Comprehensive utilization method and system for bottom slag quenching treatment of circulating fluidized bed boiler

A technology of circulating fluidized bed and boiler bottom, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burning in molten state, etc., can solve the problem of low utilization rate of CFB desulfurization ash, high failure rate of boiler slag cooler, and desulfurization The problem of low utilization rate of ash and slag can reduce the water demand of standard consistency, improve the utilization efficiency of boilers, and save boiler fuel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

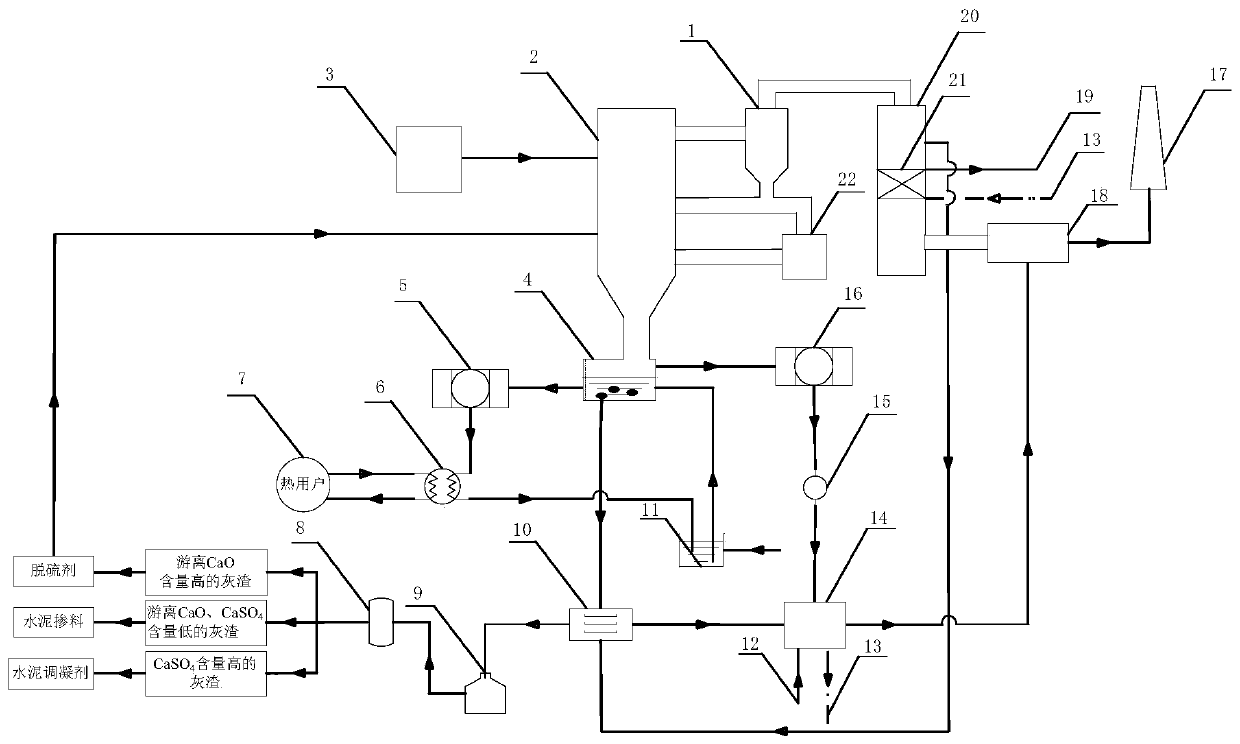

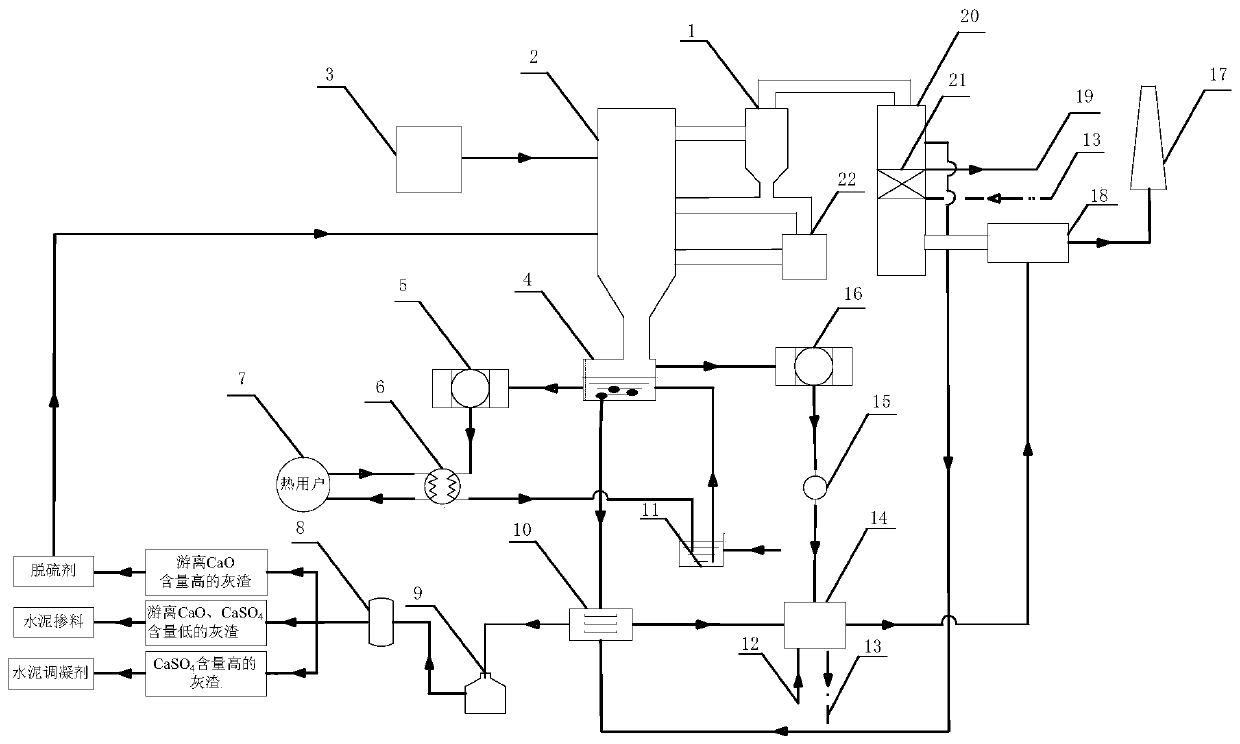

[0028] Such as figure 1 As shown, the present invention provides a comprehensive utilization system for rapid cooling treatment of circulating fluidized bed boiler bottom slag, which is mainly composed of a quenching system, a bottom slag recovery treatment system, a hot slag water waste heat utilization system and a condensation heat exchange system. It specifically includes a cyclone separator 1, a furnace 2, a coal bunker 3, a quenching slag cooler 4, a filter and slag removal device 5, a heat exchanger 6, a bottom slag component analysis and processing device 8, a bottom slag storage bin 9, a drying device 10, Water tank 11 , condensation heat exchange device 14 , steam extraction pump 15 , filter and slag removal device 16 , chimney 17 , dust collector 18 , economizer 21 and fluidized bed heat exchanger 22 .

[0029] Among them, the coal bunker 3 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com