Nanometer grade tetragonal-phase barium titanate powder and its prepn.

A phase barium titanate, nano-scale technology, applied in the field of nano-ceramics, can solve the problems of not effectively improving the electrical properties of MLCc, poor electrical properties of cubic phase barium titanate, reducing the volume of MLCc, etc. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

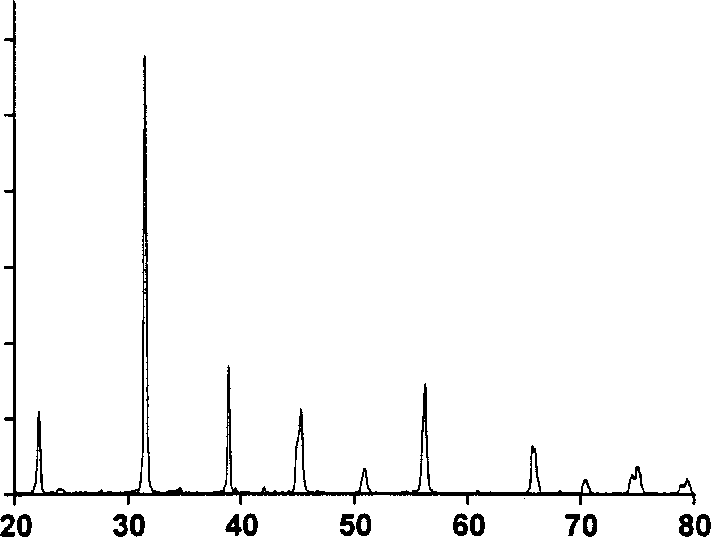

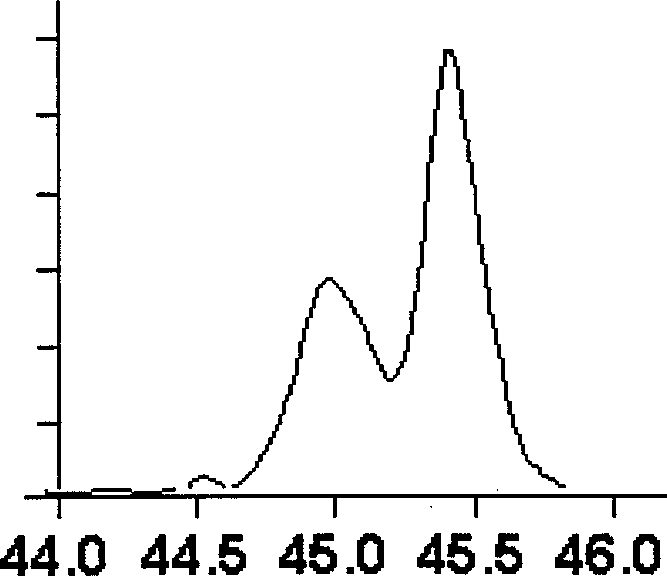

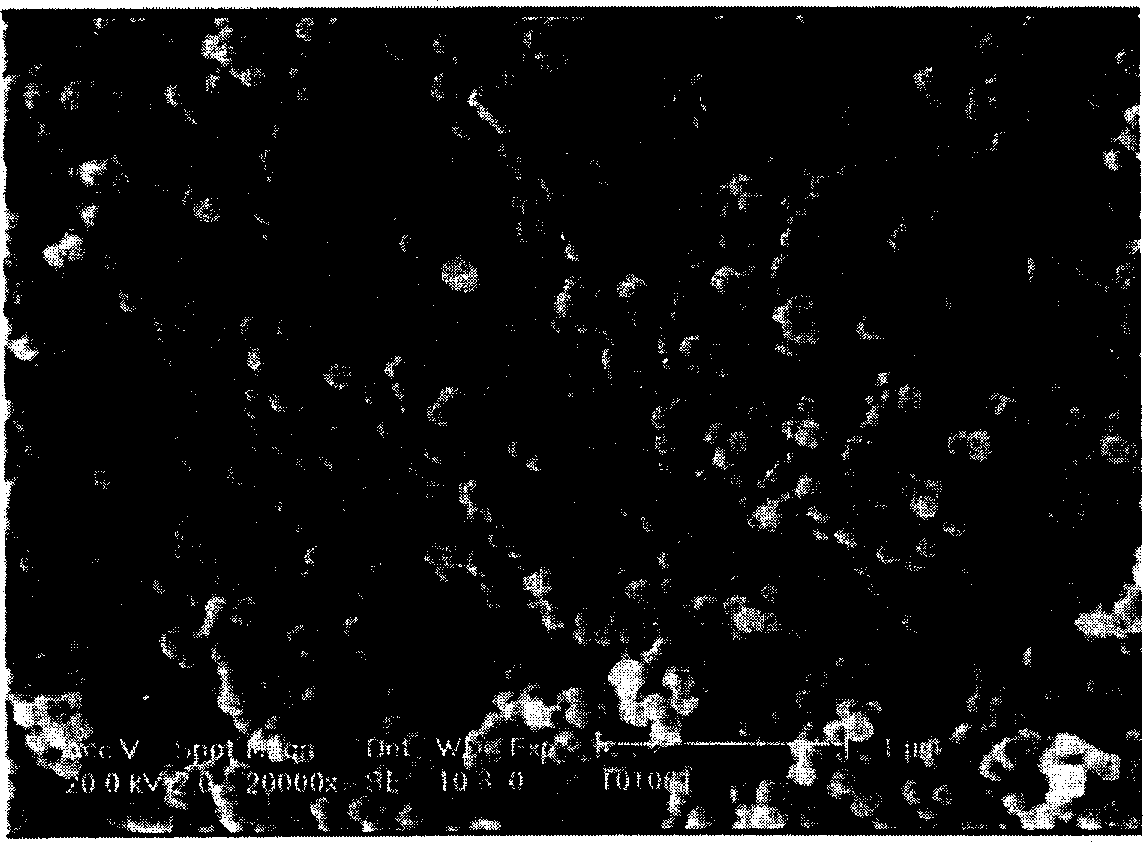

[0027] Prepare a high-concentration aqueous solution of barium chloride and titanium tetrachloride, then prepare 200 mL of a mixed solution of 0.625 M titanium tetrachloride and 1.0 M barium chloride, add 36 g of sodium hydroxide, stir well, and transfer to a container with a tetrafluoroethylene liner. In the autoclave, the temperature was raised at an average rate of 3°C / min to 240°C, and the hydrothermal reaction was carried out for 12 hours. After cooling to room temperature with the furnace, the autoclave was unloaded, and the reaction product was washed and repeated several times. After the solution was neutral, it was filtered and dried. The resulting reaction product was dried as a white powder. The crystal form of the sample was analyzed by a Rigaku powder diffractometer using CuKα radiation. The instrument model was Geigerflex D / Max 2200, and the analysis was carried out at 10-80°2θ. The particle size of the samples was measured using a SEM electron microscope. Such ...

Embodiment 2

