Efficient heat-exchanging pipe of evaporator for electric refrigerator set

A technology of heat exchange tubes and evaporators, applied in the field of evaporative heat exchange tubes, can solve the problems that the heat exchange efficiency of refrigerants cannot be improved, the temperature of the working medium in the heat exchange tubes can be reduced, and the heat exchange can not be performed effectively, so as to achieve reduction Effects of thin temperature boundary layer, enhanced fatigue resistance, and improved cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

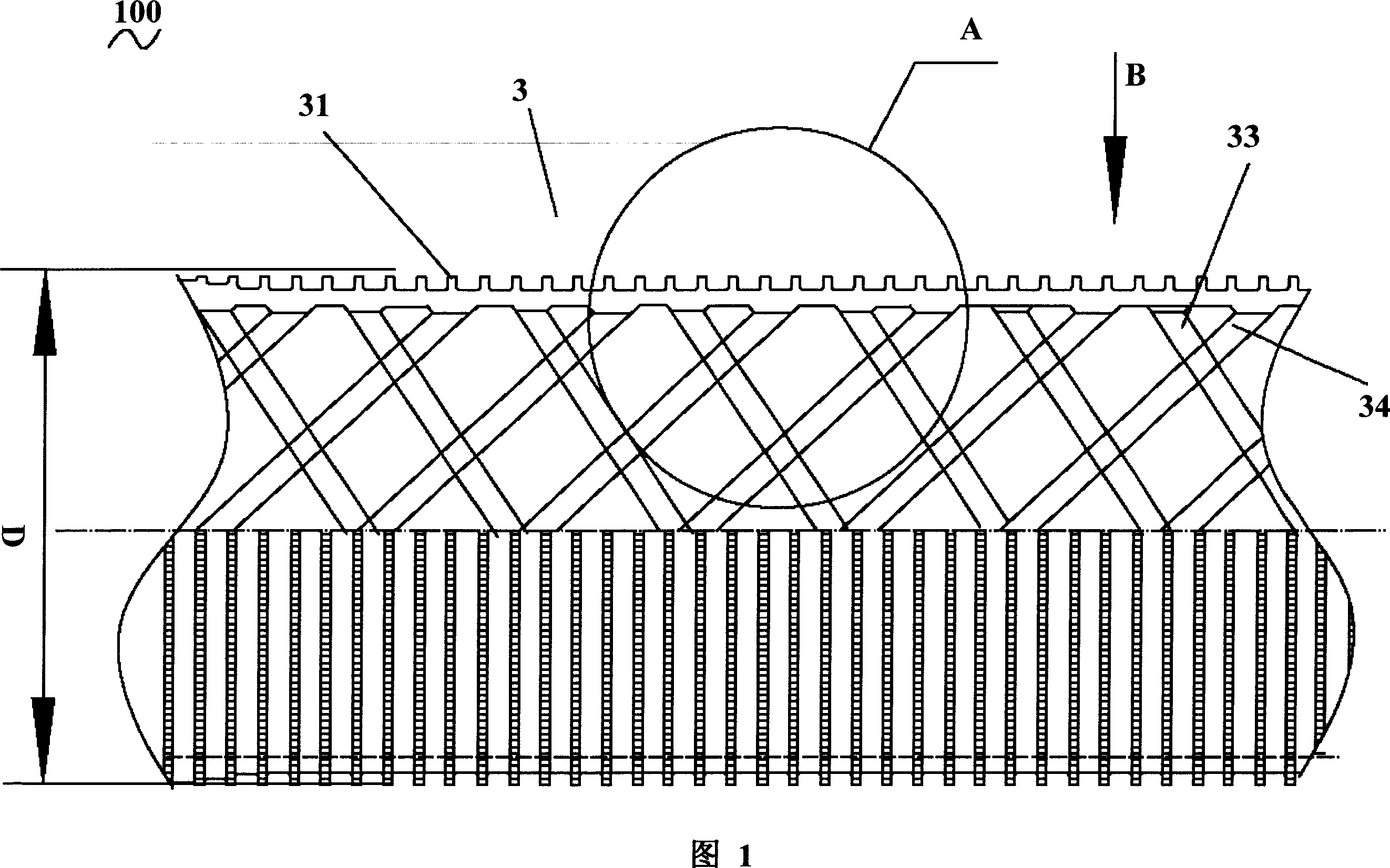

