Treatment method for metaaluminate-containing C5 resin wastewater

A meta-aluminate and treatment method technology, which is applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc., can solve the problems of biochemical system impact, high salinity, high alkalinity, etc., and achieve water quality indicators The effect of reducing, safe disposal method and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

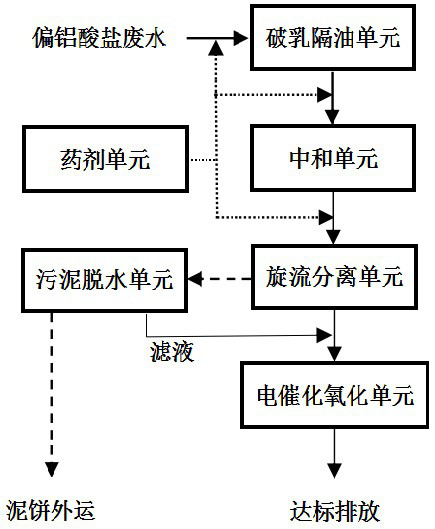

Image

Examples

Embodiment 1

[0029] Taking C5 resin wastewater containing metaaluminate produced by a resin production enterprise in Daqing as the treatment object, the pH value of the waste liquid is 12.5-13.0, the ammonia nitrogen content is 450mg / L, the COD is 2000-3000mg / L, and the petroleum content is 110mg / L, BOD 5 / COD=0.13.

[0030] A treatment method for C5 resin wastewater containing metaaluminate, comprising the following steps:

[0031] Step 1: After mixing the C5 resin wastewater containing metaaluminate with the demulsifier, it enters the oil separation unit for demulsification reaction. The residence time of the oil separation unit is 5h, and the dosage of the demulsifier is 3g / L; the oil on the upper part of the oil separation unit Periodically collected, the lower part of the sewage is pumped into the neutralization unit;

[0032] Step 2: The neutralization unit uses PLC to adjust the pH value of the wastewater online, and uses hydrochloric acid to neutralize the metaaluminate wastewate...

Embodiment 2

[0037]Taking C5 resin wastewater containing metaaluminate produced by a resin production enterprise in Fushun as the treatment object, the pH value of the waste liquid is 12.5-13.5, the ammonia nitrogen content is 430mg / L, the COD is 2500-3200mg / L, and the petroleum content is 120mg / L, BOD 5 / COD=0.14.

[0038] A treatment method for C5 resin wastewater containing metaaluminate, comprising the following steps:

[0039] Step 1: Mix the C5 resin wastewater containing metaaluminate with the demulsifier, and then enter the oil separation unit for demulsification reaction. The residence time of the oil separation unit is 4h, and the dosage of demulsifier is 4g / L; Periodically collected, the lower part of the sewage is pumped into the neutralization unit;

[0040] Step 2: The neutralization unit uses PLC to adjust the pH value of the wastewater online, and uses hydrochloric acid to neutralize the metaaluminate wastewater to neutrality; the neutralization unit has a residence time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com