[0029] Prepare a high-concentration aqueous solution of barium chloride and titanium tetrachloride, then prepare 200mL of a mixed solution of 0.625M titanium tetrachloride and 0.90M barium chloride, add 36g of sodium hydroxide, stir evenly, and transfer it to a tank with polytetrafluoroethylene In a lined autoclave, raise the temperature at an average rate of 3°C / min to 240°C, conduct a hydrothermal reaction for 18 hours, cool down to room temperature with the furnace, unload the autoclave, wash the reaction product and repeat it several times until the solution is neutral. The reaction product obtained by drying is a white powder. The crystal form of the sample was analyzed by a Rigaku powder diffractometer using CuKα radiation. The instrument model was Geigerflex D / Max 2200, and the analysis was carried out at 10-80°2θ. The particle size of the samples was measured using a SEM electron microscope. The sample has an average particle size of 75nm, a crystal phase of tetragona...

Embodiment 3

[0031] Prepare a high-concentration aqueous solution of barium chloride and titanium tetrachloride, then prepare 200mL of a mixed solution of 1.0M titanium tetrachloride and 1.2M barium chloride, add 56g of sodium hydroxide, stir evenly, and transfer to a container with a tetrafluoroethylene liner. In the autoclave, the temperature was raised at an average speed of 3°C / min to 230°C, and the hydrothermal reaction was carried out for 12 hours. After cooling to room temperature with the furnace, the autoclave was unloaded, and the reaction product was washed and repeated several times. After the solution was neutral, it was filtered and dried. The resulting reaction product was dried as a white powder. The crystal form of the sample was analyzed by a Rigaku powder diffractometer using CuKα radiation, the instrument model is Geigerflex D / Max2200, and the analysis was carried out at 10-80°2θ. The particle size of the samples was measured using a SEM electron microscope. The sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com