Fly ash baked brick prepared by washed incineration fly ash of house refuse and preparation method thereof

A technology of domestic waste incineration and sintered bricks, which is applied to the production of clay products, ceramic materials, and the removal of solid waste, etc., to achieve good macro performance, reduce potential hazards, and simple manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A fly ash sintered brick made by washing domestic waste incineration fly ash, the mass percentage of its raw materials is as follows:

[0048] Domestic waste incineration fly ash after washing 25%

[0049] Clay 60%

[0050] Feldspar 15%

[0051] A kind of fly ash sintered brick made of domestic waste incineration fly ash after washing. The main chemical components (mass percentage) in the washed fly ash, clay and feldspar are shown in Table 4.

[0052] Table 4 Chemical composition of washed fly ash, clay and feldspar (%)

[0053]

[0054] Among them, the washed fly ash is the domestic waste incineration fly ash taken from Shanghai Jiangqiao Domestic Waste Incineration Power Plant after washing;

[0055] Among them, clay is a kind of pottery clay that exists in nature, produced in Dingjiaqiao, Zhejiang;

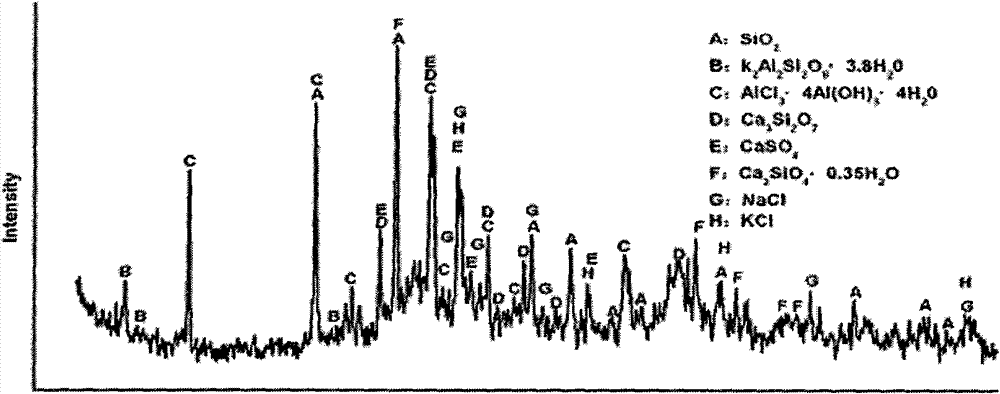

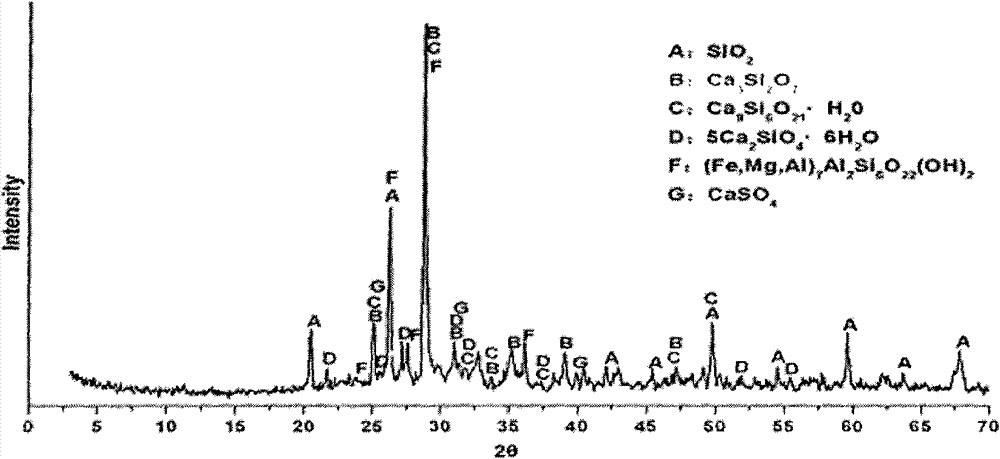

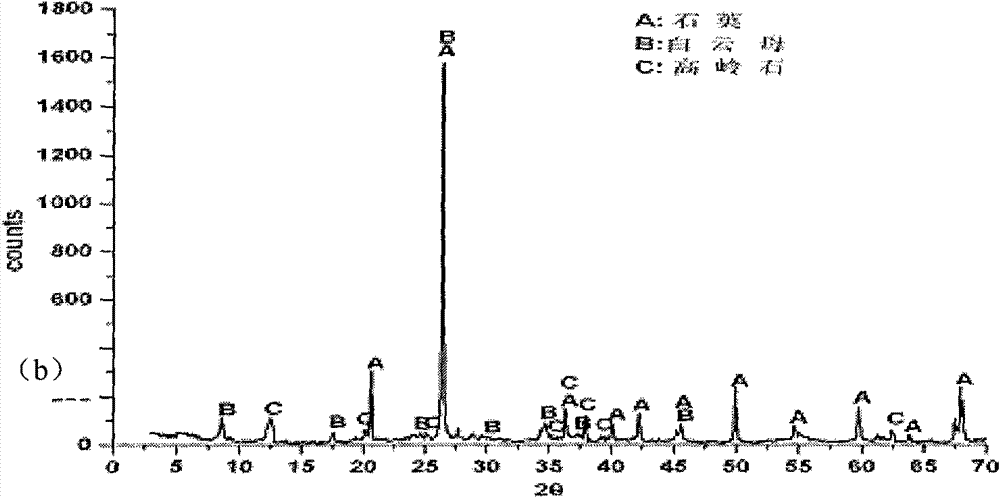

[0056] Fe in clay 2 o 3 The content of clay is relatively high, and its iron oxide composition makes the finished product appear red. The photo of clay (a) XRD...

Embodiment 2

[0059] A kind of fly ash sintered brick made by washing domestic waste incineration fly ash, the mass percentage of its raw materials is composed of:

[0060] Domestic waste incineration fly ash after washing 30%

[0061] Clay 55%

[0062] Feldspar 15%

[0063] The fly ash sintered brick made of the washed domestic waste incineration fly ash, the main chemical components (mass percentage) in the washed fly ash, clay and feldspar are shown in Table 4 in Example 1.

Embodiment 3

[0065] A fly ash sintered brick made by washing domestic waste incineration fly ash, the mass percentage of its raw materials is as follows:

[0066] Domestic waste incineration fly ash after washing 35%

[0067] Clay 60%

[0068] Feldspar 5%

[0069] The fly ash sintered brick made of the washed domestic waste incineration fly ash, the main chemical components (mass percentage) in the washed fly ash, clay, and feldspar are shown in Table 4 in the examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com