Method for evaluating relative compactness of quartz soil based on light dynamic penetration test index

A technology of relative compactness and dynamic penetration testing, which is applied in the direction of applying repetitive force/pulsation force to test material strength, strength characteristics, and measuring devices. Diameter and shape differences, etc., to achieve the effect of easy determination and reliability of parameters, easy operation, and reduced manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

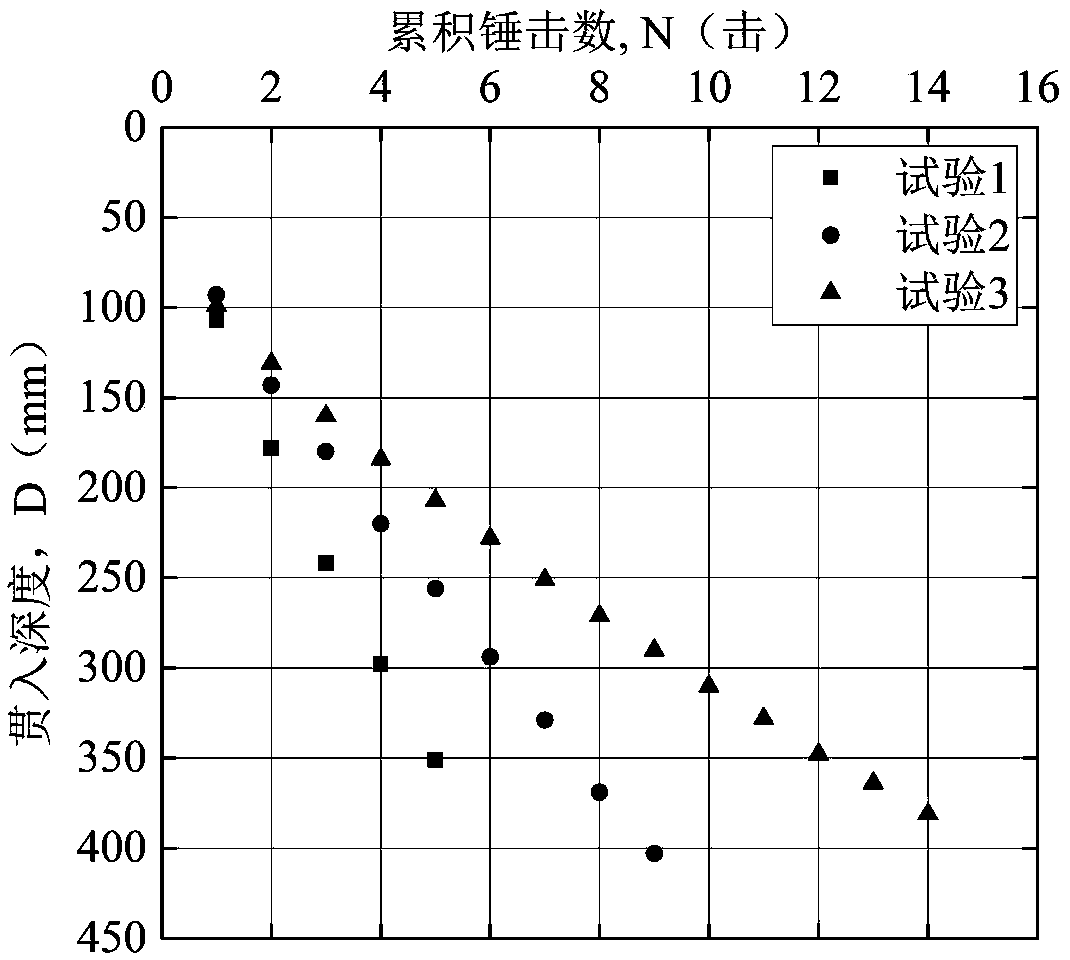

