Integrated microchannel heat exchanger with liquid homogenizing device

A liquid equalizing device and heat exchanger technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problem of uneven distribution of fluid in heat exchangers, and achieve thorough heat exchange and high heat exchange efficiency High, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

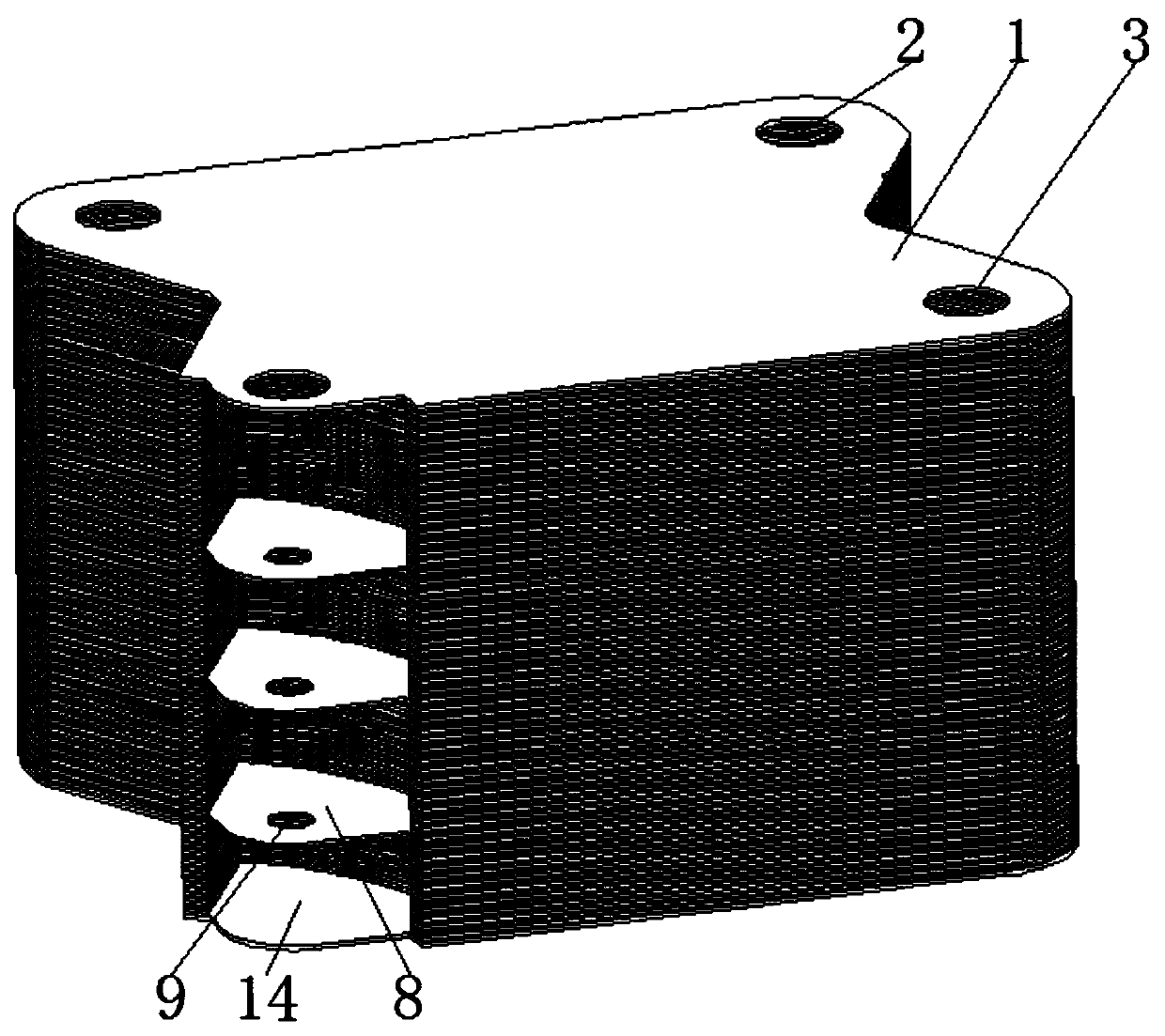

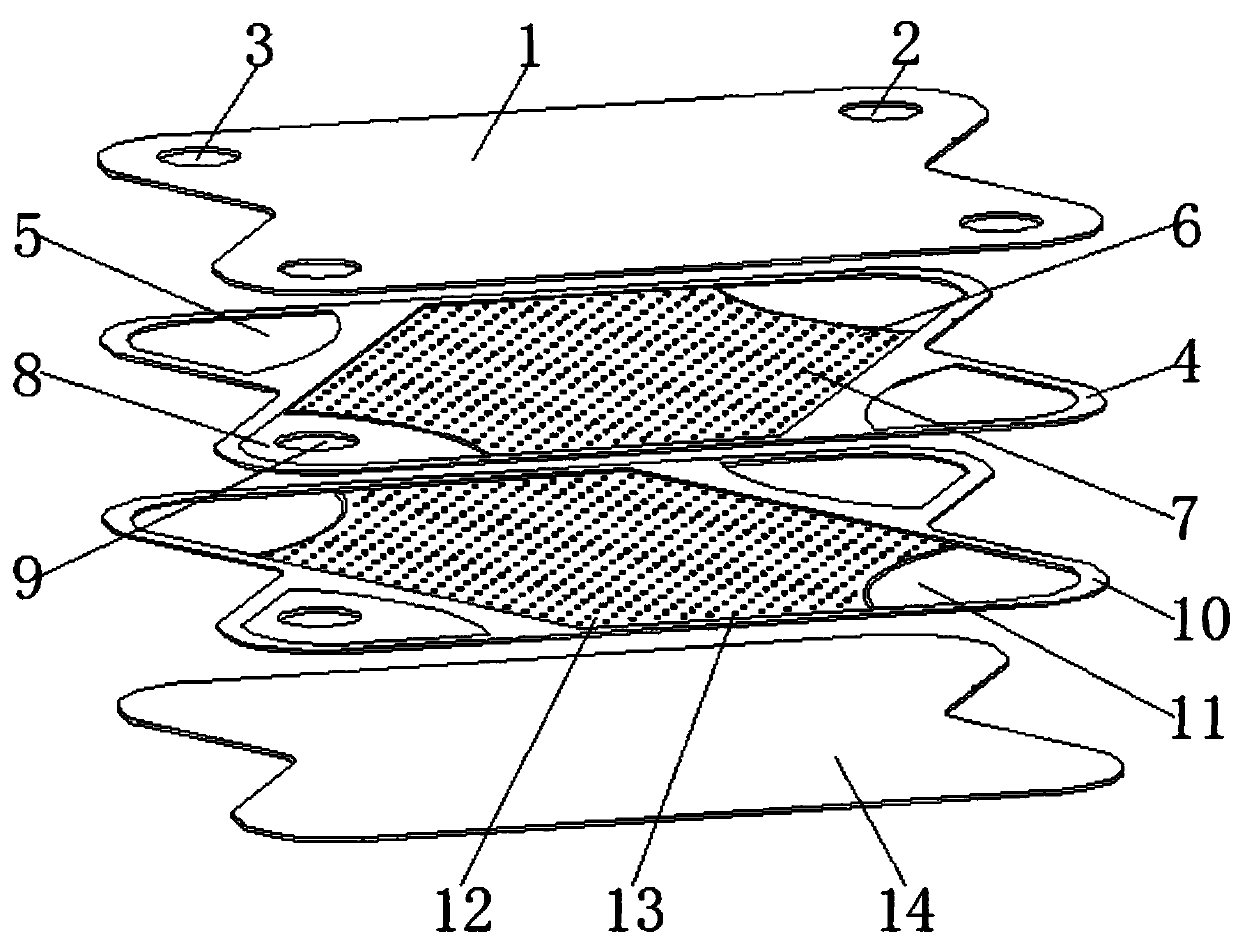

[0025] see Figure 1-3 , an integrated microchannel heat exchanger with a uniform liquid device, including a heat exchanger top plate 1, a thermal fluid interface 2 is provided on the upper surface of the heat exchanger top plate 1, and the inside of the thermal fluid interface 2 is connected to the heat exchanger top plate 1 The lower surface of the heat exchanger top plate 1 is provided with a cold fluid interface 3, the number of the hot fluid interface 2 and the cold fluid interface 3 are two, and the two hot fluid interfaces 2 and the two cold fluid interfaces 3 are staggered at the four corners of the heat exchanger top plate 1, so that the cold fluid and hot fluid can enter the bottom of the heat exchanger top plate 1 through the cold fluid interface 3 and the hot fluid interface 2 respectively, and the inside of the cold fluid interface 3 and the heat exchanger top plate 1 The lower surface of the heat exchanger top plate 1 is fixedly connected with the hot-side heat e...

