Condensing type afterheat recovering and water heating cooking oven

A waste heat recovery and condensing technology, which is applied in the field of boiler waste heat recovery, can solve the problems of low utilization rate of gas heat energy, low heat utilization efficiency, waste of gas heat energy, etc., and achieve the goal of reducing heat pollution, improving utilization rate, and thorough heat exchange Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

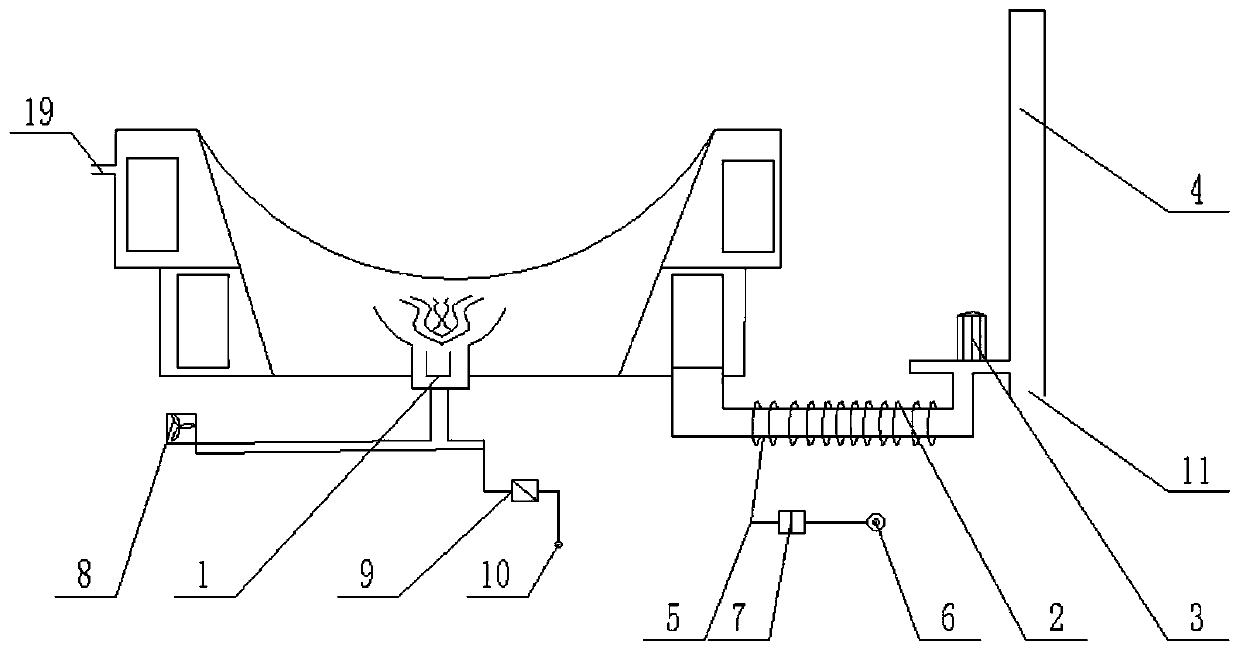

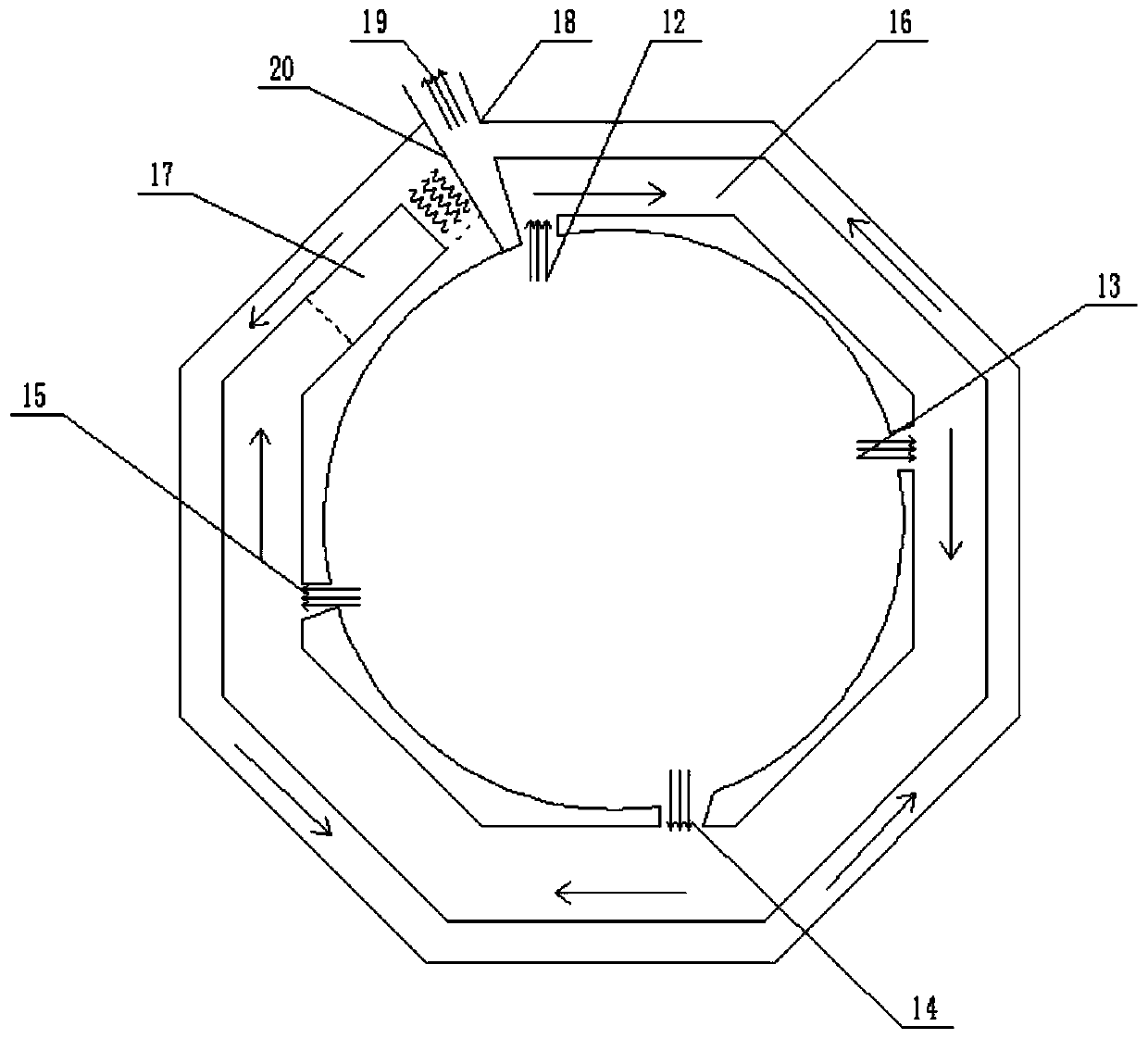

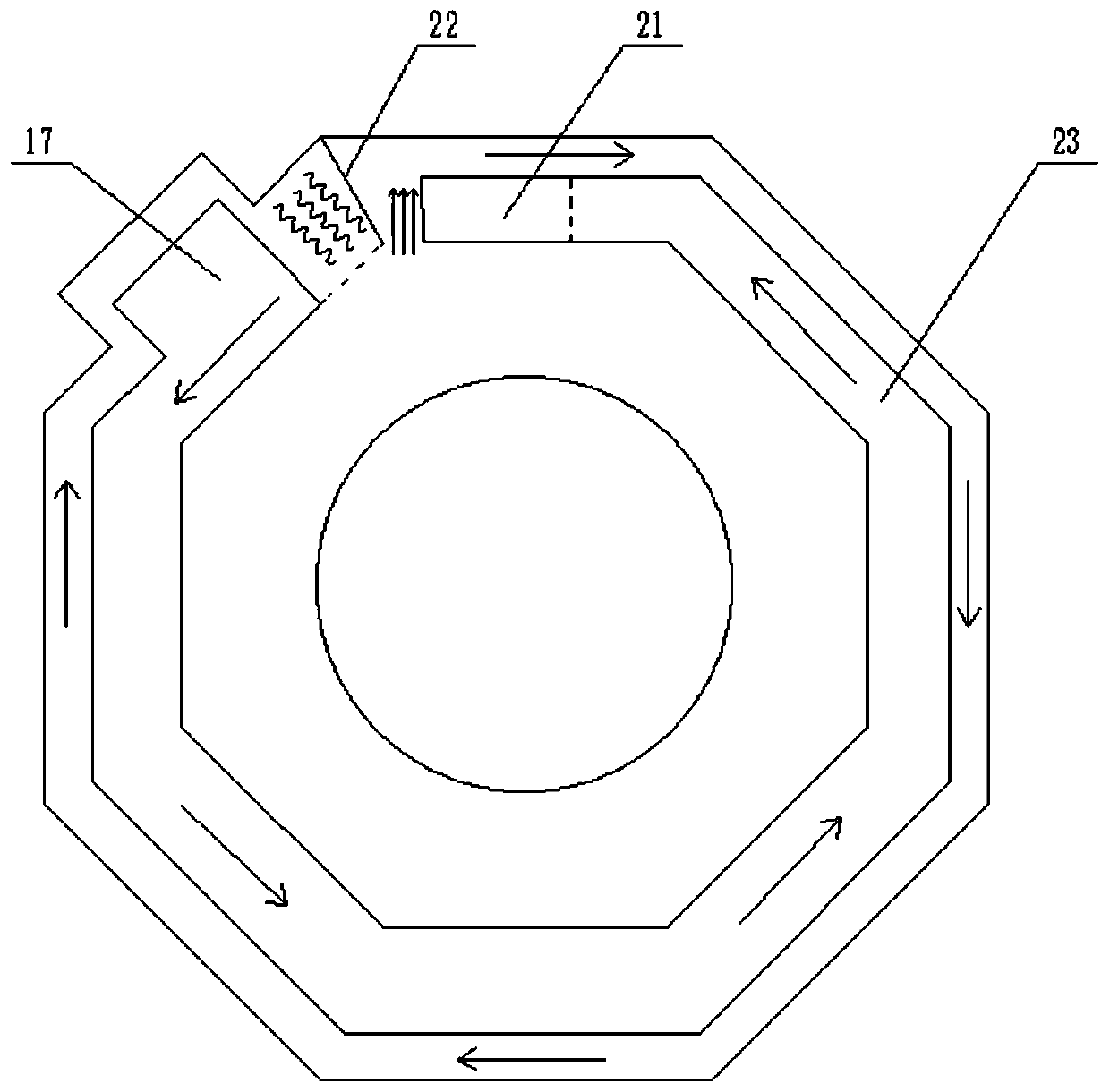

[0039] The condensing waste heat recovery hot water large pot stove provided by the preferred embodiment of the present invention includes a first air inlet 12, a second air inlet 13, a third air inlet 14 and a fourth air inlet 15; The bottom of the head 1 is connected in parallel with the gas inlet 10 and the blower 8, and the electric valve 9 is set on the connection channel between the gas inlet 10 and the burner 1; the first-stage waste heat exchange pipe 16, the second-stage waste heat exchange pipe 23, and the smoke exhaust pipe 4 It is made of stainless steel, and the fins 2 are made of copper.

