A treatment device for waste mud and cuttings of deep well sulfonated drilling fluid

A technology for drilling with polysulfonic acid and discarding mud, which is used in wellbore/well components, earthwork drilling, flushing wellbore, etc. It can solve the problems of small footprint and high treatment efficiency, reduce thermal pollution and enhance heat transfer efficiency. , the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

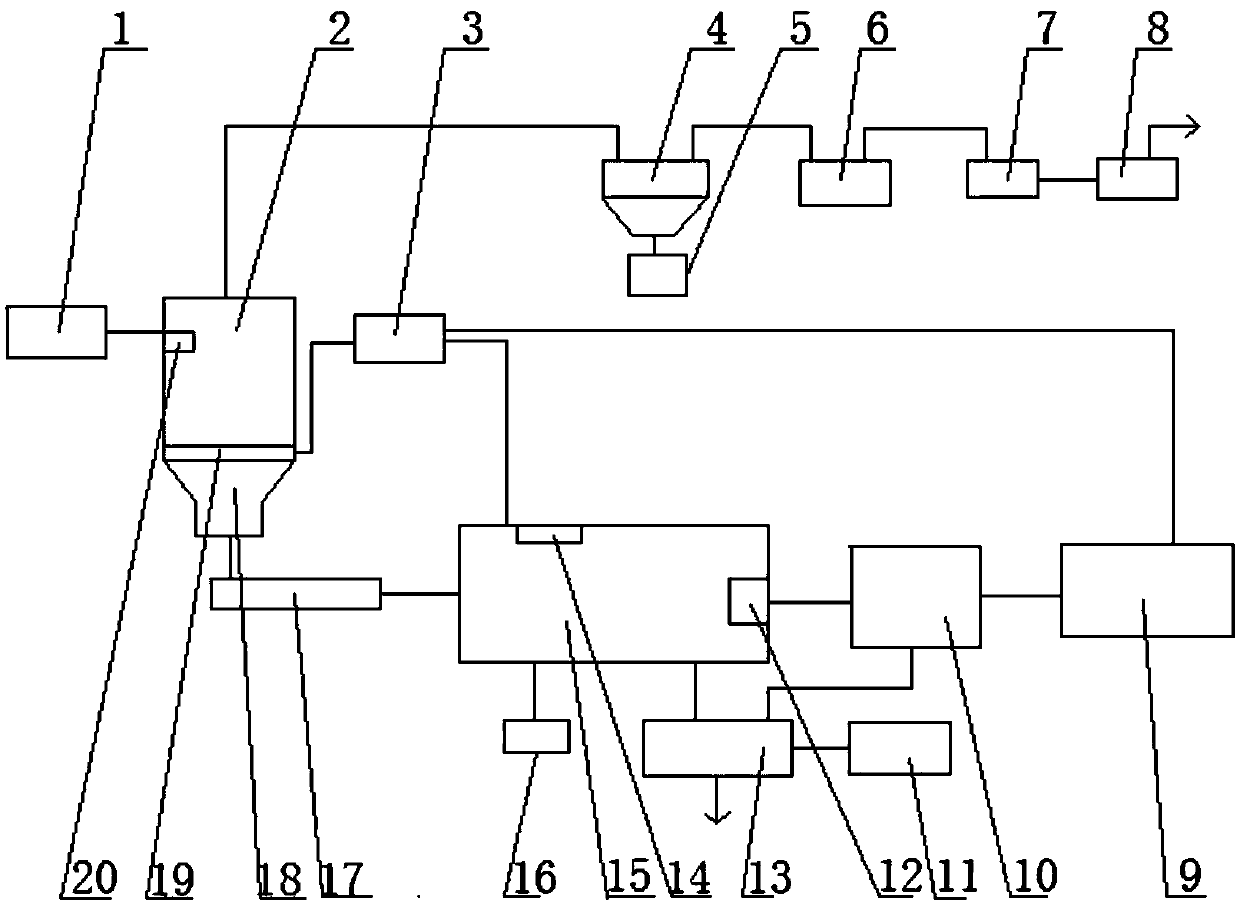

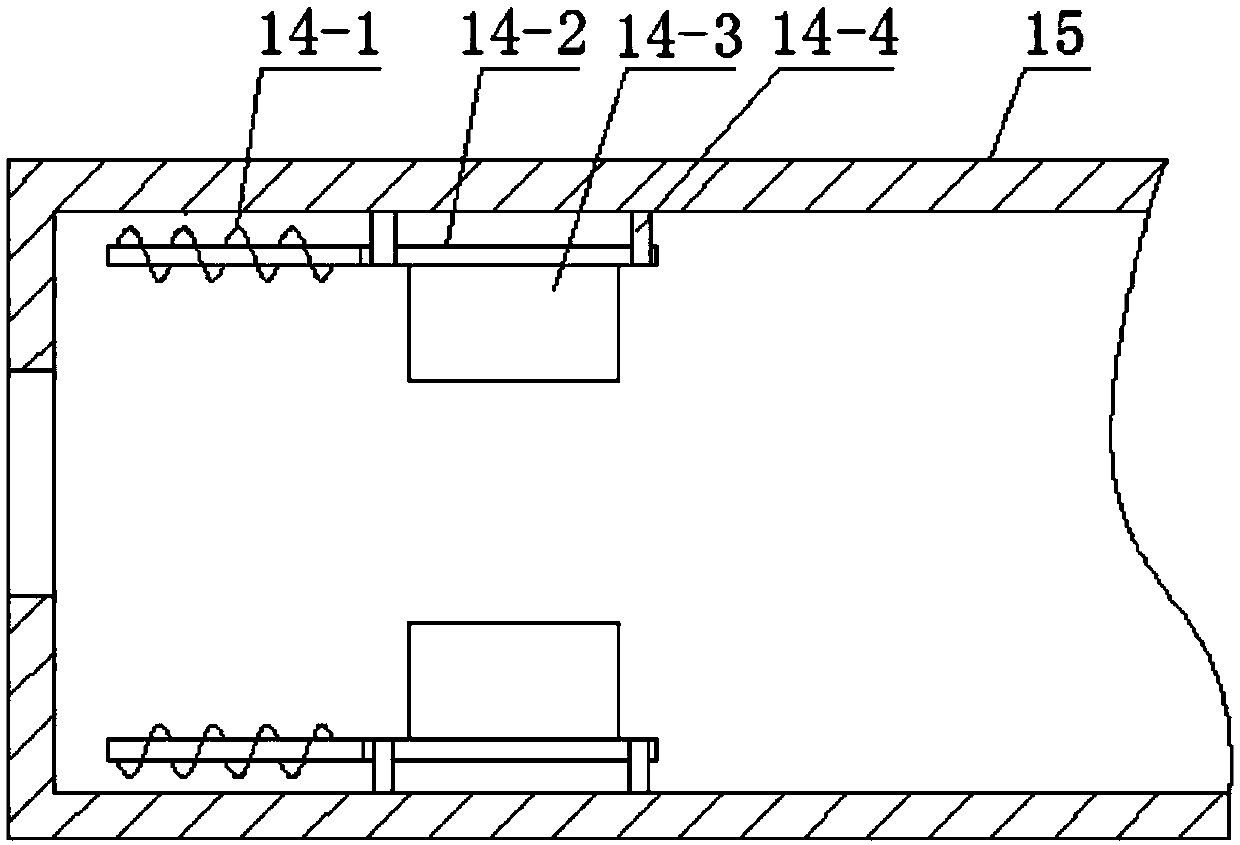

[0029] Such as figure 1 As shown, the deep well sulfur polysulfide drilling fluid waste mud and cuttings processing device of this embodiment consists of a feeder 1, a cooling heat exchange drying furnace 2, a second combustion chamber 3, a three-stage cyclone separator 4, and