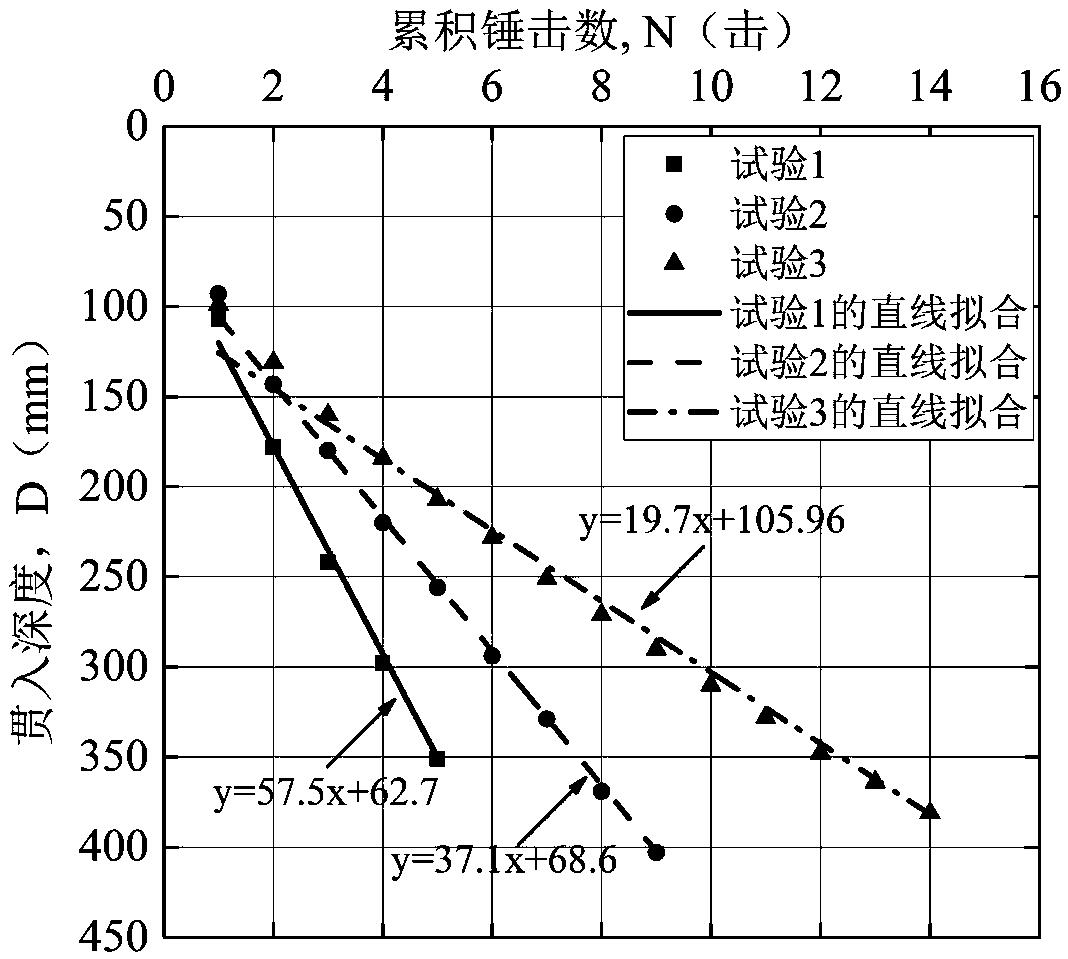

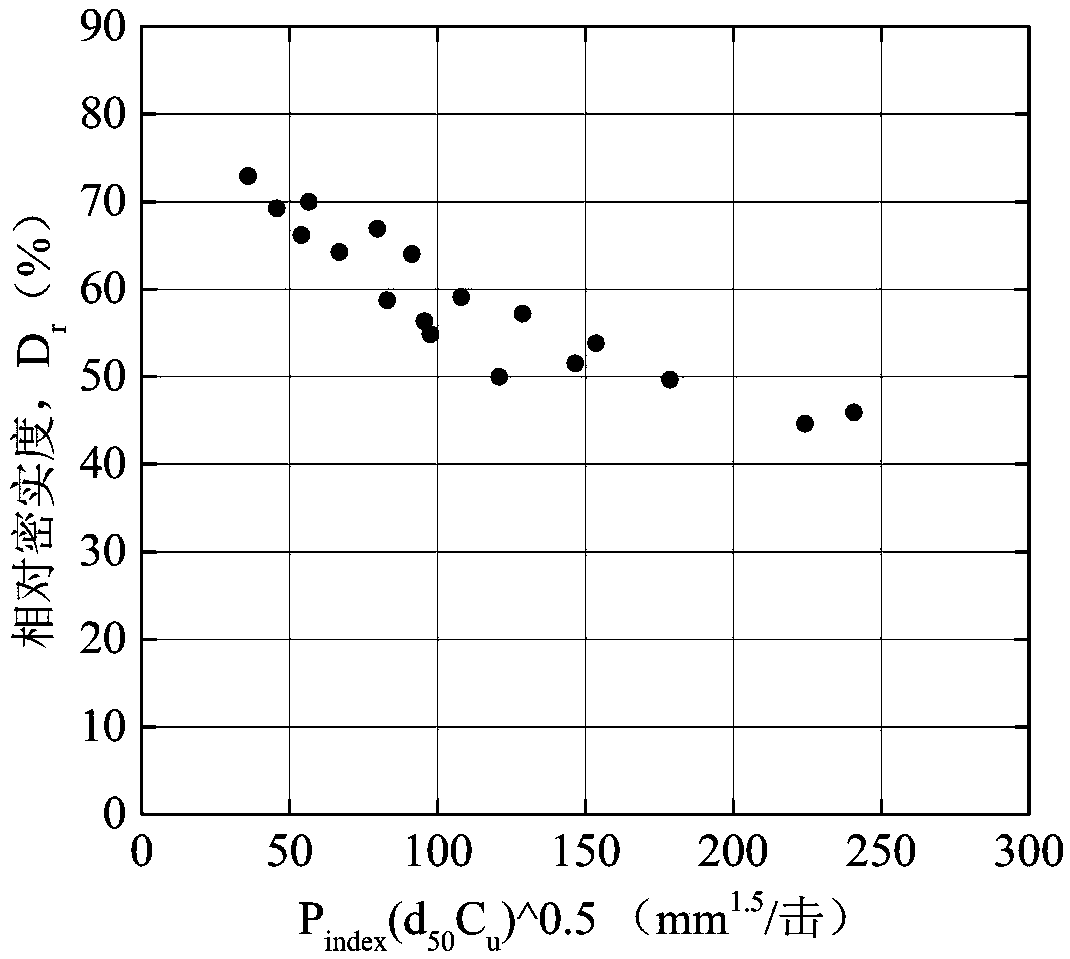

[0041] The method for evaluating the relative compactness of quartz soil based on light dynamic penetrating test index of the present invention comprises the following steps:

[0042] Step 1, drying the quartz soil sample retrieved from the site, the result obtained through the geotechnical test is: quartz gravel, its maximum dry density ρ d,max =1934kg / m 3 , the minimum dry density ρ d,min =1373kg / m 3 , average particle size d 50 =2.5mm, non-uniformity coefficient C u =6.90; quartz coarse sand, its maximum dry density ρ d,max =1764kg / m 3 , the minimum dry density ρ d,min =1373kg / m 3 , average particle size d 50 =1.5mm, non-uniformity coefficient C u =4.72.

[0043] Step 2, set nine relative compactness D for each type of calcareous soil sample ri , according to the maximum dry density ρ measured in step 1 d,max , minimum dry density ρ d,min , using the formula (1) to calculate various relative compactness D ri The dry density ρ of each type of quartz soil sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com