[0040] When working: click the switch, the blower 8 and the strong exhaust fan 3 start to work, the ignition pulse is automatically ignited, the electric valve 9 is opened, and the fuel starts to burn; , the second air inlet 13, the third air inlet 14, and the fourth air inlet 15 are evenly sucked into the first-stage waste heat exchange pipe 16; the high-temperature exhaust ga...

Embodiment 2

[0043] In this embodiment, on the basis of the first embodiment, a solenoid valve 7 is provided on the water inlet pipe 5, and the solenoid valve 7 is located between the tap water inlet 6 and the water inlet of the water tank. It also includes a temperature probe 18 arranged inside the upper chamber.

[0044] When working: a self-operated temperature control valve integrating a temperature probe and a solenoid valve 7 is adopted. When the temperature of the upper chamber reaches the set value, the solenoid valve 7 is opened; tap water enters the water tank, the lower chamber and the upper chamber in turn; the upper chamber The high-temperature water in the chamber is discharged out of the kitchen range by the tap water outlet 19.

Embodiment 3

[0046] In this embodiment, on the basis of the first embodiment, a solenoid valve 7 is provided on the water inlet pipe 5, and the solenoid valve 7 is located between the tap water inlet 6 and the water inlet of the water tank. It also includes a temperature probe 18 arranged inside the upper chamber.

[0047] When working: the temperature probe is used to transmit the temperature information to the controller, and the controller controls the solenoid valve 7 according to the temperature information. When the temperature of the upper chamber reaches the set value, the solenoid valve 7 is opened; tap water enters the water tank, the lower chamber and the upper chamber in sequence chamber; the high-temperature water in the upper chamber is discharged out of the stove body by the tap water outlet 19; and when the solenoid valve 7 breaks down, or when the tap water is cut off; when the water temperature in the upper chamber reaches the set dangerous value; the controller controls t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com