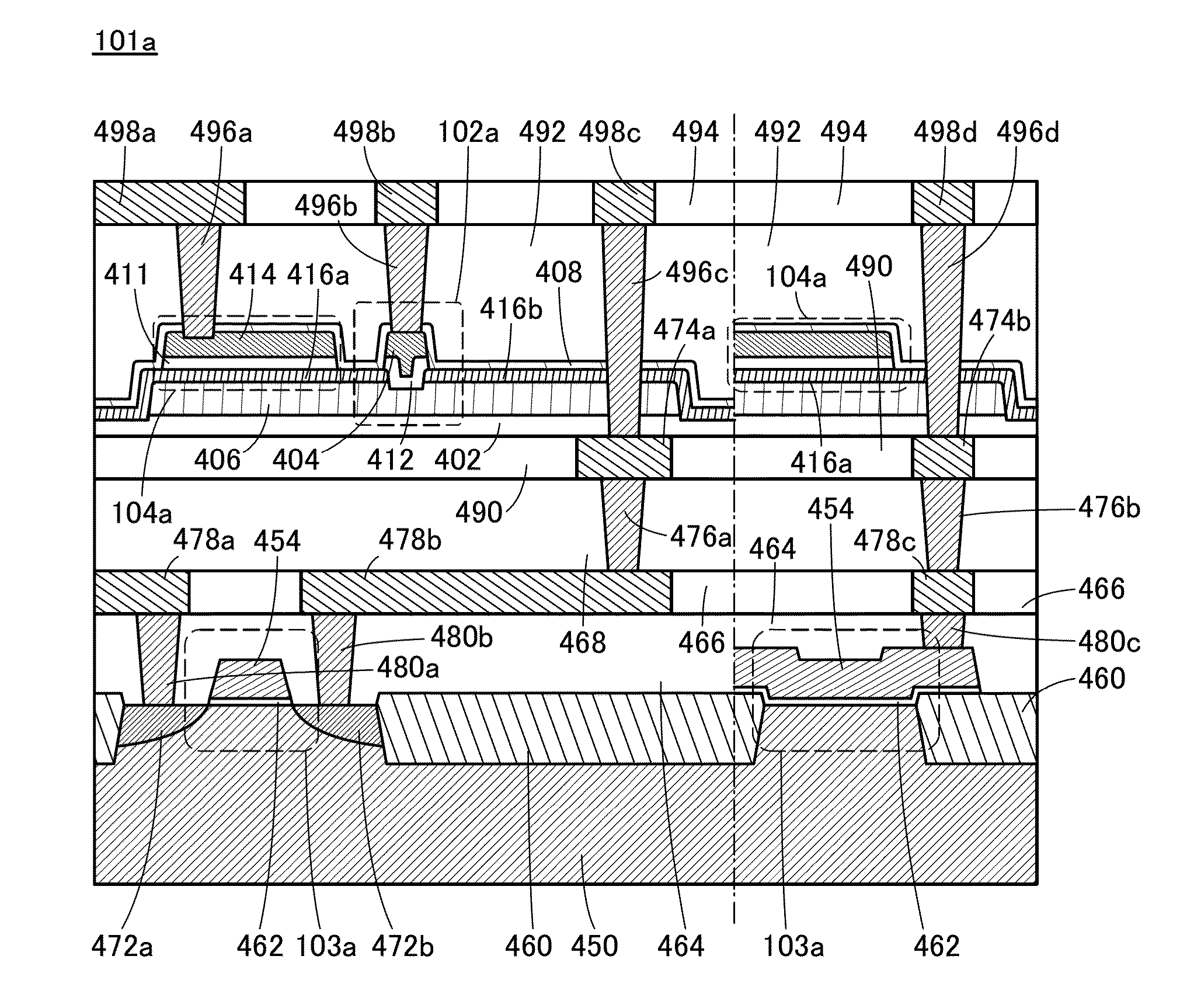

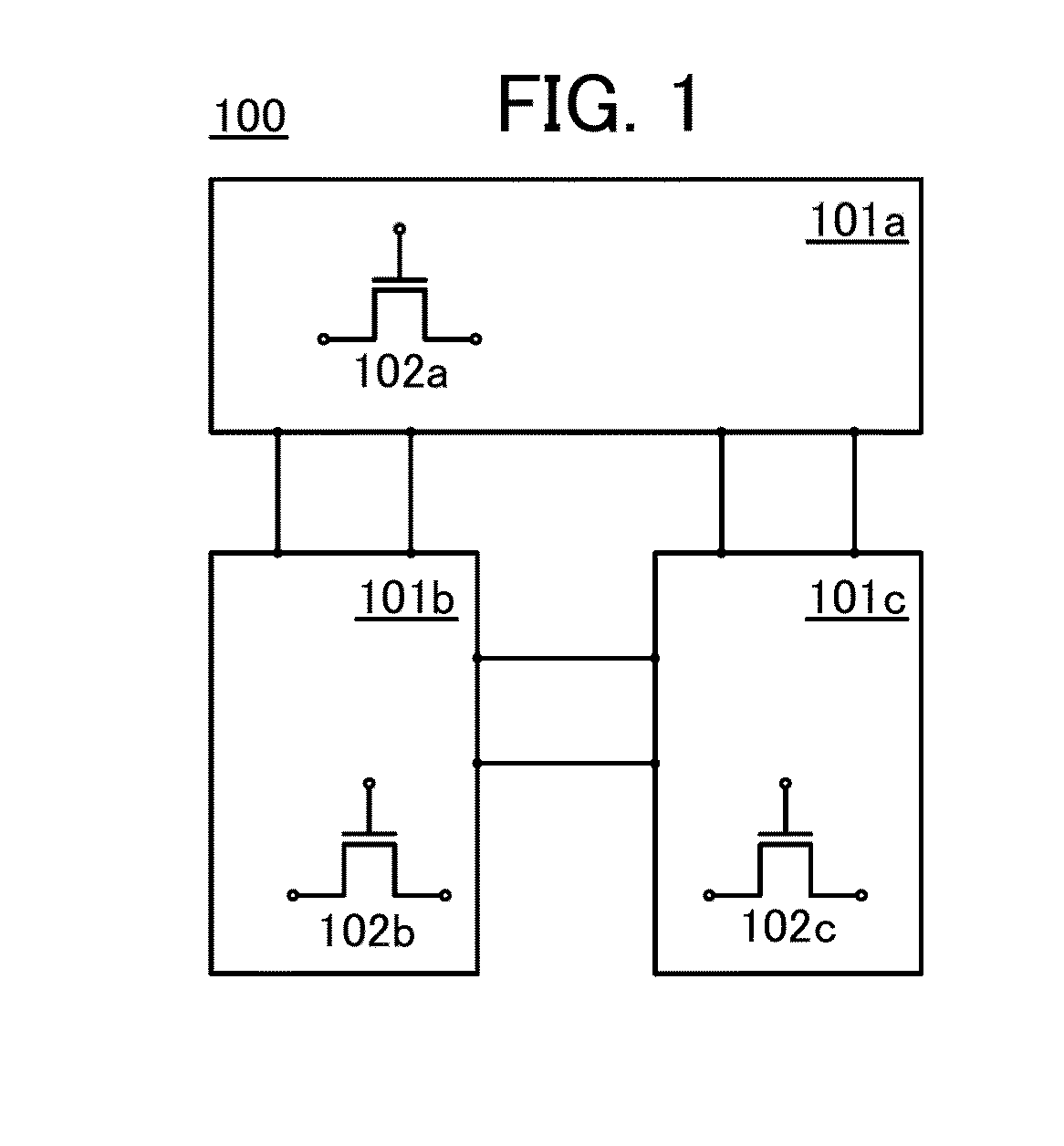

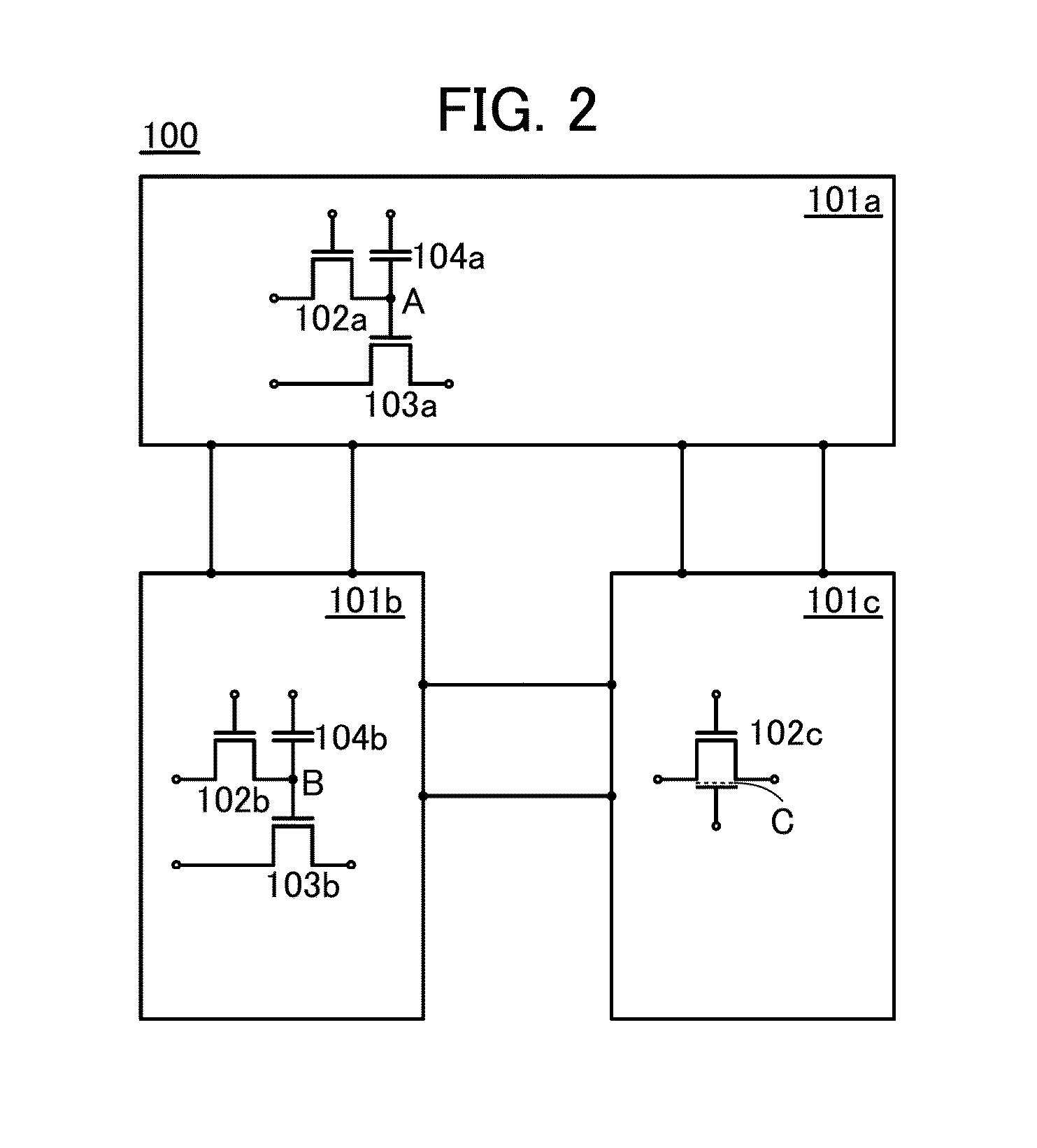

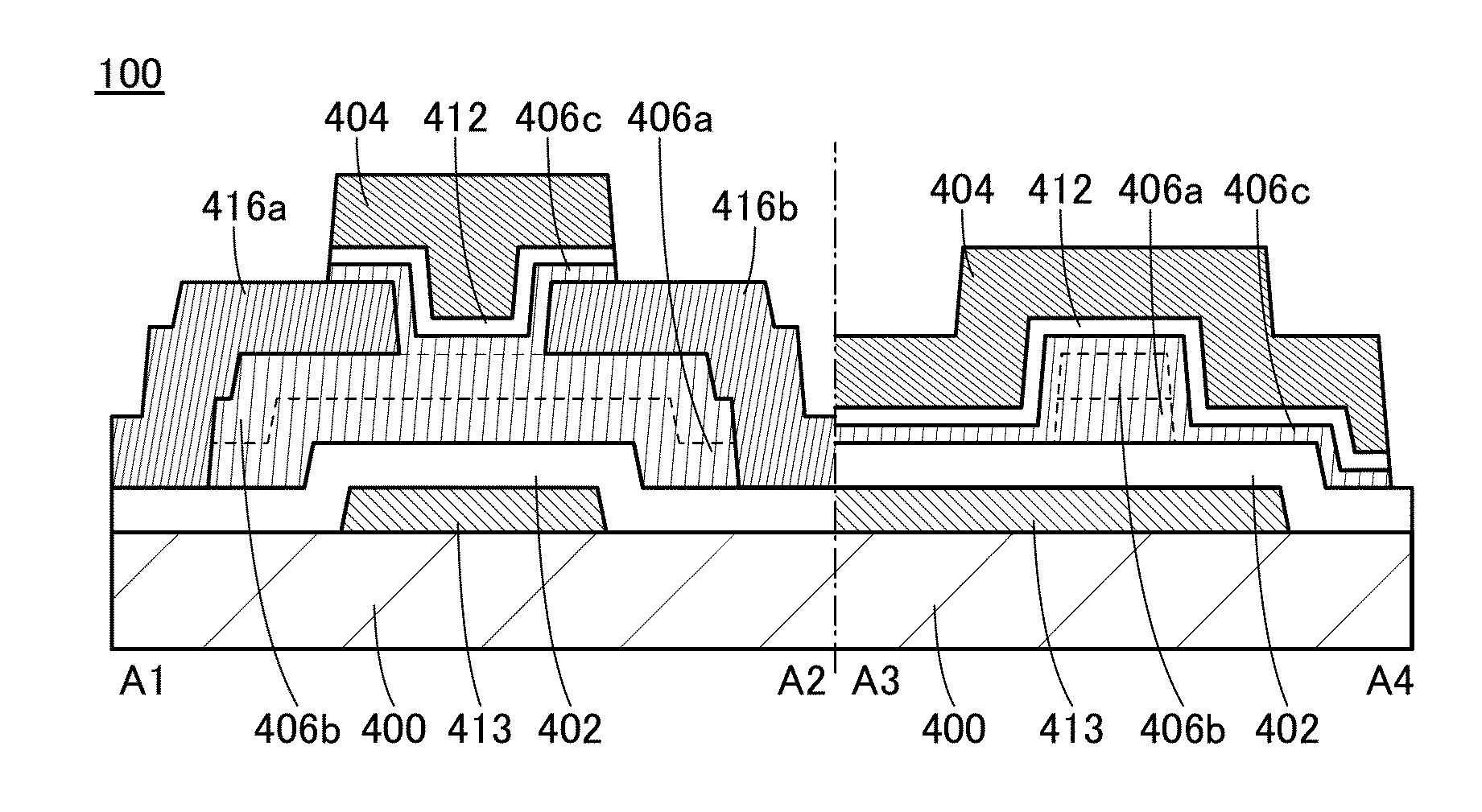

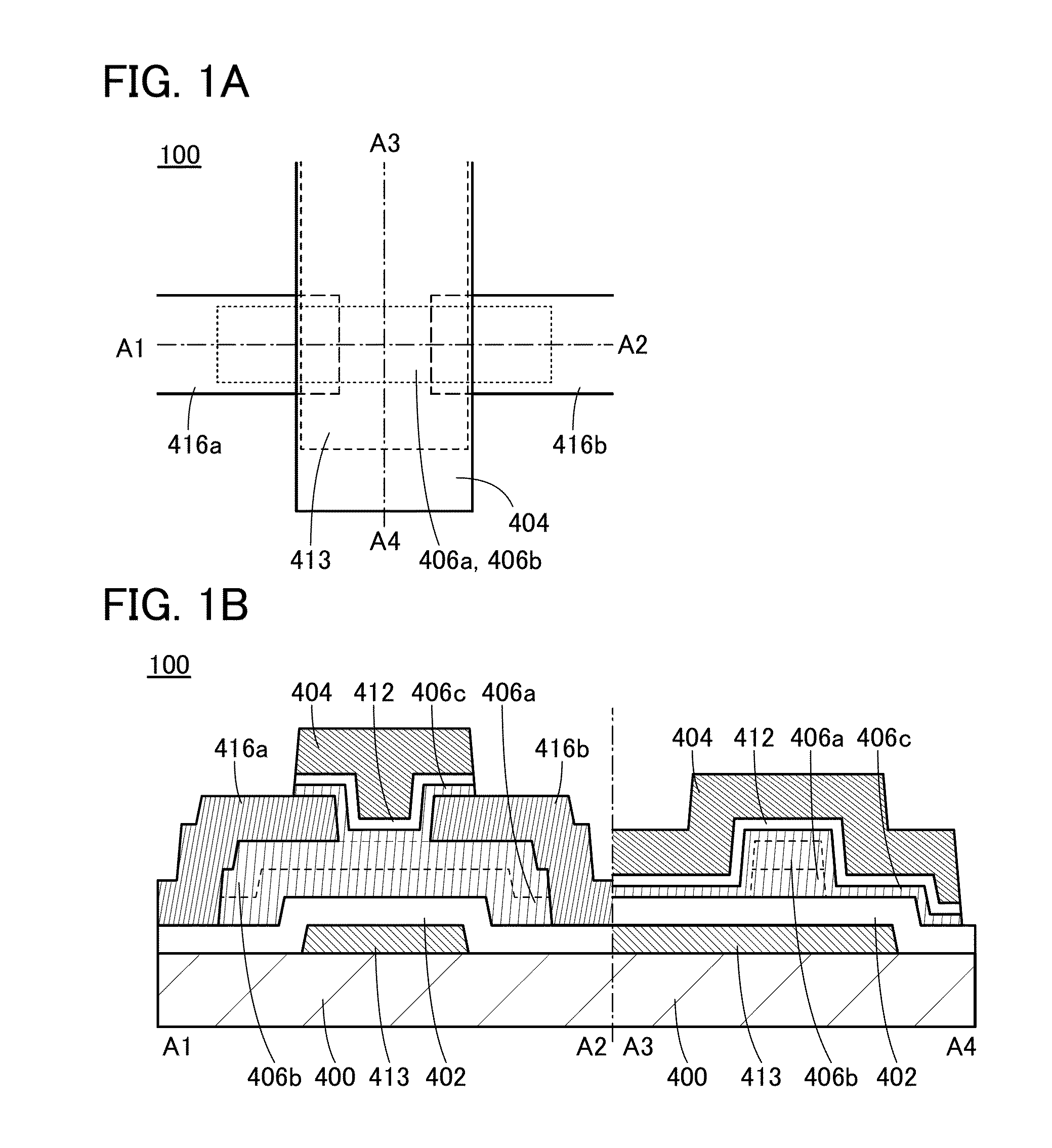

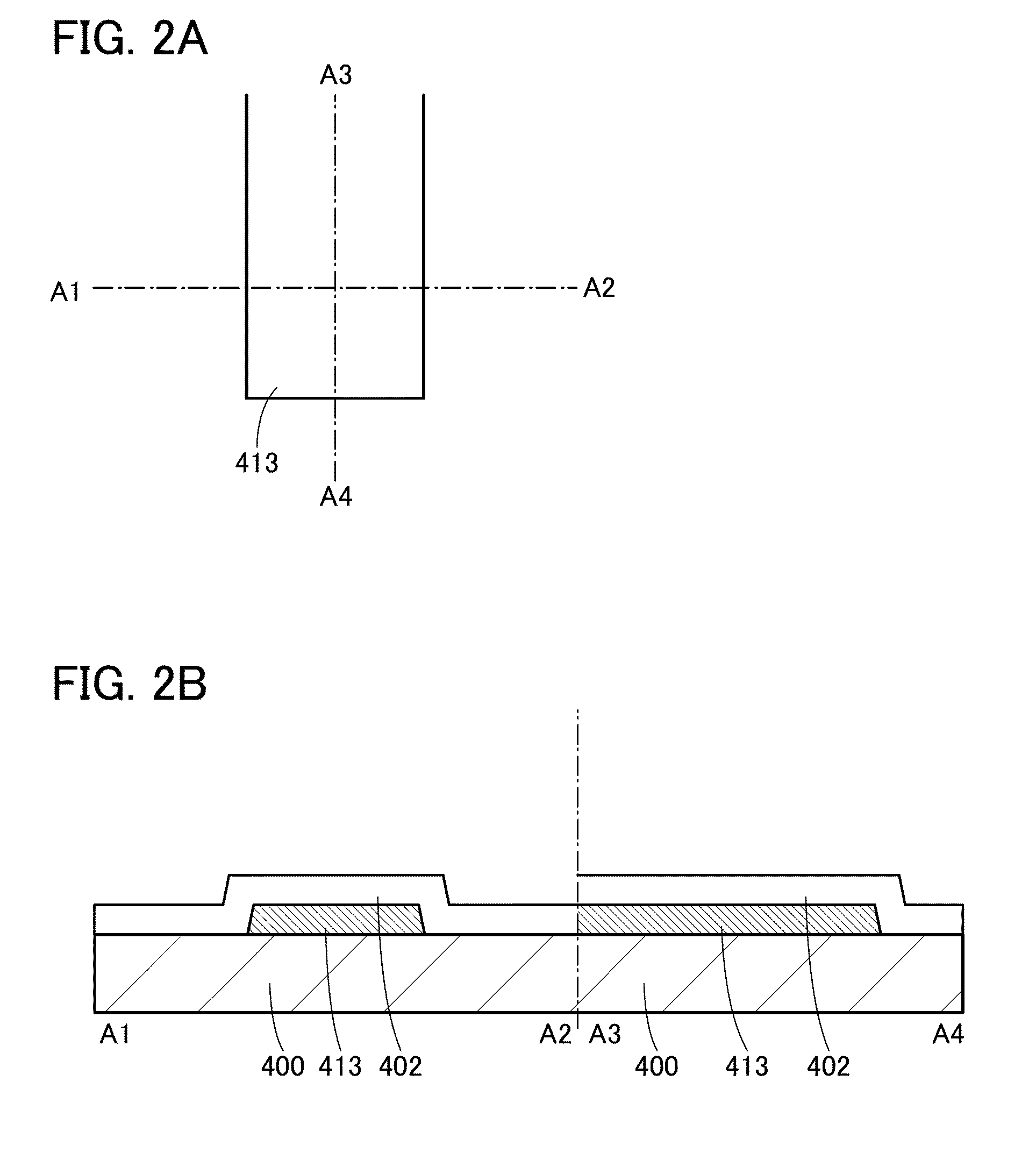

Semiconductor device

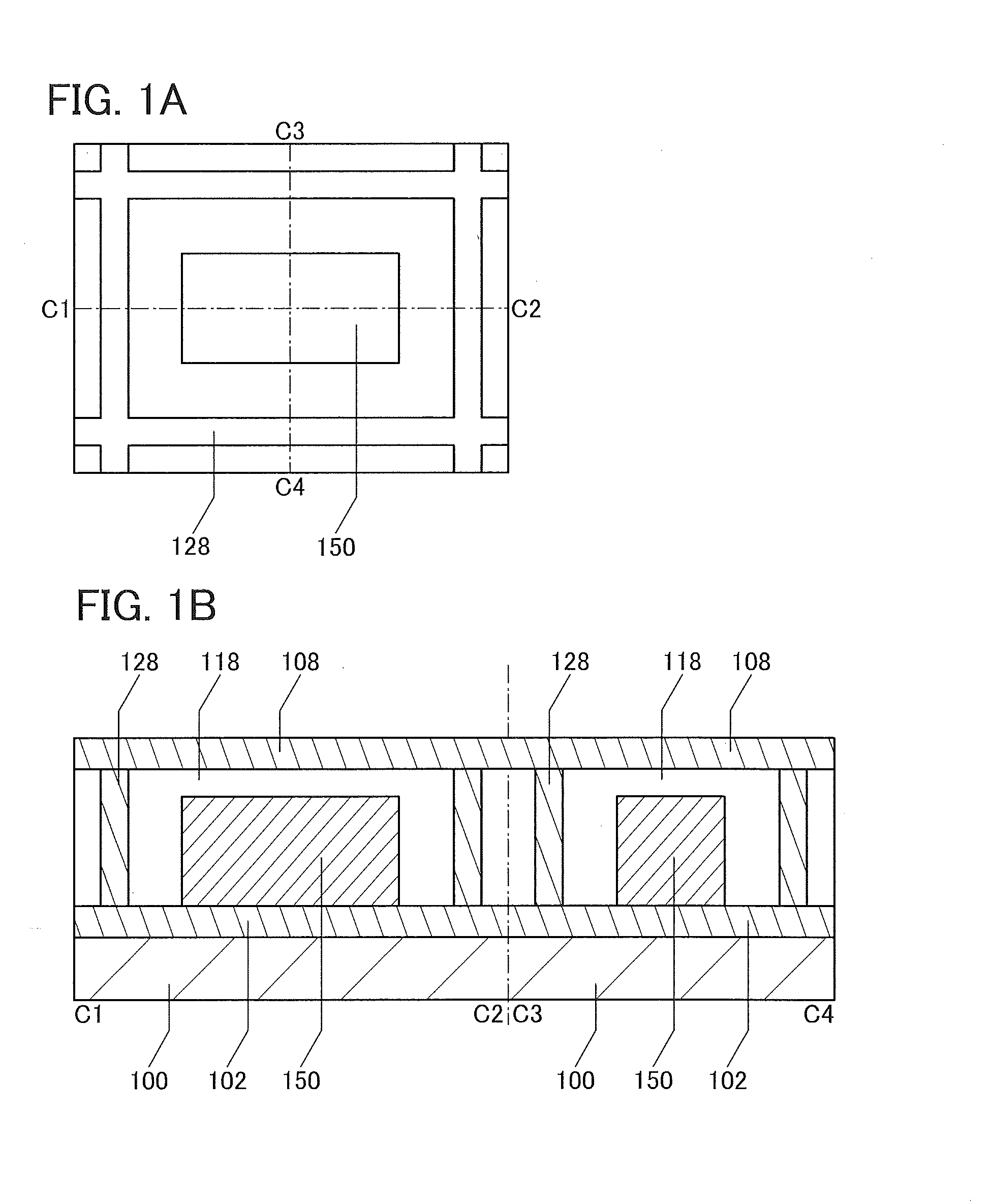

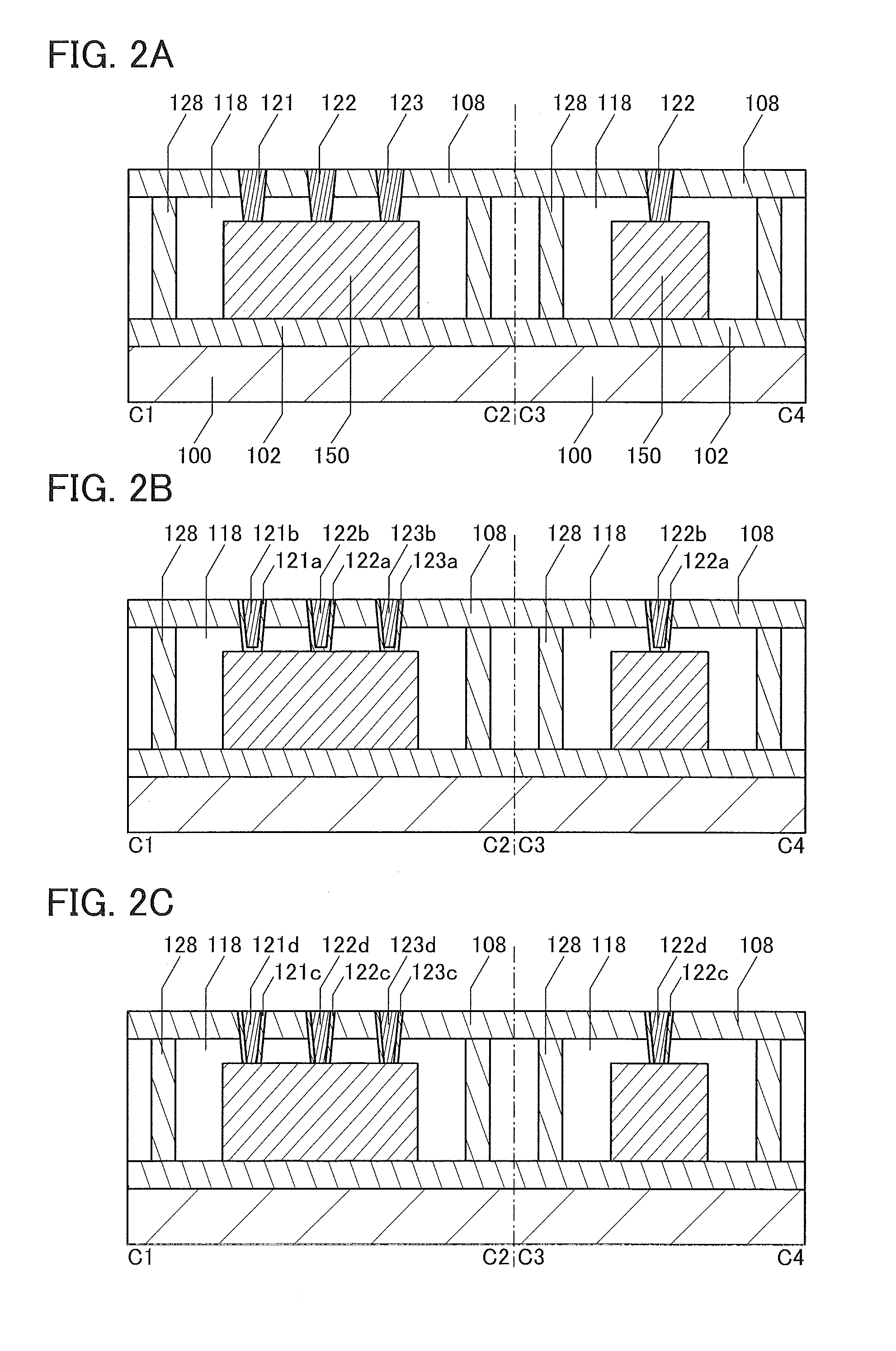

ActiveUS20160071840A1High reliabilityHigh frequency characteristicTransistorSemiconductor/solid-state device detailsOxide semiconductorPower semiconductor device

A semiconductor device that includes transistors with different threshold voltages is provided. Alternatively, a semiconductor device including a plurality of kinds of circuits and transistors whose electrical characteristics are different between the circuits is provided. The semiconductor device includes a first transistor and a second transistor. The first transistor includes an oxide semiconductor, a conductor, a first insulator, a second insulator, and a third insulator. The conductor has a region where the conductor and the oxide semiconductor overlap with each other. The first insulator is positioned between the conductor and the oxide semiconductor. The second insulator is positioned between the conductor and the first insulator. The third insulator is positioned between the conductor and the second insulator. The second insulator has a negatively charged region.

