Photo-responsive UV pressure-sensitive adhesive and preparation method of same

A pressure-sensitive adhesive and light-responsive technology, applied in adhesives, film/sheet adhesives, non-polymer organic compound adhesives, etc., can solve the problem of low peel strength and achieve high peel strength and adhesive good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

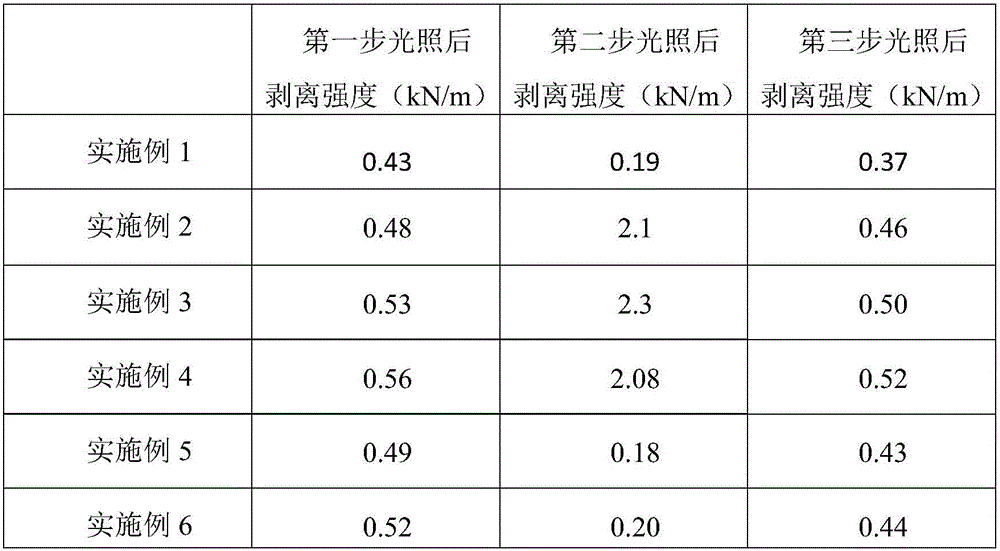

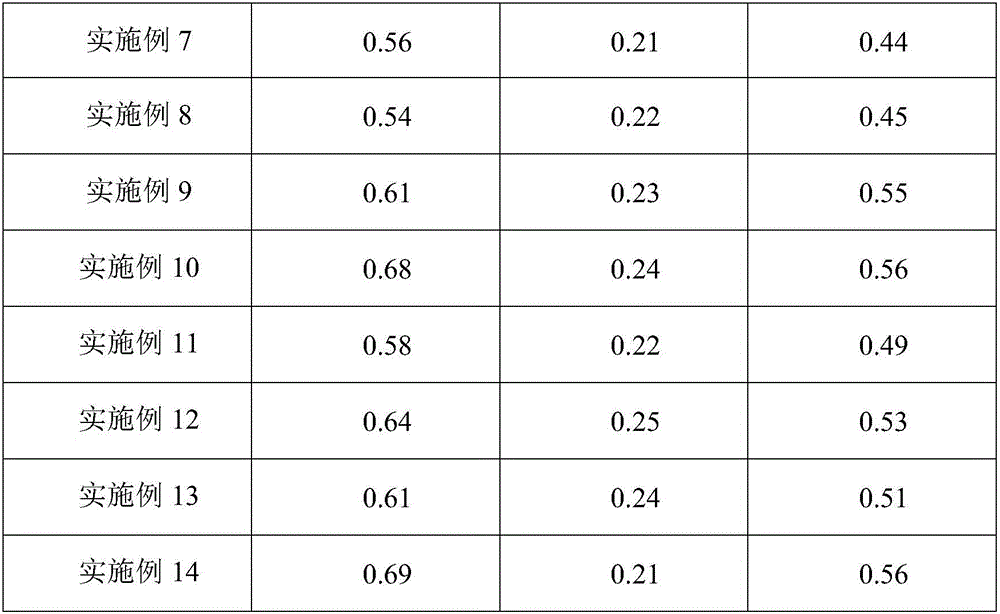

Examples

Embodiment 1

[0024] The composition of the glue includes an acrylic ester copolymer (the mass ratio of acrylic acid: octadecyl acrylate: butyl acrylate: isooctyl acrylate = 2:5:45:48 in the preparation method is 20 parts of the above four acrylic monomers added Add an initiator to 80 parts (parts by mass) of ethyl acetate solvent, the initiator is azobisisobutyronitrile, the amount of the initiator is 0.5‰ of the mass of the acrylate monomer, and the temperature is raised to 65°C for 2 hours. Raised to 75°C for 4 hours to complete the reaction of the double bond, and the solvent was removed by distillation); the photoresponsive monomer grafted the coumarin of the double bond of acrylic acid (the preparation method of the monomer was 0.05mol of 7-hydroxy -4-Methylumbelliferone and 0.05mol of ethylene carbonate were dissolved in 40ml of N,N-dimethylformamide, and 0.1mol of sodium carbonate was added, heated to 100°C and stirred for 10 hours, and the monomer was precipitated in water Afterwar...

Embodiment 2

[0026]The composition of glue comprises acrylate copolymer (preparation method is the same as embodiment 1, wherein the mass ratio of acrylate is propylene hydroxyethyl ester: dodecyl acrylate: butyl acrylate: isooctyl acrylate=2:5:45:48 , the amount of initiator acrylic acid is 0.8‰ of the ester monomer, the temperature rises to 70 ° C for 2 hours, and then the temperature rises to 90 ° C for 4 hours to completely react the double bond. The molecular weight is 300,000); Coumarin (preparation method is the same as in Example 1) according to the photoresponsive monomer in the mixture accounts for 8.4%, tetrahydrofuryl acrylate accounts for 21%, and photoinitiator 2,4,6-trimethylbenzoyl ethyl phosphate accounts for 0.6% %, and the rest is 70% of the acrylic copolymer prepared above. Mix the mixture evenly, disperse evenly and coat with a thickness of 60μm, irradiate with ultraviolet light of 390nm2 . In the second step, the light intensity of 300nm2 , light time 20min. The thi...

Embodiment 3

[0028] The composition of glue comprises acrylate copolymer (preparation method is the same as embodiment 1, wherein the mass ratio of acrylate is propylene hydroxyethyl ester: dodecyl acrylate: butyl acrylate: isooctyl acrylate=2:5:40:53 , the amount of initiator acrylic acid is ester monomer amount 1‰, molecular weight 200,000), the cinnamate of photoresponsive monomer grafting acrylic acid double bond (the hydroxyethyl acrylate of 0.02mol is dissolved in the ethyl acetate of 20ml Add 0.04 mol of triethylamine as an acid-binding agent, control the temperature at 0-5°C, add 0.04 mol of cinnamoyl chloride dropwise for 0.5 hours, then raise the temperature to room temperature and react for 7 hours, wash with water until neutral, and remove by rotary evaporation Solvent, can get photoresponsive monomer.) According to photoresponsive monomer accounts for 21% in the mixture, 2-phenoxyethyl acrylate accounts for 27.6%, photoinitiator 2-isopropylthioxanthone accounted for 1.4%, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com