A kind of preparation technology of regenerated semi-dull cationic fiber

A technology for cationic fiber and preparation process, which is applied in the field of preparation technology of regenerated semi-dull cationic fiber, can solve the problems of affecting the quality of filaments, low softening point, long drying time, etc., and achieves drying effect and high drying efficiency, and the process is simple and easy. line, the effect of excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

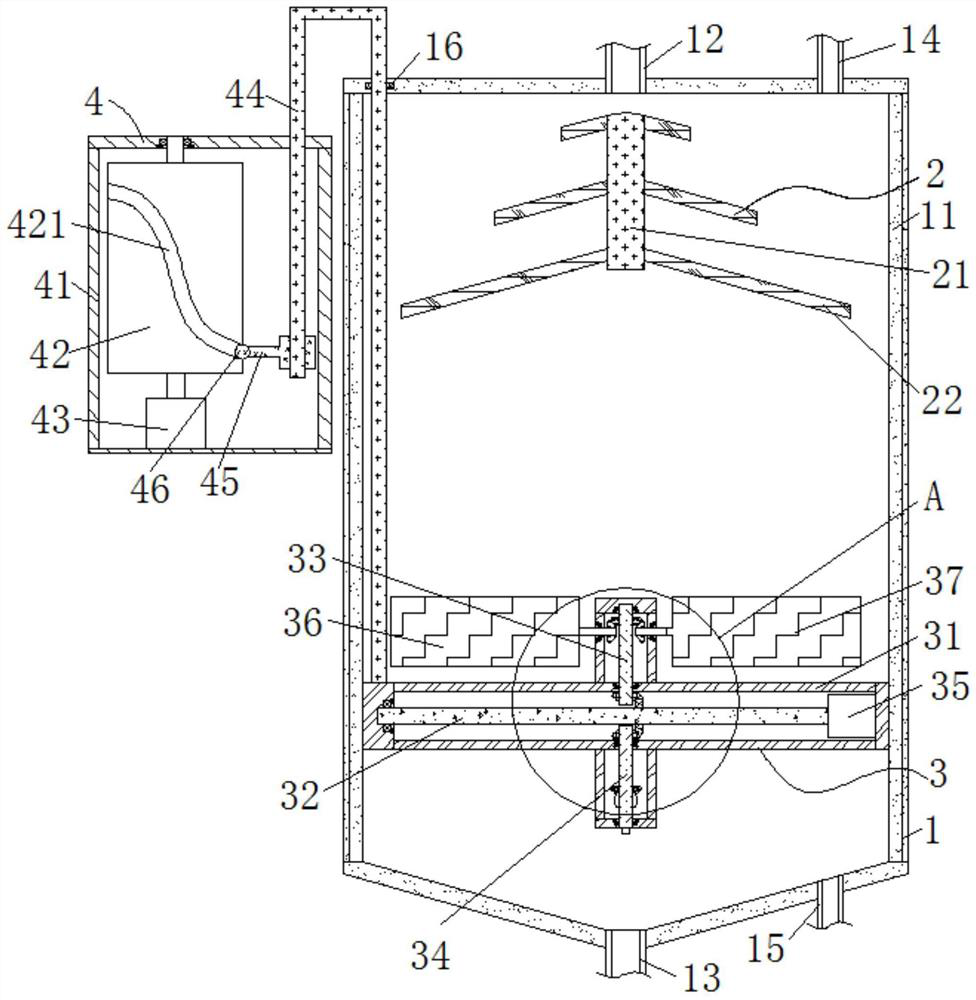

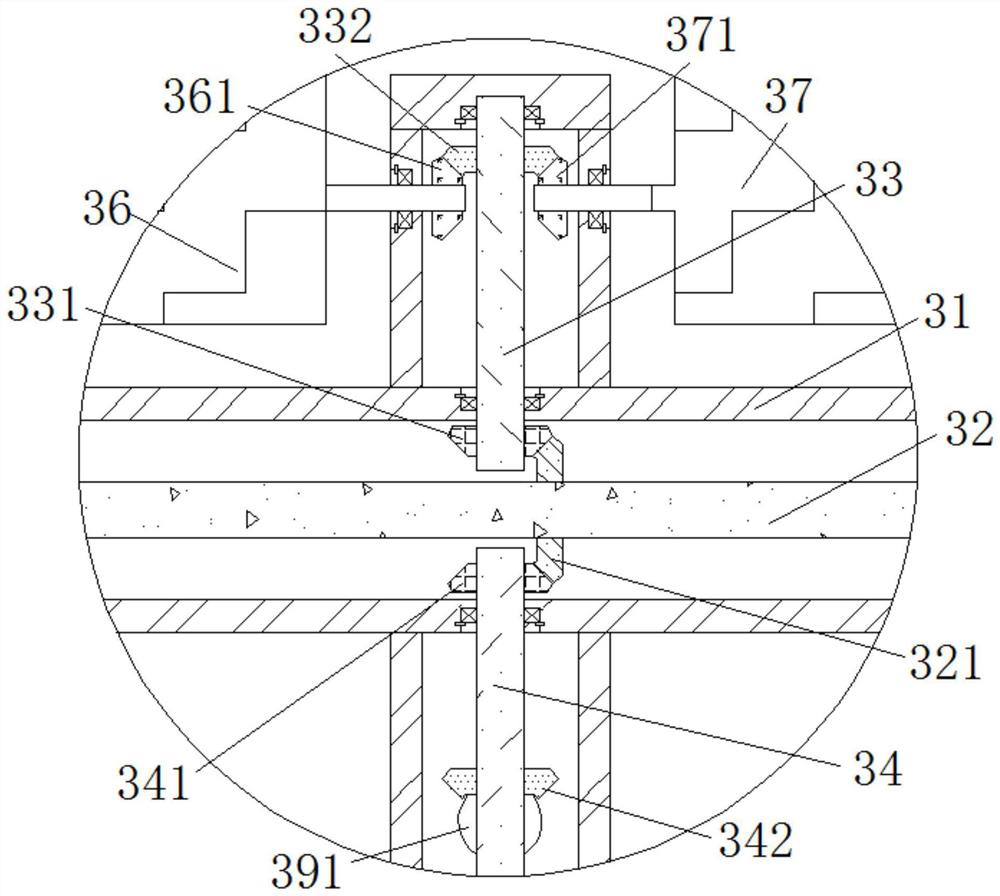

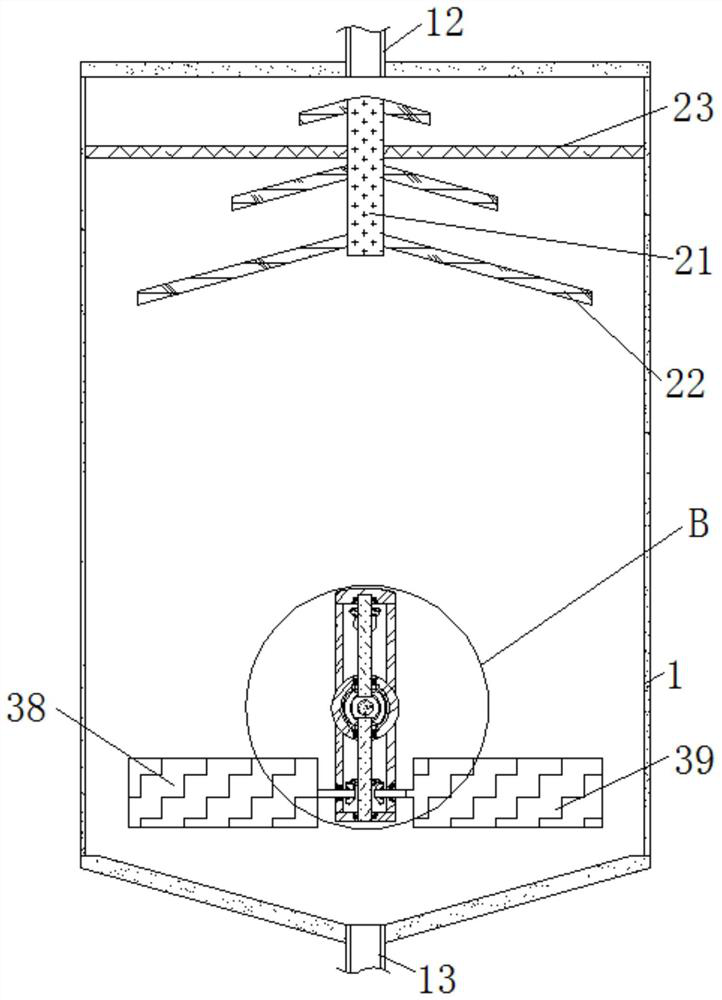

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0025] A preparation process for regenerated semi-dull cationic fibers, comprising the following steps:

[0026] (a) Add PET masterbatches with a titanium dioxide content of 2.65% into a dryer for drying; add regenerated PET cationic chips into a crystallization drying system for pre-crystallization drying; the drying temperature of PET masterbatches is 80 ° C, and the drying air pressure is 0.1 MPa; the crystallization temperature of recycled PET cationic slices is 152°C, the drying temperature is 155°C, and the drying air pressure is 0.08MPa; a high slice drying temperature can speed up the drying speed and shorten the drying time, but if the temperature is too high, the slices will be easily bonded. Cause the degradation of macromolecules and affect the uniformity of spinning melt, so the drying temperature should be controlled at the above temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com