Owner:SEMICON ENERGY LAB CO LTD

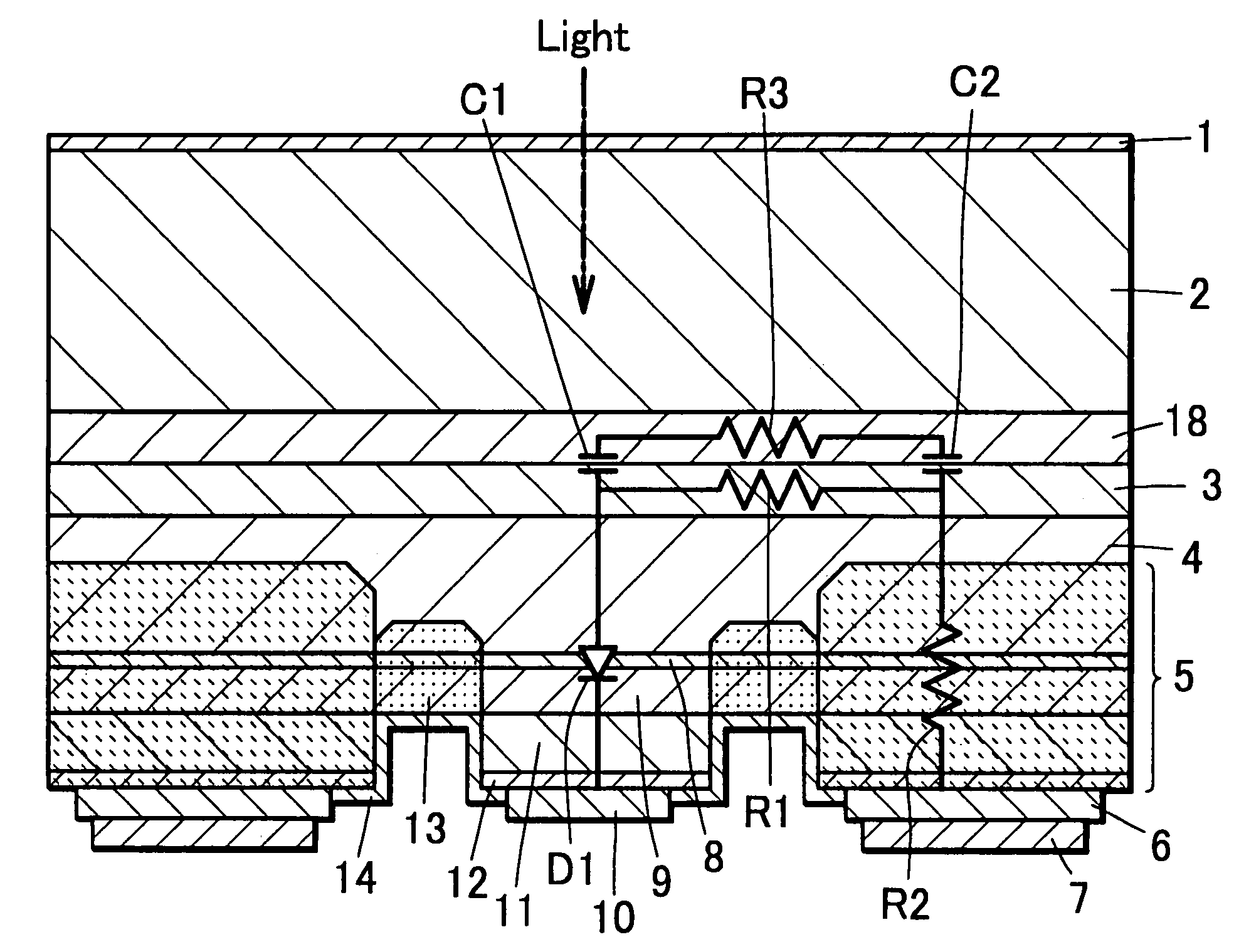

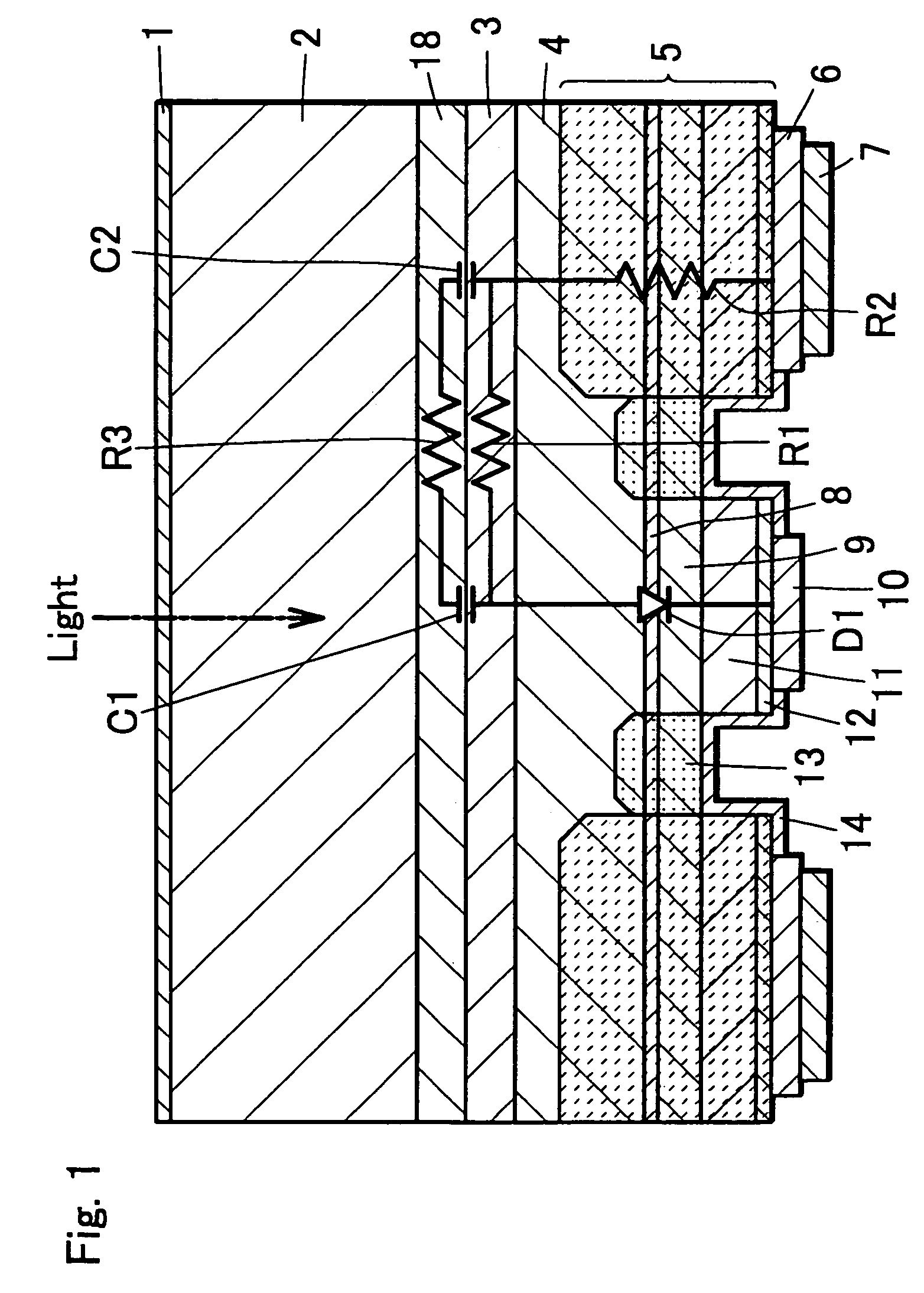

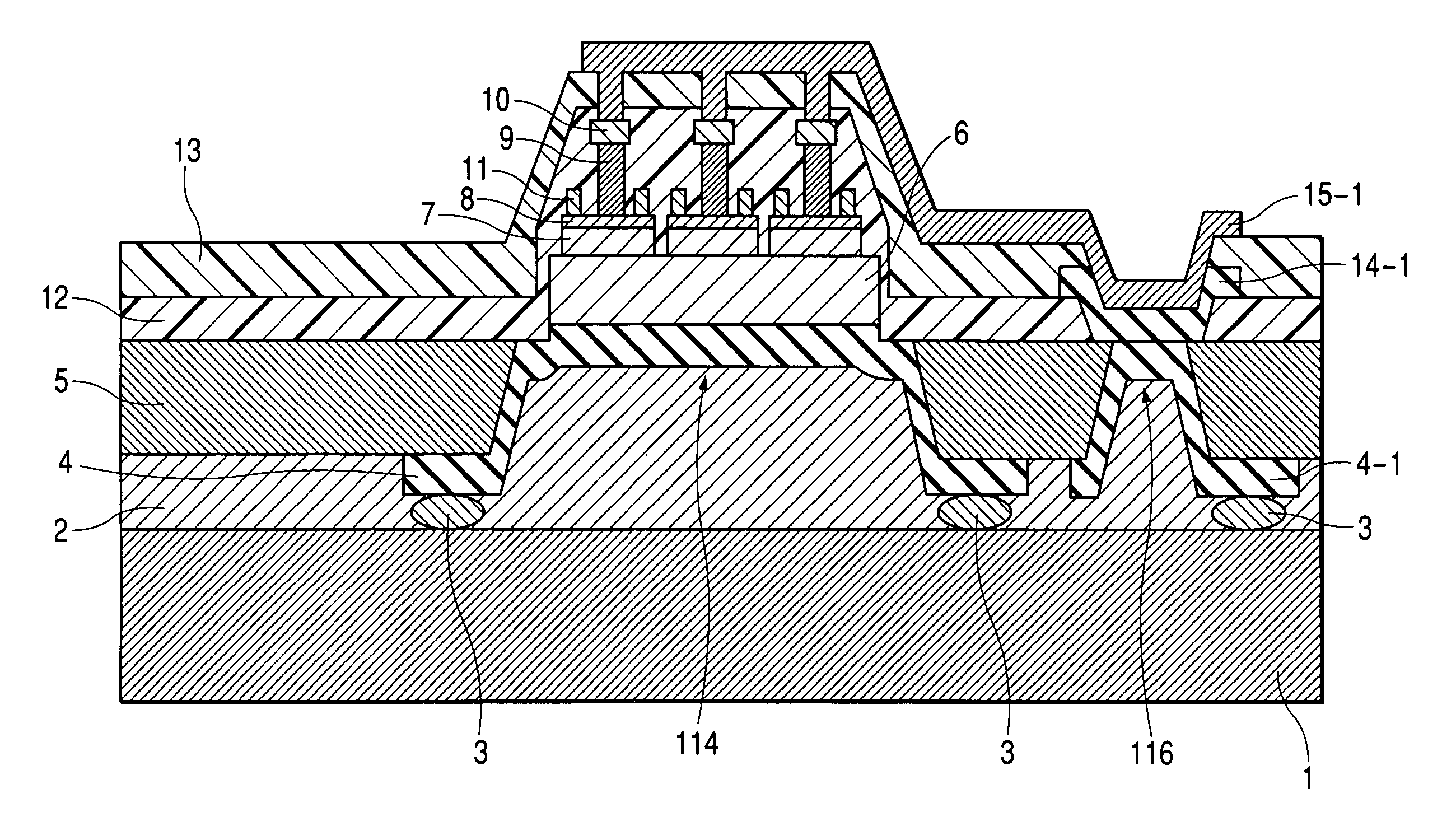

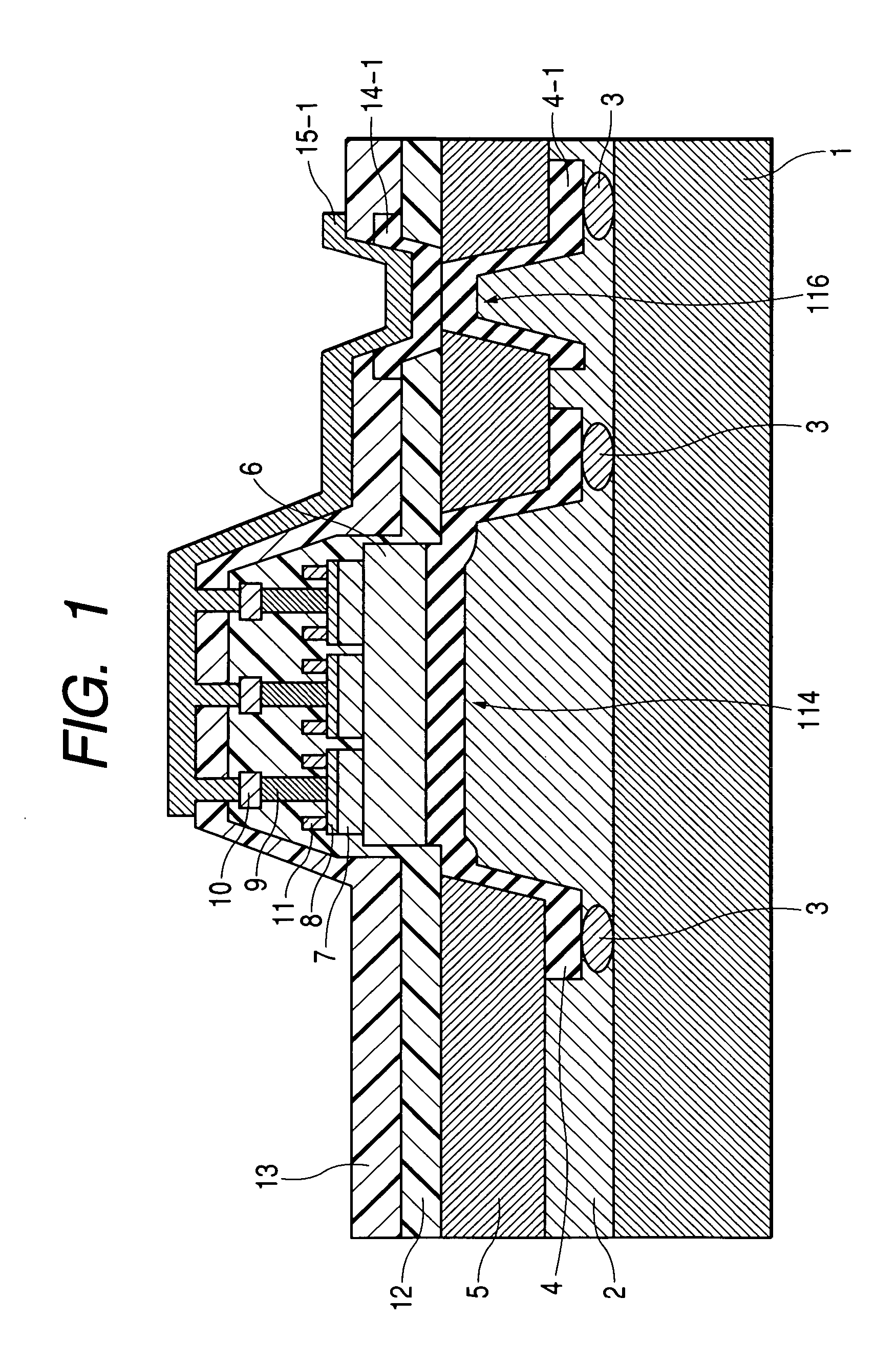

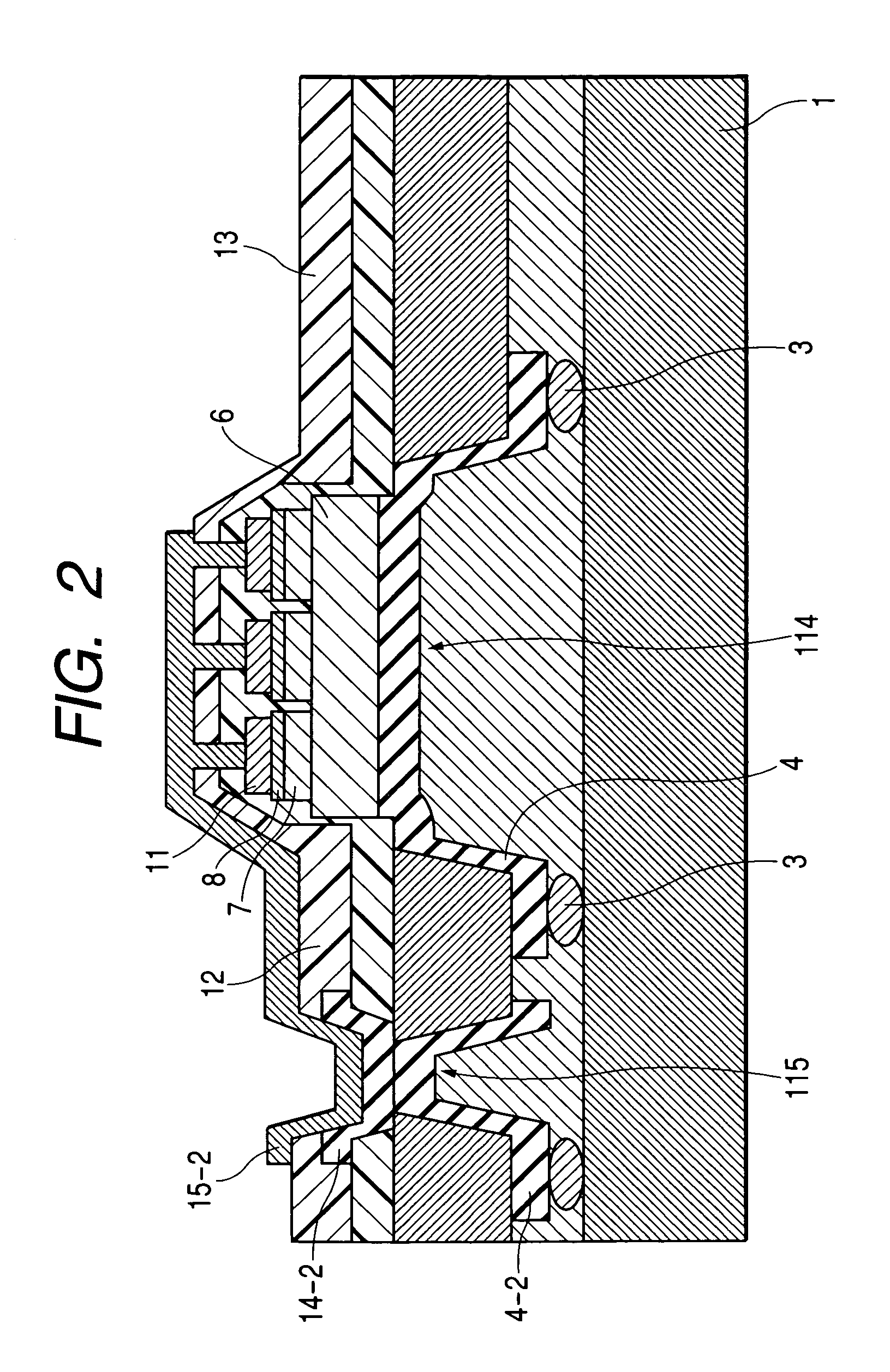

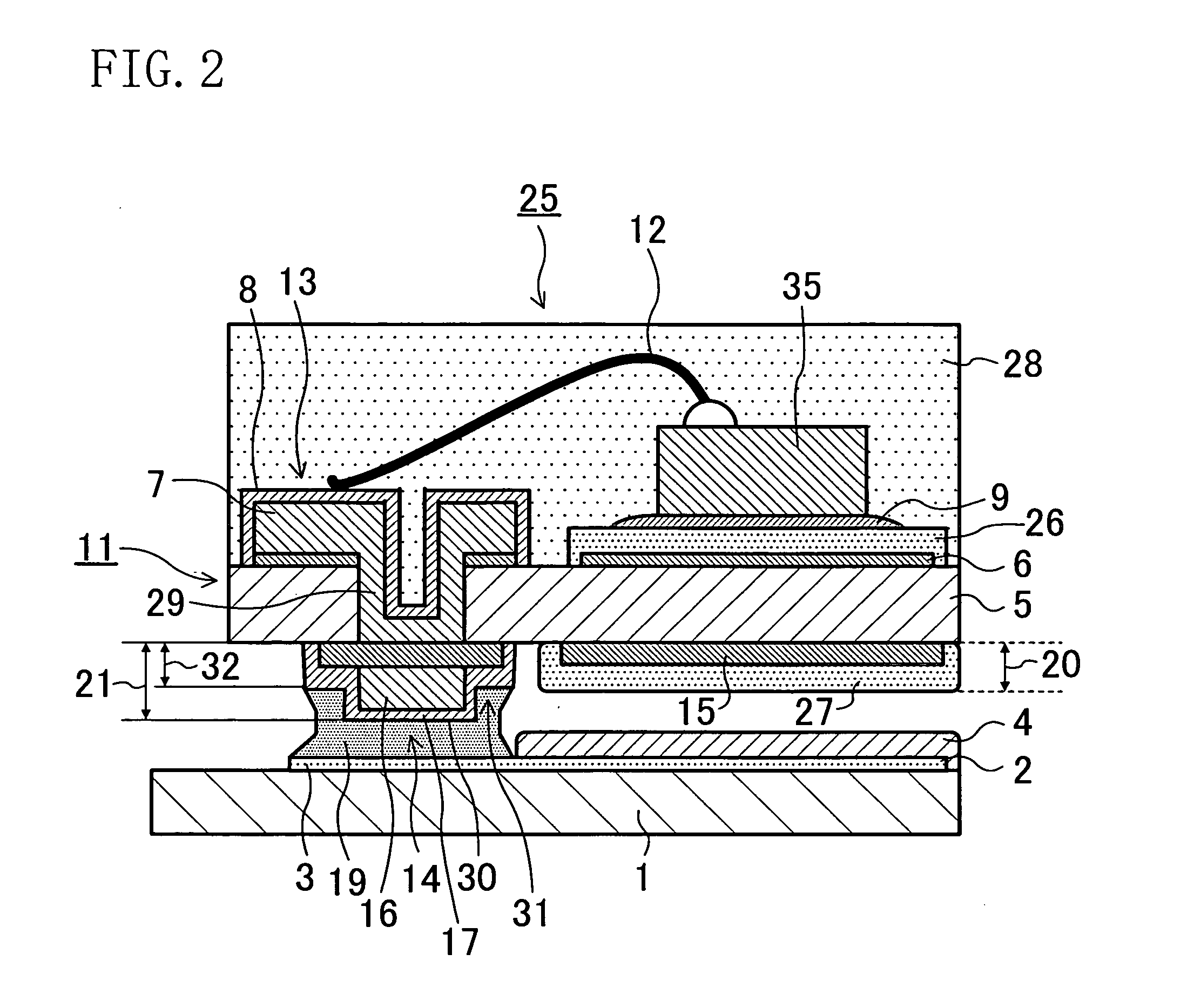

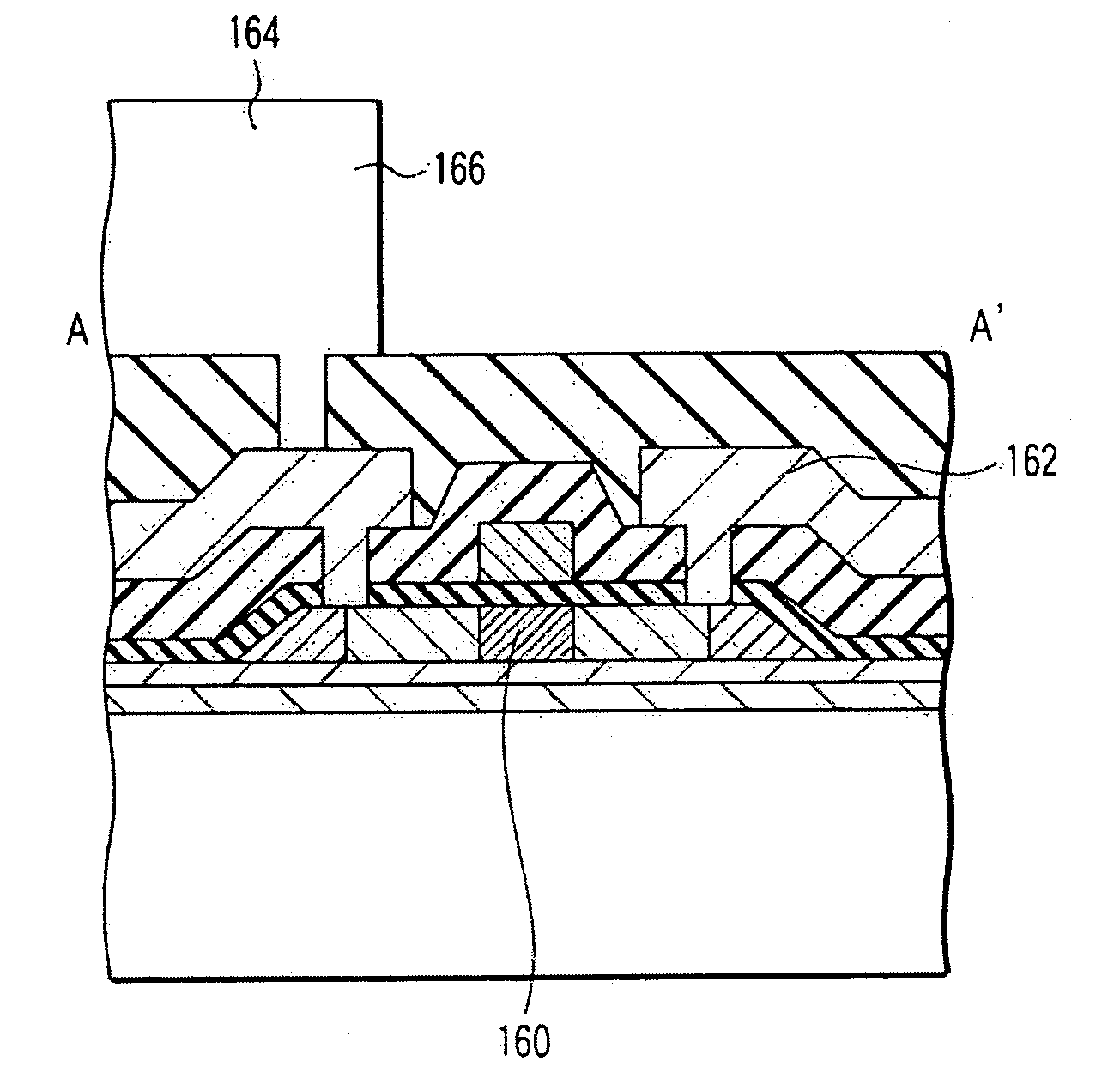

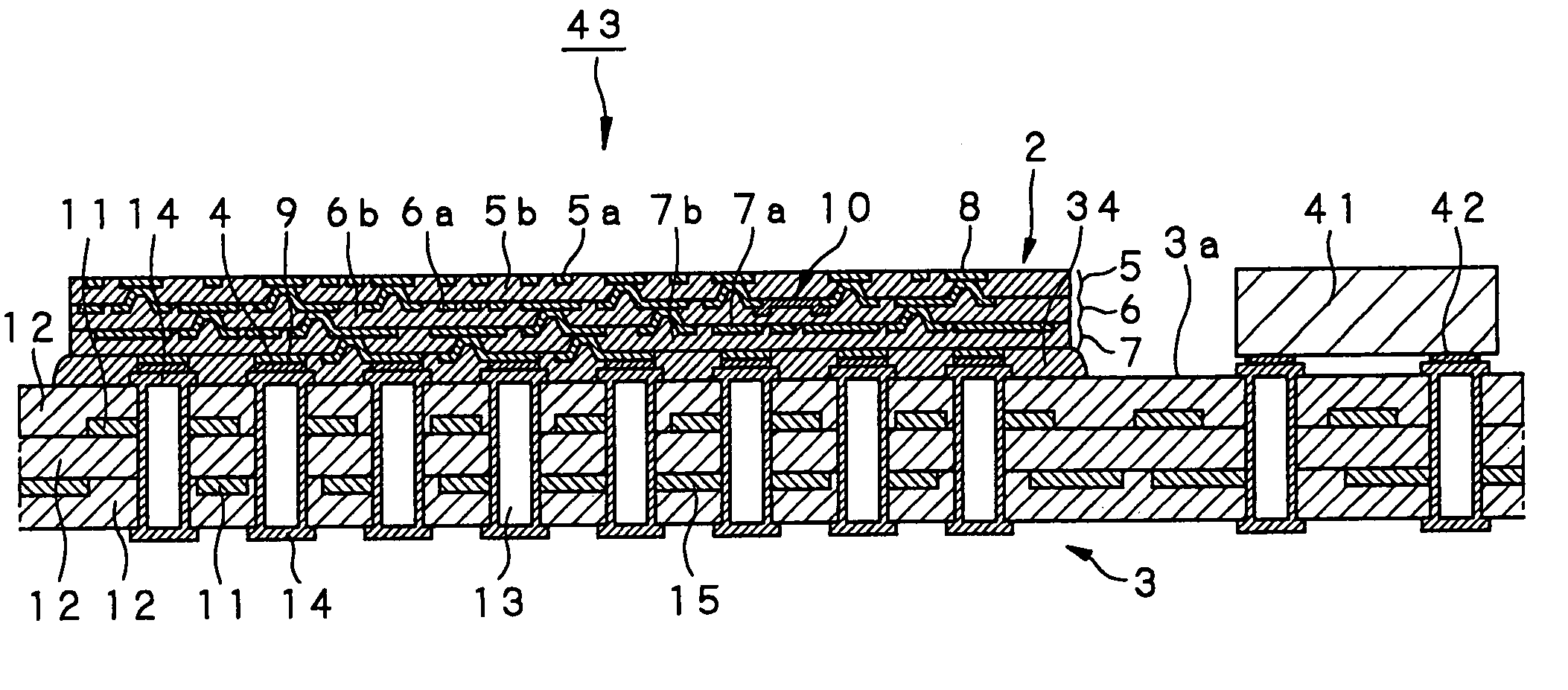

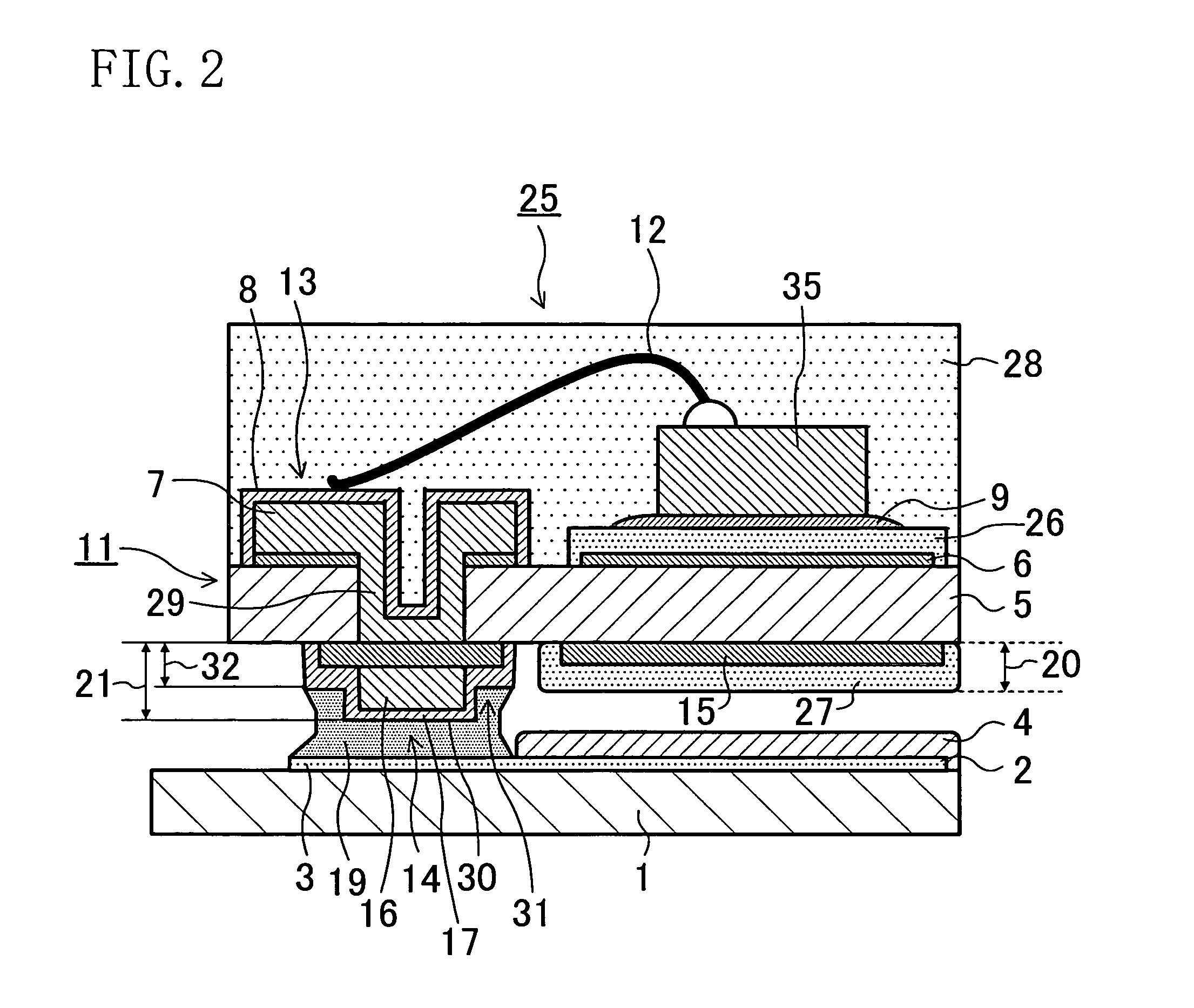

Semiconductor device having led out conductor layers, manufacturing method of the same, and semiconductor module

InactiveUS7067857B2Low variabilityHigh-frequency characteristicTransistorSemiconductor/solid-state device detailsMonolithic microwave integrated circuitHeterojunction bipolar transistor

The gist of the present invention is as follows: In a monolithic microwave integrate circuit (MMIC) using a heterojunction bipolar transistor (HBT), via holes are respectively formed from the bottom of the MMIC for the emitter, base and collector. Of the via holes, one is located so as to face the HBT. The respective topside electrodes for the other via holes located so as not to face the HBT are provided in contact with the MMIC substrate.

