Method and device for breaking polysilicon

一种多晶硅、水池的技术,应用在谷物处理等方向,能够解决影响多晶硅品质和企业的收益、不可避免大量的碎屑和微粉、降低多晶硅少子寿命等问题,达到避免金属污染问题、结构简单、易于操作的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

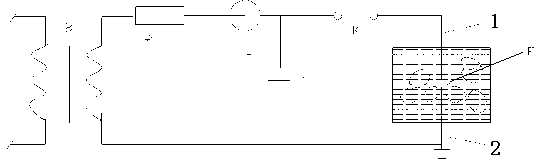

[0038] Such as figure 1 As shown, a device for crushing polysilicon, the device includes a high-voltage transformer B, a charging group R, a high-voltage rectifier G, a charging capacitor C, an isolation interval switch K, a pool F, and a first electrode 1 immersed in the pool F and the second electrode 2, wherein:

[0039] The primary winding of the high-voltage transformer B is connected to the mains, the first connection end of the secondary winding is connected to the charging group R, the high-voltage rectifier G, the isolation interval switch K and the first electrode 1 in sequence, and the second connection of the secondary winding is connected to terminal is grounded and connected to the second electrode 2, and the charging capacitor C is connected between the common end of the high-voltage rectifier G and the isolation interval switch K and the common end of the second winding and the second electrode 2.

[0040] The resistivity of the water in pool F ≥ 18.2 MΩ.cm, S...

Embodiment 2

[0042] A method for crushing polysilicon, adopting the device of embodiment 1, the method steps are as follows:

[0043] Step 1. First inject 1 / 2-3 / 4 volume of water into the pool, then put polysilicon into the water, and the water will submerge all the polysilicon;

[0044] Step 2, apply instantaneous high voltage to the pool, the electric field intensity generated by the high voltage is greater than or equal to the critical electric field intensity of the pool, the specific operations are as follows:

[0045] a. Use commercial power to charge the charging capacitor through a high-voltage transformer;

[0046] b. When the voltage of the charging capacitor reaches the breakdown voltage of the isolation interval switch, the isolation interval switch is broken down, and at this time, all the energy stored in the charging capacitor is added to the pool;

[0047] c. Repeat the above steps until all the polysilicon is crushed and stop.

[0048] Among them, the breakdown voltage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com