Method for milling end surface of large-cross-section steel component

A processing method and large-section technology, applied in metal processing equipment, milling cutters, manufacturing tools, etc., can solve the problems of short cantilever, large end milling line error, poor accuracy, etc., to achieve a simple and clear method, reduce end milling Line error, the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

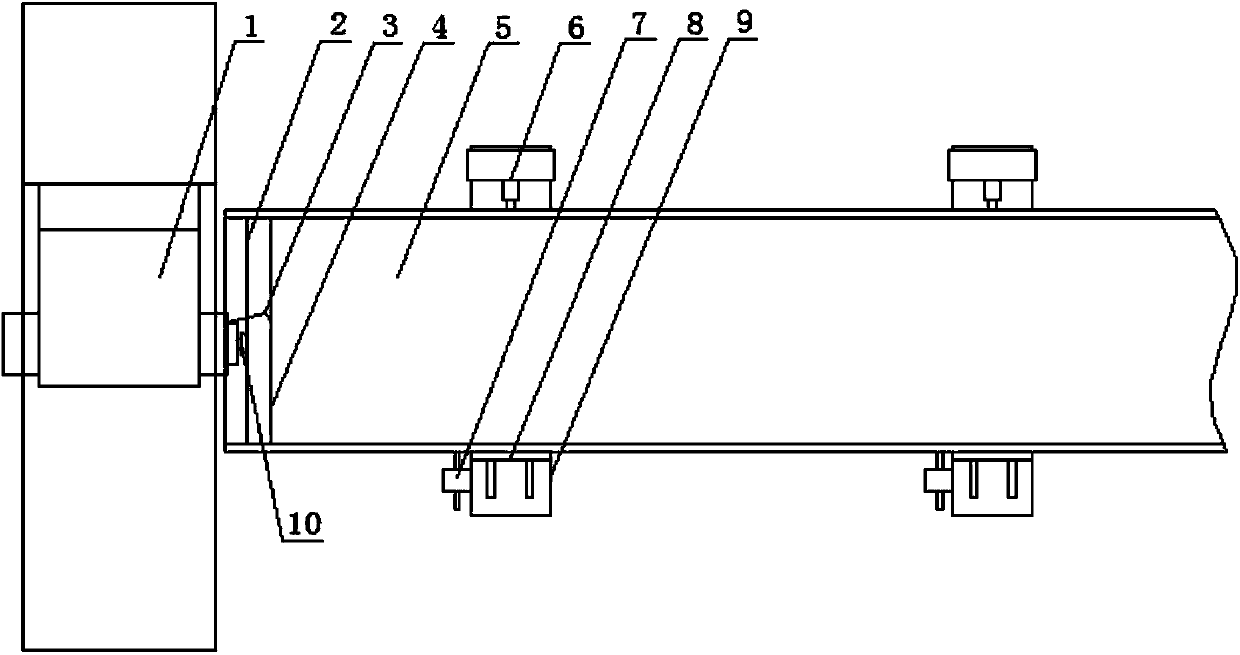

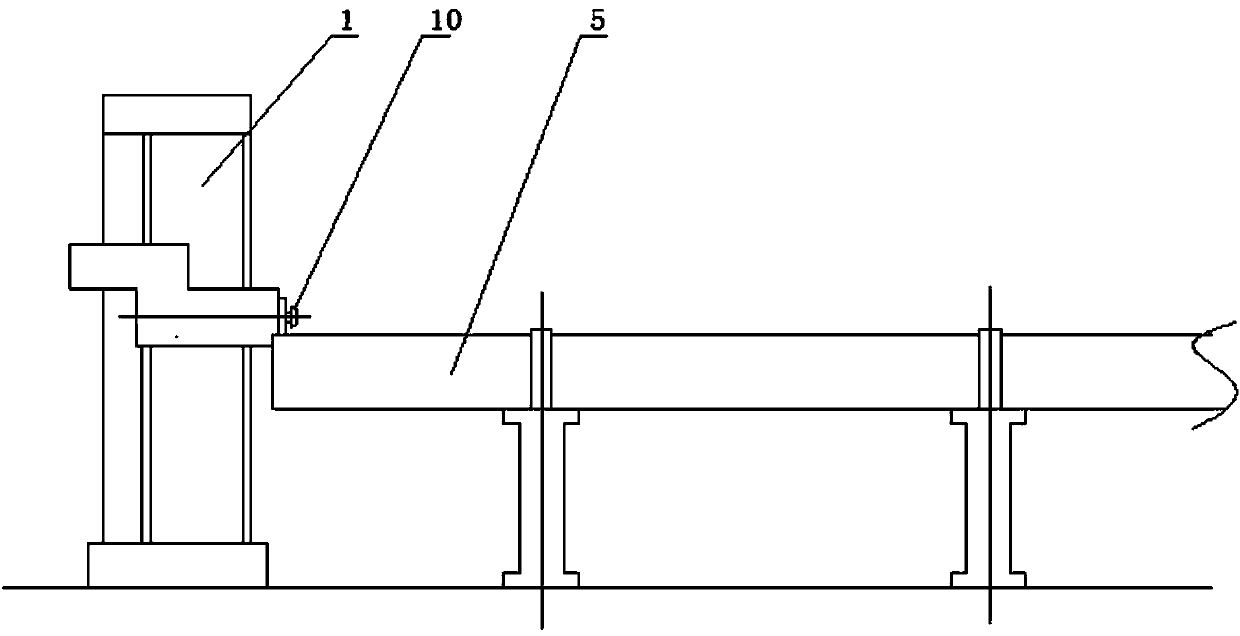

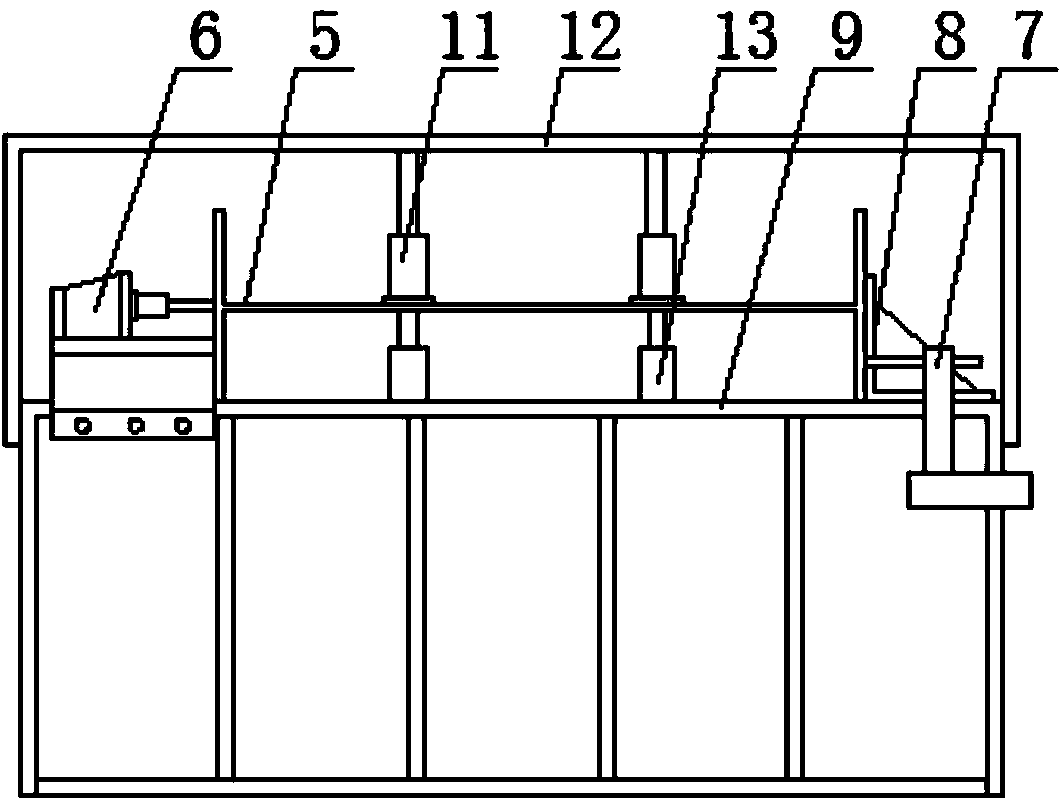

[0020] A method for end face milling of large cross-section steel components, characterized in that: the steps of the method are:

[0021] ⑴. First, correct the fabricated large-section steel member 5 to ensure that the dimensions of each member are within the allowable deviation range;

[0022] (2) Draw end milling line 2 and end milling observation line 4: use right-angle Pythagorean method to draw end milling line and end milling observation line on the wide surface of large cross-section steel members;

[0023] ⑶. Longitudinal and transverse initial adjustment of the placement position of large-section steel components: Hoist the large-section steel components on the support plane reference tire 9 of the clamping and fixing tooling. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com