Resourceful treatment process for high-concentration organic wastewater containing phosphorus and sulfur

A technology of organic wastewater and treatment process, applied in the direction of inorganic chemistry, phosphoric acid, phosphorus oxyacid, etc., can solve the problems of environmental sensitivity, difficulty in recycling phosphorus and sulfur, difficulty in processing high-concentration organic wastewater, etc., and achieve strong adaptability , Small footprint, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

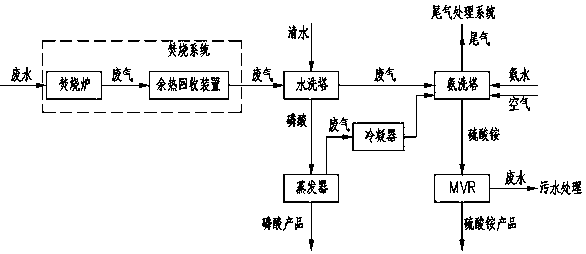

[0026] Taking the organic wastewater with high concentration of phosphorus and sulfur in a project as an example, the COD value of the organic wastewater is about 32000mg / L, the total phosphorus content is about 6000mg / L, and the total sulfur content is about 7100mg / L. Recycling treatment of the organic wastewater (for the process flow, see figure 1 ),Proceed as follows:

[0027] 1) Preheat the incinerator first, use diesel as the auxiliary fuel, and the auxiliary fuel and air burn in the incinerator to form a high temperature environment. After the temperature reaches 600°C, use the wastewater feed pump to send high-concentration wastewater to the nozzle of the incinerator, and spray feed into the incinerator through the nozzle of the incinerator. The atomized wastewater burns stably at a high temperature of 900°C.

[0028] 2) The incineration tail gas is cooled to 150°C after passing through the waste heat recovery device of the incineration system, and then passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com