Method for preparing co-production sodium chloride of precipitated barium sulfate

A technology for precipitating barium sulfate and sodium chloride, which is applied in the direction of alkali metal chloride, calcium/strontium/barium sulfate, etc., can solve the problems of complex production equipment, large amount of material transportation, low production yield, etc., and achieve high profit , The method is simple and clear, and the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

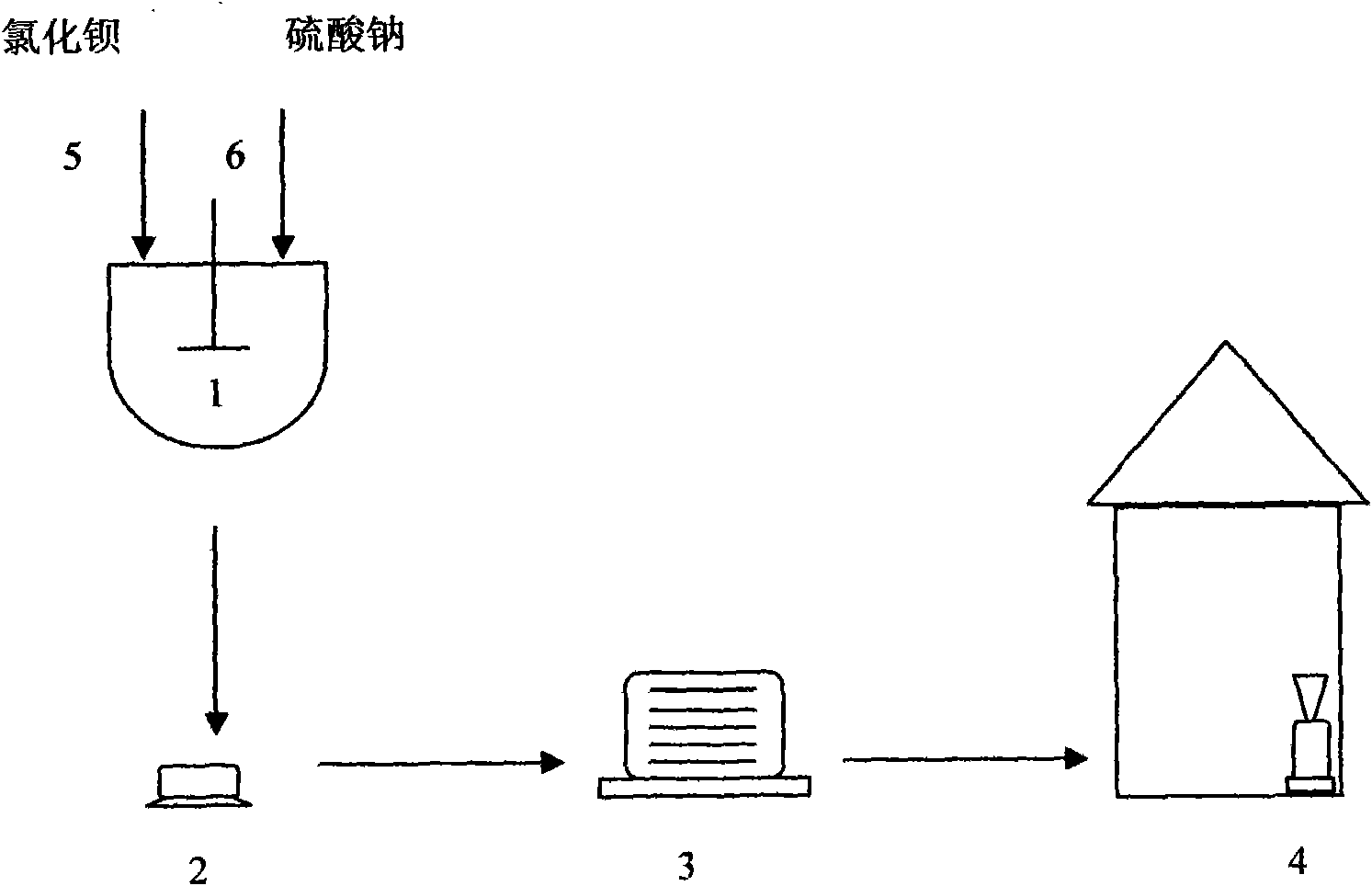

[0010] Embodiment one: 500 kilograms of barium chloride (5) is dissolved in water and the sodium sulfate (6) that dissolves is good with the mass ratio of pure matter 1: 0.38 injects in the reactor (1) li and evenly stirs simultaneously, carries out the obtaining of chemical reaction The mixed liquid of barium sulfate and sodium chloride is centrifuged (2) to get filter cake precipitated barium sulfate, then washed, dried (3), crushed (4), packaged to obtain 311.76 barium sulfate products, and the filtrate is distilled under reduced pressure to obtain industrial salt Sodium chloride. Its chemical reaction equation is:

Embodiment 2

[0011] Embodiment two: 500 kilograms of barium chloride (5) are dissolved in water and the sodium sulfate (6) that dissolves is injected into reactor (1) li with the mass ratio of pure matter 1: 0.98 and stir evenly simultaneously, carry out the obtaining of chemical reaction The mixed liquid of barium sulfate and sodium chloride is centrifuged (2) and filtered to obtain filter cake precipitated barium sulfate and then washed, dried (3), pulverized (4), packed to obtain 560.1 kg of barium sulfate product, and the filtrate is distilled under reduced pressure to obtain industrial salt sodium chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com