A Demonstration Process Method for Environmentally Friendly Recycling of Waste Power Lithium Iron Phosphate Batteries

A technology of lithium iron phosphate battery and process method, applied in battery recycling, waste collector recycling, battery pack parts and other directions, can solve problems such as no industrialized process route, and achieve the effect of reducing harm and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

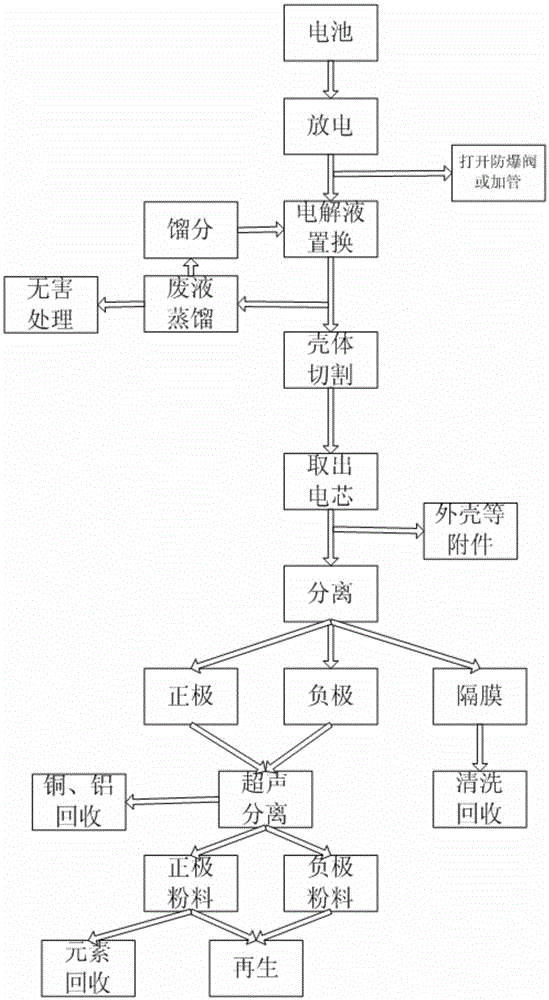

[0029] Such as figure 1 As shown, the demonstration process route of the environmentally friendly recycling of hard-shell waste power lithium iron phosphate batteries in this embodiment includes the following steps:

[0030] a) Discharge the battery safely. The discharge device is a high-current charge-discharge instrument. First discharge with a large current, and then discharge with a low current to 0V;

[0031] b) Replace the electrolyte of the discharged battery, pump out the electrolyte in the battery with a vacuum device, then add the solvent DMC to stand still, and then use a vacuum pump to pump out the liquid inside the battery, the pressure is about -0.01MPa.

[0032] c) Distill the waste liquid obtained in step (b), the distillation temperature is 90-105°C, the obtained component is DMC, which can be reused for electrolyte replacement in step b); the remaining component is EC, which is passed through the tail gas absorption device The decomposed harmful gas is remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com