Owner:HITACHI LTD

Semiconductor device

InactiveUS20050263787A1Improve featuresLower resistanceSemiconductor devicesDevice materialCompound (substance)

A semiconductor devices has a structure reducing resistances to a high frequency current. The semiconductor device includes a semi-insulating substrate, a first n-type layer made of a compound semiconductor, and a first p-type layer made of a compound semiconductor in which a signal current flows in a lateral direction, parallel to the semi-insulating substrate. The first p-type layer is sandwiched between the semi-insulating substrate and the first n-type layer. A second n type layer made of a compound semiconductor is between the semi-insulating substrate and the first p type layer. An alternating current component of the signal current flows through the second n type layer.

Owner:MITSUBISHI ELECTRIC CORP

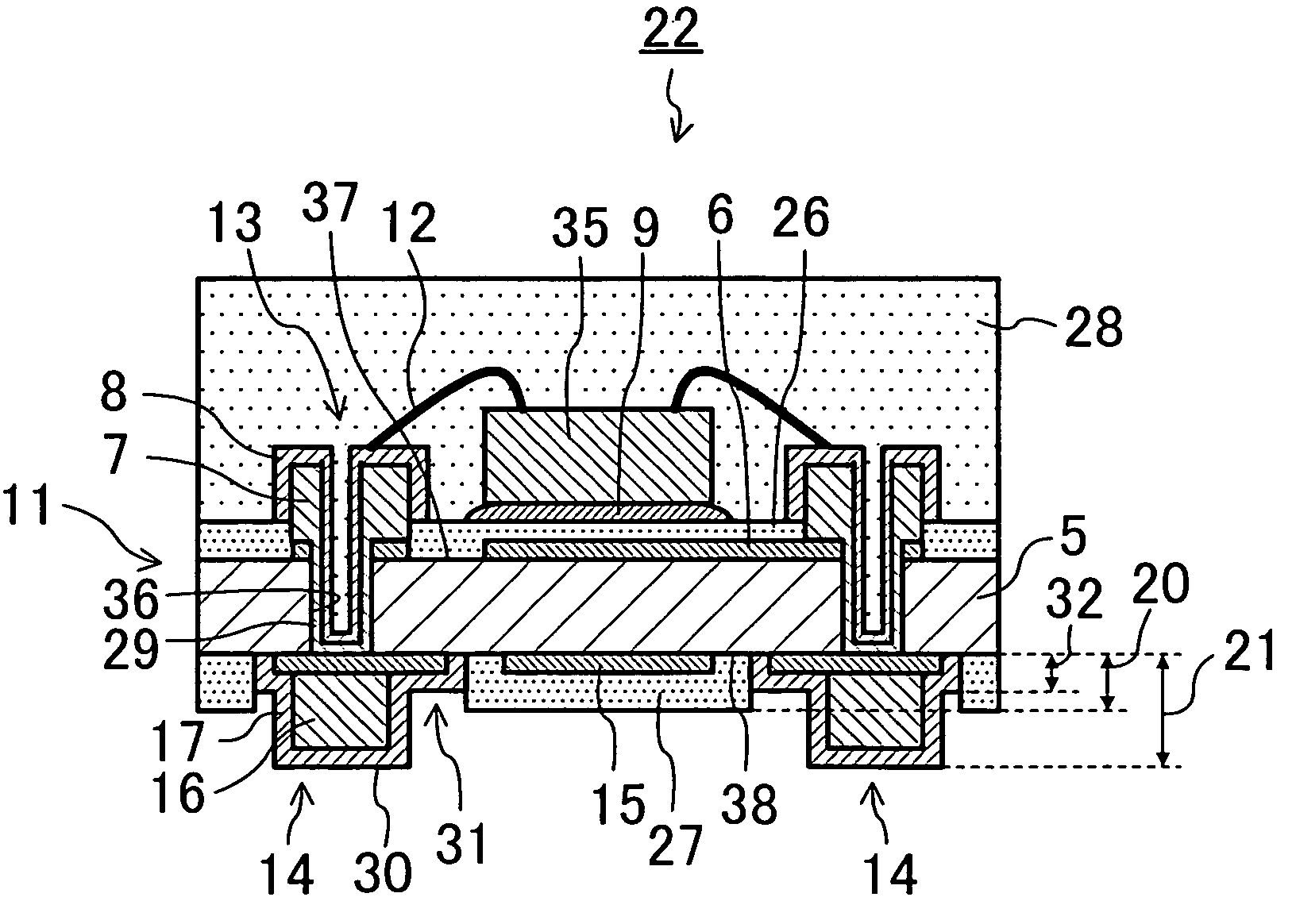

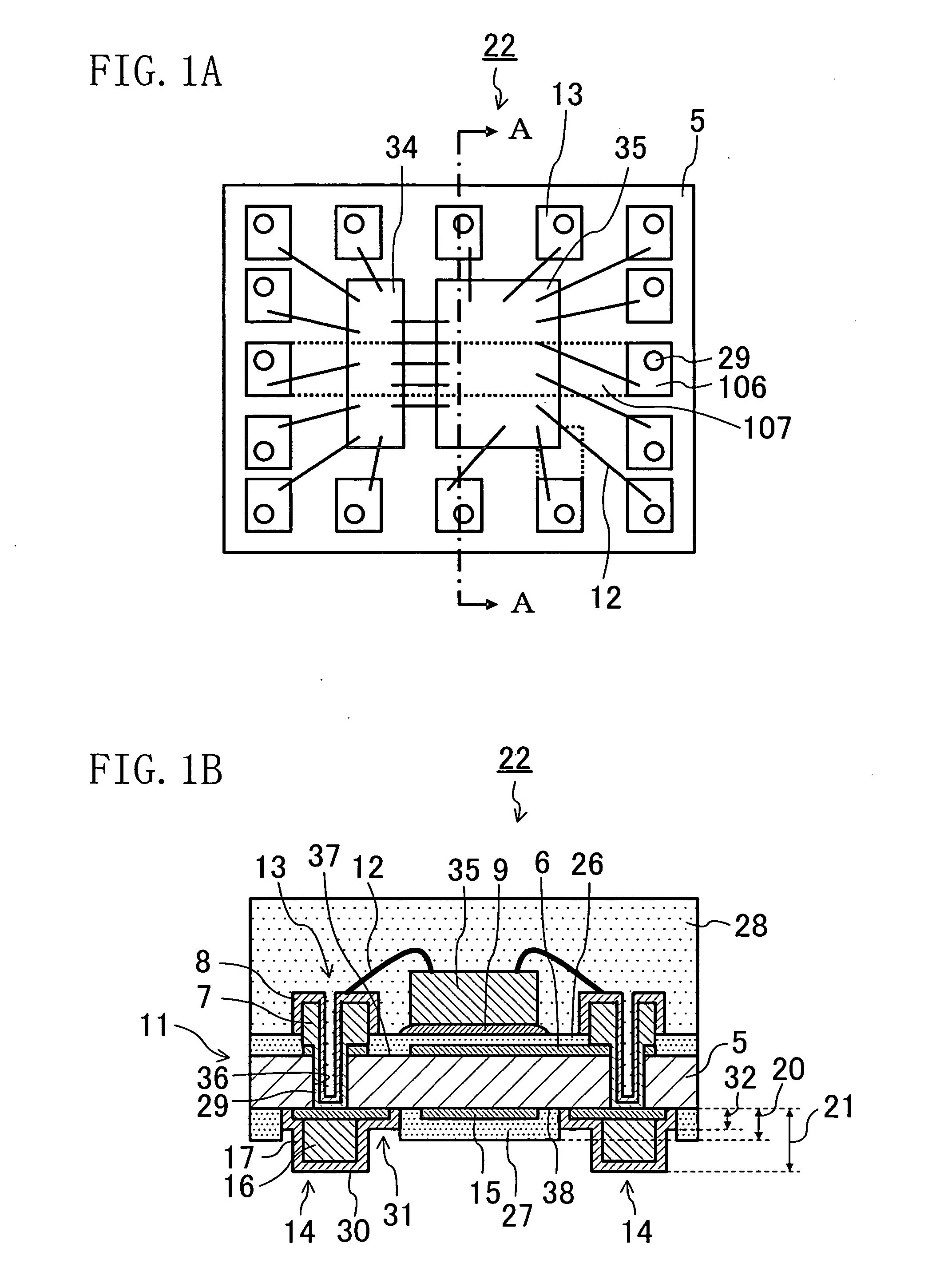

Semiconductor device, electronic apparatus comprising the same, and method for fabrication of substrate for semiconductor device used therein

InactiveUS20070170578A1Improve reliabilityHigh-frequency characteristicSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringMetal

A semiconductor device has upper electrodes and external terminals which are protruding above the both surfaces of a substrate for semiconductor device and connected to each other by penetrating electrodes, a first insulating film covering at least a metal pattern except for the portions of the first insulating film corresponding to the upper electrodes, a second insulating film covering at least another metal pattern except for the portions of the second insulating film corresponding to the external terminals, and a semiconductor element connected to the upper electrodes and placed on the substrate for semiconductor device. The solder-connected surface of the external terminal is positioned to have a height larger than that of a surface of the second insulating film. The semiconductor element is placed on the first insulating film and covered, together with the upper electrodes, with a mold resin.

Owner:PANASONIC CORP

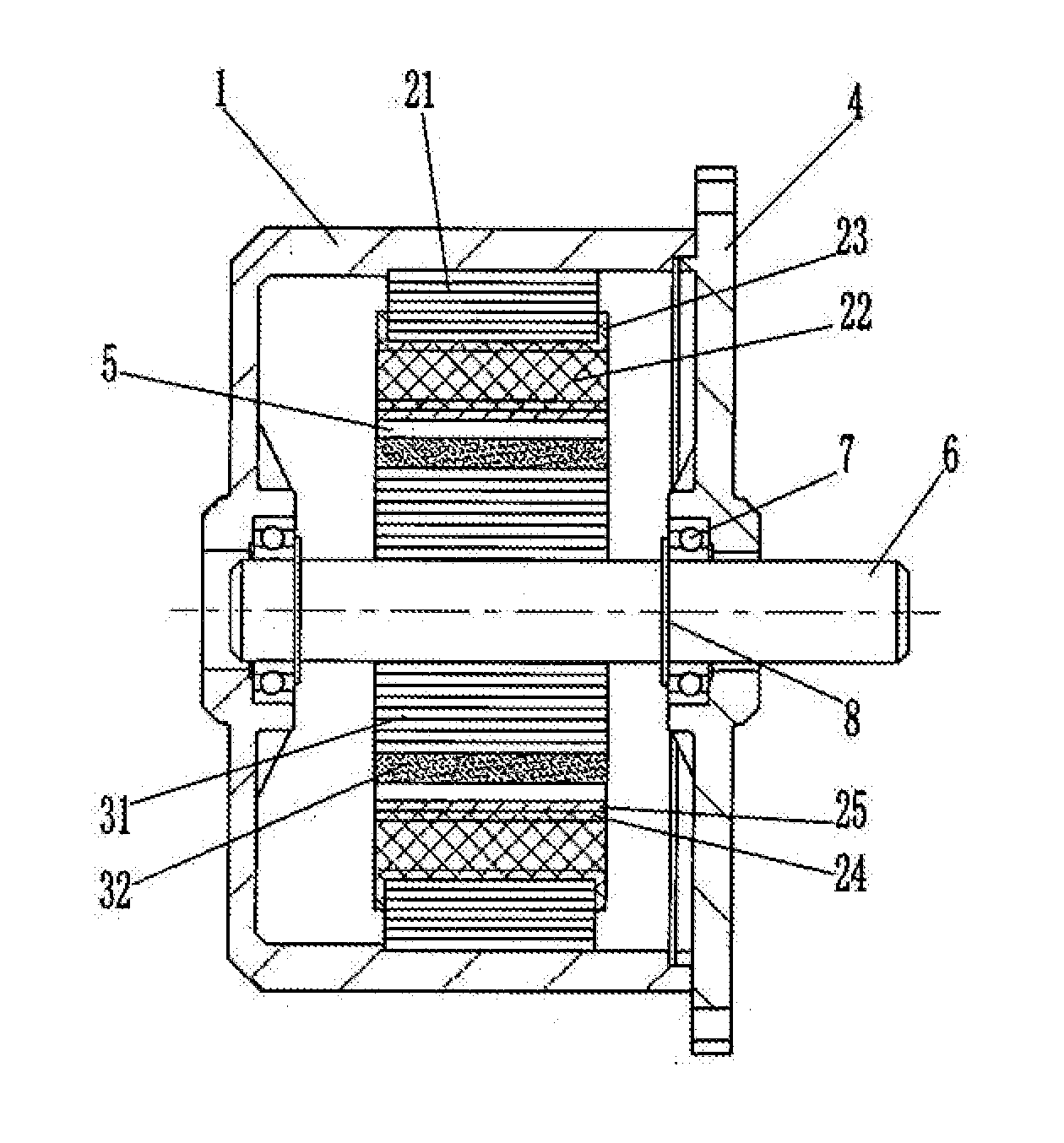

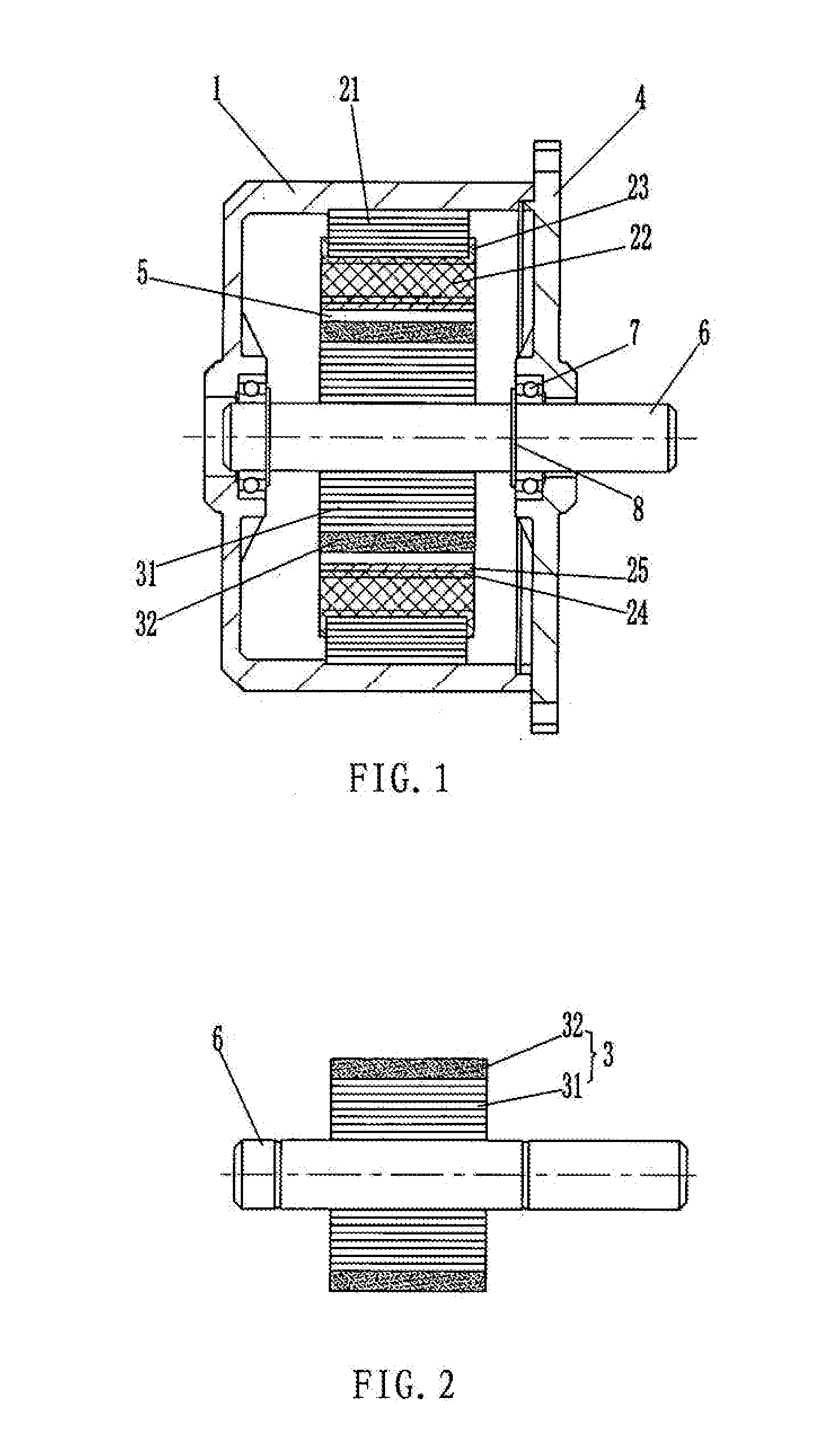

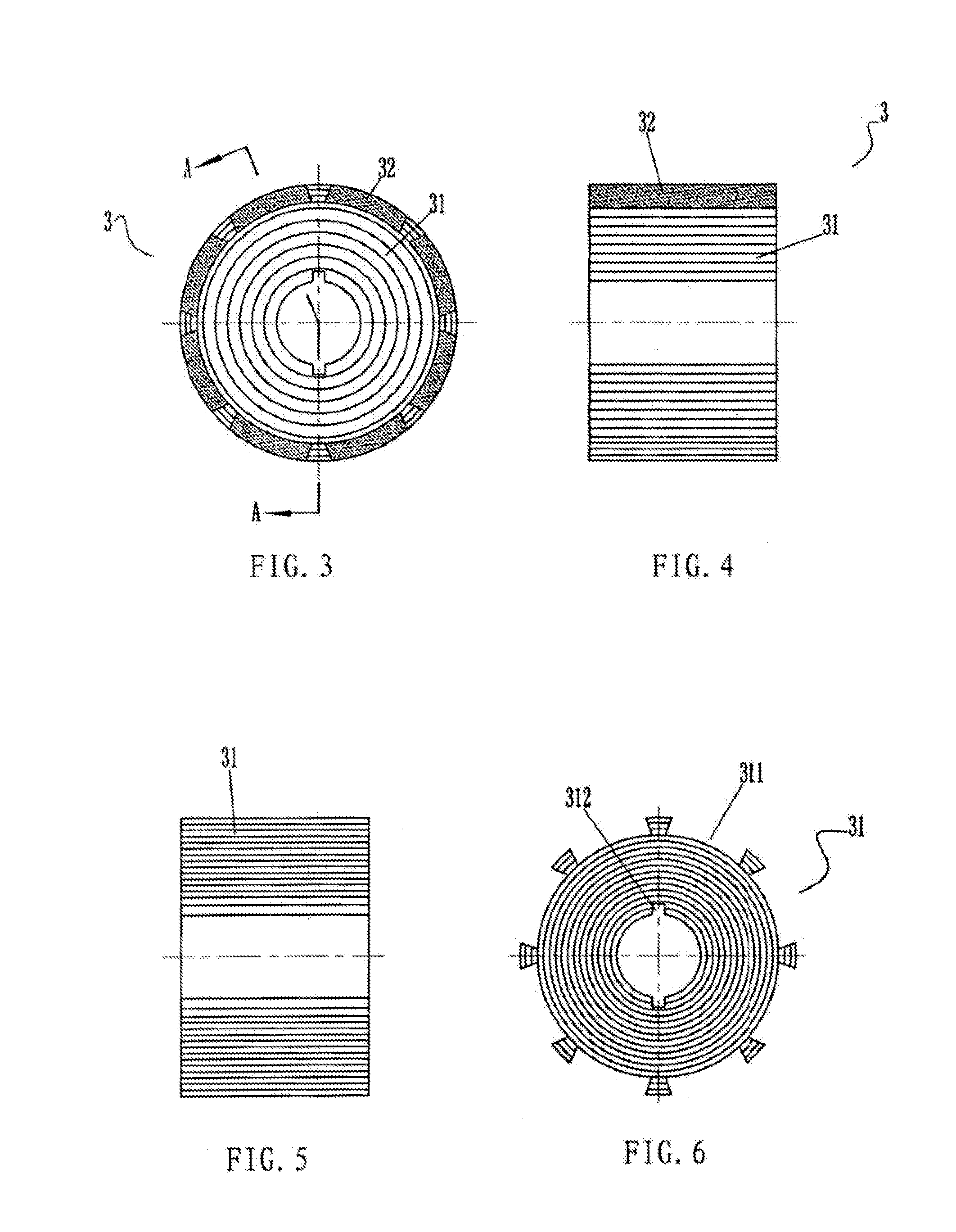

Slotless amorphous ferroalloy electric machine with radial magnetic circuit and its manufacturing method

InactiveUS20140319951A1Low eddy current lossHigh frequency characteristicWindingsMagnetic circuit rotating partsEngineeringConductor Coil

A slotless amorphous ferroalloy electric machine with radial magnetic circuit and a manufacturing method. The invention includes a stator iron core (21), a cylinder formed by winding an amorphous ferroalloy strip, a stator winding (22) is integrally in the shape of a cylinder and fixed on the internal cylindrical surface of the stator iron core (21), connecting with a metal reinforcing sleeve (25). A radial air gap (5) is arranged between the internal cylindrical surface of the metal reinforcing sleeve (25) and the external surface of a rotor (3). A rotor iron core (31) having a hollow amorphous ferroalloy cylindrical structure and the inner bore wall of the rotor iron core (31) is provided with keyway (312) used for connecting with a electric machine shaft (6) that the radial external surface of the rotor iron core (31) matches with permanent magnets (32).

