Heat energy recovery system of mute diesel generator

A diesel generator and heat energy recovery technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of low heat absorption and utilization rate of silent diesel generators, unsatisfactory heat energy recovery effect, and single structure. Reduce heat loss, complete heat exchange, and enhance the effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

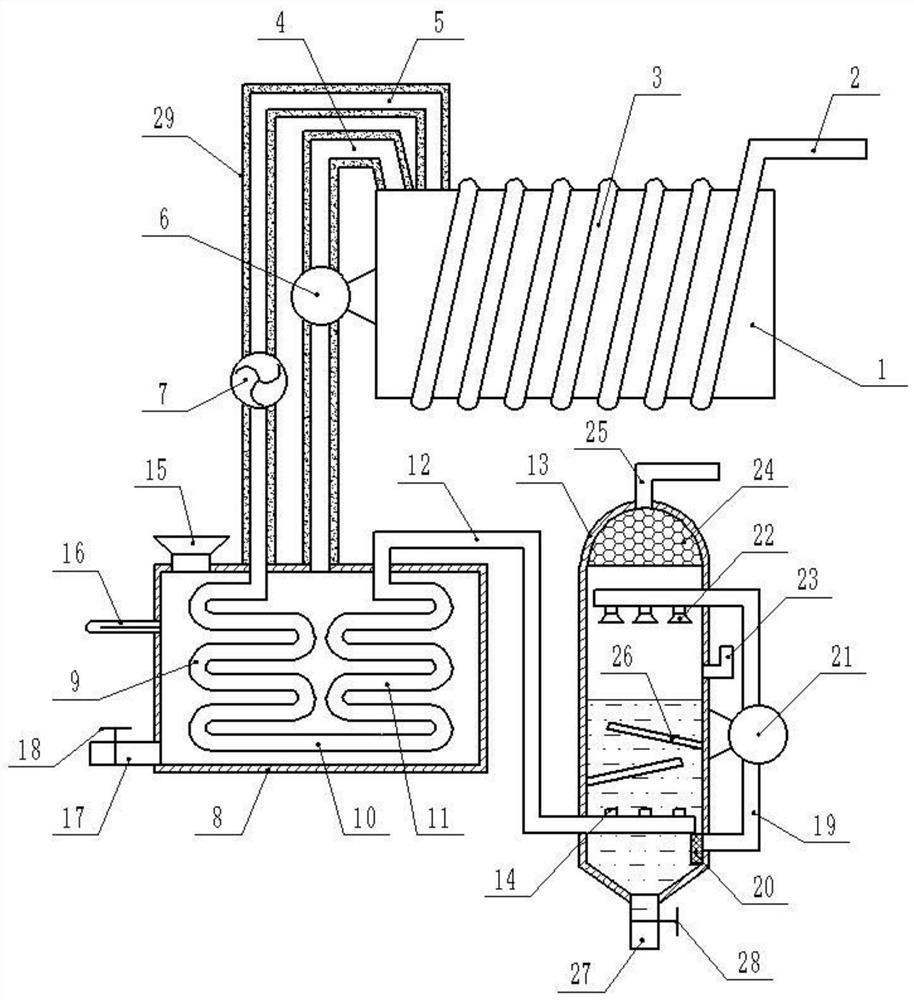

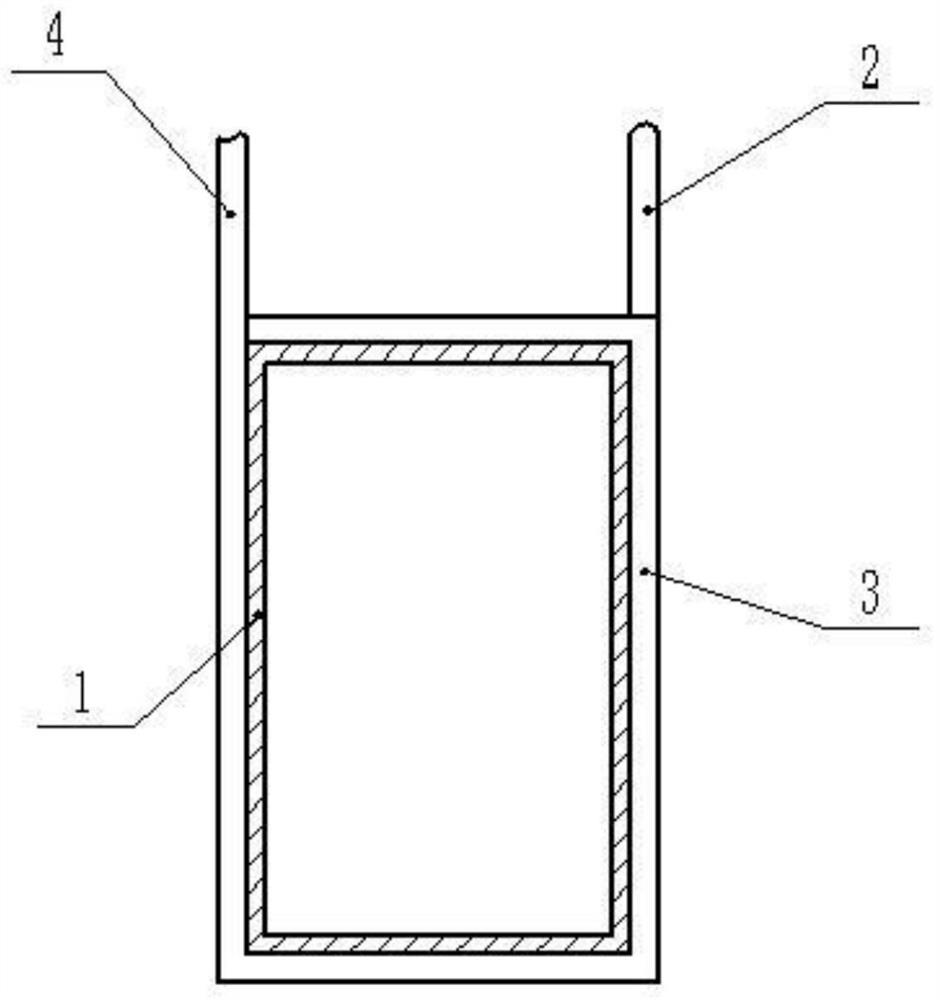

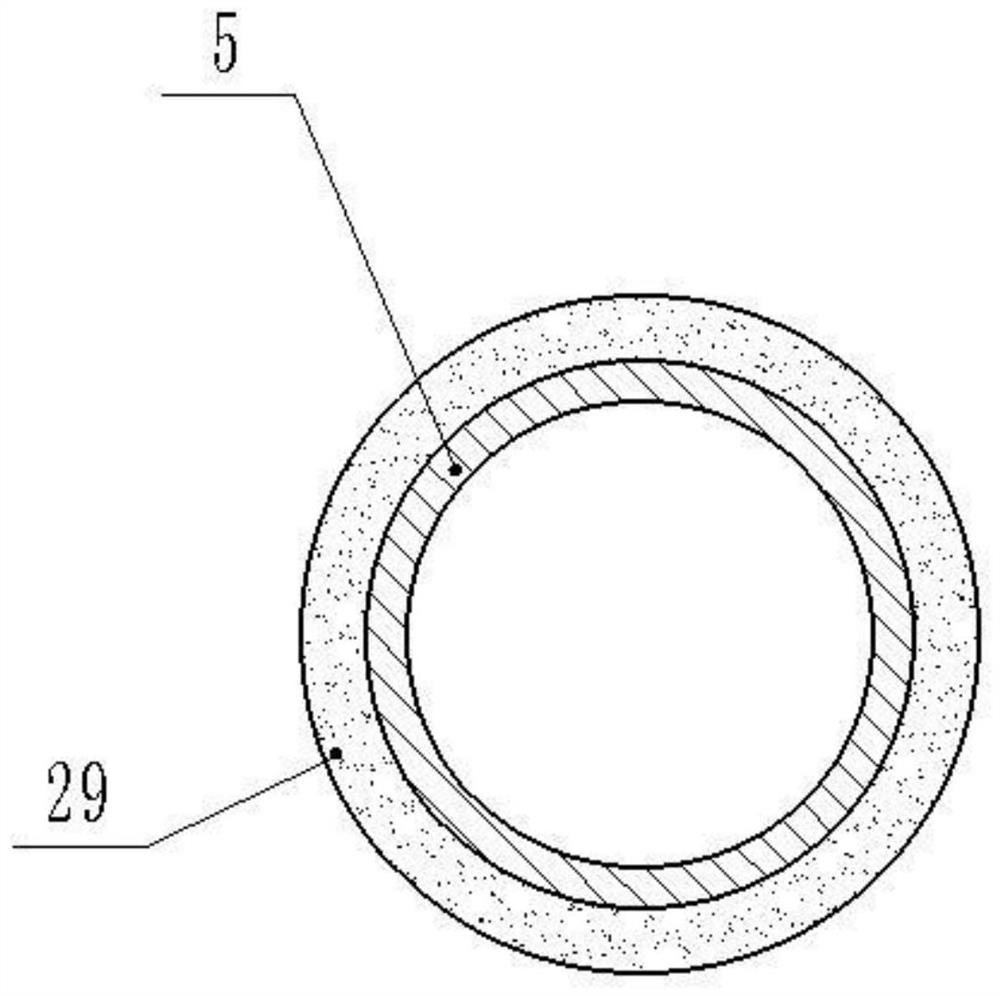

[0022] see Figure 1-6 , a heat recovery system for a silent diesel generator, comprising a silent diesel generator body 1, a smoke exhaust pipe 5, a water tank 8, a second spiral cooling pipe 11, a purification tower 13, a second water pump 21 and a deflector 26; The shell of the silent diesel generator body 1 is wound with a disc-shaped heat-absorbing pipe 3, and the upper right side of the disc-shaped heat-absorbing pipe 3 is connected with a water inlet pipe 2. The cold water in the disc-shaped heat-absorbing pipe 3 can cool the silent diesel engine. The heat emitted by the generator body 1 is absorbed, and the upper left side of the disc-shaped heat-absorbing pipe 3 is connected to the first connecting water pipe 4, and the first water pump 6 is installed on the first connecting water pipe 4, and the bottom of the first connecting water pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com