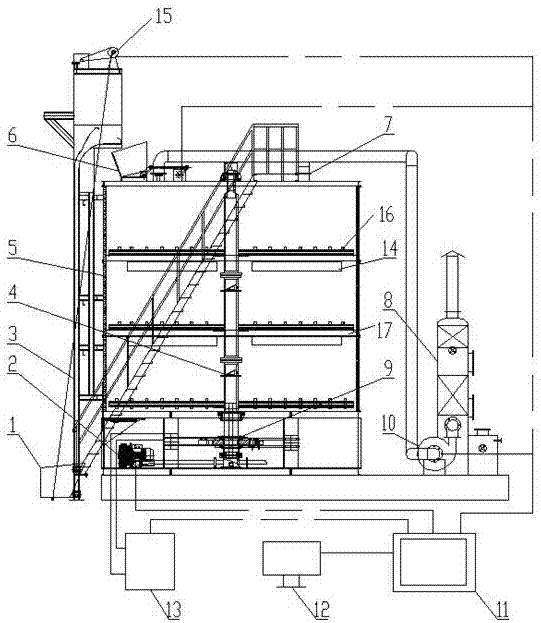

Waste fermentation device using overclocking technology

A fermentation device and waste technology, which is applied in fertilization devices, organic fertilizer equipment, organic fertilizer preparation, etc., can solve the problems of surrounding environmental impact, operator physical damage, and difficulty in collecting and disposing of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Example: Mix agricultural waste and return waste according to a certain ratio, drive the feeding silo 1 to lift through the elevator 15 (the lifting frame body 3 plays a supporting role), enter the fermentation silo 5 through the feed port 6, and The stirring device 4 and the waste fall down layer by layer under the action of its own gravity, and oxygen is sent to the waste through the vortex air pump 2, so that the waste undergoes sufficient aerobic fermentation and decomposition. The fermentation process lasts for 8 days, and the heat released during the decomposition process It can increase the temperature of the mixed waste itself, up to about 70°C, so that the water in the waste evaporates, and some organic matter is decomposed and decomposed, so as to achieve the purpose of reduction and stabilization treatment. The control box 11 controls the hydraulic pump station 13 Oil supply is driven by a hydraulic cylinder, and the power is transmitted to the stirring device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com