Owner:SHENZHEN DONG MING MOTOR ELECTRIC CO LTD +1

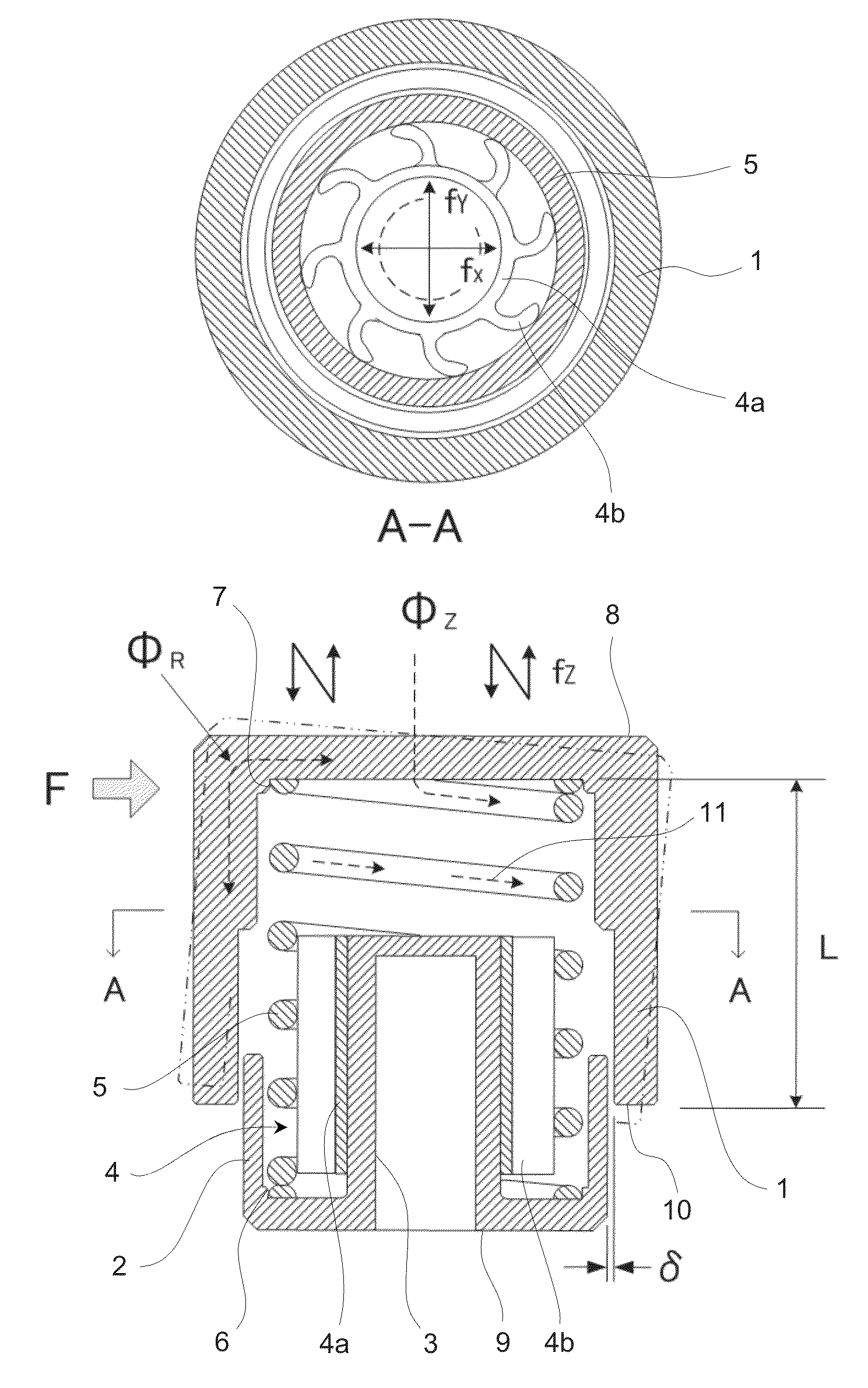

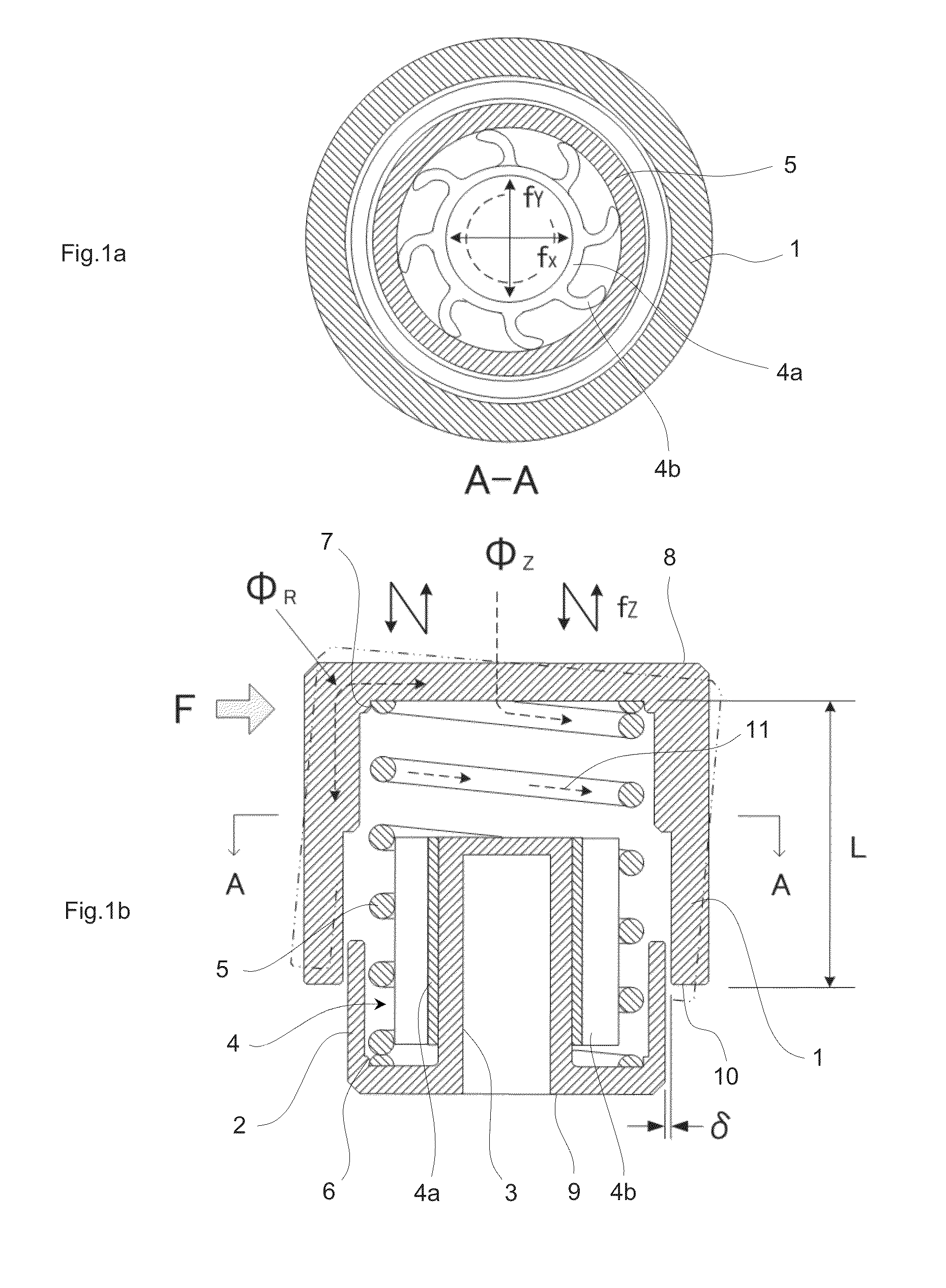

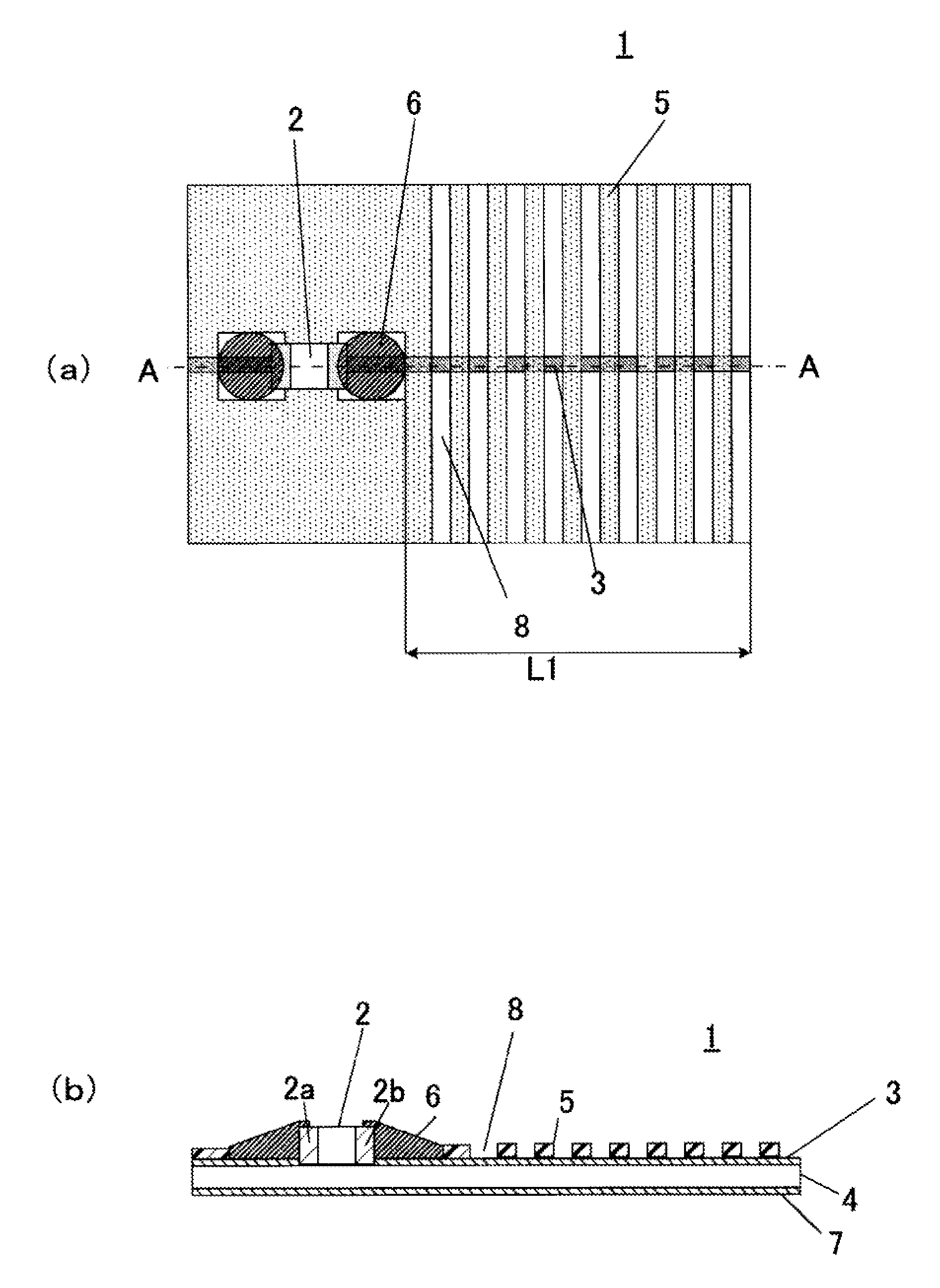

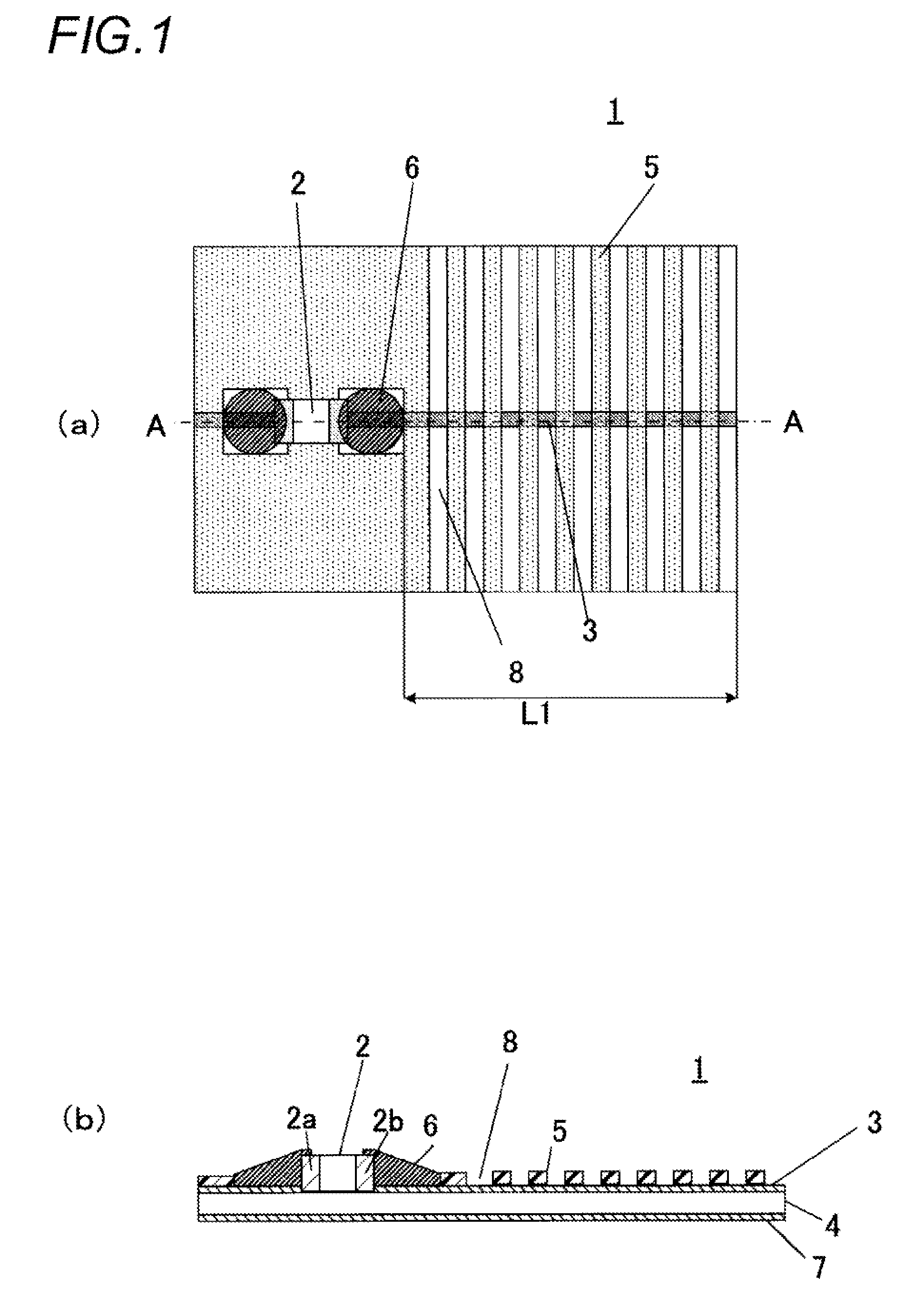

Insulator for audio and method for evaluating same

ActiveUS8833511B2High-frequency characteristicImprove featuresPortable framesNon-rotating vibration suppressionSound imageImage resolution

Owner:TOKKYOKIKI CORP

Semiconductor Device, Module, and Electronic Device

InactiveUS20160155850A1Stable electrical characteristicsReduce leakage currentTransistorSolid-state devicesHydrogenComputer module

Provided is an element with stable electrical characteristics or a device including plural kinds of elements with stable electrical characteristics. The semiconductor device includes a first insulator, a transistor over the first insulator, a second insulator over the transistor, and a third insulator over the second insulator. The second insulator includes an opening reaching the first insulator. The opening is filled with a fourth insulator. The first insulator, the third insulator, and the fourth insulator each have a lower hydrogen-transmitting property than the second insulator.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device, method for manufacturing semiconductor device, module, and electronic device

InactiveUS20160155849A1Stable electrical characteristicsReduce leakage currentTransistorSolid-state devicesPower semiconductor deviceGate insulator

A semiconductor device with stable electrical characteristics is provided. Alternatively, a semiconductor device having normally-off electrical characteristics is provided. A semiconductor device includes a gate electrode, a gate insulator, and an oxide semiconductor, the oxide semiconductor contains fluorine in a channel formation region, and a fluorine concentration in the channel formation region is higher than or equal to 1×1020 atoms / cm3 and lower than or equal to 1×1022 atoms / cm3. Note that fluorine is added by an ion implantation method.

Owner:SEMICON ENERGY LAB CO LTD

Coaxial cable end-processing structure, coaxial cable shielding terminal and press-fastening apparatus

InactiveUS7425161B2Easy to carryReduce the number of partsAntenna connectorsConnections effected by permanent deformationCoaxial cableElectrical and Electronics engineering

An intermediate portion of an insulating sheath of a coaxial cable is removed, and a first insulating sheath portion is drawn toward a second insulating sheath portion, so that a braid is projected into an annular shape outwardly from an interval between opposed ends of the first and second insulating sheath portions to form an annular projecting braid portion, and this annular projecting braid portion is fixed so as to be connected to a portion (that is, a braid fixing portion) of a coaxial cable shielding terminal for connection to an end portion of the coaxial cable. This connecting and fixing operation is effected by press-contacting or press-clamping.