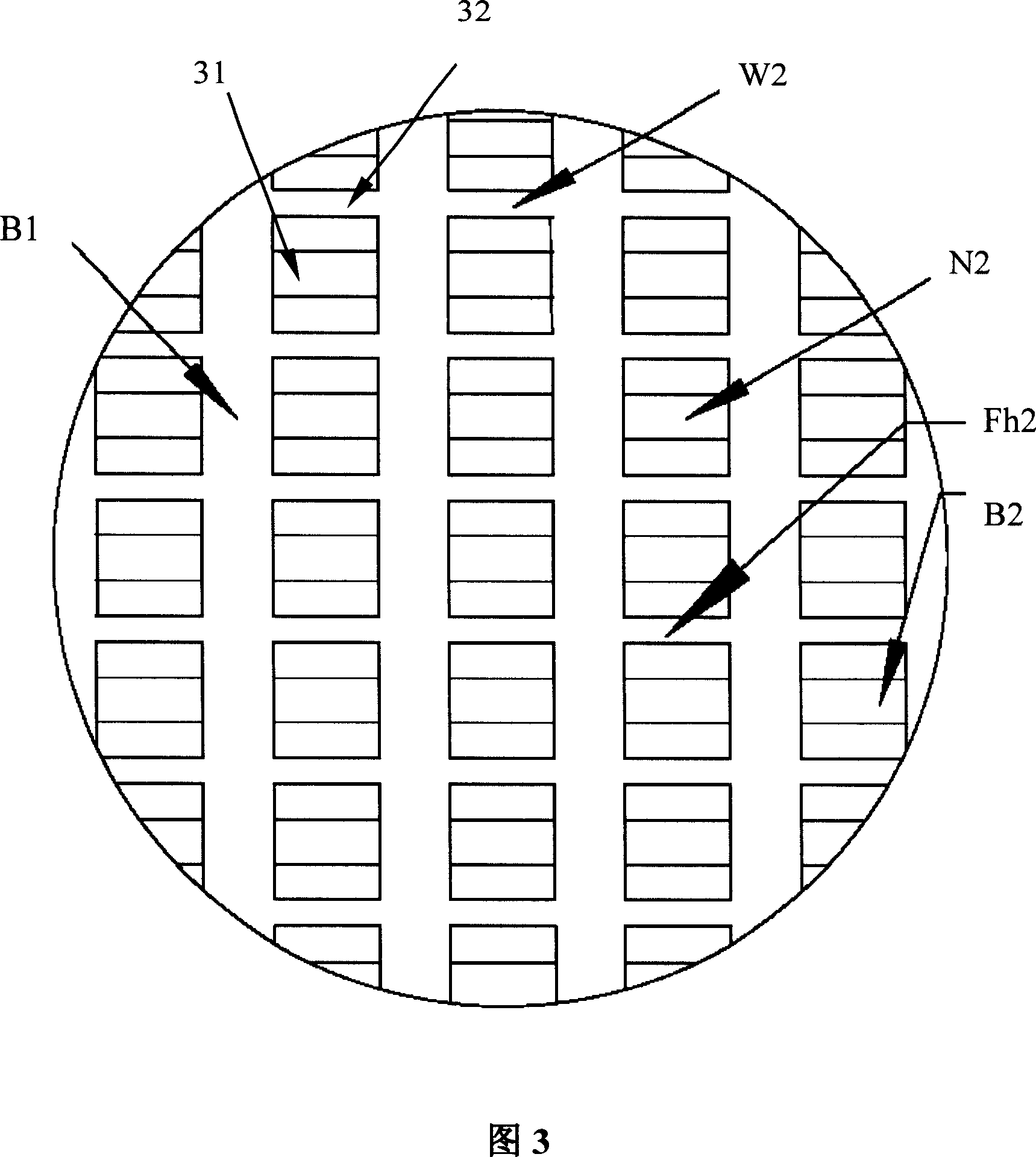

[0020] Please refer to FIG. 1, the heat exchange tube 100 of the present invention includes polished rod parts (that is, the unprocessed part of the polished tube, not shown) at both ends of the heat exchange tube 100, and fins 31 between the two polished rod parts. The fin part 3, the transition part between the polished rod part and the fin part 3 (that is, the part where the incomplete fin is formed, not numbered), the primary internal teeth 33 and the secondary internal teeth 34 arranged on the inner surface of the tube. Preferably, the heat exchange tube 100 of the present invention is made of copper material.

