Technical process for supercritical water treatment of polychlorinated biphenyls (PCBs) waste and complete plant thereof

A technology of supercritical water and polychlorinated biphenyls, which is applied in the direction of protection devices against harmful chemical agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

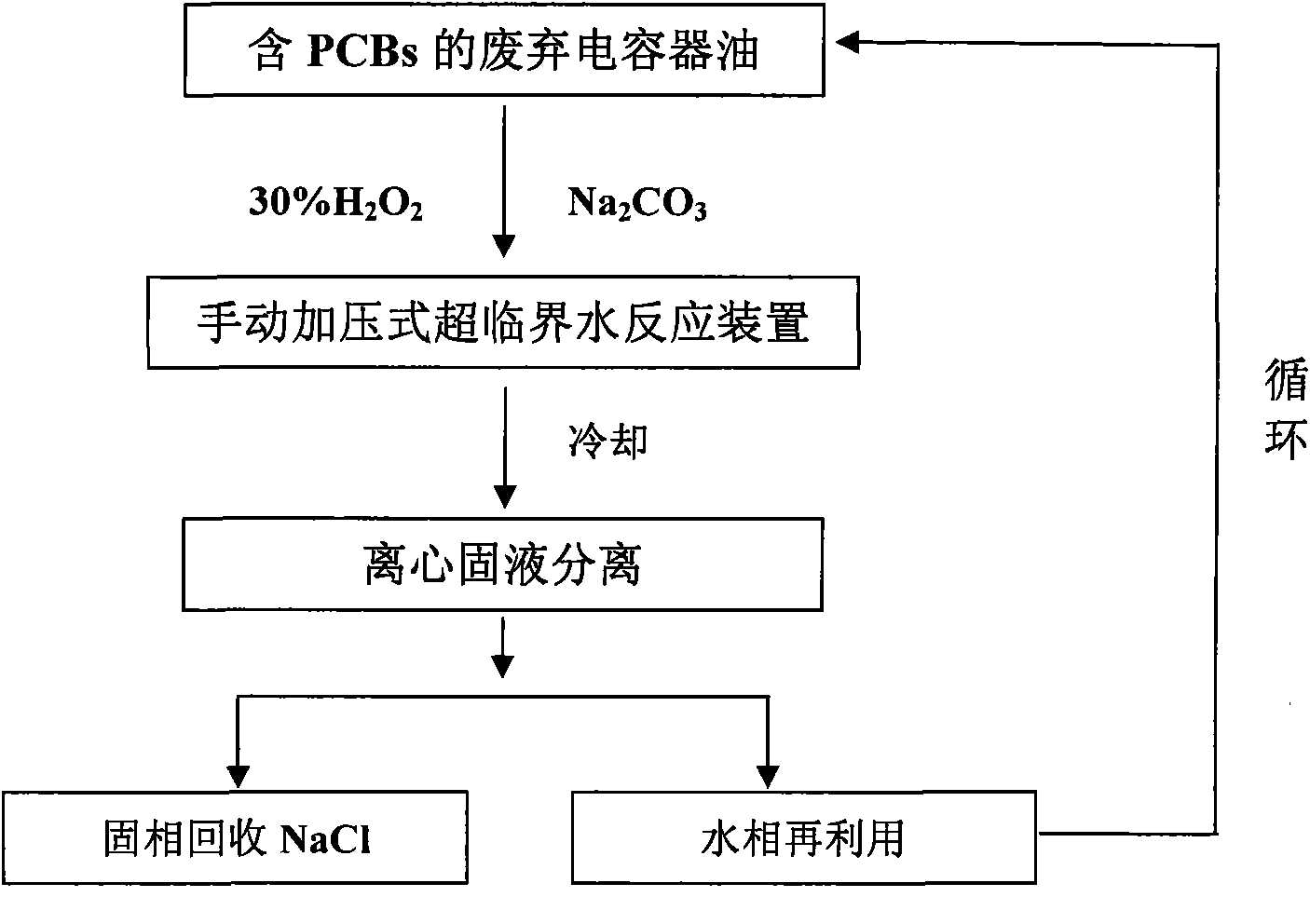

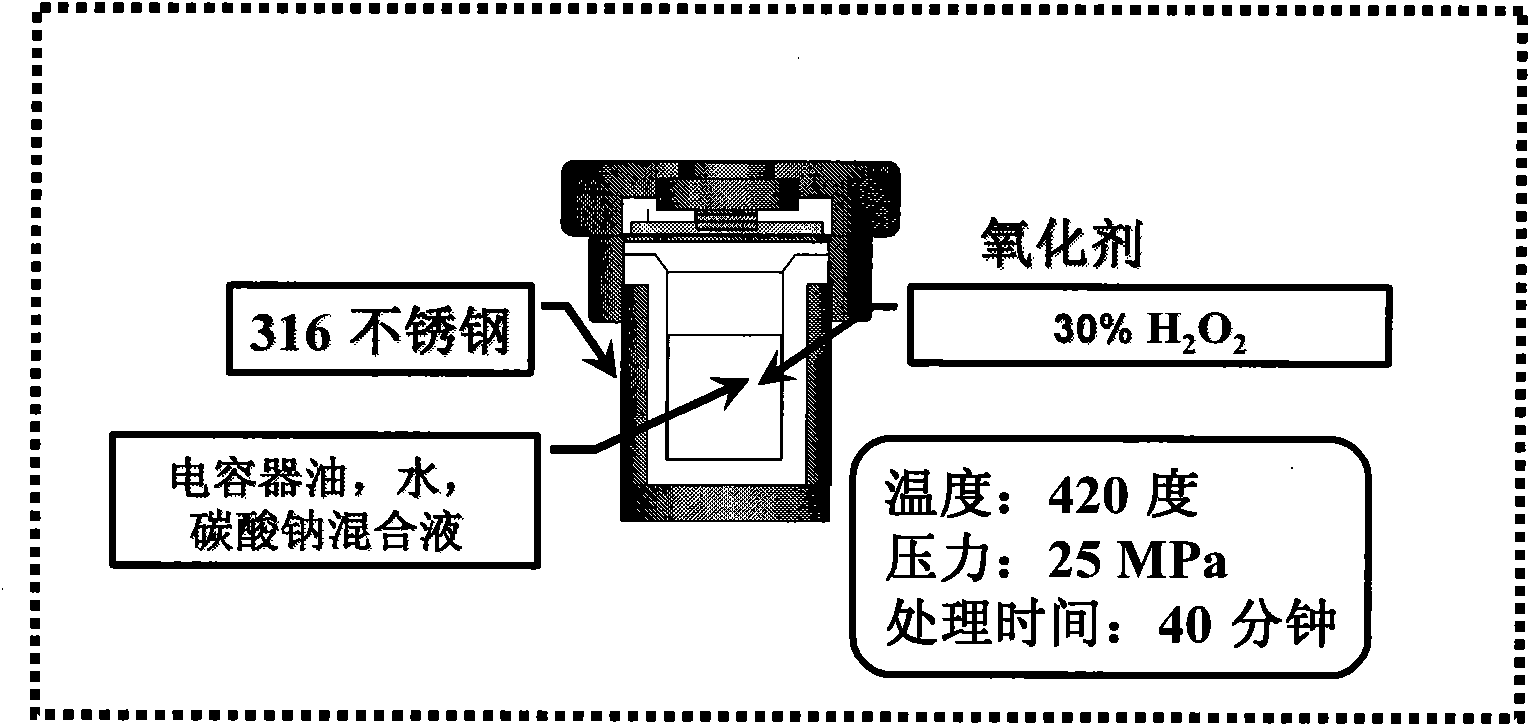

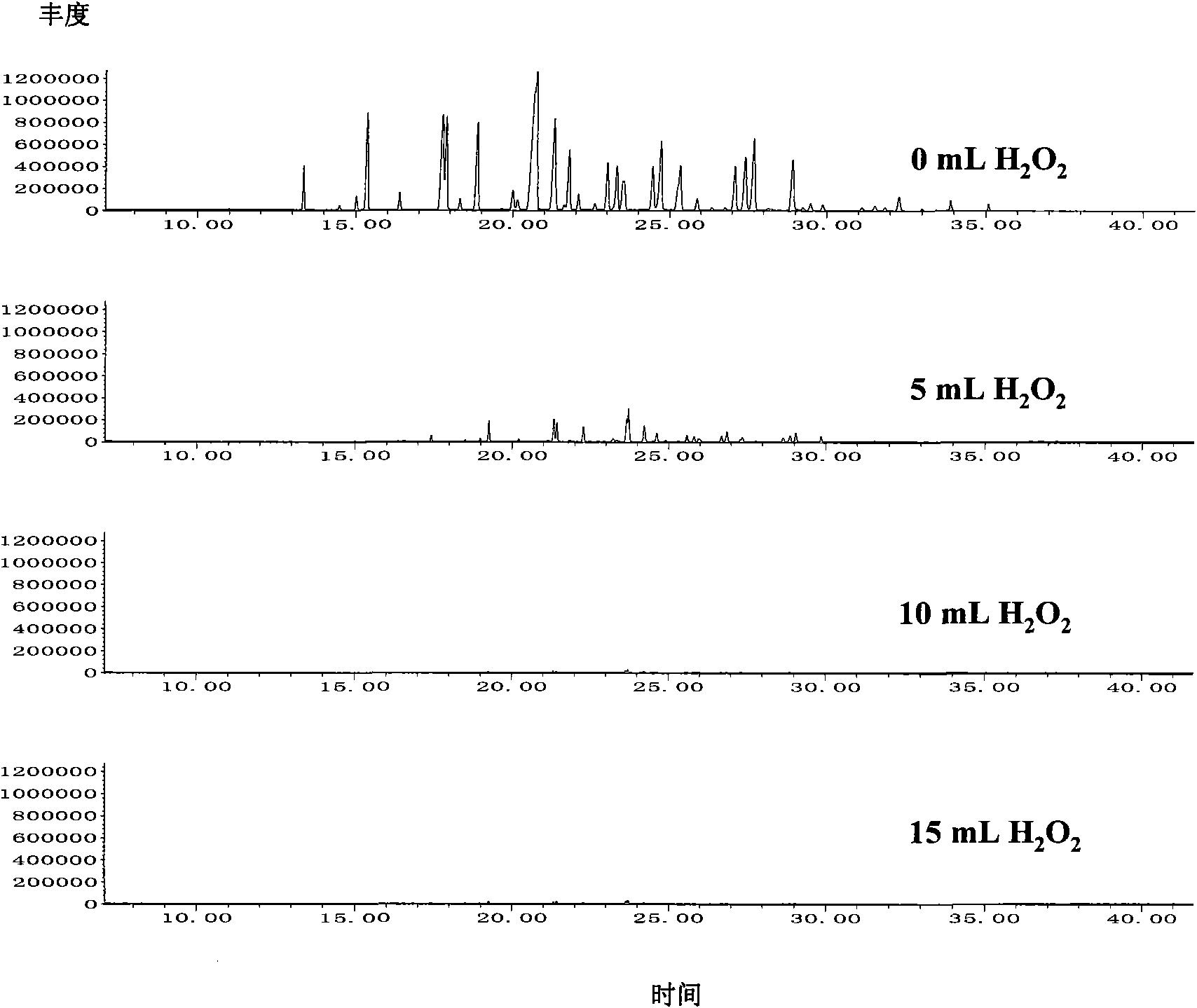

[0009] Such as figure 1 and figure 2 As shown, 1ml of waste capacitor oil containing 60% (w / w%) PCBs is placed in the reaction kettle of a manual pressurized supercritical water reaction device with a volume of 100ml, and the density of the capacitor oil is 1.5g / ml. Add 70ml of deionized water to the reaction kettle, then add 1g of Na 2 CO 3 , and finally add 10ml H 2 o 2 Immediately afterwards, seal the reaction kettle, heat it after tightening, and start timing after the temperature rises to 420°C. At this time, the pressure in the container is controlled at 25MPa by a manual pressurization device, and the heating is stopped after 40 minutes of reaction. After the temperature drops to room temperature, the reactor body is opened, and the reactant is transferred to a centrifuge tube. After centrifugation, the solid phase is NaCl formed during the reaction; the liquid phase is rinsed with n-hexane, the washing liquid is combined with the liquid phase, and the liquid phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com