A kind of silicon calcium potassium fertilizer cooling process and equipment

A silicon-calcium-potassium fertilizer and cooling process technology, which is applied in the chemical industry, fertilization equipment, fertilizer mixture, etc., can solve the problems of difficult effective use of heat, clinker stickiness and clogging, clinker clumping and large lumps, etc., so as to improve the operation rate of equipment , reduce production costs, improve the effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

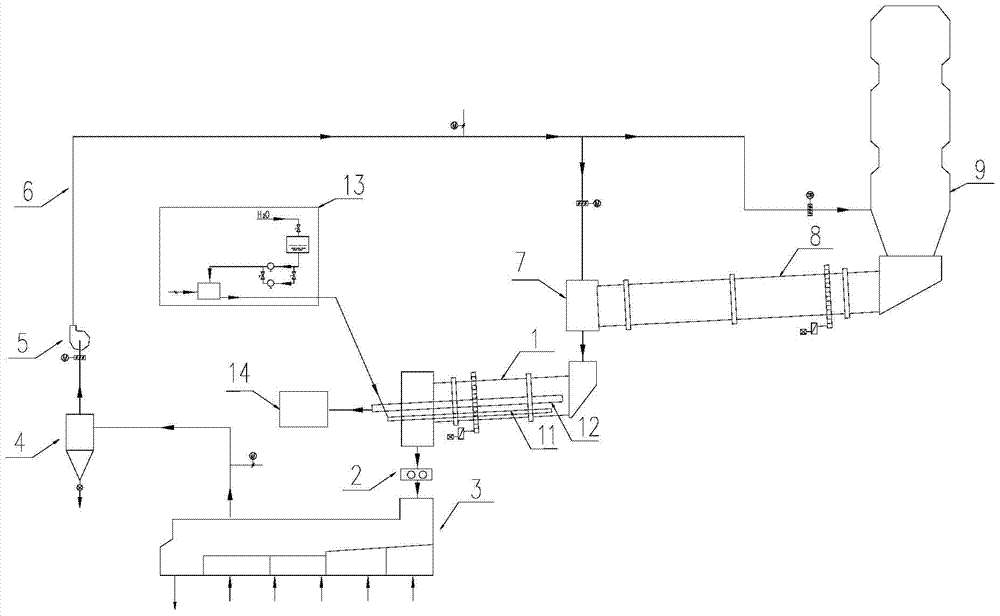

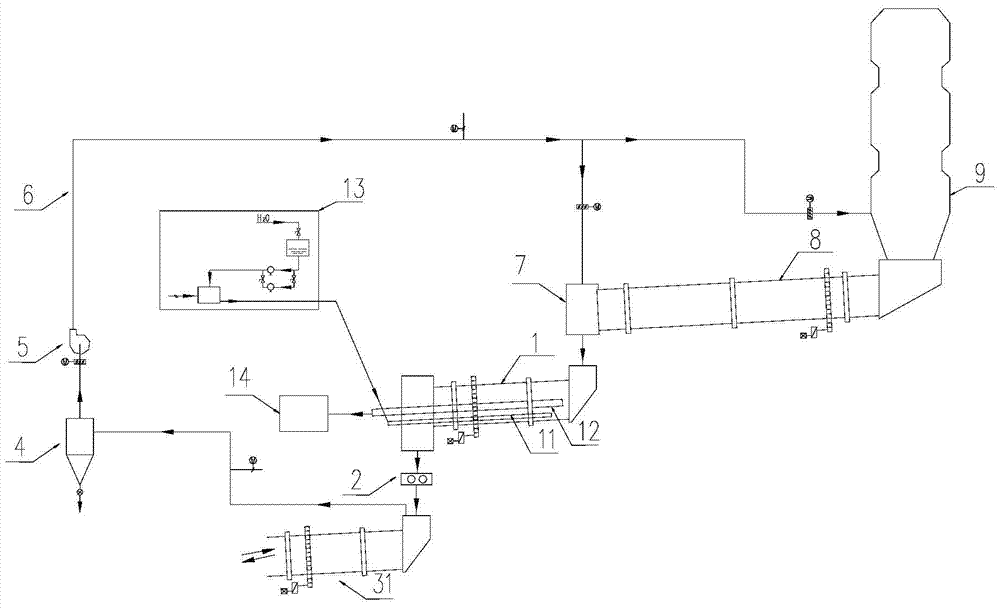

[0019] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

[0020] See figure 1 with figure 2 , A silicon-calcium-potassium fertilizer cooling process, including the following steps:

[0021] 1) The first single-cylinder cooler with built-in water spray pipes and exhaust pipes is used to spray water to cool the silicon-calcium-potassium fertilizer clinker out of the kiln to 500-700°C; among them, the water spray cooling process is: When water comes into contact with the high-temperature viscous clinker or bulk silicon-calcium-potassium fertilizer clinker entering the first single-tube cooler, the surface temperature of the high-temperature viscous clinker or bulk clinker decreases rapidly, and the water absorbs heat and becomes water vapor. Exhaust the air duct to the steam treatment system;

[0022] 2) Using a high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com