Rich-lean gas burner and mounting method thereof

A gas burner, rich and thin technology, applied in the combustion method, gas fuel burner, burner and other directions, can solve the problems of difficulty in adjusting the emission level, difficulty in uniform design, large mold development cost, etc., to avoid misfire and Combustion vibration, uniform and smooth distribution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

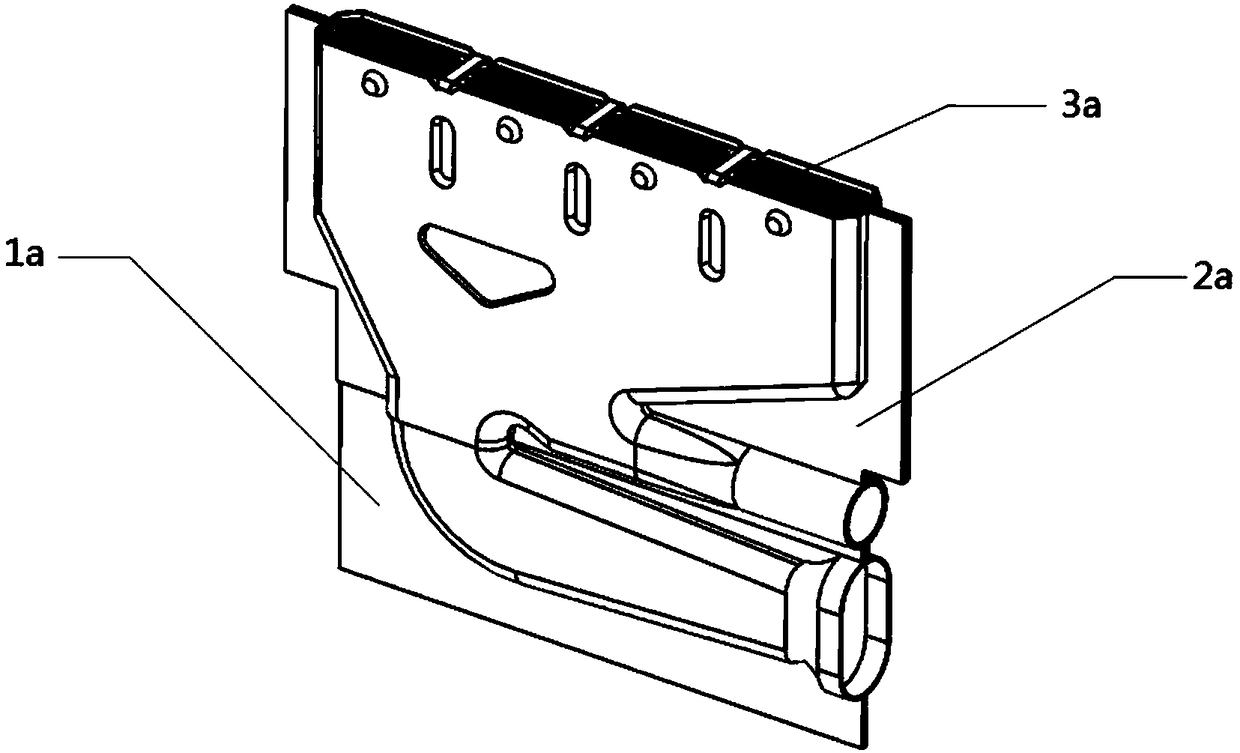

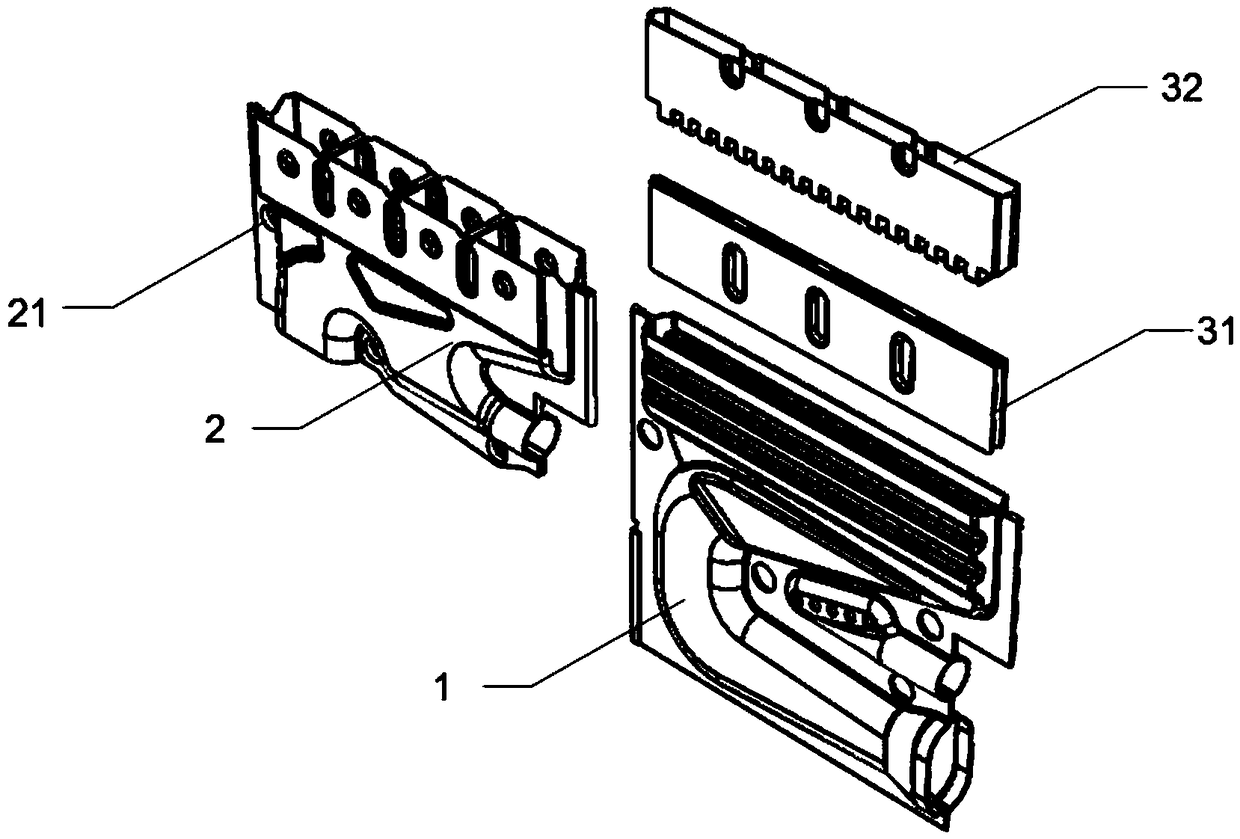

[0040] A rich-lean gas burner provided in this embodiment has a structure such as Figure 3-7 As shown, it includes an inner shell 1 and an outer shell 2. The top of the housing 2 is provided with a number of bridges 22 connecting the two side walls. The outer casing 2 and the inner casing 1 are respectively provided with a plurality of outer positioning holes 21 and inner positioning holes 12 at overlapping positions, and the inner positioning holes 12 are provided with flanges for riveting.

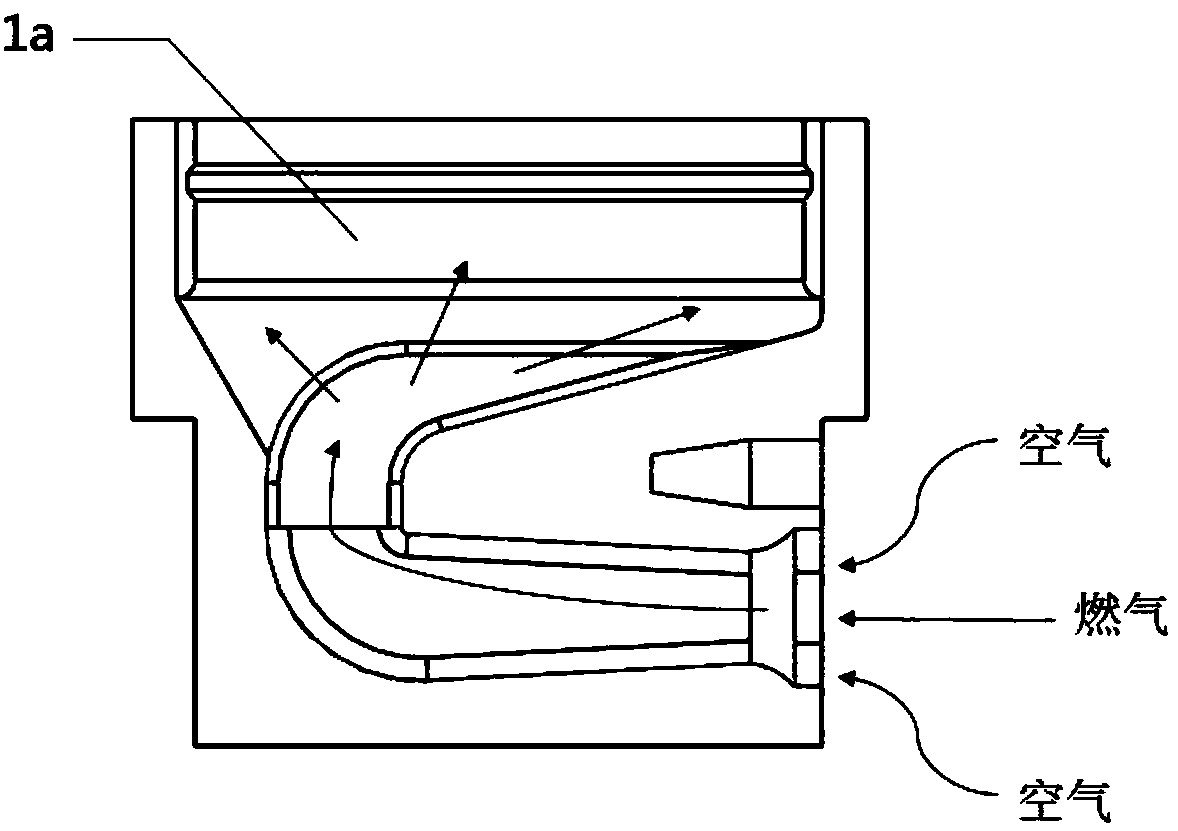

[0041] The inner shell 1 is provided with a light-side gas inlet 4 , a rich-side gas inlet 5 , a gas mixing channel 6 and a rich-side gas outlet 7 , and the light-side gas inlet 4 is located at the front end of the gas mixing channel 6 . The outer casing 2 is sheathed outside the inner casing 1 and forms a connected rich-side mixing space between the two. The rich-side gas inlet 5 and the rich-side gas outlet 7 communicate with the rich-side mixing space.

[0042]The upper part of the...

Embodiment 2

[0050] A method for installing a rich-lean gas burner applied in Embodiment 1, comprising the following steps:

[0051] Place the inner fire hole plate 31 inside the outer fire hole plate 32 to form a fire hole plate assembly;

[0052] Place the fire hole plate assembly in the fire hole plate installation section 11 of the inner shell 1;

[0053] Set the outer casing 2 outside the inner casing 1, align the outer positioning hole 21 with the inner positioning hole 12 and perform riveting to form a finished thick-thin gas burner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com