Embodiment 2

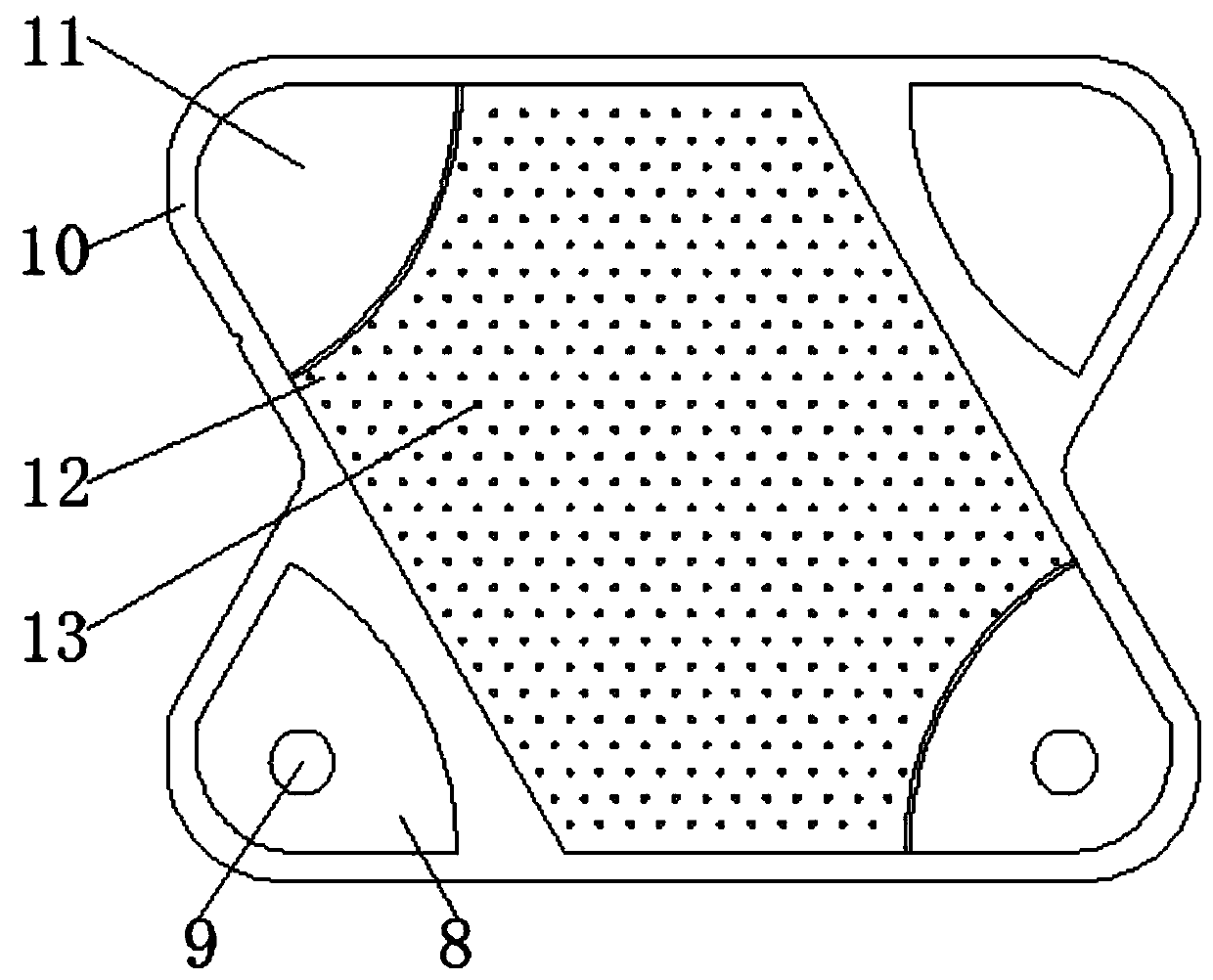

[0028] see Figure 4 , the upper surface of the damping plate 8 is provided with a damping hole 9, the inside of the damping hole 9 is connected with the lower surface of the damping plate 8, the number of the damping holes 9 is three, and the three damping holes 9 are evenly arranged on the bottom of the damping plate 8 On the surface, the three damping plates 9 disperse the fluid, so that the distribution of the fluid is more uniform.

Embodiment 3

[0030] see Figure 5 , the upper surface of the damping plate 8 is provided with a damping hole 9, the inside of the damping hole 9 communicates with the lower surface of the damping plate 8, the cross section of the damping hole 9 is elliptical, and the elliptical damping hole 9 makes the area of the fluid flow Larger, more fluid enters the lower surface of the damping plate 8 through the damping hole 9, so that the heat exchange effect of the fluid is better, and the efficiency of the heat exchanger is higher.

[0031]To sum up, the integrated microchannel heat exchanger with liquid equalization device is provided with the top plate 1 of the heat exchanger, the heat exchange plate 4 on the hot side, the heat exchange plate 10 on the cold side and the bottom plate 14 of the heat exchanger, The fluid can pass through the top plate of the heat exchanger 1 and enter the hot side heat exchange plate 4 and the cold side heat exchange plate 10 for heat exchange, and the first flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com