Heat pump hot water unit

A technology of heat pump hot water and heat pump main engine, which is applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve the problems of slow temperature rise of water tanks, low heat transfer efficiency, insufficient energy saving, etc., achieve thorough heat exchange, save operating costs, and benefit storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

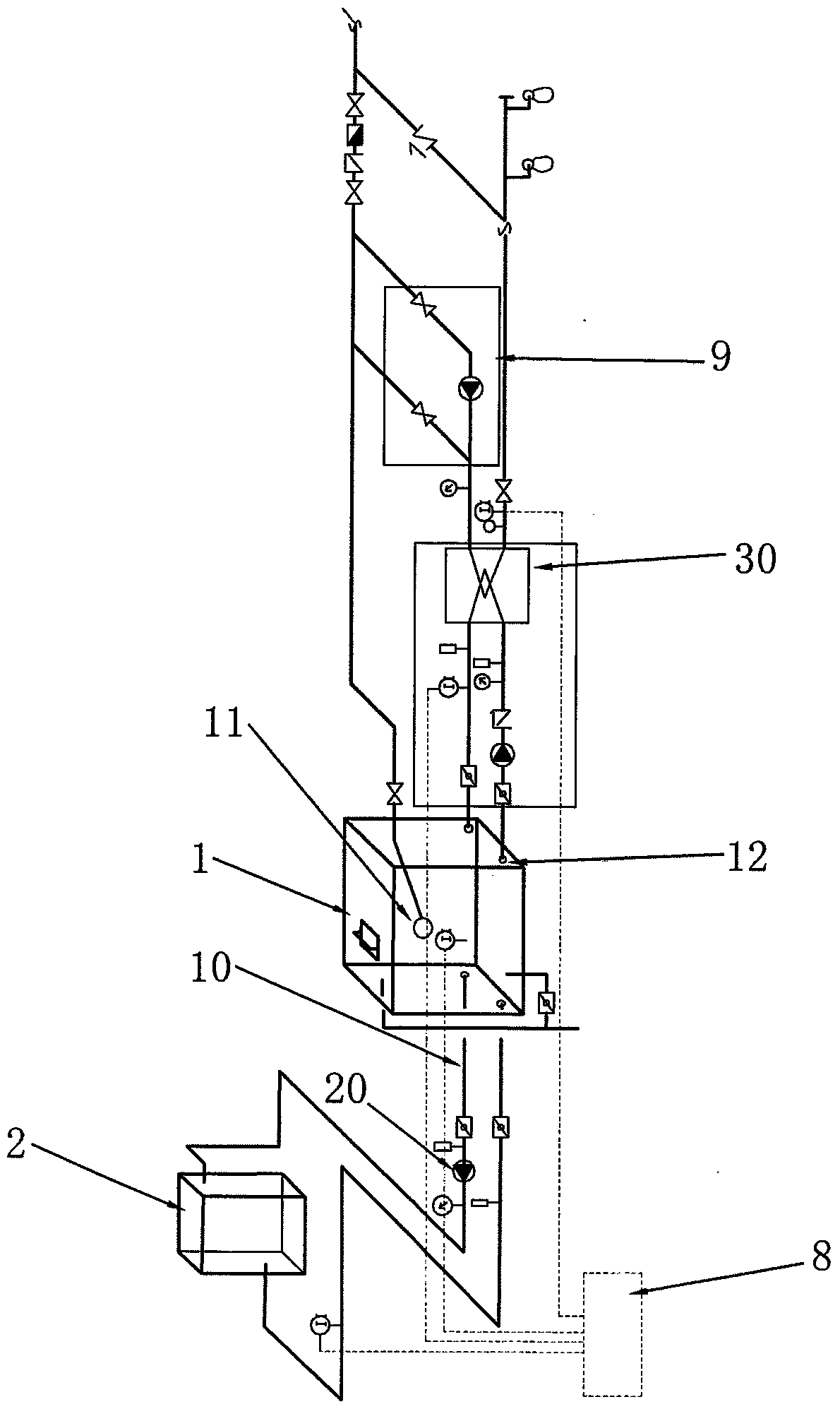

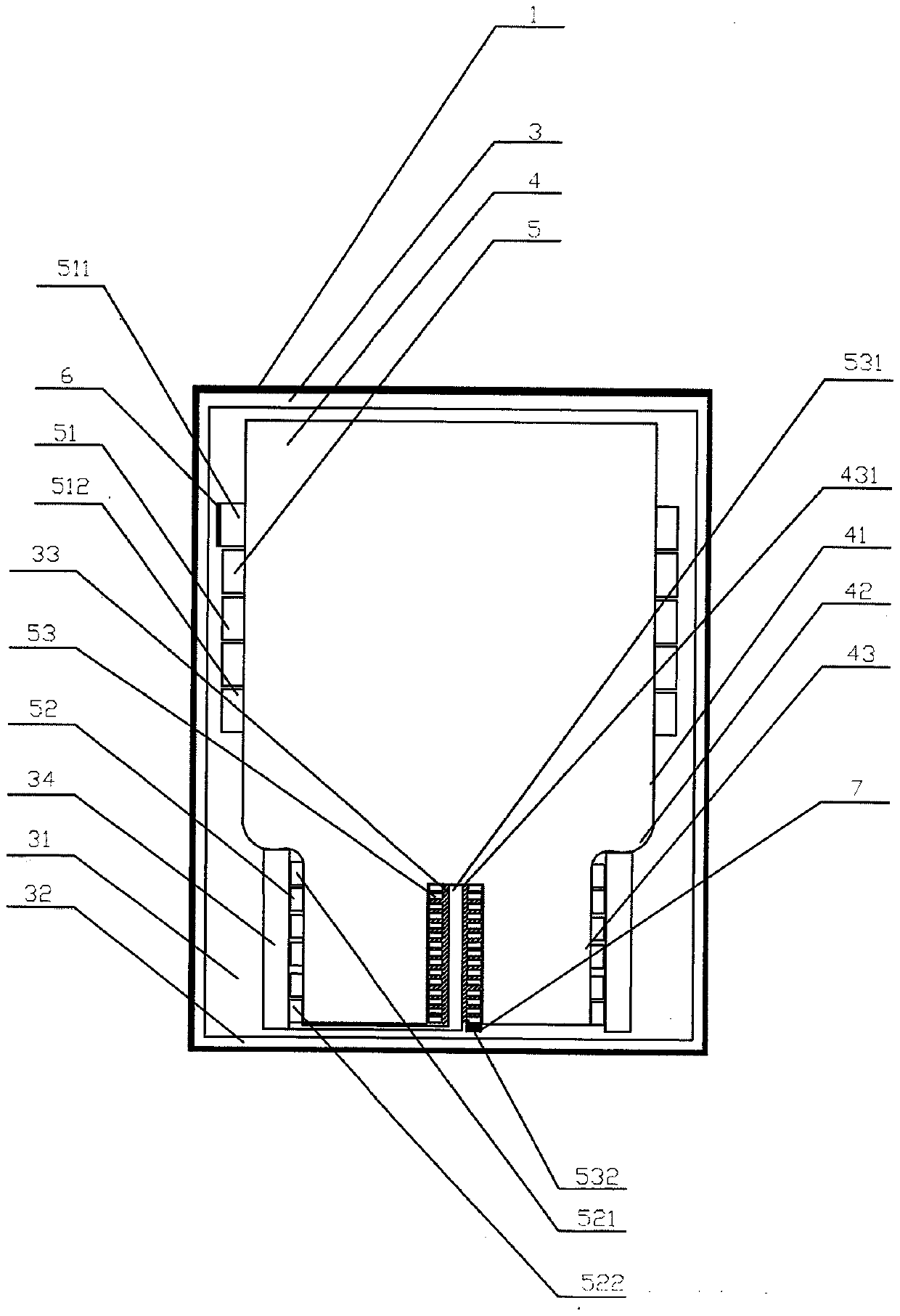

[0022] Such as Figure 1-Figure 2 The shown heat pump water heating unit includes a hot water storage tank 1 and a heat pump main engine 2. The hot water storage tank 1 is provided with an insulation layer 3, an inner tank 4 and a heat exchange coil 5. The described The hot water storage tank 1 is provided with a hot water outlet 11 and a cold water inlet 12, the heat pump host 1 is connected to the hot water storage tank 2 through a circulating water pipe 6, and the circulating water pipe 6 is provided with a circulating water pump 61, the described The hot water storage tank 1 is also provided with a heat replacement device 7 connected with the hot water storage tank 1; the inner tank 4 includes an inner tank upper section 41, an inner tank middle section 42 and an inner tank lower section 43, and the inner tank middle section 42 is an S-shaped structure, the lower section 43 of the liner is parallel to the upper section 41 of the liner in the vertical direction and is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com