Ultralow-viscosity pressure-sensitive adhesive and ultralow-viscosity protective film

A technology of pressure-sensitive adhesives and pressure-sensitive adhesive layers, applied in adhesives, adhesive types, ester copolymer adhesives, etc., can solve unsolved problems such as ultra-low adhesive peeling force, organic solvent environmental pollution, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

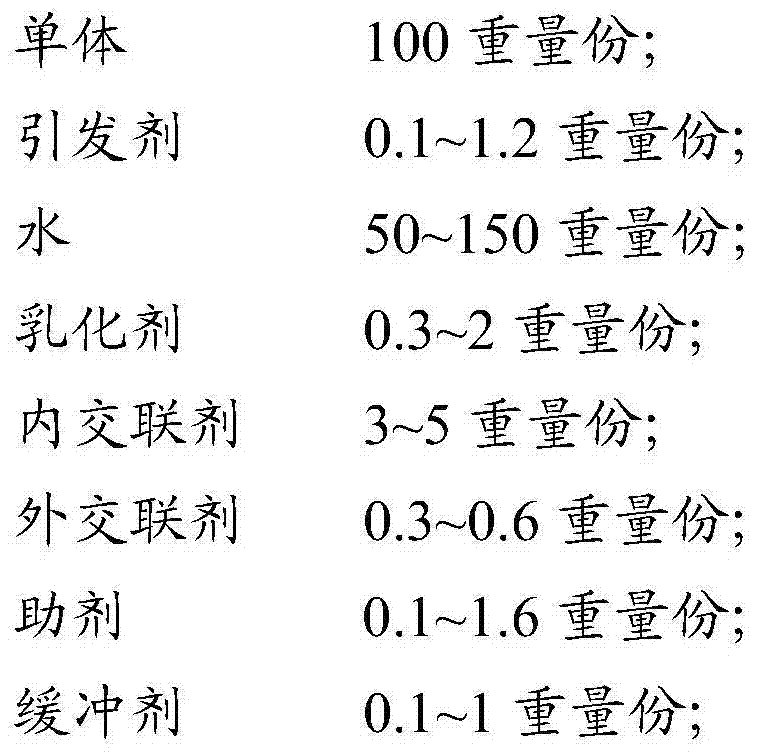

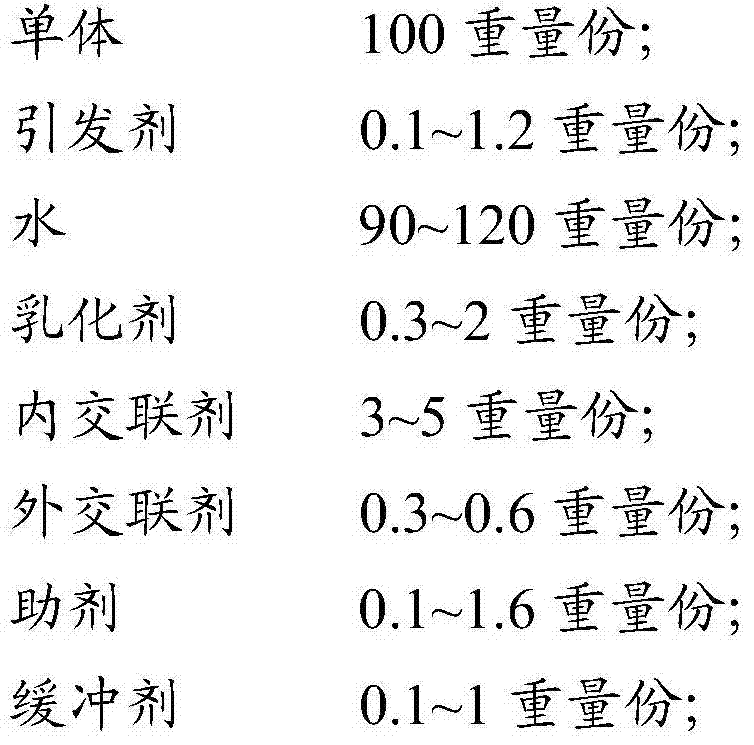

[0047] The present invention also provides a method for preparing the above-mentioned ultra-low viscosity pressure-sensitive adhesive, comprising:

[0048] Dividing 50-150 parts by weight of water into three parts, water I, water II and water III;

[0049] Divide 0.3-2 parts by weight of emulsifier into two parts, emulsifier I and emulsifier II;

[0050] Mix water 1, emulsifier 1, 100 parts by weight of monomers and 3 to 5 parts by weight of internal crosslinking agent, and stir to obtain a pre-emulsion;

[0051] mixing water II with 0.1 to 1.2 parts by weight of an initiator to obtain a dilute initiator solution;

[0052] Mix water III, emulsifier II, 0.1-1 parts by weight buffer with part of the pre-emulsion, heat, then add part of the dilute initiator solution, continue heating, and then add the remaining pre-emulsion and the remaining dilute initiator solution dropwise, Insulation reaction, finally cool down and add 0.1-1.6 parts by weight of additives, stir and filter t...

