A kind of recovery treatment method of galvanized pickling waste hydrochloric acid

A technology for recovery and treatment of waste hydrochloric acid, applied in metallurgical wastewater treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve problems such as cross-contamination, increased difficulty of waste acid treatment, increased cost, etc. Environmental protection, easy maintenance and management, and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

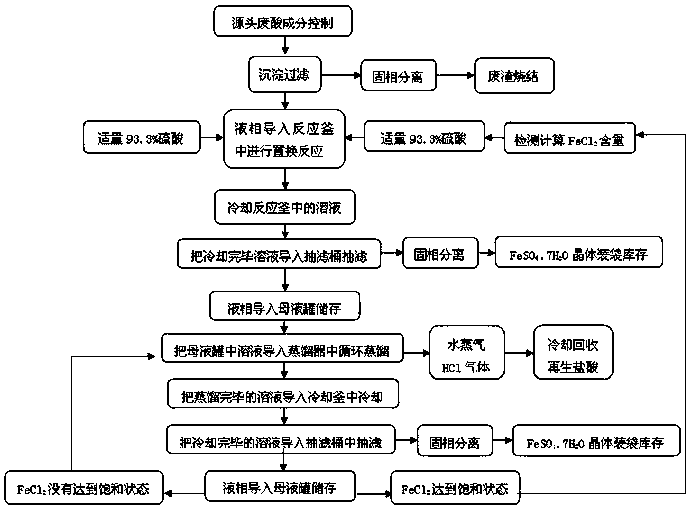

Method used

Image

Examples

Embodiment 1

[0049] Required equipment: sedimentation tank, filter press, waste acid storage tank, mother liquor storage tank, sulfuric acid replacement reaction kettle, circulating steam distillation device, cooling kettle, suction filtration device, vacuum negative pressure device.

[0050] Steps:

[0051] 1. Sediment filtration

[0052] Put the galvanized parts that need to be pickled in a special pickling tank and pickle them with hydrochloric acid. There is no backwashing process for galvanized parts in the pickling tank. The pickling solution is used repeatedly until it fails. According to experience, it is generally considered that the pickling solution When the specific gravity reaches 1.2 to 1.4, the pickling solution is considered to be invalid, discarded, and treated as a waste acid solution. It was detected that the density was greater than 1.2g / mL containing hydrochloric acid and FeCl 2 The spent acid solution is recovered separately. The waste acid solution is first introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com