Preparation method for preparing facing bricks by modifying household waste incinerated fly ash

A domestic waste incineration and fly ash technology, which is applied in the field of fly ash treatment, can solve the problems that the solidified fly ash cannot be utilized as a resource, the landfill cost of hazardous waste is high, and dioxin cannot be destroyed. Sustainable development, saving landfill costs and land resources, and promoting low-carbon development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

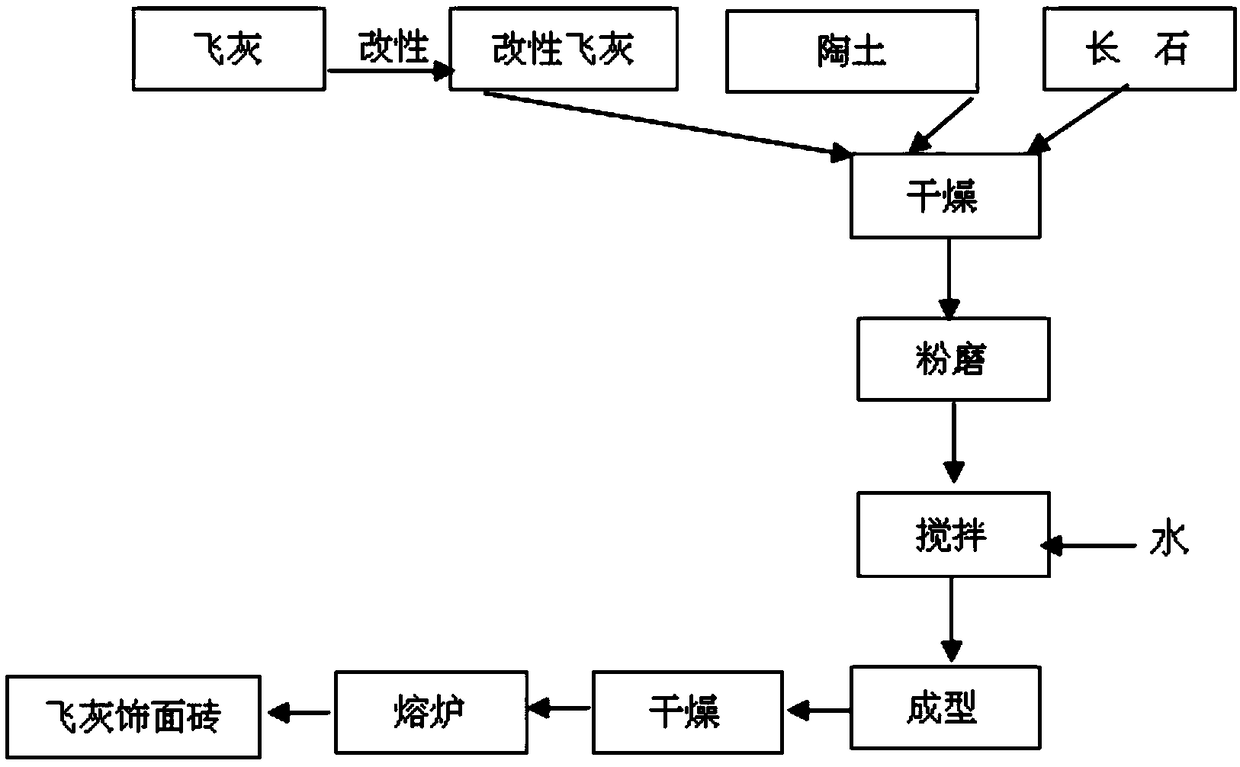

[0018] The invention provides a method for preparing decorative bricks modified by domestic waste incineration fly ash, which comprises the following steps:

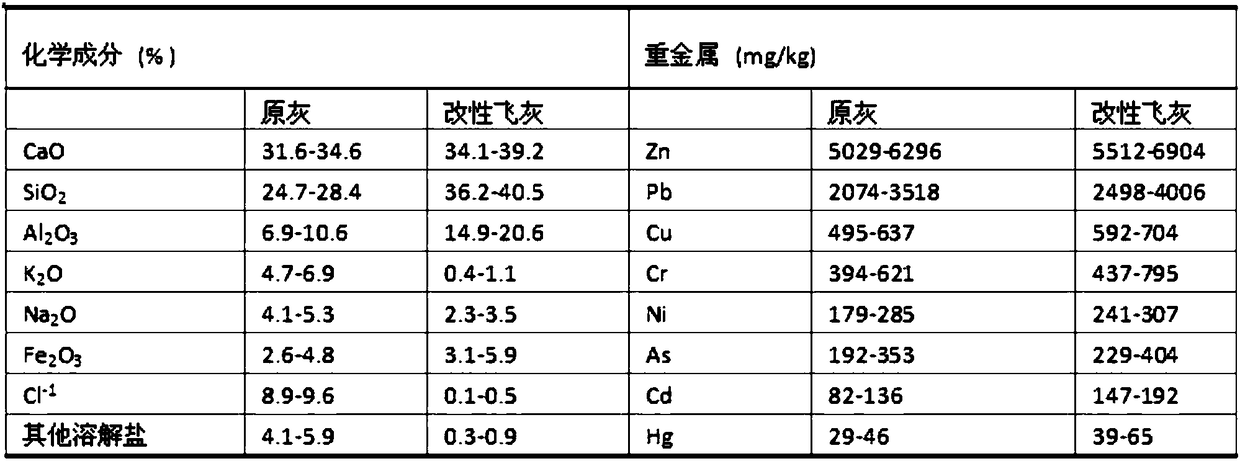

[0019] 1) Using 0.5 mol / L NaOH solution as a modifier, mixing the modifier with domestic waste incineration fly ash according to a certain solid-to-liquid ratio, then washing with water, suction filtering, and drying to obtain modified fly ash; Among them, the liquid-solid ratio of modifier and fly ash is 1:10, the time of modification treatment is 8h, and the stirring speed is 120rpm;

[0020] 2) After mixing the modified fly ash, clay and feldspar, place it in a drying room for ventilation and drying for 36 to 48 hours at a drying temperature of 20±5°C, and then grind it. The equipment used for grinding is combined grinding equipment. The grinding equipment includes jaw crusher and Raymond mill. When grinding, the mixed material is firstly crushed in the jaw crusher, and the material after primary crushing is transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com