Owner:YAZAKI CORP

Display device and electronic device using thin-film transistors formed on semiconductor thin films which are crystallized on insulating substrates

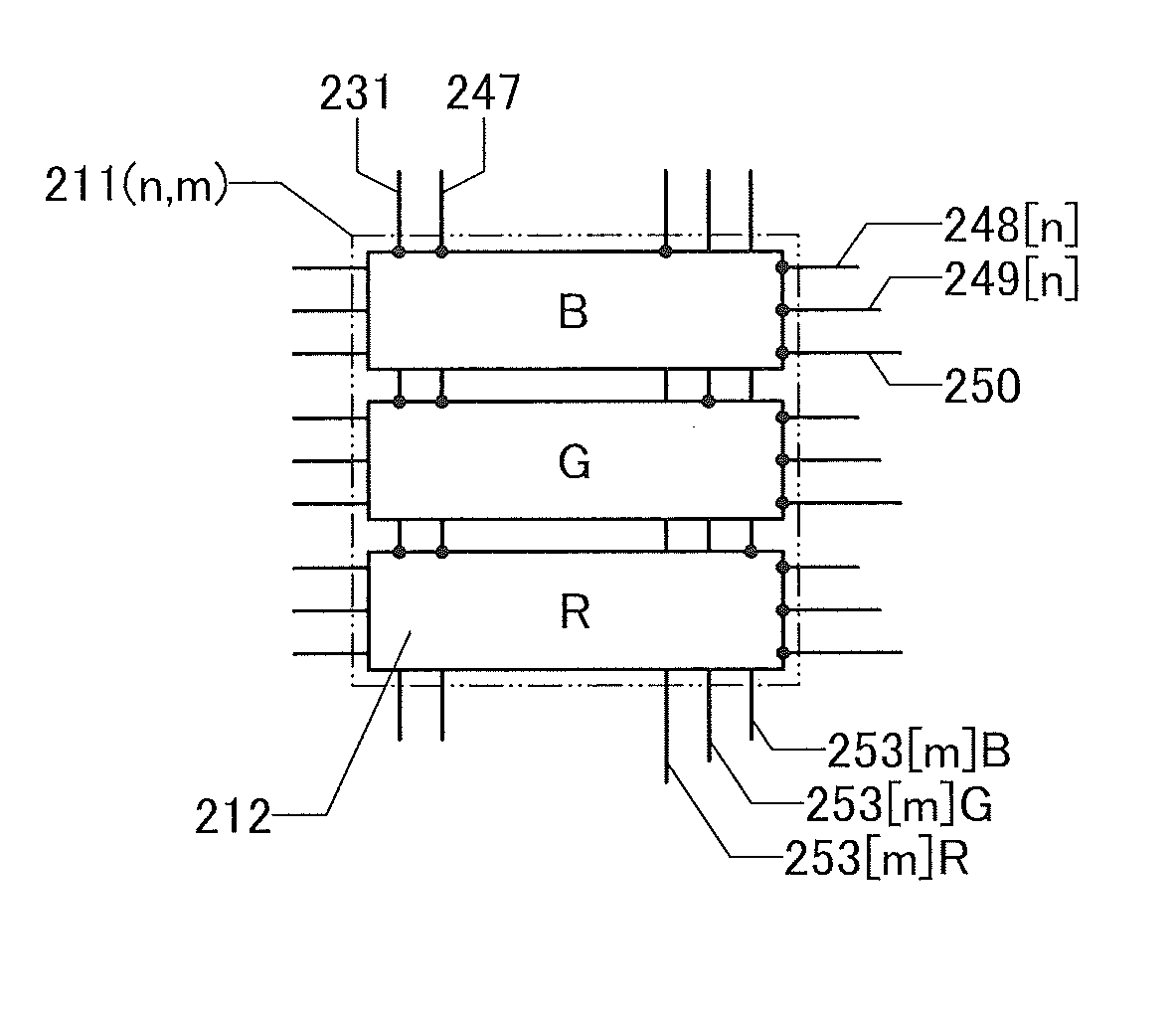

InactiveUS20080283843A1High-frequency characteristicAntenna supports/mountingsSolid-state devicesControl signalDisplay device

A method of receiving video data, a control signal, etc. via a non-contact transmission path is adopted, and a receiving circuit for receiving and amplifying a signal is formed on the same insulating substrate as a display device. Thus, there are provided a thin-film transistor which is formed in a semiconductor thin film that is formed on the insulating substrate and crystallized in a predetermined direction, and an inductor for forming an inductive-coupling circuit, which is formed by using an electrically conductive thin film provided on the insulating substrate. The direction of movement of carriers flowing in the thin-film transistor is parallel to the direction of crystallization of the semiconductor thin film, and the inductor and the thin-film transistor are integrated so as to be electrically coupled directly or indirectly.

Owner:SHARP KK

Substrate and substrate module

ActiveUS7671709B2OptimizationHigh-frequency characteristicMultiple-port networksCross-talk/noise/interference reductionEngineeringGround pattern

A substrate module includes a first substrate and a second substrate. The first substrate comprises a base material; a transmission line in which a signal line is sandwiched between two ground patterns, on the surface of the base material; a ground pattern on the rear surface of the base material; and an exposed portion in which the ground pattern on the substrate surface is exposed by partially cutting out the base material and the ground pattern on the substrate rear surface. The second substrate comprises a base material and a transmission line in which a signal line is sandwiched between two ground patterns, on the surface of the base material. In connecting a transmission line of the first substrate and that of the second substrate, the ground patterns of the first and second substrates are fused with each other at the exposed portion and fixed.

Owner:FUJITSU LTD

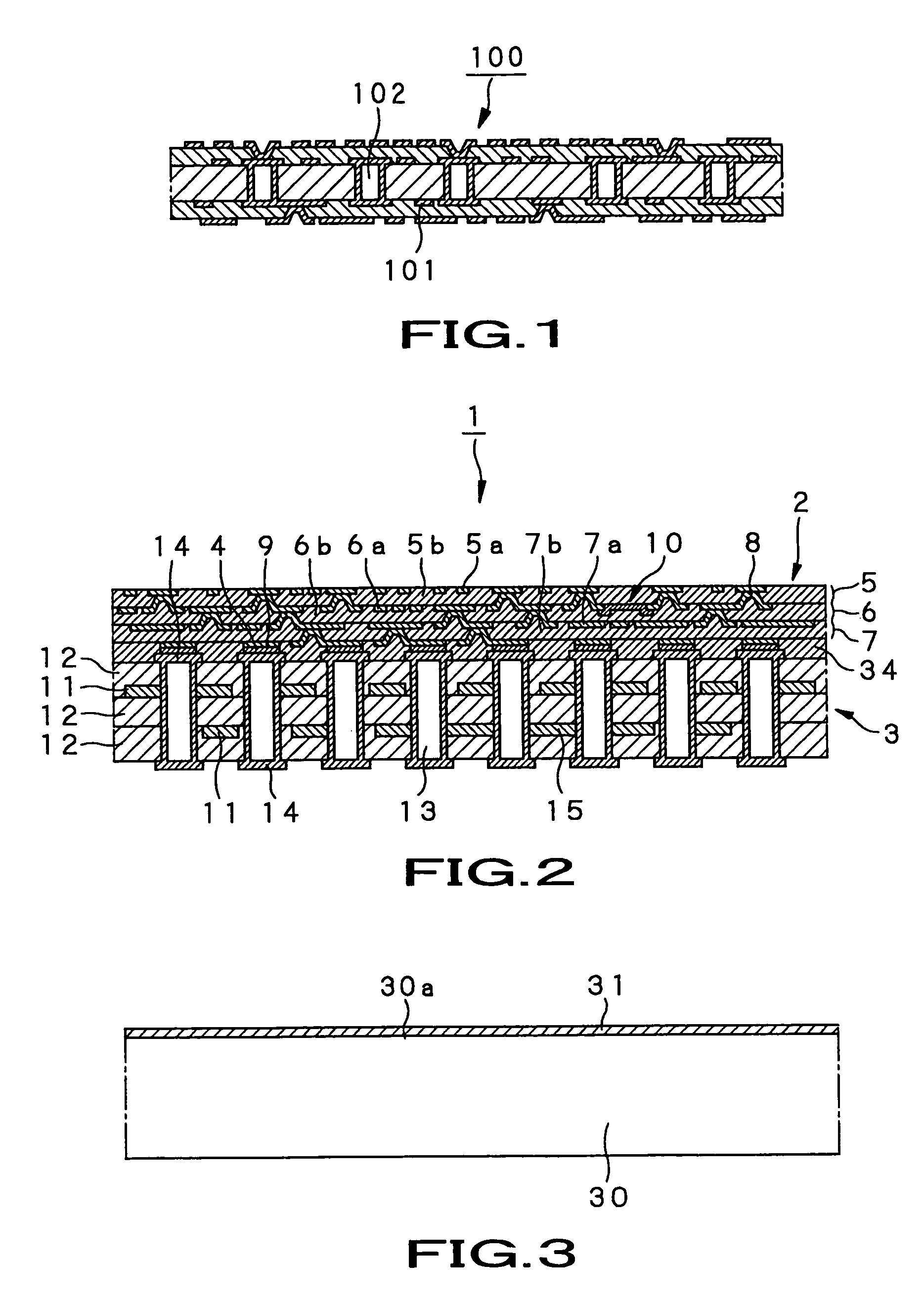

Circuit substrate device, method for producing the same, semiconductor device and method for producing the same

InactiveUS7138294B2Increase productivityShorten production timeSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorEngineering

Owner:SONY CORP

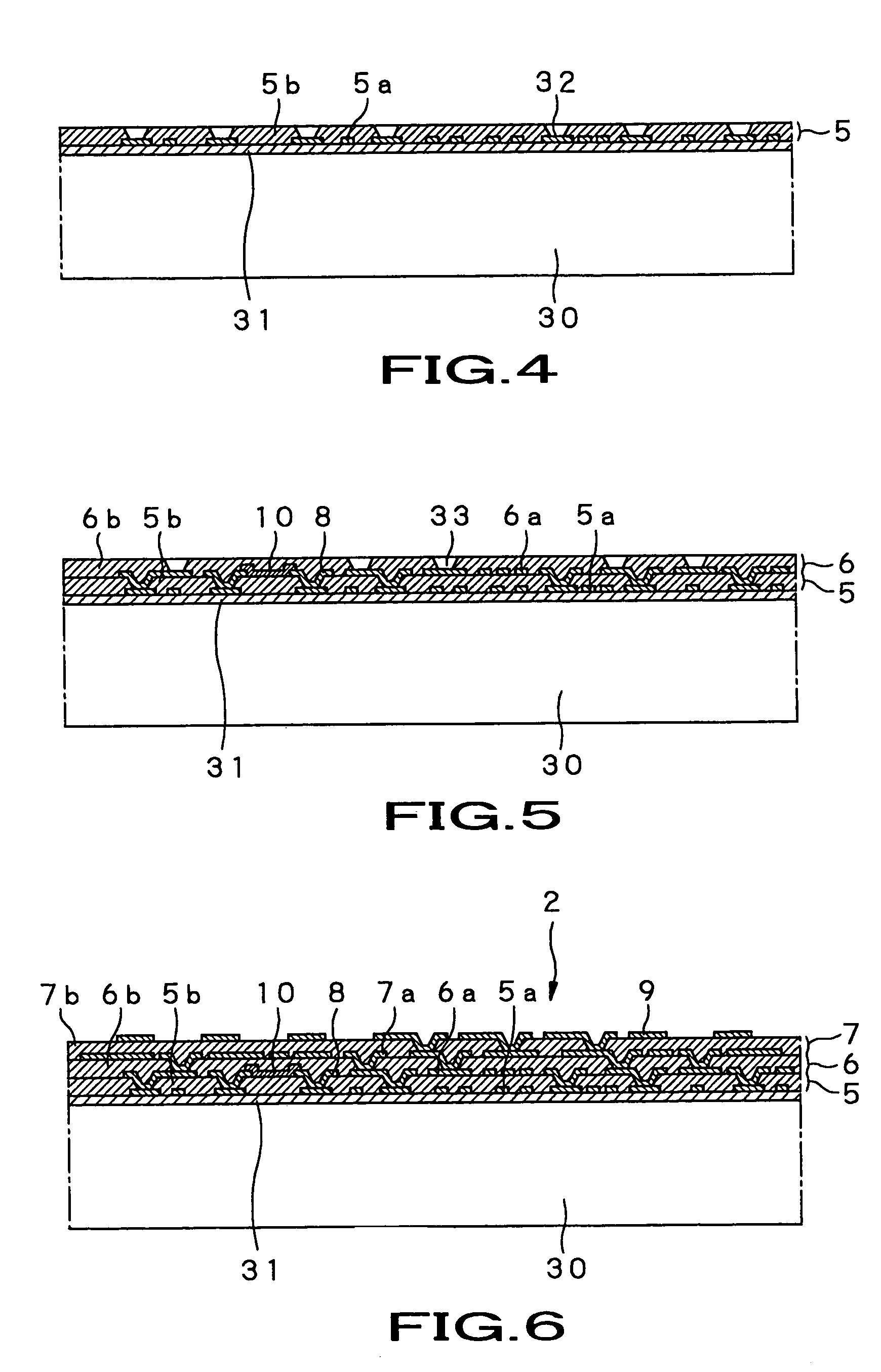

Method for producing metal-clad laminate, and metal-clad laminate

ActiveUS20190001628A1High frequency characteristicImprove adhesion strengthInsulating substrate metal adhesion improvementData processing applicationsRoll-to-roll processingPolymer science

Provided is a method for producing a metal-clad laminate of a thermoplastic liquid crystal polymer film (TLCP film) and a metal sheet(s) bonded to at least one surface of the film using roll-to-roll processing. The metal sheet has a surface with a ten-point average roughness (Rz) of 5.0 μm or less to be bonded to the TLCP film. The method includes preparing the laminate, dry-treating the laminate by subjecting the laminate passed through a dry zone satisfying the following conditions (1) and (2):(1) a drying temperature of lower than the melting point of the TLCP film,(2) for a drying period of 10 seconds or longer, andheat-treating the dried laminate by subjecting the laminate passed through a heating zone on a temperature condition of not lower than the melting point of the TLCP film successively after the dry treatment.

Owner:KURARAY CO LTD

Semiconductor device, electronic apparatus comprising the same, and method for fabrication of substrate for semiconductor device used therein

InactiveUS7719119B2Improve reliabilityHigh-frequency characteristicSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringMetal

A semiconductor device has upper electrodes and external terminals which are protruding above the both surfaces of a substrate for semiconductor device and connected to each other by penetrating electrodes, a first insulating film covering at least a metal pattern except for the portions of the first insulating film corresponding to the upper electrodes, a second insulating film covering at least another metal pattern except for the portions of the second insulating film corresponding to the external terminals, and a semiconductor element connected to the upper electrodes and placed on the substrate for semiconductor device. The solder-connected surface of the external terminal is positioned to have a height larger than that of a surface of the second insulating film. The semiconductor element is placed on the first insulating film and covered, together with the upper electrodes, with a mold resin.

Owner:PANASONIC CORP

Electrical plug connector

ActiveUS20210091500A1High-frequency characteristicWider thicknessSecuring/insulating coupling contact membersCoupling contact membersMetallic enclosureMechanical engineering

An electrical plug connector includes a metallic shell, an insulated housing, a power terminal group, and a signal terminal group received in the metallic shell. Each terminal of the power terminal group includes a first contact portion, a second contact portion, and a positioning plate that are formed as a clamp structure. The first contact portion extends from an upper portion of the positioning plate and is above the insertion cavity of the insulated housing. The second contact portion extends from a lower portion of the positioning plate and is below the insertion cavity of the insulated housing. Each terminal of the signal terminal group is side-by-side arranged with the corresponding terminal of the power terminal group. A cross-sectional area of each terminal of the signal terminal group is less than a cross-sectional area of the corresponding terminal of the power terminal group.

