Copper-based amorphous sheet material for brazing and preparation method thereof

A sheet material, brazing technology, applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problem of inability to accurately control the width and thickness of the strip, unable to meet the application requirements, and large size deviation of the amorphous strip To achieve the effect of simple and controllable production process, improve welding wetting performance, and ensure molding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

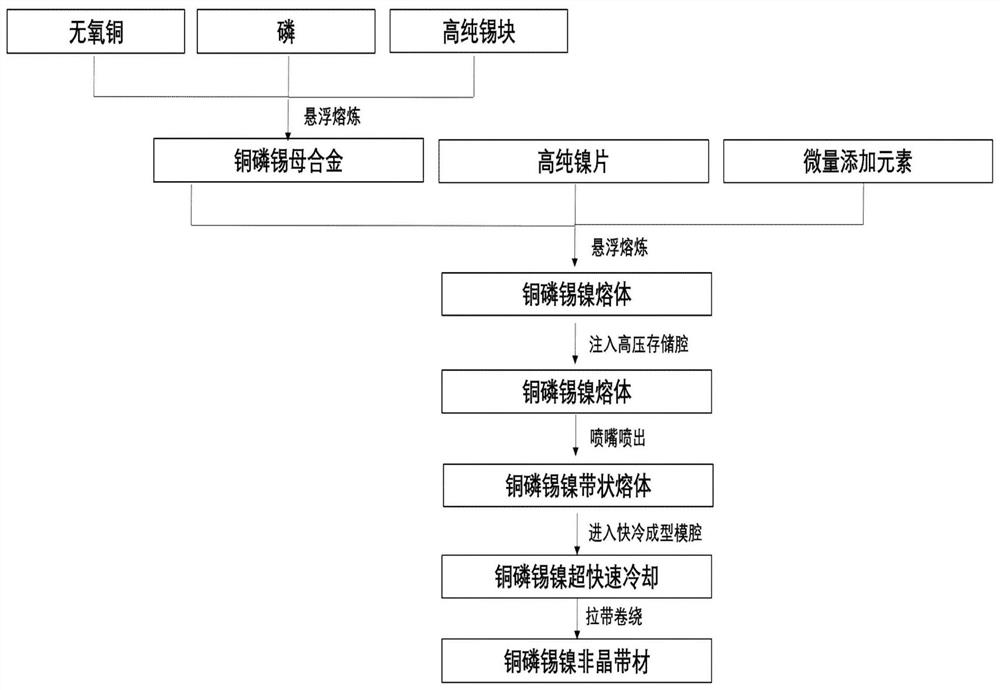

[0039] see figure 1 , a copper-based non-wafer material for brazing, the material components of the copper-based non-wafer are mainly metal copper, phosphorus, metal tin, metal nickel, metal titanium, metal indium, wherein the copper content is: 86.35 wt%, the phosphorus content is 5 wt%, the tin content is 7.5 wt%, the nickel content is 1 wt%, and the cobalt content is 0.15 wt%.

[0040] The steps of the preparation method include:

[0041] The first step is to weigh 43.175Kg of electrolytic copper plate, 2.5Kg of phosphorus, and 3.75Kg of tin block respectively.

[0042] In the second step, the material in the first step is added to the suspension melting furnace, and vacuum melting is carried out. The melting temperature is 1280° C., and the temperature is kept for 30 minutes to obtain a copper-phosphorus-tin master alloy.

[0043] The 3rd step, respectively weigh 0.5Kg nickel sheet, 75g cobalt, mix with the copper-phosphorus-tin mother compound in the above-mentioned sec...

Embodiment 2

[0049] The main difference from Example 1 is that in this example, the trace element added is titanium, and the copper-based non-wafer has a thickness of 0.04 mm and a width of 5 mm.

[0050] The material components of the copper-based non-wafer are mainly metallic copper, phosphorus, metallic tin, metallic nickel, metallic titanium, and metallic indium, wherein the copper content is 86.35 wt%, the phosphorus content is 5 wt%, the tin content is 7.5 wt%, and the nickel content is 1 wt%, titanium content is 0.15 wt%.

[0051] like figure 1 , the preparation method of the copper-based non-wafer material of the present embodiment, the operation steps are as follows:

[0052] Step 1: Weigh 43.175Kg electrolytic copper plate, 2.5Kg phosphorus, and 3.75Kg tin block respectively.

[0053] The second step: adding the above-mentioned materials in the first step into the suspension melting furnace, and carrying out vacuum melting at a melting temperature of 1300° C., holding the tempe...

Embodiment 3

[0059] The main difference from Example 2 is that in this example, the trace addition elements are titanium and indium, and the copper-based non-wafer has a thickness of 0.05 mm and a width of 20 mm.

[0060] In the preparation of the copper-based non-wafer material in this example, the material components of the copper-based non-wafer are mainly metal copper, phosphorus, metal tin, metal nickel, metal titanium, and metal indium, wherein the copper content is 86.3wt%, and the phosphorus content is 5wt%. , the tin content is 7.5 wt%, the nickel content is 1 wt%, the titanium content is 0.1 wt%, and the indium content is 0.1 wt%.

[0061] The preparation method steps include:

[0062] Step 1: Weigh 43.15Kg of high-purity copper powder, 2.5Kg of phosphorus, and 3.75Kg of tin block respectively.

[0063] The second step: adding the above-mentioned materials in the first step into a suspension melting furnace, and performing vacuum melting at a melting temperature of 1280° C., kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com