barite collection Tank 5, bag dust collector 6, desulfurization tower 7, water film dust collector 8, gas storage tank 9, combustion chamber 10, air supply fan 11, hot air nozzle 12, heat exchange device 13, anti-bonding device 14, high temperature heat Decomposition furnace 15, collection tank 16, dry chemical feed device 17, collection bin 18, gas distributor 19, and feed device 20 are connected to form.

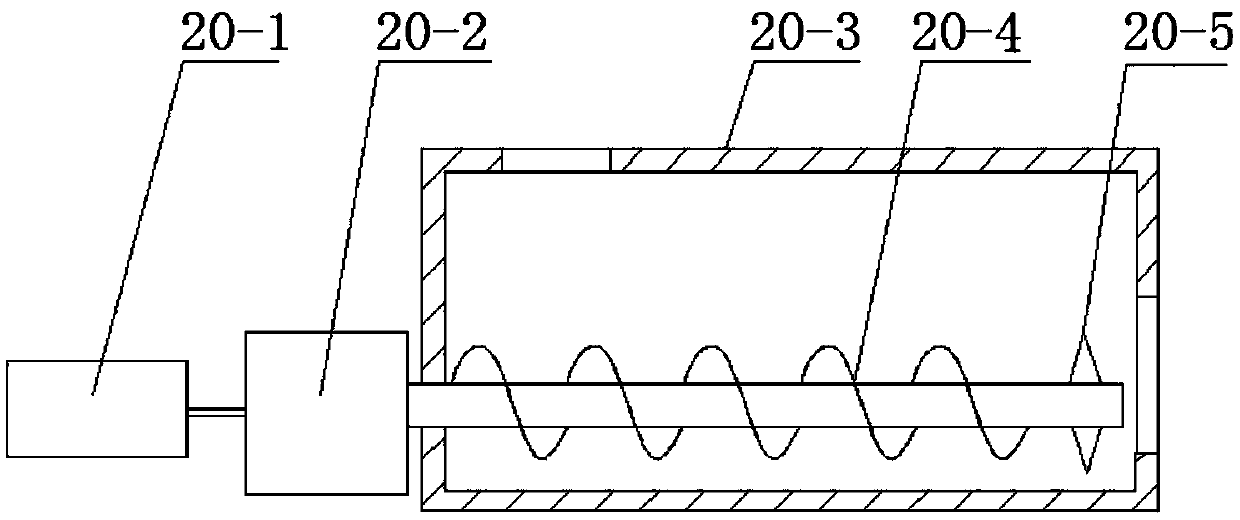

[0030] The feeding machine 1 communicates with the feeding device 20 inside the cooling heat exchange drying furnace 2 through pipelines. Such as figure 2As shown, the feeding device 20 is composed of a motor 20-1, a speed reducer 20-2, a feeding cylinder 20-3, a screw propeller 20-4 and a cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com