Complete-set device for recycling metal in waste lithium battery

A technology of waste lithium batteries and complete sets of devices, applied in the field of environmental protection, can solve problems such as endangering the human ecological system environment, air, soil and water pollution, and natural environment impact, and achieve simple and clear design principles and methods, and realize resource recycling. The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

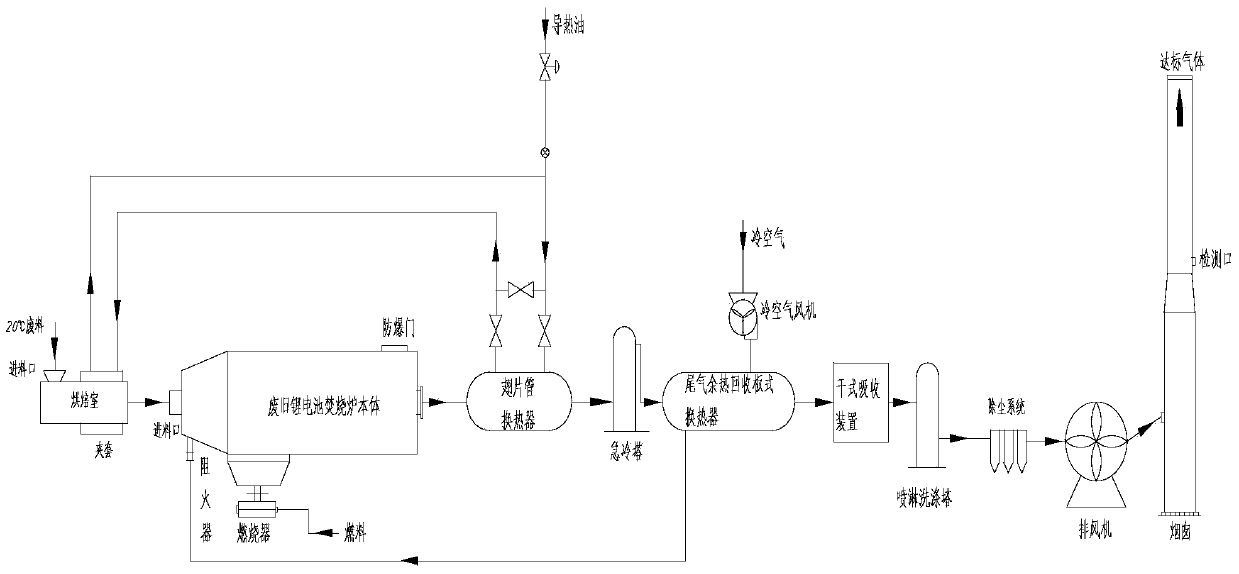

[0027] The complete set of equipment for metal recovery in waste lithium batteries is described below in conjunction with the process flow chart of the complete set of equipment.

[0028] The present invention consists of a baking chamber, a waste lithium battery incinerator body, a finned tube heat exchanger, a quench tower, a plate heat exchanger for exhaust waste heat recovery, a feed and pipeline system, an electric control system, a flue gas purification device, an induced draft fan, independent chimney.

[0029] First, the waste lithium battery is crushed and pretreated, and the material is fed; then it enters the baking room for a baking, and then enters the rotary incinerator for secondary combustion to achieve full combustion and decomposition of the lithium battery; then it is discharged by the finned tube heat exchanger The flue gas is cooled once, and the heat-conducting oil used for cooling is used to preheat the lithium battery in the baking chamber; the flue gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com