Hammer crusher for ceramic manufacturing

A hammer crusher, ceramic technology, applied in the direction of grain processing, etc., can solve the problems that the cover plate cannot be closed, the operation steps are increased, and the ceramic raw materials fall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

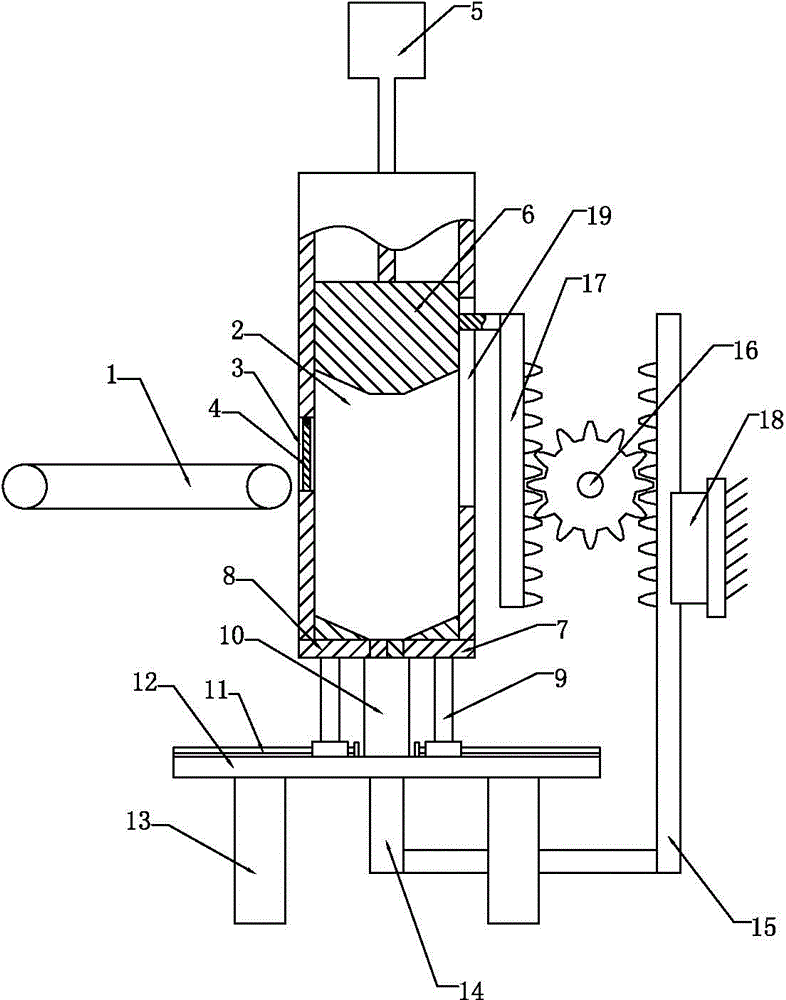

[0016] The reference signs in the drawings of the description include: conveyor belt 1, crushing cylinder 2, feed port 3, cover 4, hydraulic cylinder 5, crushing weight 6, second plate 7, first plate 8, support rod 9, support Barrel 10, slide rail 11, support plate 12, pole 13, rubber push rod 14, second rack 15, gear 16, first rack 17, chute 18, through groove 19.

[0017] The embodiment is basically as attached figure 1 Shown: a hammer crusher for making ceramics, including a crushing cylinder 2, a crushing weight 6 is slidingly connected to the upper part of the crushing cylinder 2, and the crushing weight 6 is driven by a hydraulic cylinder 5, and the wall of the crushing cylinder 2 below the crushing weight 6 is opened. There is a feed port 3, a conveyor belt 1 is provided on the left side of the feed port 3, a discharge port is opened at the bottom of the crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com