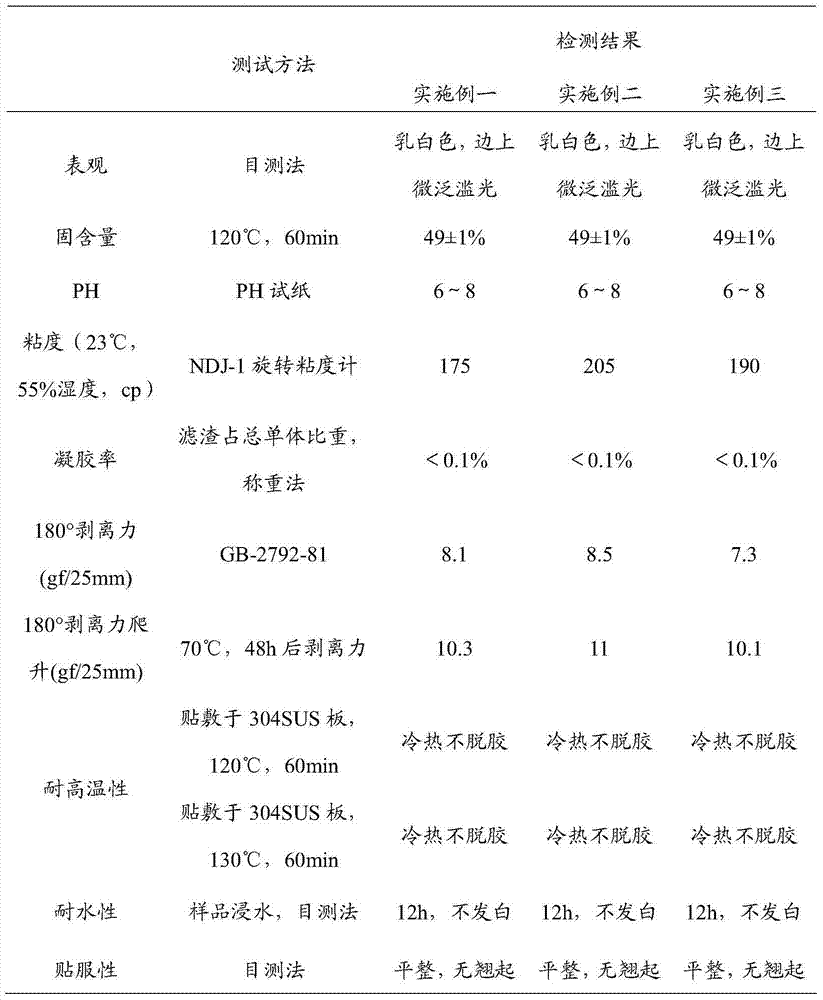

Embodiment 1

[0076] 1.1 Weigh 129g of deionized water, 3.2g of emulsifier (the specific composition is allyloxynonylphenol polyoxyethylene ether ammonium sulfate), 10g of acrylic acid, 180g of butyl acrylate, 96g of 2-ethylhexyl acrylate, 3.6 g of acetoacetoxyethyl methacrylate and 10 g of hydroxyethyl methacrylate were placed in a beaker, and stirred at high speed until the milky white emulsion was obtained, which was the pre-emulsion.

[0077] 1.2 Weigh 60g of deionized water and 1.2g of ammonium persulfate and mix evenly to obtain a dilute initiator solution.

[0078] 1.3 Add 141g of deionized water, 0.6g of emulsifier, 0.9g of sodium bicarbonate and 21.45g of 1.1 to a 1L four-necked bottle equipped with a nitrogen gas guide tube, a thermometer, a condenser tube, and a constant-pressure low-price funnel. Pre-emulsion, stir and heat up to 72°C, add 15g of the dilute initiator solution obtained in 1.2 to initiate the reaction, when the reaction temperature is stable at 80°C, start to drop...

Embodiment 2

[0082] 2.1 Weigh 129g deionized water, 3.2g emulsifier (the specific composition is allyloxynonylphenol polyoxyethylene ether ammonium sulfate), 7.5g acrylic acid, 190g butyl acrylate, 86g 2-ethylhexyl acrylate 1. Put 3.63g of acetoacetoxy ethyl methacrylate and 7.5g of hydroxyethyl methacrylate in a beaker, and stir at a high speed until the milky white emulsion is formed, which is the pre-emulsion.

[0083] 2.2 Weigh 60g of deionized water and 1.2g of ammonium persulfate and mix evenly to obtain a dilute initiator solution.

[0084] 2.3 Add 141g of deionized water, 0.6g of emulsifier, 0.9g of sodium bicarbonate and 21.3g of 2.1 to a 1L four-necked bottle equipped with a nitrogen gas guide tube, a thermometer, a condenser tube, and a constant-pressure low-price funnel. Pre-emulsion, stir and heat up to 72°C, add 15g of the dilute initiator solution obtained in 2.2 to initiate the reaction, when the reaction temperature is stable at 80°C, start to drop the remaining pre-emulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com