Online monitoring device for aluminium cell cathode current

A cathode current and monitoring device technology, applied in the field of aluminum electrolytic cells, can solve the problems of incompatibility, lack of precision, complicated and unsafe measurement methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

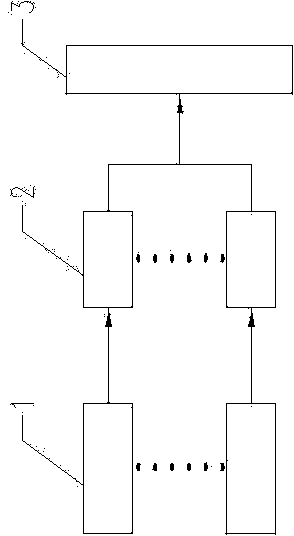

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0009] exist figure 1 Among them, one end of the DC current sensor 1 is connected to the signal converter 2 , and the other end of the signal converter 2 is connected to the liquid crystal display 3 .

[0010] The DC current sensor 1 detects the real current of the soft connection of the cathode of the aluminum electrolytic cell, and the signal converter 2 converts the signal into a digital signal and transmits it to the LCD 3 by RS485 communication. The LCD 3 displays the real-time current and current of each cathode guide rod. The current distribution working simulation state diagram of the whole electrolyzer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com