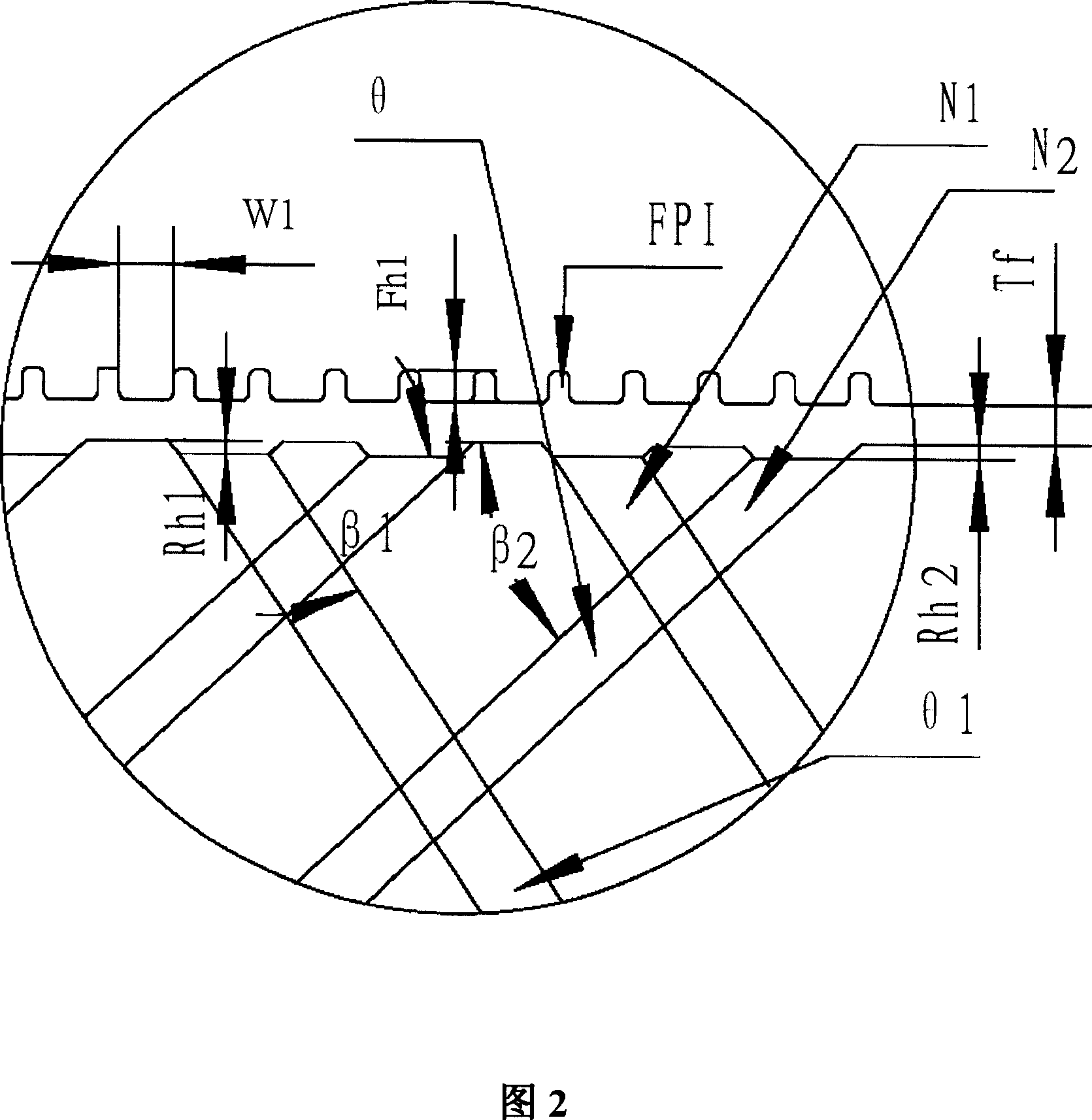

[0021] Preferably, the primary internal teeth 33 and the secondary internal teeth 34 both have a triangular structure, and the top and bottom of the primary internal teeth 33 and the secondary internal teeth 34 can be smoothly tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com