Highly-smooth polyethylene film and manufacturing method thereof

A polyethylene film, polyethylene technology, applied in chemical instruments and methods, flexible coverings, packaging, etc., can solve the problems of large differences in friction coefficient, affecting packaging production, uneven precipitation, etc., to achieve uniform distribution and Effect of stable, high slip friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

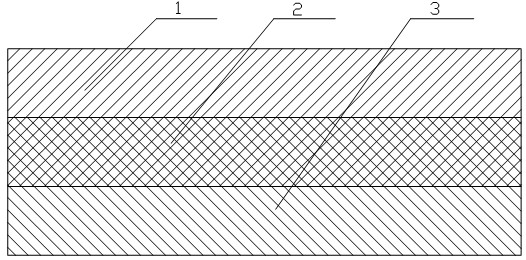

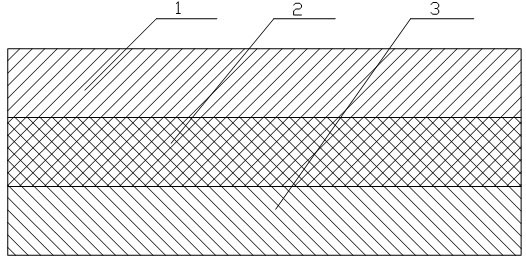

[0012] The preparation method of the high-slip polyethylene film is as follows: low-density polyethylene and linear low-density polyethylene with a mass ratio of 10:90 to 90:10 are used as the outer layer, and low-density polyethylene with a mass ratio of 10:90 to 90:10 is used as the outer layer. Density polyethylene and linear low-density polyethylene are used as the middle layer, and low-density polyethylene, linear low-density polyethylene and silicone slippery anti-sticking agent are used as the inner layer with a weight ratio of 50:50:0.5 to 50:50:10. They are respectively mixed by a quantitative batching device, put into an extruder for plasticizing and extruding, extruded through a three-layer co-extruded die, and rolled up after inflation to obtain a high-smooth polyethylene film.

[0013] The present invention uses multi-layer co-extrusion blow molding equipment and process, including the following processes: material mixing process, feeding process, plasticizing extr...

Embodiment 1

[0015] Get low-density polyethylene and linear low-density polyethylene for outer layer, and the mass ratio is: 50%:50%;

[0016] Get the low-density polyethylene and linear low-density polyethylene used in the middle layer, and the mass ratio is: 50%:50%;

[0017] Get low-density polyethylene, linear low-density polyethylene and organosilicon slippery anti-sticking agent that inner layer is used, and weight ratio is: 50%:50%:4%;

[0018] The thickness ratio of the outer layer, the middle layer, and the inner layer is: 1:2:1; the thickness of the film is 70 microns.

[0019] The above proportioned materials are processed by multi-layer co-extrusion blow molding equipment and technology, including the following processes: mixing process, feeding process, plasticizing extrusion process, inflation traction process, air ring cooling process, herringbone splint process, Traction roller traction process, corona treatment process, film winding process.

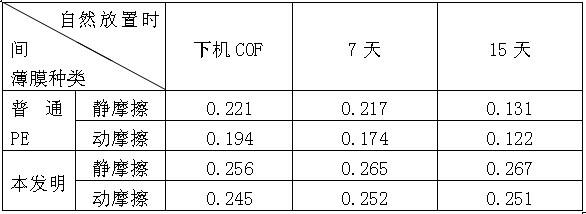

[0020] The friction coeffic...

Embodiment 2

[0023] Get low-density polyethylene and linear low-density polyethylene for outer layer, and the mass ratio is: 10%:90%;

[0024] Get the low-density polyethylene and linear low-density polyethylene used in the middle layer, and the mass ratio is: 90%:10%;

[0025] Get low-density polyethylene, linear low-density polyethylene, metallocene linear low-density polyethylene and organosilicon slippery anti-sticking agent for inner layer, and the weight ratio is: 50%:50%:2%;

[0026] The thickness ratio of the outer layer, middle layer and inner layer is 1:1:1; the film thickness is 20 microns.

[0027] The above proportioned materials are processed by multi-layer co-extrusion blow molding equipment and technology, including the following processes: mixing process, feeding process, plasticizing extrusion process, inflation traction process, air ring cooling process, herringbone splint process, Traction roller traction process, corona treatment process, film winding process.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com