Owner:ADVANCED CONNECTEK INC

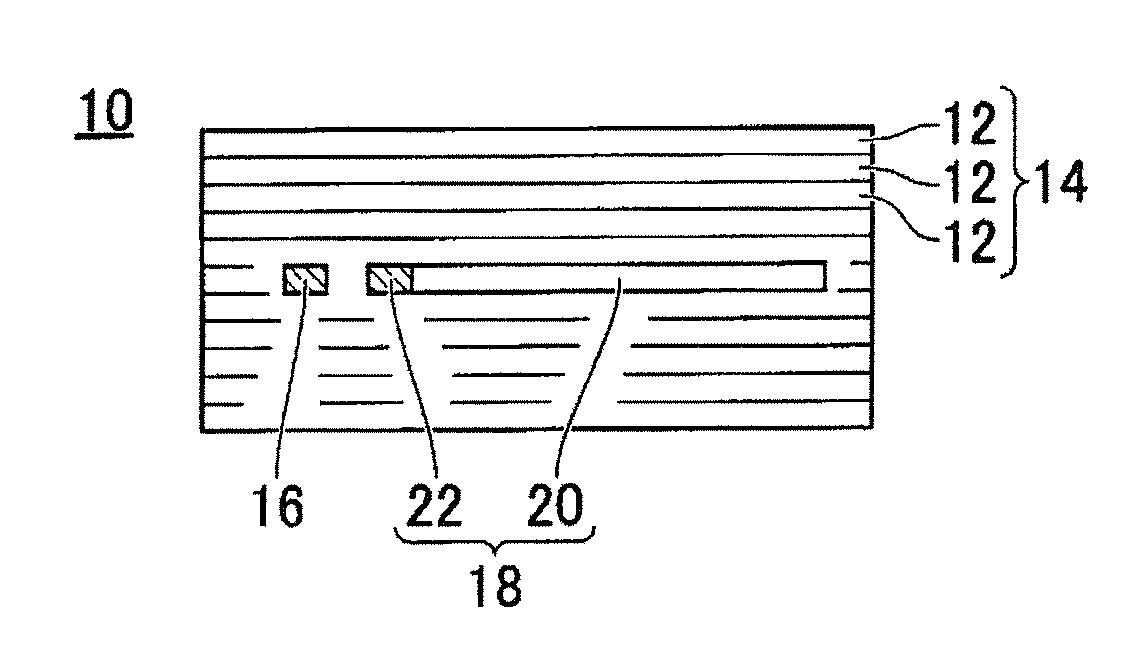

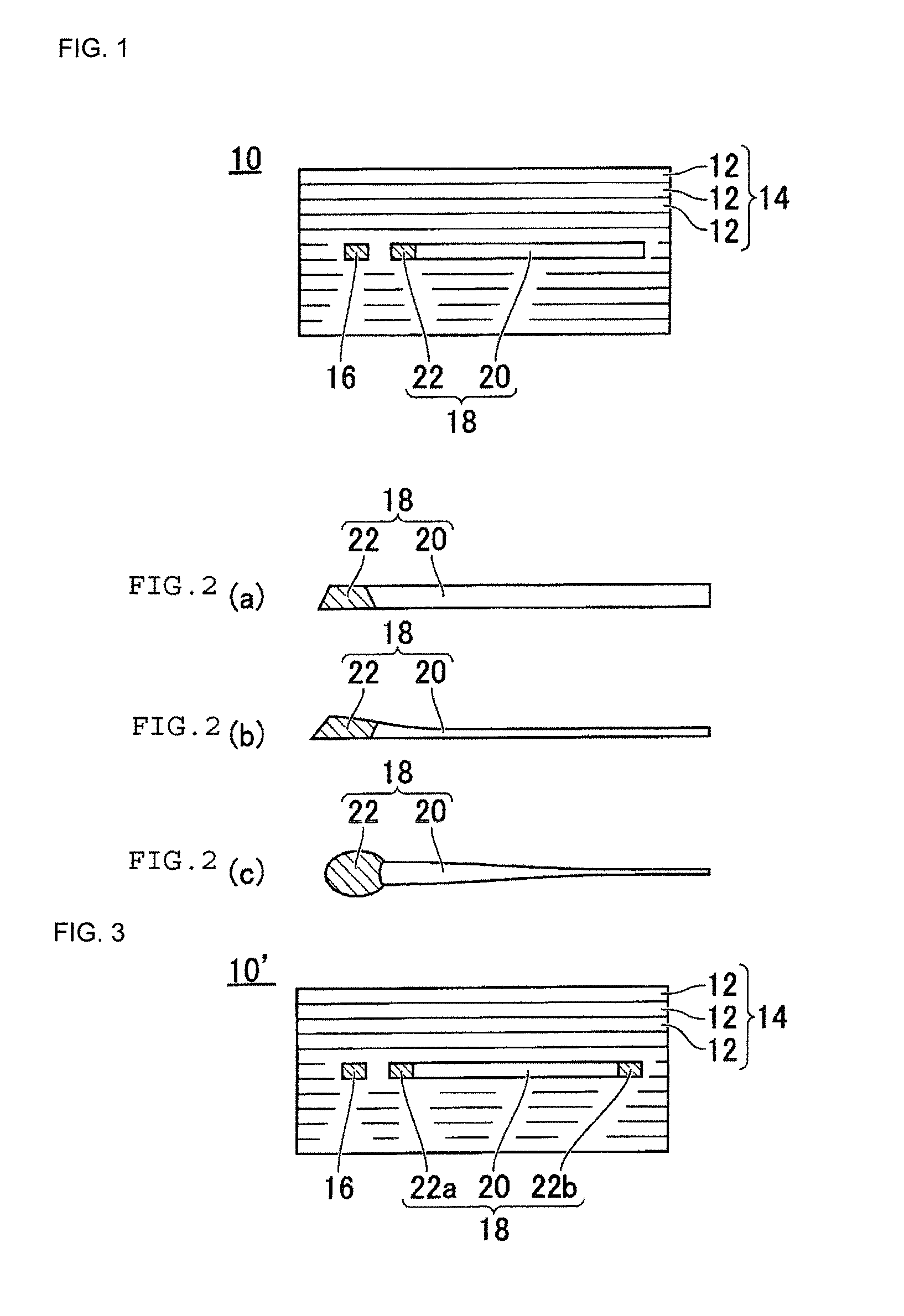

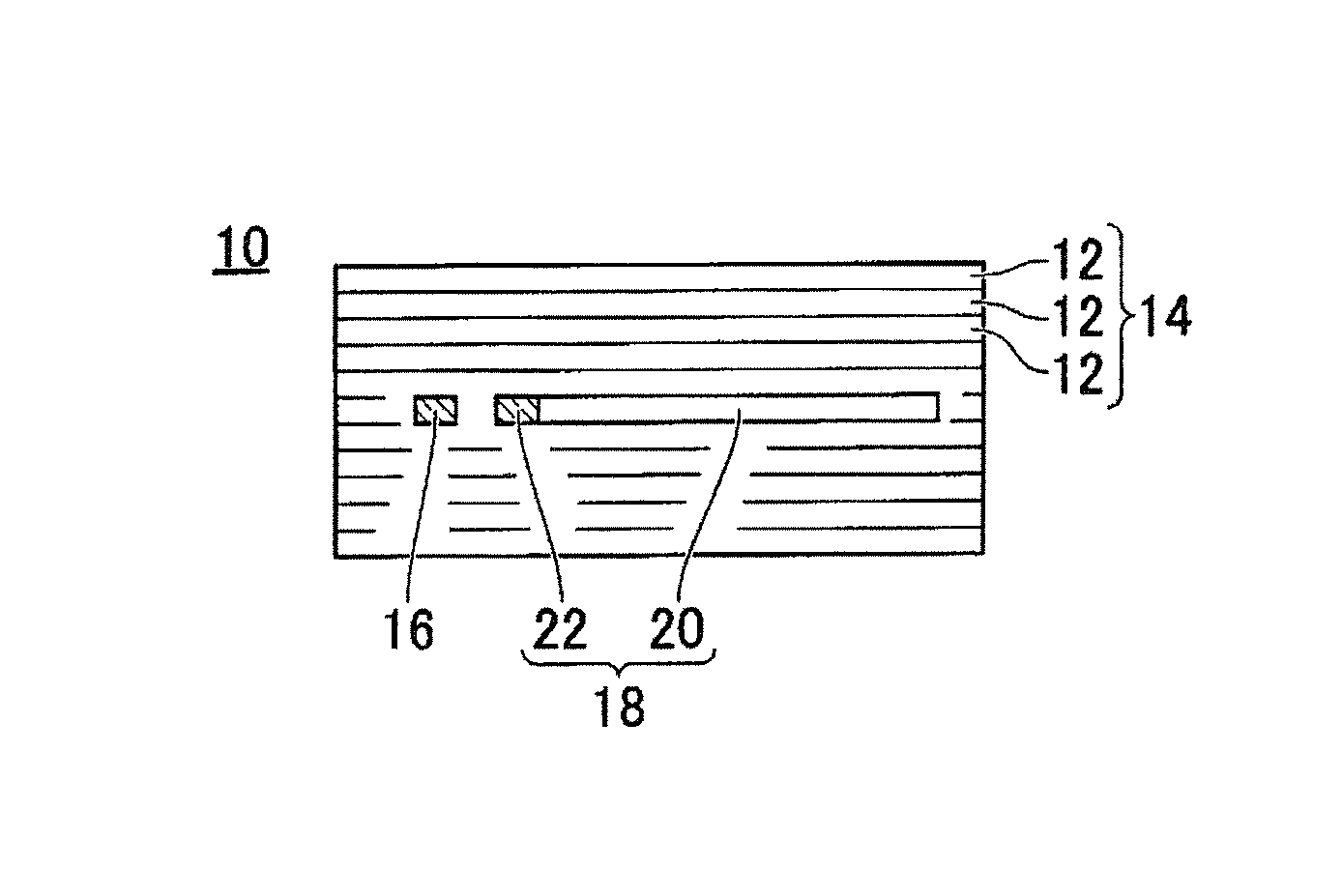

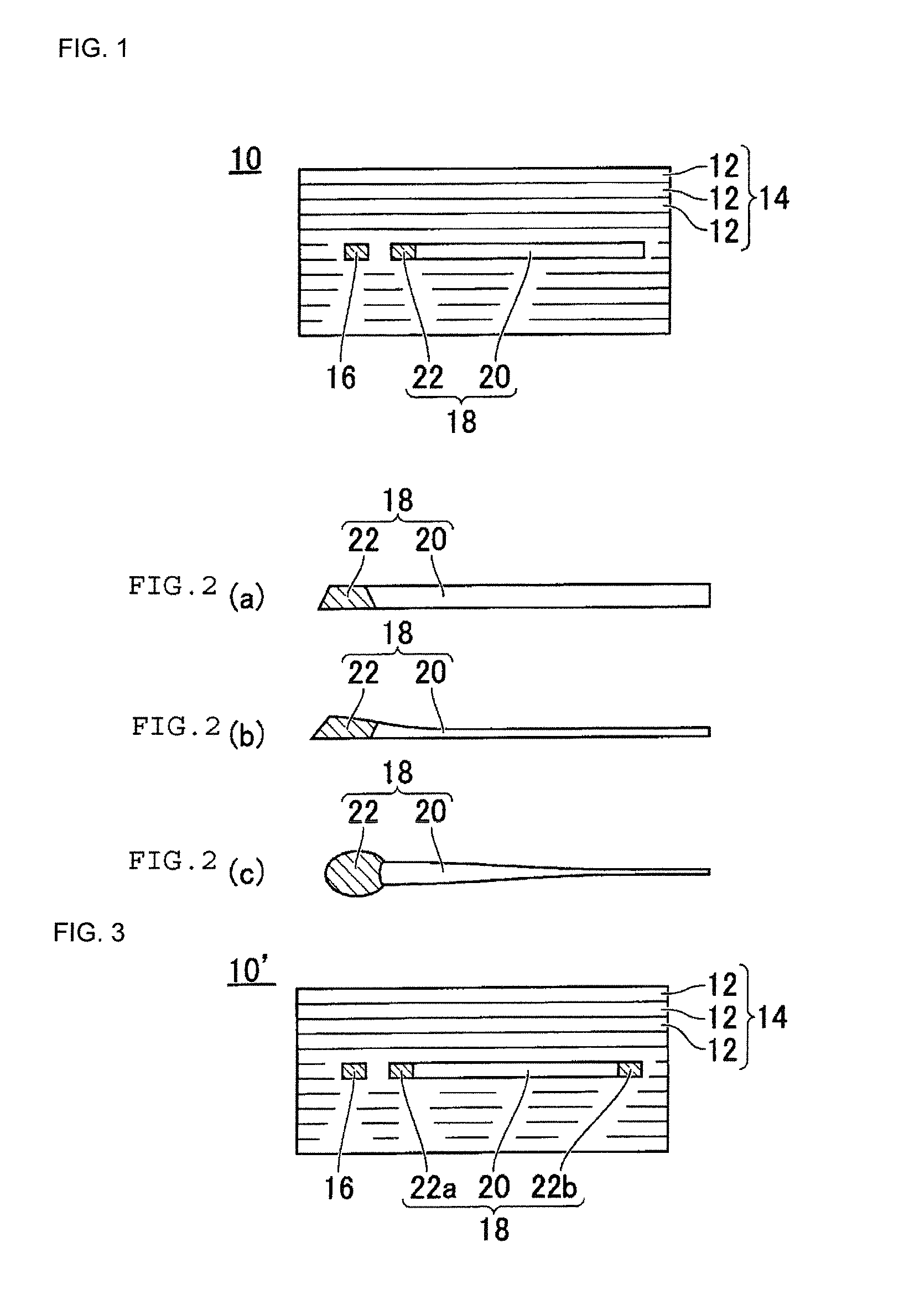

Electronic component and manufacturing method therefor

ActiveUS20150156868A1Small sizeExcellent characteristicsFixed capacitor electrodesFixed capacitor dielectricPlanar electrodeOptoelectronics

The electronic component of this invention includes a multilayer ceramic substrate 14 composed of a plurality of ceramic layers 12. A wiring electrode 16 and a planar electrode 18 are formed on a ceramic layer 12, which is an insulating layer. The planar electrode 18 is formed so as to be spaced apart from the wiring electrode 16 at the certain interval. An edge portion 22 is formed in a region of the planar electrode 18 adjacent to and spaced apart from the wiring electrode 16 at a certain interval. A central portion 20 is formed in a region of the planar electrode 18 other than the edge portion 22. At least the composition of the central portion 20 is different from the composition of the wiring electrode 16, and the composition of the edge portion 22 is the same as the composition of the wiring electrode 16.

Owner:MURATA MFG CO LTD

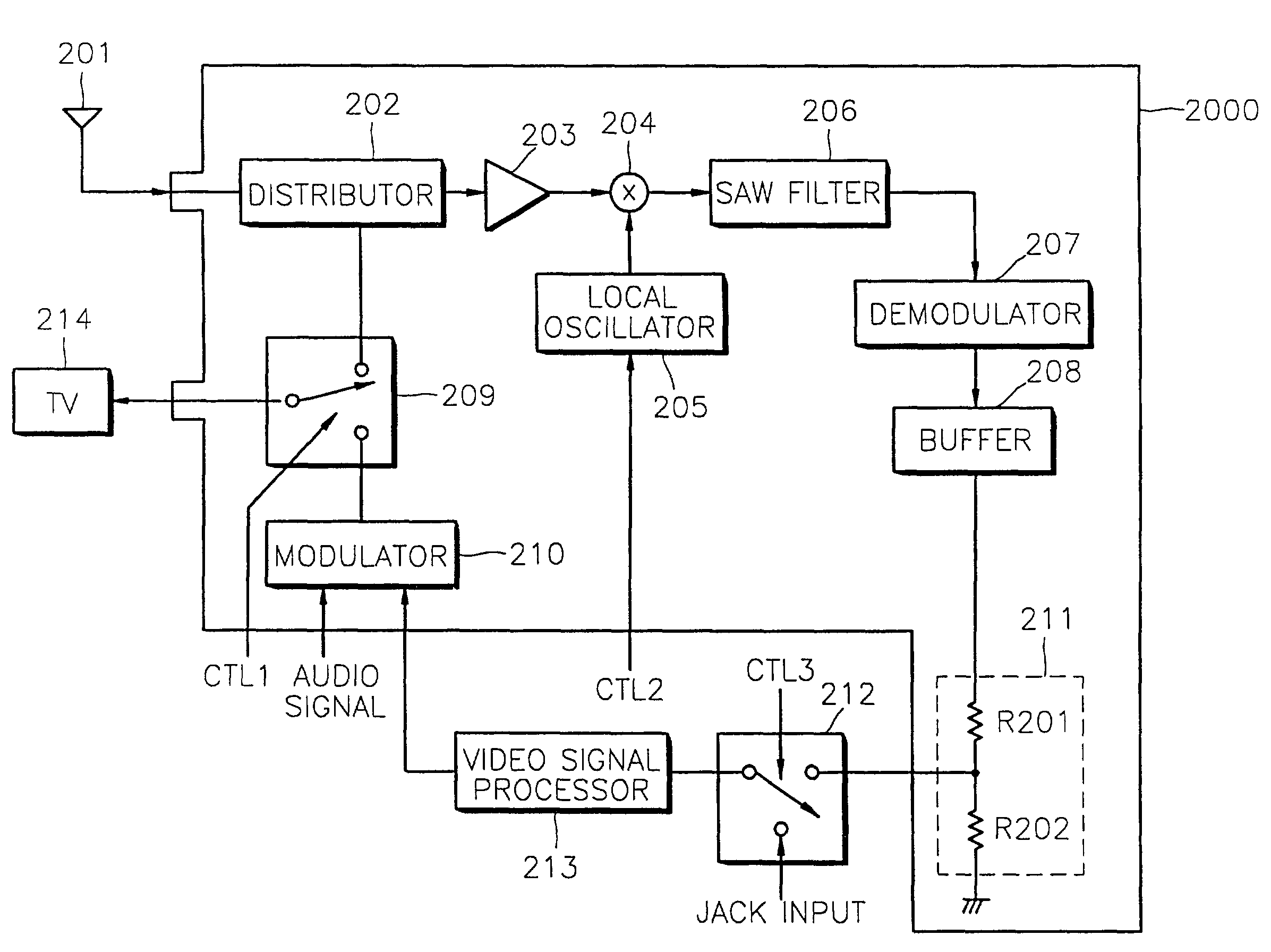

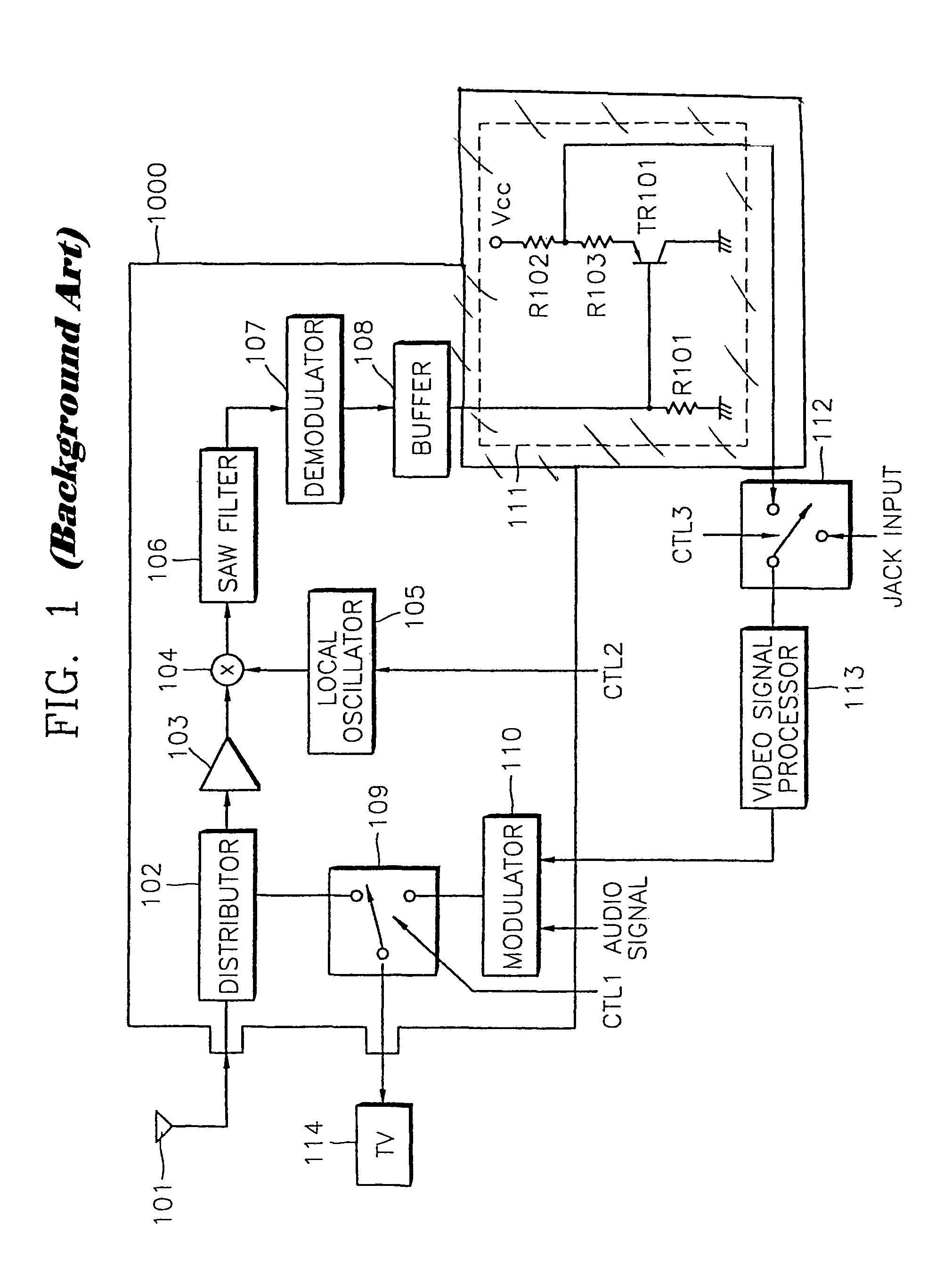

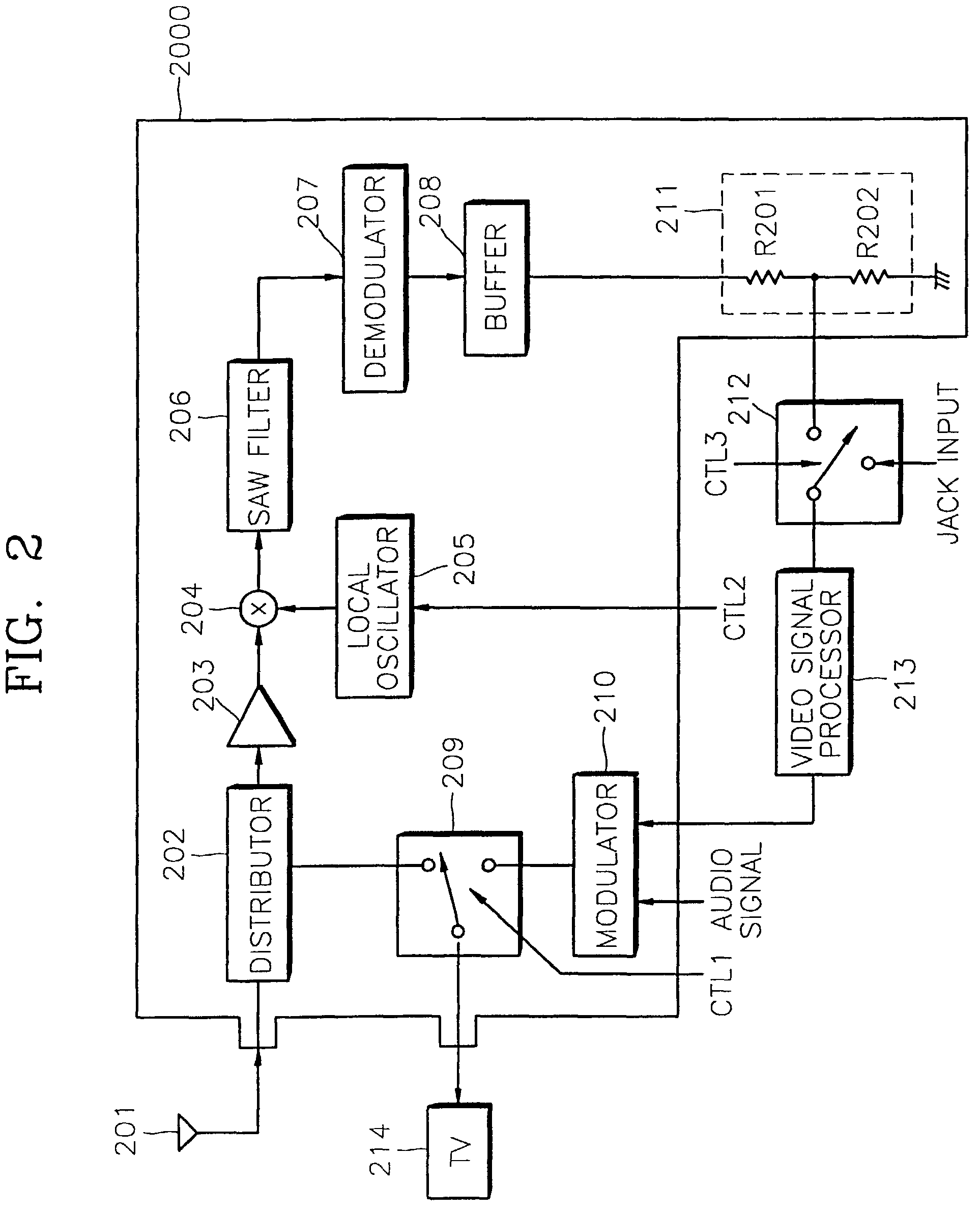

Tuner circuit

InactiveUS8520148B2Small currentHigh frequency characteristicTelevision system detailsColor signal processing circuitsData bufferIntegrated circuit

A tuner circuit and a method of designing a tuner circuit for removing a buffer circuit for video drive for increasing drive current capacitance added to an output terminal is provided, unlike a buffer for small-current drive installed in a tuner circuit. The method of designing a tuner circuit has a buffer installed in an integrated circuit (IC) of small-current drive in a video output terminal, and includes an RF converting portion, a tuning portion and a demodulation portion, in which a video output signal of the buffer in IC is input to an input circuit for processing a signal without an external buffer for drive, and the amount of attenuation of a signal at high frequency due to small drive current is measured to improve a frequency characteristic of a video signal in the tuner circuit in proportion to the amount of attenuation. Thus, an additional buffer for drive is not required, so that the number of devices is reduced, to thereby lower the material costs.

