Nano ceramic metal composite powder for 3D printing and application

A 3D printing and metal composite technology, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve the problems of easy agglomeration of nano-ceramic particles, poor matrix interface bonding, poor wettability, etc., and achieve nano-ceramic phase distribution. The effect of uniformity, solving agglomeration and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A nano-ceramic-metal composite powder for 3D printing and its application, with René 104 nickel-based superalloy as the matrix, TiC ceramic particles with an average particle size of 2.5 μm as the reinforcing phase, and the added mass percentage is 2.0%.

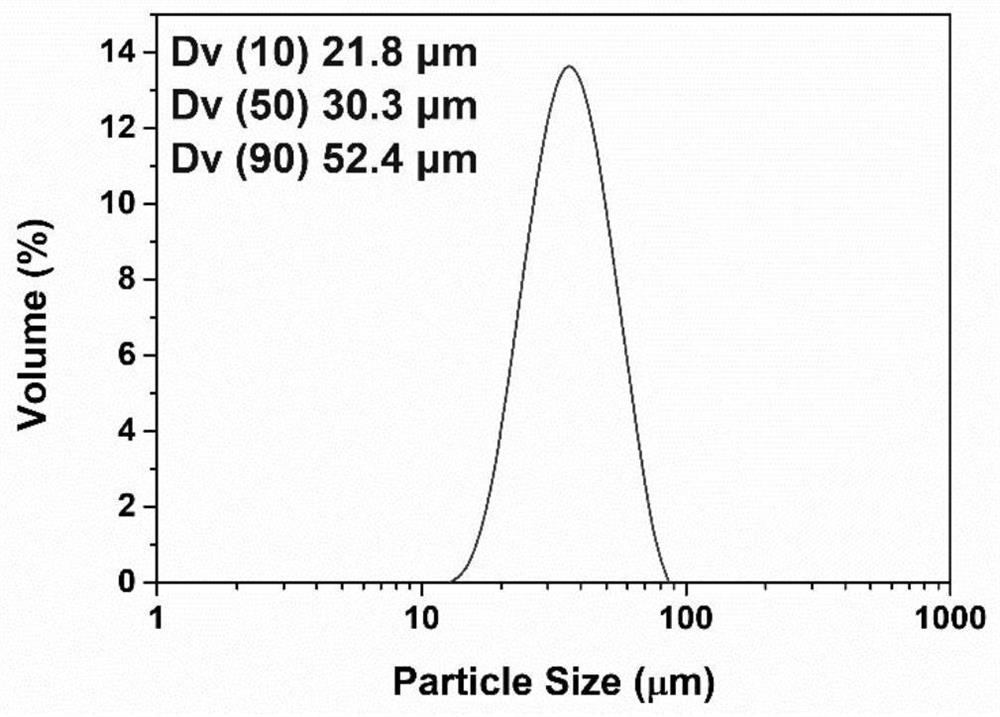

[0044] The matrix material is René104 nickel-based superalloy spherical powder with a particle size of 15-53 μm. The composition of René104 nickel-based superalloy is: 20.6Co~13Cr~3.4Al~3.9Ti~3.8Mo~2.1W~2.4Ta~0.9Nb ~0.05Zr~0.03B~0.04C~the balance is Ni.

[0045] Described a kind of nano ceramic metal composite powder and application for 3D printing, the steps are as follows:

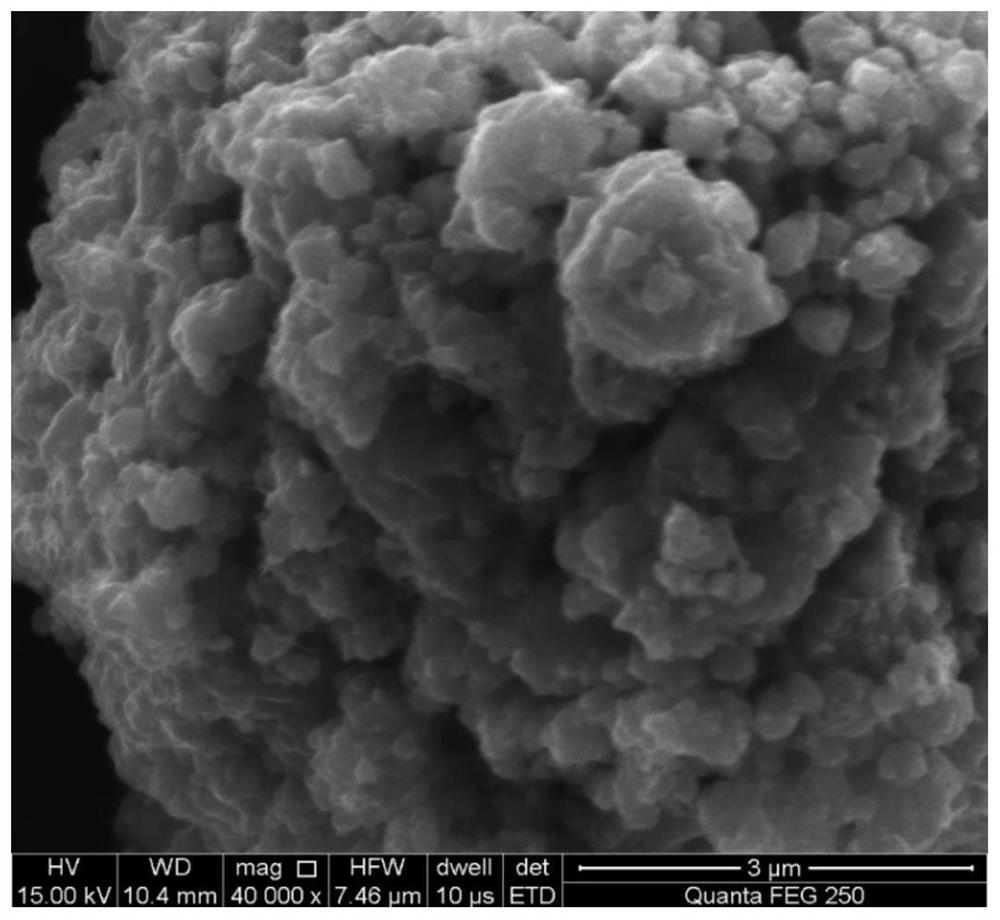

[0046] (1) First mix TiC ceramic particles with an average particle size of 2.5 μm and part of the René104 nickel-based superalloy powder (ratio: 2:3), and then use a high-energy ball mill to perform wet grinding and dry grinding to obtain nano-ceramic Composite powder with evenly distributed particles;

[0047] (2) In an inert gas atmosphere,...

Embodiment 2

[0061]According to the present invention, a nano-ceramic-metal composite powder for 3D printing uses the raw materials in the forming method of silicon carbide particle-reinforced aluminum-based composite materials based on the selective laser melting technology described in the Chinese patent (CN108480625A) to prepare spherical composite powders. powder, and adopt the SLM process parameters of the Chinese patent (CN108480625A) embodiment to prepare SiC / AlSi10Mg composite material. include:

[0062] Spherical AlSi10Mg powder with an average particle size of 30 μm is used as the matrix, and SiC powder with an average particle size of 10 μm is used as the reinforcing particle, wherein the mass fraction of SiC powder is 10%, and the purity of both is above 99.9%. The specific preparation steps are as follows:

[0063] (1) Firstly, mix the SiC ceramic particles with an average particle size of 10 μm and some AlSi10Mg powders (the ratio is 1:2), and then use a high-energy ball mill...

Embodiment 3

[0074] A nano-ceramic-metal composite powder for 3D printing and its application, with TC4 titanium alloy as the matrix and TiB with an average particle size of 5 μm 2 The ceramic particles are the reinforcing phase, and the added mass percentage is 2.0%. The base material is TC4 titanium alloy spherical powder with a particle size of 53-106 μm.

[0075] Described a kind of nano ceramic metal composite powder and application for 3D printing, the steps are as follows:

[0076] (1) First, the TiB of the said ratio 2 The ceramic particles are mixed with some TC4 alloy powders (the ratio is 2:3), and then the high-energy ball mill is used for wet grinding and dry grinding to obtain a composite powder with uniform distribution of nano-ceramic particles;

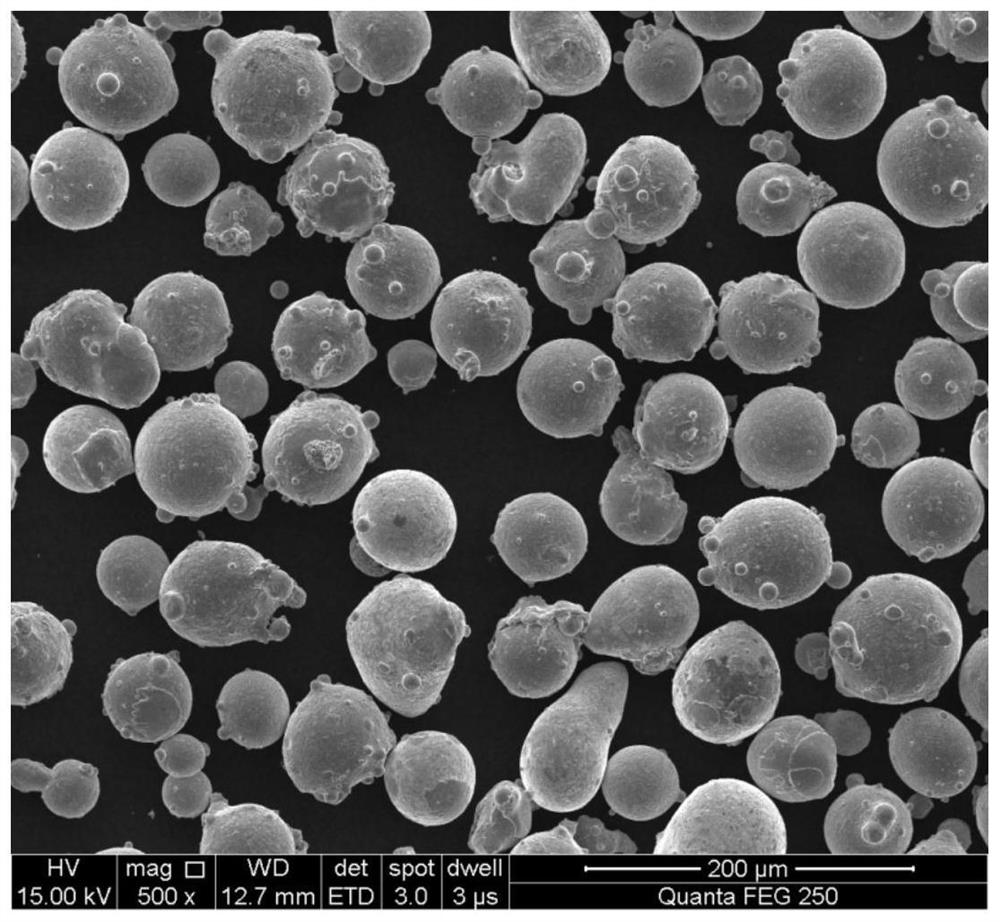

[0077] (2) In an inert gas atmosphere, place the composite powder obtained in step (1) in a plasma spheroidization device for spheroidization and cooling to obtain a spherical composite powder with uniform distribution of nano-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com