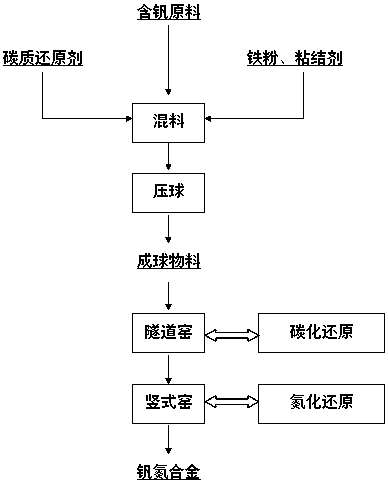

Method for continuously and efficiently producing vanadium-nitrogen alloy with high nitrogen content

A vanadium-nitrogen alloy and high nitrogen-containing technology is applied in the field of continuous and efficient production of high-nitrogen-content vanadium-nitrogen alloys, and can solve the problems of increasing the carbon content of vanadium-nitrogen alloys, limiting the unit output of a vertical kiln, affecting the appearance of finished products, and the like. Improve utilization efficiency, optimize dynamic environment, and improve the effect of unit output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The specific process of this method for continuously and efficiently producing vanadium-nitrogen alloys with high nitrogen content is as follows.

[0024] (1) Mixing pressure ball: vanadium-containing raw material: carbonaceous reducing agent = 4.6:1 (weight), the amount of binder added is 3% of the weight of carbonaceous reducing agent; the vanadium-containing raw material is vanadium pentoxide ; The density of the pelletized material is greater than 2500kg / m 3 .

[0025] (2) Carbonization reduction: The atmosphere in the kiln body of the tunnel kiln is blast furnace gas, and at a temperature of 1200 ° C, the retention time of the pelletized material is 8 hours.

[0026] (3) Nitriding reduction: keep N in the vertical kiln 2 Velocity 120m 3 / h, the retention time of carbonized material from entering the kiln to discharging is 14h;

[0027] Among them, the high-temperature section is kept at 1500 °C, and the high-temperature section is kept for 10 hour...

Embodiment 2

[0029] Embodiment 2: The specific process of the method for continuously and efficiently producing vanadium-nitrogen alloys with high nitrogen content is as follows.

[0030] (1) Mixing pressure ball: vanadium-containing raw material: carbonaceous reducing agent = 4:1 (weight), the amount of binder added is 2.2% of the weight of carbonaceous reducing agent; the vanadium-containing raw material is vanadium trioxide ; The density of the pelletized material is greater than 2500kg / m 3 .

[0031] (2) Carbonization reduction: The atmosphere in the tunnel kiln is blast furnace gas, the temperature is 1100°C, and the retention time of the pelletized material is 9 hours.

[0032] (3) Nitriding reduction: keep N in the vertical kiln 2 Velocity 150m 3 / h, the retention time of carbonized material from entering the kiln to discharging is 15h;

[0033] Among them, the high temperature section is kept at 1400 ° C, and the high temperature section is kept for 9 hours; the low temperature...

Embodiment 3

[0035] Embodiment 3: The specific process of the method for continuously and efficiently producing vanadium-nitrogen alloys with high nitrogen content is as follows.

[0036] (1) Mixing pressure ball: vanadium-containing raw material: carbonaceous reducing agent = 3.5:1 (weight), the amount of binder added is 1% of the weight of carbonaceous reducing agent; the vanadium-containing raw material is ammonium metavanadate ; The density of the pelletized material is greater than 2500kg / m 3 .

[0037] (2) Carbonization reduction: The atmosphere in the kiln body of the tunnel kiln is mixed gas, the temperature is 1000°C, and the retention time of the pelletized material is 7 hours.

[0038] (3) Nitriding reduction: NH is kept in the vertical kiln 3 Velocity 100m 3 / h, the retention time of carbonized material from entering the kiln to discharging is 10h;

[0039] Among them, the high temperature section is kept at 1600 ° C, and the high temperature section is kept for 8 hours; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com