Owner:SAMSUNG ELECTRONICS CO LTD

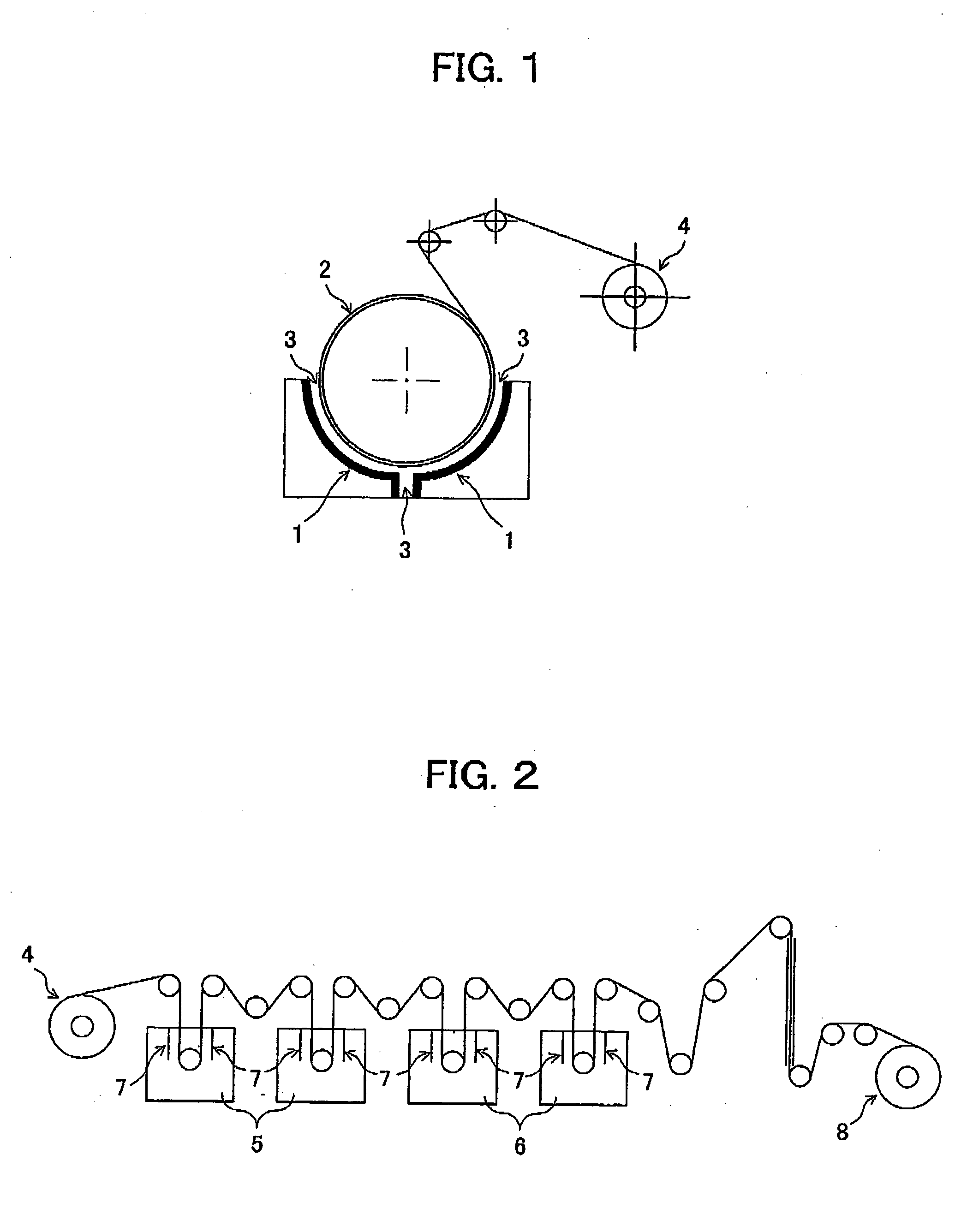

Wiring board and high frequency module using same

InactiveUS9431357B2High-frequency moduleHigh strengthPrinted circuit assemblingSemiconductor/solid-state device detailsResistPower strip

A high frequency module wiring board includes a wiring section for high frequency transmission, and a solder resist layer formed upon the wiring section. The solder resist layer covers the wiring section so as to have an opening section at a part of the wiring section in a region extending within a predetermined distance from an input / output terminal of a chip component.

Owner:PANASONIC CORP

Electronic component and manufacturing method therefor

ActiveUS9565757B2Small sizeExcellent characteristicsFixed capacitor electrodesFixed capacitor dielectricPlanar electrodeOptoelectronics

The electronic component of this invention includes a multilayer ceramic substrate 14 composed of a plurality of ceramic layers 12. A wiring electrode 16 and a planar electrode 18 are formed on a ceramic layer 12, which is an insulating layer. The planar electrode 18 is formed so as to be spaced apart from the wiring electrode 16 at the certain interval. An edge portion 22 is formed in a region of the planar electrode 18 adjacent to and spaced apart from the wiring electrode 16 at a certain interval. A central portion 20 is formed in a region of the planar electrode 18 other than the edge portion 22. At least the composition of the central portion 20 is different from the composition of the wiring electrode 16, and the composition of the edge portion 22 is the same as the composition of the wiring electrode 16.

Owner:MURATA MFG CO LTD

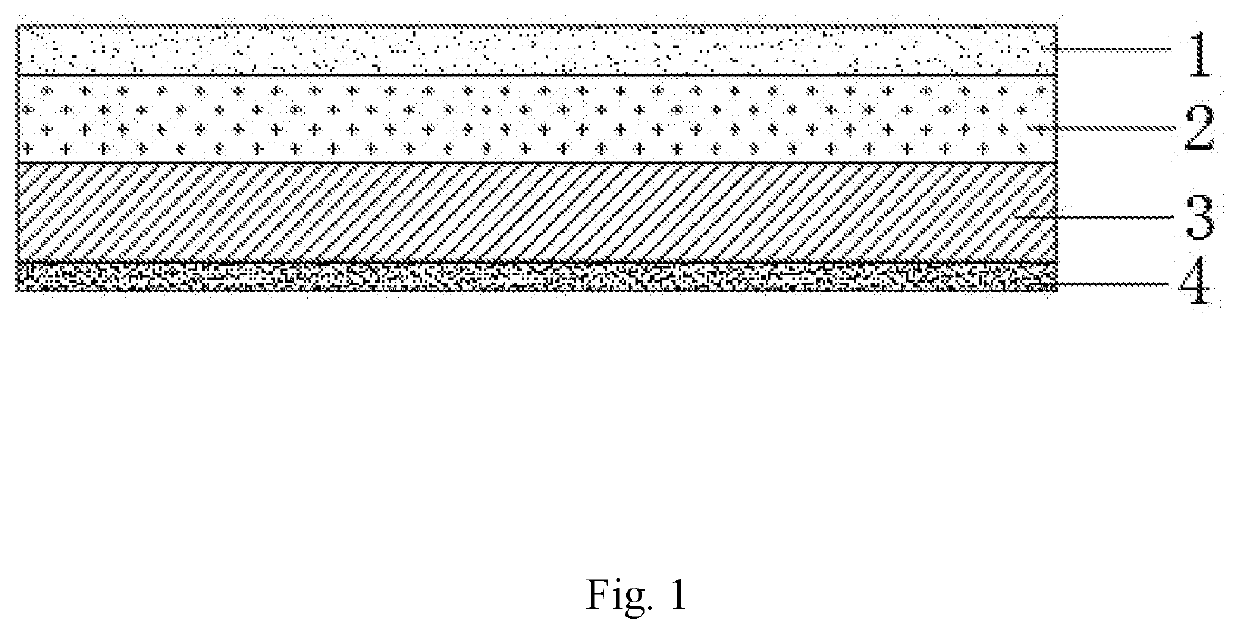

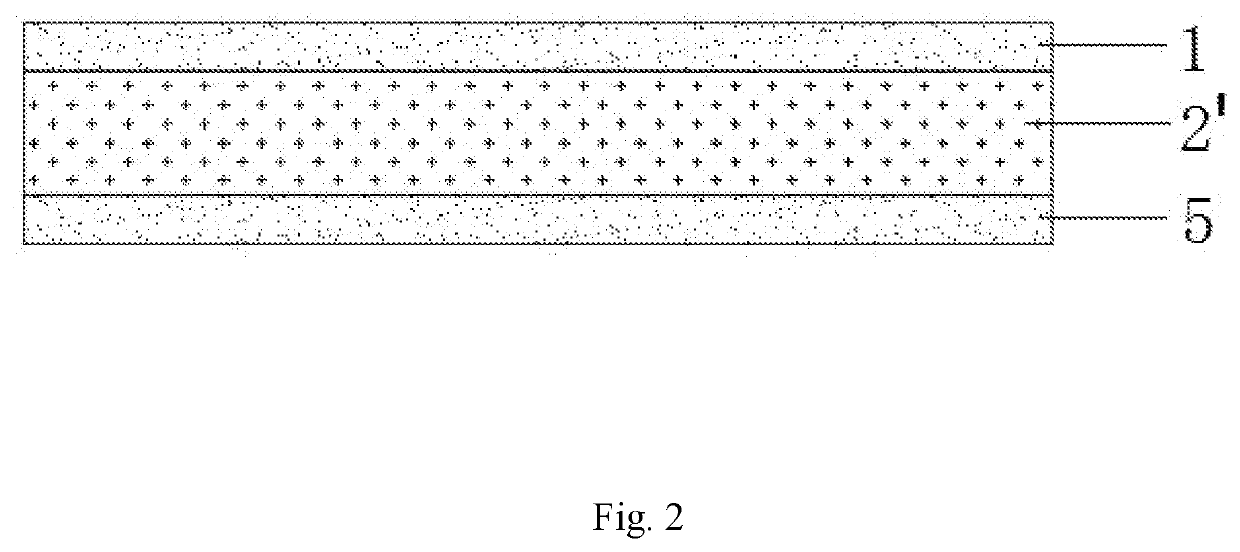

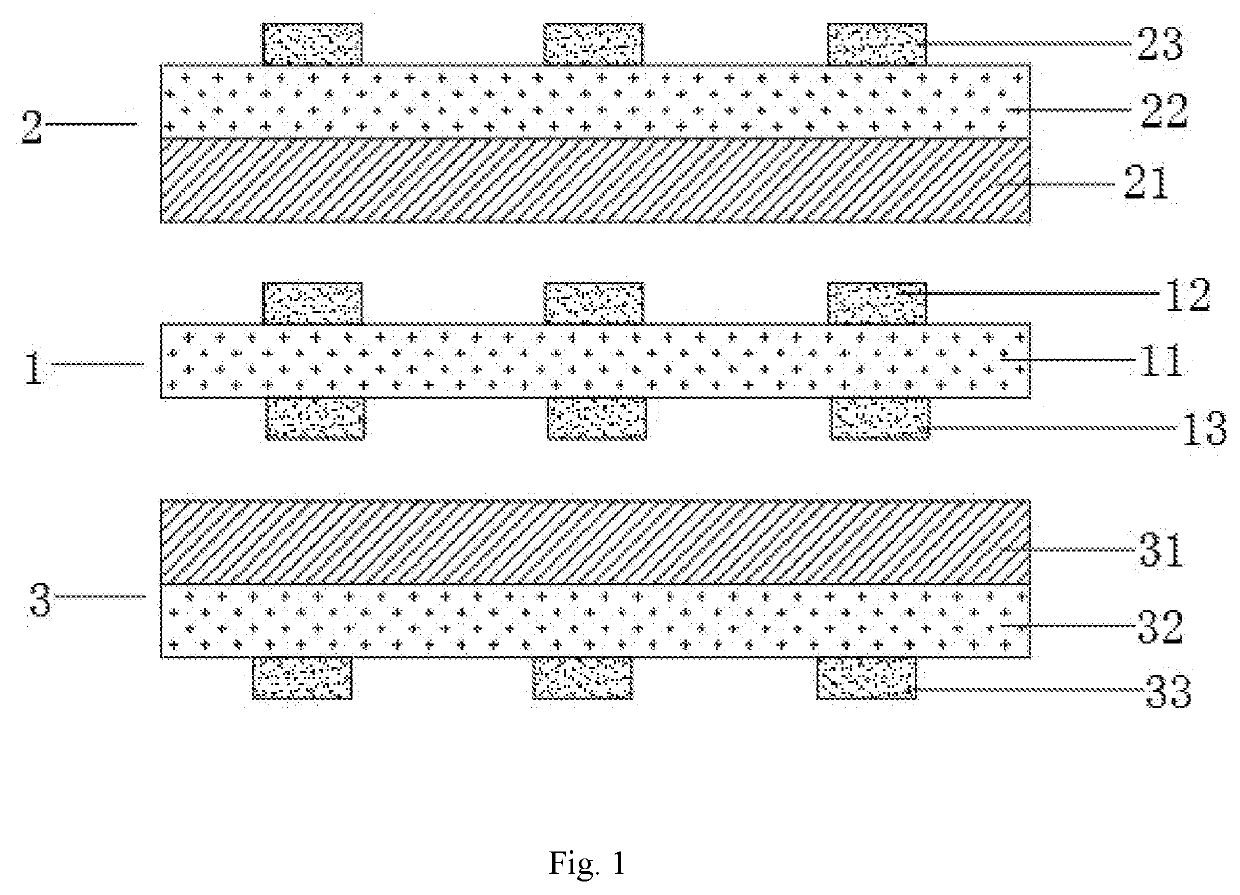

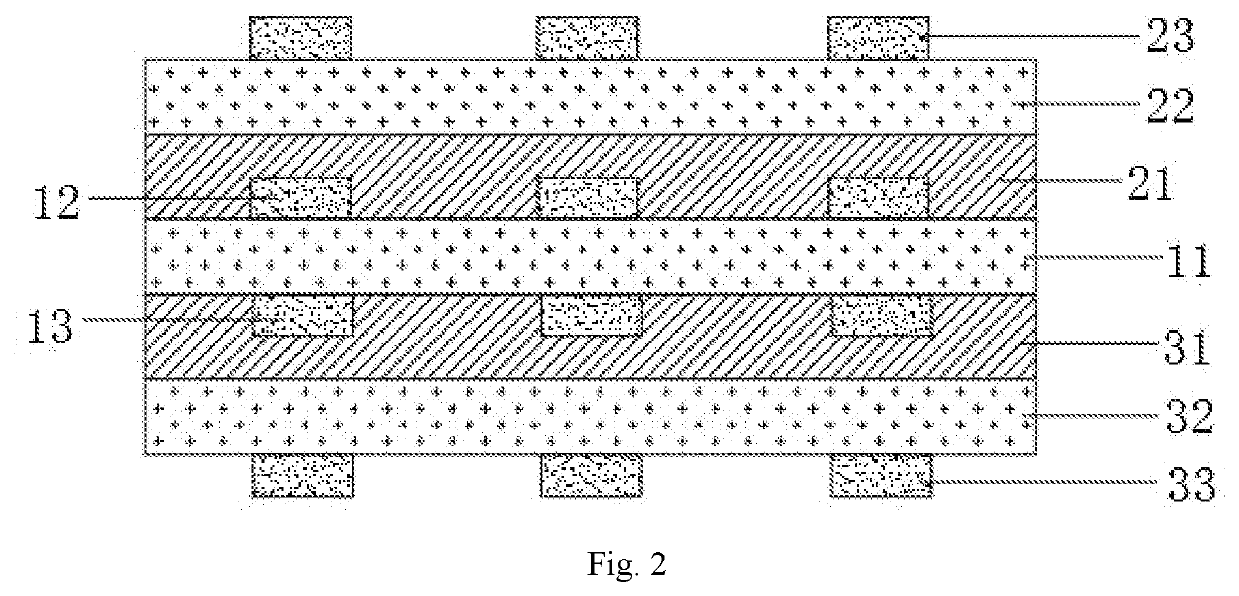

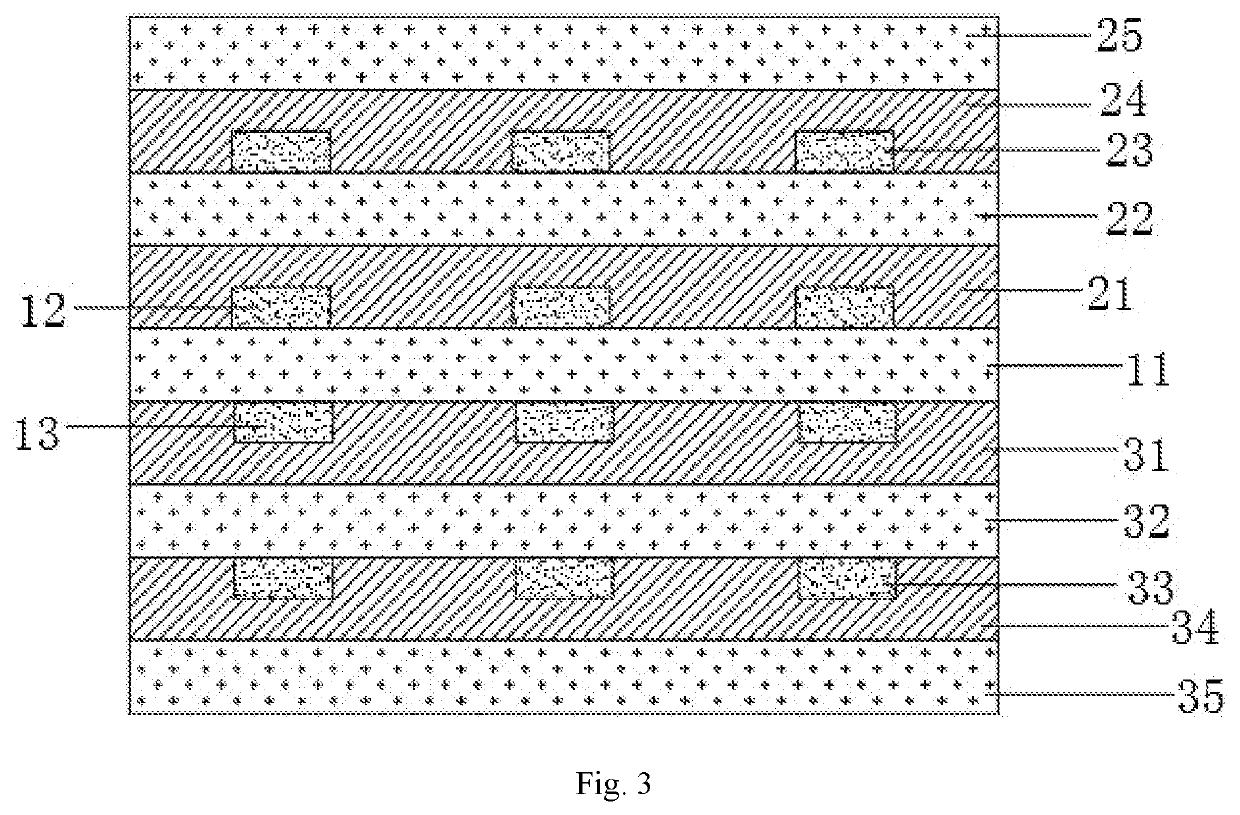

Method for preparing novel material layer structure of circuit board and article thereof

PendingUS20220272845A1Simple manufacturing processIncrease circuit speedLight absorption dielectricsDielectric materialsAdhesiveThin membrane

The present invention discloses a method for preparing a novel material layer structure of a circuit board, comprising the steps of: (1) combining a film with a copper layer to form an FCCL single-sided board; (2) applying a semi-cured functional material layer on a back side of the film of the FCCL single-sided board, wherein the semi-cured functional material layer is an MPI film, an LCP film, a TFP film, a PTFE film, a copper ion migration resistant film, an LDK high-frequency functional adhesive, a copper ion migration resistant adhesive, or a mixture of the LDK high-frequency functional adhesive and the copper ion migration resistant adhesive to form a novel material layer structure for a circuit board. An article prepared by performing the above methods is also disclosed. The prepared novel material layer structure of the circuit board has high-frequency characteristics and / or copper ion migration resistance, and can be used as an integral structure. In the circuit board manufacturing process, it can be manufactured as the circuit board manufacturing material to be different circuit board structures, which brings great convenience for subsequent circuit board manufacturing and simplifies the manufacturing process.

Owner:LI LONGKAI

Method for manufacturing multi-layer flexible circuit board and article thereof

PendingUS20220330437A1Manufacturing process is simplified and convenient to manufacturingEnsure safety and normal operation of circuitCross-talk/noise/interference reductionPrinted circuit aspectsFlexible circuitsHemt circuits

The present invention discloses a method for manufacturing a multi-layer flexible circuit board, comprising the steps of: (1) manufacturing a double-sided FPC flexible board; (2) manufacturing a novel material layer structure; (3) hot pressing at least one group of upeer novel material layer structures on the circuits on the upper and / or lower surfaces of the double-sided FPC flexible board; forming a protective layer on the circuits of an outermost novel material layer structure and / or on exposed circuits of the double-sided FPC flexible board so as to obtain a multi-layer flexible circuit board. The present invention also discloses a multi-layer flexible circuit board manufactured by performing the above-mentioned method. The manufacturing process of the present invention is simplified, convenient and efficient; the multi-layer flexible circuit board not only greatly simplifies the novel material layer structure and reduces the overall thickness, but also has the function of high-speed transmission of high-frequency signals, especially suitable for new 5G technology products. It can protect and resist the migration of copper ions when it is energized between circuits so as to ensure the safety and normal operation of circuits.

Owner:LI LONGKAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com